Ambulance Car Logistics using Shortest Path Achievement Tree in

Plant Simulation

Jolana Sebestyénová

a

and Peter Kurdel

b

Institute of Informatics, Slovak Academy of Sciences, Bratislava, Slovakia

Keywords: Discrete Event Systems, Object Oriented Modelling, Simulation, Logistics, Graph, Shortest Path,

Achievement Tree, Tecnomatix Plant Simulation, Resource Statistics, In Memory Database, SQlite, Data

Retrieval.

Abstract: Tecnomatix Plant Simulation software based on discrete-event modelling and simulation provides all the

necessary equipment to operational modelling of real-world systems. Models created in it can be useful in

different ways. Running long time simulation of some model, the user can retrieve a sufficiently big amount

of information and data, in adequate degree similar to real world data because of wide range possibilities to

use random parameters in the model. These data retrieved from simulation can be further used to analysis and

test of new design, control, or decision strategies. Model of a simple tracks network with an ambulance car

serving patients from houses along the tracks is used as a test case. The motion of the car is controlled using

a shortest path achievement tree, prepared in an Excel file and read into the Plant Simulation model. Part of

the data received from the model simulation is stored in SQLite in-memory database to be exported for further

analysis.

1 INTRODUCTION

Discrete event modelling and simulation of dynamic

systems present a wide range of research effort for

many years. For example, heuristic scheduling of a

production process using a statecharts model was

described in (Kurdel & Sebestyénová, 2011).

Creation of a distributed flexible manufacturing

system’s model with logistics requires data exchange

and intensive communication between distributed

places. In earlier works of the authors, workflow for

a multi-agent system with voice user interfaces in a

changing environment was described in

(Sebestyénová & Kurdel, 2014a) and multimodal

aspects of communication was given in

(Sebestyénová & Kurdel, 2014b).

All the necessary equipment to operational

modelling of real-world systems is prepared in Plant

Simulation software based on discrete-event

modelling and simulation (Bangsow, 2015). Dealing

with just substantial aspects, it can simulate long-

lasting manufacturing plant operation in seconds.

a

https://orcid.org/0000-0003-4677-9972

b

https://orcid.org/0000-0002-8080-2411

To reflect the natural hierarchy of systems to be

simulated requires a well-structured simulation

models. To this purpose, Plant Simulation offers a

basic object Frame which can be put into the

RootFrame (the main object of the model) or in

another Frame. In this way, complex tasks can be

broken down into manageable parts, using object-

oriented modular design and programming.

Smith (2013) presents a review on the usage of

simulation for construction and functioning of

manufacturing systems. Blaga et al. (2018) compares

modelling based on Petri nets to Tecnomatix Plant

Simulation for management of manufacturing

process. Vavrík, Gregor & Grznár (2017) described

Computer simulation as an instrument for the

optimisation of logistics using automated guided

vehicles.

In the paper, an extension of the authors’ work

(Sebestyénová & Kurdel, 2019) is presented. Model

of a simple tracks network with an ambulance car

serving patients from houses along the tracks,

partially inspired by (Mes, 2017, pp. 91-92) will be

used as a test case. Part of the data received from the

model simulation will be stored in SQLite in-memory

214

Sebestyénová, J. and Kurdel, P.

Ambulance Car Logistics using Shortest Path Achievement Tree in Plant Simulation.

DOI: 10.5220/0008493402140220

In Proceedings of the 3rd International Conference on Computer-Human Interaction Research and Applications (CHIRA 2019), pages 214-220

ISBN: 978-989-758-376-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

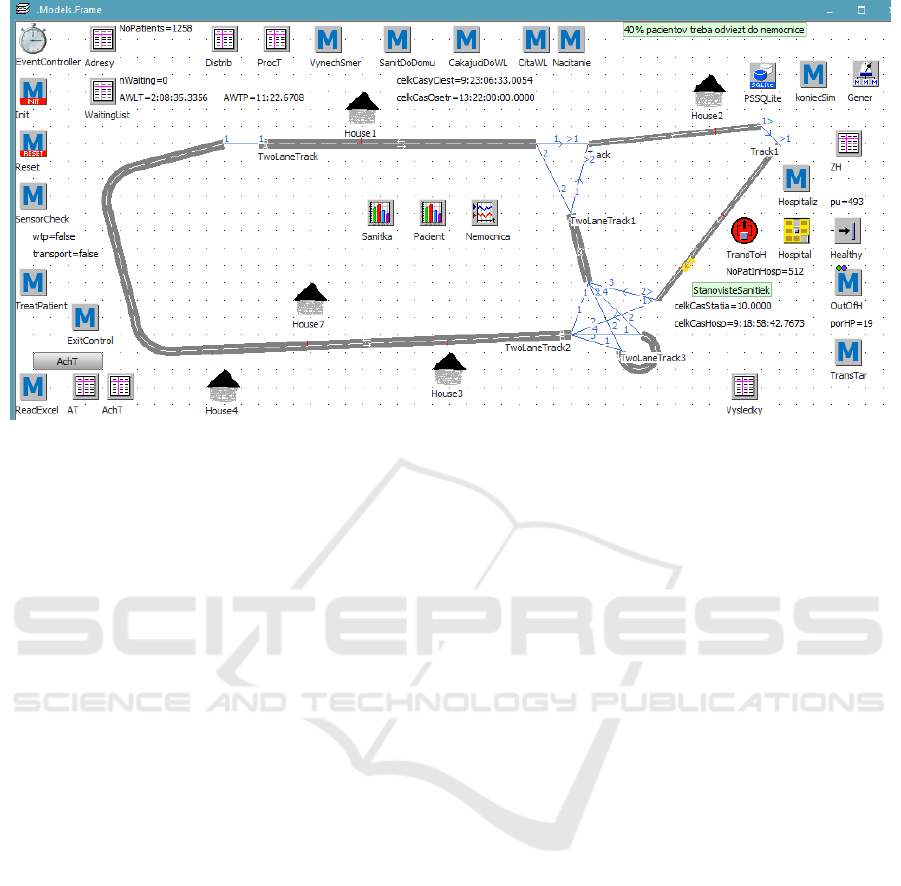

Figure 1: Model’s main frame in Plant Simulation with 2 one-way tracks and 4 two-lane tracks at end of simulation.

database to be exported for further analysis, which

can be done in the model as well as outside of it.

2 MODEL OF A TRACKS

NETWORK WITH AN

AMBULANCE CAR

The tracks network considered in the paper consists

of 4 two-lane tracks where cars can move in two

directions and 2 one-way tracks with two crossroads.

Connectors between two-lane tracks work for both

traffic directions, but connectors connecting one-lane

tracks distinguish the traffic directions. The

TwoLaneTrack3 is only used to change the moving

direction of the car, if needed. Along the routes there

are 5 houses where patients turn up at some random

time and one hospital where some of the patients need

to be transported after a short treatment at home.

In commercial applications, animation and

visualisation of results are often used to

communication with the user. In research works, it is

adequate to concentrate on functional aspects and use

animation only during debugging. This enables to run

long time simulation retrieving sufficiently big

amount of data. The Interpreter executes the source

code written in programming language SimTalk

entered into any Method object. SimTalk 2.0 is used

in the model. In the proposed model’s main frame, the

most important objects are the routes of a tracks

network, as can be seen in Fig. 1.

The model contains one ambulance car (AC)

derived from a Transporter type mobile unit from the

Plant Simulation Class library (corresponding class is

named CