Distributing Intelligence among Cloud, Fog and Edge in Industrial

Cyber-physical Systems

Jonas Queiroz

1

, Paulo Leit

˜

ao

2

, Jos

´

e Barbosa

2

and Eug

´

enio Oliveira

1

1

University of Porto, Faculty of Engineering - LIACC, Porto, Portugal

2

Research Center in Digitalization and Intelligent Robotics (CeDRI), Instituto Polit

´

ecnico de Braganc¸a, Braganc¸a, Portugal

Keywords:

Cyber-physical Systems, Edge Computing, Artificial Intelligence, Data Analysis, Multi-agent Systems.

Abstract:

The 4th industrial revolution advent promotes the reorganization of the traditional hierarchical automation

systems towards decentralized Cyber-Physical Systems (CPS). In this context, Artificial Intelligence (AI) can

address the new requirements through the use of data-driven and distributed problem solving approaches, such

those based on Machine-Learning and Multi-agent Systems. Although their promising perspectives to en-

able and manage intelligent Internet of Things environments, the traditional Cloud-based AI approaches are

not suitable to handle many industrial scenarios, constrained by responsiveness and data sensitive. The solu-

tion lies in taking advantage of Edge and Fog computing to create a decentralized multi-level data analysis

computing infrastructure that supports the development of industrial CPS. However, this is not a straightfor-

ward task, posing several challenges and demanding new approaches and technologies. In this context, this

work discusses the distribution of intelligence along Cloud, Fog and Edge computing layers in industrial CPS,

leveraging some research challenges and future directions.

1 INTRODUCTION

The era of the 4th industrial revolution (4IR), usually

called I4.0, promotes the digitalization of traditional

factories towards intelligent ones that are more flex-

ible, robust, efficient, adaptive and competitive (Lu,

2017). This revolution is based on several disruptive

ICT technologies, namely Internet of Things (IoT),

Cloud Computing, Big Data and Machine-Learning

(ML), which are glued by Cyber-Physical Systems

(CPS) (Bauer et al., 2015). CPS comprise a set of net-

worked cooperating and autonomous entities, com-

bining cyber and physical counterparts. They are suit-

able to solve problems in complex and large-scale

systems that can be found in smart manufacturing,

smart cities, smart electrical grids and smart health

(Leit

˜

ao et al., 2016; Khaitan and McCalley, 2015).

In this context, Artificial Intelligence (AI) is a key

enabler for the realization of the envisioned CPS and

their features, like autonomy, self-awareness and dy-

namic reconfigurability. In industrial environments,

the use of AI can contribute to develop intelligent de-

cision support and control systems, smart machines

and products, and consequently intelligent production

systems and factories (Wuest et al., 2016; Lee et al.,

2018). For instance, AI provides ML algorithms that

are capable to learn and extract patterns from data,

devising models for prediction and data-driven deci-

sions. The increased computational processing power

together with the availability of huge amounts of data,

mainly powered by the IoT, have contributed to their

increasing adoption in various applications.

However, AI goes beyond ML algorithms, also

providing distributed approaches, such those based

on Multi-Agent System (MAS) (Wooldridge, 2002),

which works as vessels for AI algorithms. MAS com-

pletely fits the CPS due to its inherent characteris-

tics of modularity, autonomy and cooperation (Leit

˜

ao

et al., 2016). In such approach, the system behav-

ior emerges from the interaction among autonomous

agents, where the decisions are taken in a decentral-

ized way, in opposition to centralized structures that

are not able to address requirements related to flexi-

bility, robustness, and on-the-fly reconfigurability.

This raises pertinent questions regarding which,

how and where these key enabling technologies

should be deployed. Traditionally, Cloud infrastruc-

tures provide on demand storage and processing ca-

pabilities. However, CPS go beyond traditional IoT

applications, envisioning devices with embedded pro-

cessing capabilities, capable to make decisions and

interact with other entities. In this context, the de-

Queiroz, J., Leitão, P., Barbosa, J. and Oliveira, E.

Distributing Intelligence among Cloud, Fog and Edge in Industrial Cyber-physical Systems.

DOI: 10.5220/0007979404470454

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 447-454

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

447

velopment of Fog and Edge Computing (CISCO,

2015) have allowed to deploy data processing capabil-

ities close to the data sources, thus attending impor-

tant industrial requirements, such as, data-sensitive,

responsiveness and constrained network bandwidth

(Breivold and Sandstr

¨

om, 2015). While the physical

systems are deployed at the Edge, the cyber systems

are distributed along the Fog and Cloud layers.

This paper aims to provide a discussion and raise

concepts, technologies, challenges and benefits re-

garding how intelligence, particularly related to data

analysis, can be distributed and balanced along Cloud,

Fog and Edge layers for the development of industrial

CPS. While some straightforward benefits encompass

the design and development of more autonomous and

adaptive systems, the challenges arise with the in-

creasing complexity to manage such distribution.

The remaining of this paper is organized as fol-

lows. Section 2 overviews the concepts of Cloud, Fog

and Edge Computing, and Section 3 discusses the dis-

tribution of intelligence by these layers. Section 4

discusses the related challenges in industrial CPS and

points out some research directions. Finally, Section 5

rounds up the paper with the conclusions.

2 CLOUD-FOG-EDGE FOR CPS

In the context of CPS, these computing paradigms de-

fine what, where and how computational resources are

deployed. Although the terms Fog and Edge Com-

puting have been used interchangeably (Chiang and

Zhang, 2016), this paper follows the definition where

Fog comprises the intermediary layer between Cloud

and IoT devices, while Edge considers IoT-based end

devices with embedded processing capabilities.

2.1 Cloud - Everything as a Service

Cloud envisions high performance computing and

data storage, promoting the shift from local corporate

computational resources to remote large scale data

centers, which are provided as services over the In-

ternet (Duan et al., 2015). Cloud offers a large pool

of virtualized resources, managed dynamically and

transparently, and following a multi-tenant and pay-

per-use model (Mell et al., 2011).

In spite of its benefits, the Cloud presents some

drawbacks that hinder its widely adoption as the busi-

ness model for many companies. For example, infor-

mation security and privacy are important concerns

(Xiao and Xiao, 2013), since companies fear having

third-parties controlling their sensitive data. The net-

work connection and bandwidth are other concerns,

mainly in data intensive scenarios where transfer large

amounts of data can be expensive and lead to latency

issues and network bottlenecks (Bonomi et al., 2014;

Xu et al., 2014; Breivold and Sandstr

¨

om, 2015).

Despite the Cloud technology has been widely

used by web-based companies, its adoption in other

domains, such as health-care, transportation, energy

and manufacturing, has increased considerably. In

this context, Cloud provides a highly suitable frame-

work to handle the massive amounts of data, attending

their growing demand for information management

and data analysis services. In the 4IR, it has been

seen as a new manufacturing paradigm (Ren et al.,

2017; Bauer et al., 2015; Lu, 2017).

2.2 Fog - Cloud Closer to Data Source

Although the Cloud offers efficient solutions to man-

age the huge volume of data, there are an increasing

demand for real-time, data-sensitive and constrained

network applications (e.g., in industrial domain) (Xu

et al., 2014; Breivold and Sandstr

¨

om, 2015). In this

context, Fog Computing (Bonomi et al., 2014) was

leveraged as a complementary paradigm to cover the

limitations of centralized Cloud approaches, address-

ing the challenges to perform data analysis locally,

close to the data sources (Chiang and Zhang, 2016).

It comprises a layer between Cloud applications and

IoT devices, providing a more direct, reliable, secure

and fast link between them, also reducing the amount

of data and transmitting more meaningful information

to Cloud. At this level, the data processing can be

performed by network equipment, computers, mobile

devices, as well as local servers (Bonomi et al., 2014).

Fog inherits most of the Cloud technologies, but

considering constrained hardware. Moreover, it en-

ables the decentralization of data analysis, decision-

making and control, increasing local components au-

tonomy, thus contributing to the shift of the tradi-

tional centralized automation pyramid to a decentral-

ized, flexible and self-organized approach. Besides

the aforementioned benefits, it faces some challenges,

e.g., the use of non-general purpose devices, lack of

frameworks for the development of algorithms opti-

mized for constrained devices, and for the manage-

ment of Fog nodes and their services (Shi et al., 2016).

2.3 Edge - The Edge of IoT

The extreme edge of the network is represented by

IoT-based devices that usually have constrained com-

putational resources, limited to collect and send data

or execute commands. However, there is a growing

number of IoT devices and platforms with consider-

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

448

able embedded computational resources (Al-Fuqaha

et al., 2015). Like in Fog Computing, the focus is

mainly to support local data analysis, but now it is di-

rectly embedded in the device itself. In this domain,

there is an increasing number of AI applications (e.g.,

online speech, image and video processing), which

are pushing the development of dedicated AI chips for

such devices and related equipment (Ota et al., 2017).

The Edge also faces several limitations (Al-

Fuqaha et al., 2015), mainly regarding the hetero-

geneity of devices and platforms, which increases

the complexity of application development, leading to

proprietary and non-standardized solutions. Other is-

sue concerns how to enable Edge Computing in the

huge number of legacy equipment that cannot be sim-

ply replaced by modern ones. Regarding security, al-

though the local processing can help with the data

anonymization, connect such devices to the network

demand extra security procedures.

The Edge devices are represented by advanced

IoT devices, such as those based on System-on-Chip

and single-board computer (e.g., FPGA, Raspberry

Pi and smartphones). They also include device gate-

ways, i.e., devices that connect a set of highly con-

strained devices to the network. In industry such de-

vices include Programmable Logic/Automation Con-

trollers (PLC/PAC), which already present advanced

processing capabilities and network connection based

on standardized protocols like OPC-UA.

3 AI DISTRIBUTION IN CPS

3.1 Intelligence at Cloud, Fog and Edge

Currently there is a hype of using the Cloud to store

the huge volume of the real-time data collected by a

vast number of IoT devices, and to run powerful data

analysis algorithms to extract valuable knowledge re-

lated to prediction and optimization. In fact, several

reports, namely McKinsey (Bauer et al., 2015) and

PwC (Geissbauer et al., 2016), refer Cloud Comput-

ing as a disruptive technology for the implementation

of the Industry 4.0. However, the Cloud is not the

solution for everything, with some data requiring to

be processed as close as possible to its source and

in real-time. Additionally, sending, storing and pro-

cessing all the data in the Cloud could be expensive,

constrained by the network latency and connectivity.

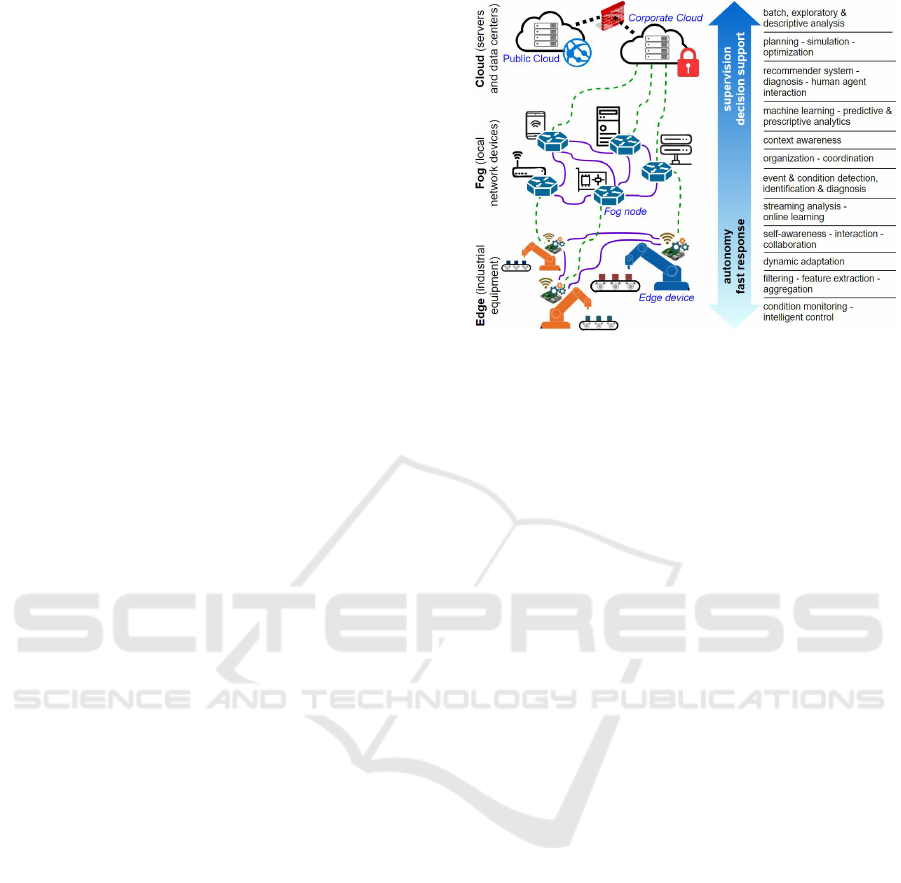

In this sense, the challenge lies in distributing in-

telligence by the Cloud, Fog and Edge layers, as illus-

trated in Figure 1. In fact, this distribution is strongly

advised, where we “should not send all collected data

to be processed in the Cloud, but instead to make

Figure 1: Intelligence distribution among Cloud-Fog-Edge.

analysis in the Edge” as sustained by J. Truchard from

National Instruments at IFAC IMS’16, and “analyz-

ing data close to the device that collected the data can

make the difference between averting disaster and a

cascading system failure” (CISCO, 2015).

Regarding the intelligence distribution, Figure 1

(right side) illustrates how different kinds of industrial

related tasks that can be supported by AI approaches

may be distributed from Cloud to Edge. This distribu-

tion is not unique, where the same task can coexist in

different layers, handling different system functional-

ities. More details regarding the application of AI/ML

in industrial environments can be found in the related

surveys (Fei et al., 2019; Wang et al., 2018).

Table 1 summarizes several data-driven AI aspects

of Cloud, Fog and Edge in industrial CPS. In gen-

eral, at the Edge or Fog the intelligence is governed by

rule-based and simple data analysis tasks. Since they

comprise execution instead of development environ-

ments, i.e., they are not designed to build or train ML

data models, which should be performed at the Cloud.

For instance, classification and prediction data models

can be easily deployed at these devices, since after the

model creation, their execution comprises the simple

verification of a set of rules or equations (e.g., deci-

sion tree or even Neural Network algorithms). For in-

stance, regarding the Deep Learning, there are several

works that propose the distribution of the neural net-

work layers along Cloud to Edge, which besides of-

fload the computation in central servers can also pro-

vide a local fast and partial response (Li et al., 2018).

Additionally, when considering Edge devices with

their limited resource and very local and incomplete

view of the system, the outcomes of the data analy-

sis will be very simple and highly uncertain. On the

other hand, at the Fog it is possible to reduce the lev-

els of uncertainty, since the related equipment have

more computational power and a wide view of the en-

Distributing Intelligence among Cloud, Fog and Edge in Industrial Cyber-physical Systems

449

Table 1: Data-driven AI aspects of Cloud, Fog and Edge in industrial CPS.

- Cloud Fog Edge

Scope Big Data and AI platforms and

tools for development, manage-

ment, planning and optimization

Computing platforms for low-latency

data processing and integration of cy-

ber and physical components

End devices enhanced with moni-

toring, data preprocessing and fil-

tering capabilities

Data volume, va-

riety and velocity

(persistence)

Huge volume of heterogeneous ex-

ternal, historical and stream data

(very long-term)

Mid-volume of multiple data streams

and no or short-term historical data

(mid/short-term)

Low volume of local raw stream

data (very short-term/transient)

Data processing

type (coverage)

Advanced batch and stream data

analysis (huge number of heteroge-

neous sources)

Lightweight data integration, batch

and stream preprocessing and analysis

(many local sources)

Simple stream preprocessing, fil-

tering and data analysis (sin-

gle/very few sources)

Responsiveness Long and mid-term with optimal

solutions

Near real-time with reason-

able/reliable solutions

Very fast (hard real-time), but

simple/non-optimal solutions

Intelligent fea-

tures (algorithm

complexity)

Complex pattern detection, pre-

scriptive decision support (Big

Data and advanced ML)

Local context-awareness, predictive

decision support and dynamic adapta-

tion (mid/advanced ML)

Self-awareness, autonomy and

collaboration (lightweight, rule-

based and built-in data analysis)

Hardware devices

(organization / lo-

cation)

Remote powerful data centers (cen-

tralized / multiple hops)

Local network equipment, micro

servers and computing devices / plat-

forms (distributed / one hop)

IoT and non-IoT device gateways

(decentralized / embedded, direct

connection)

Examples of de-

vices in industrial

contexts

General or industrial, public or

private Cloud infrastructures and

servers

Industrial network routers, supervi-

sory and control room servers, work-

station computers

PLCs, PACs, machines with em-

bedded computing boards (FP-

GAs), AGVs, Robots

Examples of sup-

ported tasks and

applications

Business Intelligence, simulation,

scheduling and interactive tools to

support decision/operational tasks

Augmented reality, predictive super-

visory and control systems (asset con-

dition, product quality, process status)

Self-adaptive monitoring and

control, dynamic reconfiguration,

M2M collaboration

vironment. The diversity of Fog components enables

to host almost any kind of AI-based application. In

this sense, Fog nodes are responsible for a variety of

data intensive applications, including the integration

and processing of multiple real-time streams.

Considering all these aspects, at the Edge and Fog

levels some examples of application that use AI in in-

dustrial automation includes system real-time moni-

toring, early detection of abnormality and local diag-

noses (Aazam et al., 2018).

Besides its virtually unlimited computational re-

sources, Cloud provides the centralization of data

combined with powerful processing capabilities,

which can ease the complexity of data analysis. This

makes Cloud suitable for the development of Big

Data analysis solutions for both operational and busi-

ness levels, and specially considering their integra-

tion. Different from Edge and Fog, which are highly

suitable for the operational levels, Cloud fits better the

needs of enterprise and business levels, since it can

face latency, bandwidth and security issues. In this

sense, most of the operational tasks will require a pri-

vate corporate Cloud or Fog-based infrastructure.

In summary, Cloud provides optimization and

continuous improvement, but lacks responsiveness,

while Edge devices are resource constrained and can

easily saturate with processing, but offer real-time

monitoring and fast response. Fog can help to reduce

the overload of both Cloud and Edge, and at the same

time handle other issues. On the other hand, when

compared with Edge and Cloud, Fog may present

higher levels of complexity, mainly regarding its gate-

way role, since it needs to support the integration of a

wide number of heterogeneous devices, protocols and

technologies. In this sense, it is clear that there should

exist a balance of the computational resources among

each one of these layers, and just as important as, an

appropriate interconnection of them.

3.2 Connecting Computing Layers

There is no doubt that the decentralization of data

analysis from Cloud to Fog and Edge layers is es-

sential to attend the 4IR requirements. However, it

does not depend only on the decentralization of tasks,

but in the way the components are interconnected ver-

tically and horizontally, and how they can support

each other. In this context, AI goes beyond ML data-

driven approaches, where MAS can support the de-

sign and management of such components, allowing

to develop intelligent and self-organized distributed

systems. MASs are based on the concept of au-

tonomous and cooperative agents, that work as a ves-

sel for different kinds of processing and control AI

algorithms. In this sense, agents can be distributed

along the Cloud, Fog and Edge layers, encapsulat-

ing the system functionalities and collaborating with

each other (Pico-Valencia and Holgado-Terriza, 2018;

Wang et al., 2016; Leit

˜

ao et al., 2016).

Although MAS can provide standardized commu-

nication interfaces that can cope with the complexity

posed by the devices heterogeneity, usually they do

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

450

not attend hard real-time constraints or run in con-

strained devices, such those found at the Edge layer

(Calvaresi et al., 2017). In such scenarios, agents

may be deployed at Fog and Cloud layers, while the

Edge components should interact using standardized

service-oriented or lightweight IoT communication

solutions, e.g., MQTT, CoAP or OPC-UA.

In this context, while the Edge covers the physical

systems, the Fog and Cloud encompass an interme-

diate and a high-level layer of cyber systems. Fog

directly supports Edge, mainly regarding time con-

strained tasks, while offloading Cloud systems. On

the other hand, Cloud applications have a global view

of the system, which enable them to support the lower

layer components. Therefore, Cloud applications take

advantage of the operational data combined with busi-

ness information to provide actionable information

for business level personnel and engineers. Besides

supporting strategic decision-making, or operational

engineers (e.g., enhancing their skills during the plan-

ning and execution of interventions), it can generate

knowledge to be used in the different layers (e.g., up-

dated rules for monitoring systems at the Edge).

4 CHALLENGES

As previously discussed, AI is an enabler to develop

industrial CPS, playing two main roles: provide data-

driven approaches to endow cyber and physical com-

ponents with data analysis capabilities, and provide

distributed system and knowledge management ap-

proaches to endow such components with autonomy,

reasoning and collaborative capabilities. In this con-

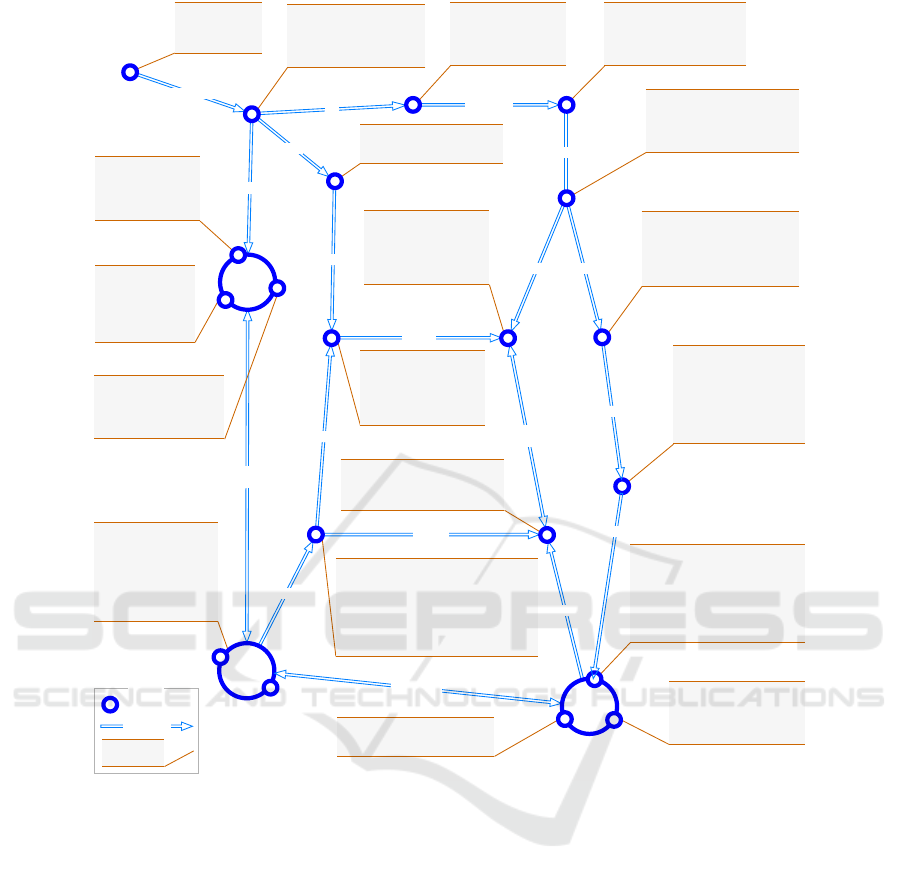

text, several cross concerns can be leveraged along

the development of industrial CPS, such those illus-

trated in Figure 2. Based on that, some scientific and

technological challenges can be identified, such those

listed in Table 2. Their expected development diffi-

culty and business priority are also presented, based

on the 4IR visions, requirements and technologies.

4.1 Decentralization

The distribution of data processing capabilities con-

tributes with the decentralization of decision-making

and control, which is crucial for the fully fulfillment

of industrial CPS, mainly regarding the system adapt-

ability and autonomy. However, it is not a straightfor-

ward task, presenting several issues, for example the

performance of conventional centralized data-driven

AI approaches can be drastically affected when con-

sidering a small set of attributes or number of sam-

ples. Thus, this multi-level (glocal - global and lo-

cal) data analysis, demands special concerns regard-

ing what kind of data processing capabilities should

be performed in each computational layer, as well as

the mechanisms to manage the components (horizon-

tal and vertical) interaction and other communication

and interoperability issues.

Additionally, mechanisms and policies should be

designed to cope with the system complexity and

emergent behavior, enforcing the components to re-

spect a set of rules and constraints, thus also assuring

the QoS and Trust, regarding the reliability and secu-

rity of shared information and resources.

4.2 Intelligent Machines and Products

The development of intelligent machines and prod-

ucts is another key aspect in industrial CPS. The chal-

lenge is not limited to the use of the next generation

of intelligent equipment that natively support AI fea-

tures, but mainly to adapt traditional approaches and

embed them in the existing constrained device plat-

forms. This requires the need to consider smooth mi-

gration approaches.

The intelligence in such components will be

achieved through the development of decentralized

collaborative self-reconfigurable and coordination al-

gorithms and policies. These mechanisms can in-

crease the autonomy, flexibility and response time,

but also the complexity of the system and its com-

ponents, thus comprising a main trade-off when

compared with centralized approaches. The sys-

tem adaptation nervousness is another issue in such

self-reconfigurable and distributed environments that

should be managed.

On the other hand, enable these components to au-

tonomously take decisions and control raises several

security concerns, e.g., when considering their inter-

action with people. In this context, the lack of ex-

plicitly explanation for the outputs of ML approaches

is one of the main reasons that prevents the fully au-

tonomous AI-based control systems. Thus, requiring

further research to assure the deterministic behavior

of AI approaches and in what kind of industrial appli-

cations they could be safely applied. Also in this con-

text, the certification of AI software is an important

issue that should be addressed to assure the security

and proper operation of such systems.

Another essential requirement in industrial do-

main is related to the development of predictive an-

alytics. However, given the impact of prediction in

industrial decision making, it is only valuable when

presenting high accuracy and proper response time.

Distributing Intelligence among Cloud, Fog and Edge in Industrial Cyber-physical Systems

451

legend

are

have

are used to

is supported by

is based on

supports

Embedded

computing

- Infrastructure (wired

wireless)

- Bandwidth & costs

- Connectivity/Availability

- Reliability

-Topology(P2P, Pub/Sub)

- Scalability / service-oriented

- Protocols/ Middleware

- Proprietary & ind. standards

- Data model

- Constrainedresources

processing, memory,storage)

- Power supply

processed by

enables

- M2M comm., negotiation,

collaboration, information share

& trust (mechanisms & protocols)

- Self-organization

- Distributedapproaches (MAS)

- IoT-based platforms

- Mobility

- Interoperability

- Real-timeoperating system

- Plug&Play

- Cloud platforms,

providers&infrastructures

(public/private)

- Business model

compliance

- Data management

services (Storage/Analysis)

- Virtualization / XaaS

- Embed AI/ML

- Responsiveness

- Dynamic env. & limited

view/context

- Data analysis uncertainty

- Stream analysis

smart machines/ products

- Autonomy / event-driven

- Emergent behavior

- Self-awareness

- Adaptability(Monitor-

Analyze-Plan-Act)

produces >

< consumes

enables

- Virtual/Augmented Reality

- Human-in-the-loop

- Personal assistants &

Intelligent interfaces(support

& enhancetask execution)

- Heterogeneous / distributed

resource integration/coordination

- Predictive/prescriptive analytics

- Availability/frequency

(stream/batch)

- Volume,variety/type

(discrete/continuous)

(time-series,

measurements, text, img)

- Storage (SQL/NoSQL),

aggreg./integrate

- Legacy equip.

(adapt / replace)

Smooth migration

- Gateway devices

- Sensor techs.,

tasks,environment

- Sensitivity, signal

conditioning,sampling

- Reliability

- Reconfigurability

- Reactivity

(resp. time)

- Control: stochastic

- deterministic /

discrete - continuous

- Portability, ergonomics,

usability, interactivity

- Platforms, user interfaces

- Machine interaction

& collaboration

Industrial

Digitization

Networked

connects

Edge

Devices

interact with >

< receive support

Intelligent

physical

systems

Data &

information

Business

Operational

- Latency & bottlenecks

- Data security & privacy

- Net. equip. (brokers/gateways)

- Vertical/horizontal integration

- Edge & Cloud load balancing

(data aggreg., preproc., analysis)

provide

Cloud-based

solutions

complement

Fog

Nodes

supports

- Business: Enterprise Resource

Planning; Business Intelligence;

Customer Relationship, Supply Chain

&Product Lifecycle Management

- Operation: planning,

optimization, maintenance,

simulation, modeling

- Operational & Business integration

produces >

< consumes

- Cyber systems & Digital Twin

- Actionable information

- Output accuracy, resp.time,

interpretability &Quality of Service

Embedded

systems

Monitoring

- Big Data frameworks & automated tools

- Data scientists & domain knowledge

- Model build/train/tune & interpretability

- (un)supervised & reinforcement learning

- Extract Transform Load, explore & extract

features/knowledge/patterns

- Knowledge representation & sharing

- Unlabeled & imbalanceddatasets

supports

supports

Edge data

analysis

Data

Analysis

services

IoT-based

communication

Component

interaction

ML/Data

Mining

Systems

Agent

Human

Interaction

Supervision

Management

Control

Human-

machine

interface

CPS elements

relationship

- Cross

concerns

host applications for

Figure 2: Cross concerns of AI decentralization towards industrial CPS.

4.3 Industrial Big Data

Industrial Big Data mostly comprises raw time-series

data from hundreds to thousands of heterogeneous de-

vices, complemented with business data (e.g., logis-

tics, sales and customers). In this context, besides re-

moving the barriers between business and operational

layers, the challenge is to develop approaches capable

to proactively use business information to redefine the

course of operations and in the same way, adapt the

business strategies based on operational data.

As aforementioned, data has been considered a

key asset in any industry, however collecting and stor-

ing everything only increases the costs and complex-

ity to extract value from it. In spite of the bene-

fits of preprocess the data close to the data sources,

this should be handled carefully, since some algo-

rithms can mistakenly remove or cover important val-

ues. Additionally, some applications may require to

transfer raw data, e.g., Digital Twin. This reinforces

the need to harmonize the data processing at the Edge.

In industrial domain, mainly regarding the opera-

tional level, besides overcoming data uncertainty, reli-

ability and incompleteness, the ML algorithms should

be able to handle imbalanced or unlabeled datasets.

Both are very common aspects in such environments,

given that abnormalities are not so common, and usu-

ally are not proper labeled. This restricts the use of

supervised learning algorithms, raising the need to

adopt techniques to enforce the user feedback in the

annotation of data samples. However, the user inter-

action at the Edge and Fog layers may not be feasible,

thus leveraging the importance of unsupervised learn-

ing approaches in the operational levels.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

452

Table 2: Challenges for implementing intelligence in industrial CPS.

Key Aspect Major Challenges Difficulty Priority

Decentralization

Decentralized and collaborative data analysis high medium

Synchronization and management of glocal data analysis medium high

Control the system emergent behavior high low

Intelligent machines

and products

Embed AI in constrained device platforms medium medium

Self-reconfigurable and collaborative mechanisms high high

Completely autonomous decision-making high low

Predictive and proactive analytics medium high

Industrial Big Data

Synergy between operational and business information medium low

Efficient and reliable data acquisition and management low high

ML algorithms dedicated to industrial Big Data medium medium

Support data uncertainty, reliability and incompleteness high medium

Infrastructures and

tools

Enhanced automated data analysis tools medium low

CPS frameworks and testbeds medium high

Knowledge representation and sharing low medium

Multi-disciplinary knowledge and expertise in AI and CPS high high

Human Agent Interaction high high

4.4 Infrastructures and Tools

There are several challenges, not only related to

frameworks, tools and standards for the development

and testing, but also in terms of professionals with

multi-disciplinary skills capable to develop and use

such systems. In spite of the existence of several

frameworks to assist and automate several data anal-

ysis tasks, usually being able to find ML models that

outperform the ones developed by hand, most prob-

lems still require domain knowledge which refrains

the complete process automation. This illustrates

that even considering the higher level of automation,

the human presence will be still required to develop,

maintain and also operate such complex systems.

In the same sense, Human Agent Interaction ap-

proaches aim to provide dynamic, interactive and in-

telligent interfaces for personnel interacting software

and physical systems. These approaches take advan-

tage of computer vision, speech recognition and aug-

mented/virtual reality, to create a partnership between

human and system that can enhance their productivity

and efficiency, as well as the quality of the outcomes.

Another important aspect is the need to test and

evaluate the CPS solutions before the deployment in

real environments, allowing to demonstrate their fea-

sibility to industrial stakeholders. In this context, a

major challenge lies in the development of dedicated

CPS frameworks and testbeds, considering bench-

marks and real case studies, not only capable to sup-

port the integration of the related technologies but

also to test, monitor and evaluate the distributed and

emergent behaviors.

5 CONCLUSIONS

In the 4IR, AI-based approaches cannot be seen any-

more as just promising solutions, but instead as a must

for any industrial system. On the other hand, in spite

of the large potentialities offered by Cloud-based AI

approaches, it is clear that they are not suitable to at-

tend some important requirements of industrial CPS,

namely the fast response, limited bandwidth and data

sensitive. Moreover, sending all the raw data to the

Cloud is costly and makes no sense, since most of it

is meaningless and carries no significant value. How-

ever, the processing capabilities at or near the physi-

cal levels are very limited, not only regarding the con-

strained computational resources, but also the lack of

context-awareness. In this context, this paper high-

lights the need and importance to achieve a balanced

distribution of intelligence and computational capa-

bilities among Cloud, Fog and Edge computing lay-

ers, aiming to achieve the desired levels of customiza-

tion and dynamic adaptability envisioned by the 4IR.

The envisioned solution considers to take advan-

tage of the technologies provided by each one of these

layers to create a decentralized multi-level and col-

laborative data analysis infrastructure for the design

and development of intelligent machines, products

and systems. In this context, it is raised and discussed

the emerging requirements, trade-off, issues and some

major challenges that need to be properly addressed.

It is also pointed out some research directions related

to key concepts, approaches and technologies for the

successfully exploitation of such industrial CPS.

Distributing Intelligence among Cloud, Fog and Edge in Industrial Cyber-physical Systems

453

ACKNOWLEDGEMENTS

This work is part of the GO0D MAN

project that has received funding from

the European Union’s Horizon 2020

research and innovation programme

under grant agreement N

o

723764.

REFERENCES

Aazam, M., Zeadally, S., and Harras, K. A. (2018). Deploy-

ing fog computing in industrial internet of things and

industry 4.0. IEEE Transactions on Industrial Infor-

matics, 14(10):4674–4682.

Al-Fuqaha, A., Guizani, M., Mohammadi, M., Aledhari,

M., and Ayyash, M. (2015). Internet of things: A

survey on enabling technologies, protocols, and ap-

plications. IEEE Communications Surveys Tutorials,

17(4):2347–2376.

Bauer, H., Baur, C., Camplone, G., and et. al. (2015). Indus-

try 4.0: How to Navigate Digitization of the Manufac-

turing Sector. Technical report, McKinsey Digital.

Bonomi, F., Milito, R., Natarajan, P., and Zhu, J. (2014).

Fog Computing: A Platform for Internet of Things and

Analytics, pages 169–186. Springer.

Breivold, H. and Sandstr

¨

om, K. (2015). Internet of things

for industrial automation – challenges and technical

solutions. In 2015 IEEE Int’l Conf. on Data Science

and Data Intensive Systems, pages 532–539.

Calvaresi, D., Marinoni, M., Sturm, A., Schumacher, M.,

and Buttazzo, G. (2017). The Challenge of Real-time

Multi-agent Systems for Enabling IoT and CPS. In

Proc. of Int’l Conf. on Web Intelligence, pages 356–

364. ACM.

Chiang, M. and Zhang, T. (2016). Fog and IoT: An

Overview of Research Opportunities. IEEE Internet

of Things Journal, 3(6):854–864.

CISCO (2015). Fog Computing and the Internet of Things:

Extend the Cloud to Where the Things Are. Technical

report, Cisco, white paper.

Duan, Y., Fu, G., Zhou, N., Sun, X., Narendra, N., and Hu,

B. (2015). Everything as a service (xaas) on the cloud:

origins, current and future trends. In 8th IEEE Inter-

national Conf. on Cloud Computing, pages 621–628.

Fei, X., Shah, N., Verba, N., Chao, K.-M., Sanchez-

Anguix, V., Lewandowski, J., James, A., and Usman,

Z. (2019). Cps data streams analytics based on ma-

chine learning for cloud and fog computing: A survey.

Future Generation Computer Systems, 90:435 – 450.

Geissbauer, R., Vedso, J., and Schrauf, S. (2016). Industry

4.0: Building the digital enterprise. Technical report,

PwC.

Khaitan, S. K. and McCalley, J. D. (2015). Design tech-

niques and applications of cyberphysical systems: A

survey. IEEE Systems Journal, 9(2):350–365.

Lee, J., Davari, H., Singh, J., and Pandhare, V. (2018). In-

dustrial artificial intelligence for industry 4.0-based

manufacturing systems. Manufacturing Letters,

18:20–23.

Leit

˜

ao, P., Colombo, A., and Karnouskos, S. (2016). In-

dustrial automation based on Cyber-Physical Systems

technologies: Prototype implementations and chal-

lenges. Computers in Industry, 81:11–25.

Leit

˜

ao, P., Karnouskos, S., Ribeiro, L., Lee, J., Strasser, T.,

and Colombo, A. W. (2016). Smart agents in indus-

trial cyber-physical systems. Proceedings of the IEEE,

104(5):1086–1101.

Li, L., Ota, K., and Dong, M. (2018). Deep learning for

smart industry: Efficient manufacture inspection sys-

tem with fog computing. IEEE Transactions on In-

dustrial Informatics, 14(10):4665–4673.

Lu, Y. (2017). Industry 4.0: A survey on technologies, ap-

plications and open research issues. Journal of Indus-

trial Information Integration, 6:1–10.

Mell, P., Grance, T., and et al. (2011). The NIST definition

of cloud computing.

Ota, K., Dao, M. S., Mezaris, V., and Natale, F. G. B. D.

(2017). Deep learning for mobile multimedia: A

survey. ACM Trans. Multimedia Comput. Commun.

Appl., 13(3s):34:1–34:22.

Pico-Valencia, P. and Holgado-Terriza, J. A. (2018). Agen-

tification of the internet of things: A systematic lit-

erature review. International Journal of Distributed

Sensor Networks, 14(10).

Ren, L., Zhang, L., Wang, L., Tao, F., and Chai, X. (2017).

Cloud manufacturing: key characteristics and applica-

tions. International Journal of Computer Integrated

Manufacturing, 30(6):501–515.

Shi, W., Cao, J., Zhang, Q., Li, Y., and Xu, L. (2016). Edge

computing: Vision and challenges. IEEE Internet of

Things Journal, 3(5):637–646.

Wang, J., Ma, Y., Zhang, L., Gao, R. X., and Wu, D. (2018).

Deep learning for smart manufacturing: Methods

and applications. Journal of Manufacturing Systems,

48:144–156. Special Issue on Smart Manufacturing.

Wang, S., Wan, J., Zhang, D., Li, D., and Zhang, C.

(2016). Towards smart factory for industry 4.0: a

self-organized multi-agent system with big data based

feedback and coordination. Computer Networks,

101:158–168.

Wooldridge, M. (2002). Introduction to Multiagent Systems,

volume 30. John Wiley and; Sons, Inc.

Wuest, T., Weimer, D., Irgens, C., and Thoben, K.-D.

(2016). Machine learning in manufacturing: advan-

tages, challenges, and applications. Production &

Manufacturing Research, 4(1):23–45.

Xiao, Z. and Xiao, Y. (2013). Security and privacy in cloud

computing. IEEE Communications Surveys Tutorials,

15(2):843–859.

Xu, L. D., He, W., and Li, S. (2014). Internet of things in

industries: A survey. IEEE Transactions on Industrial

Informatics, 10(4):2233–2243.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

454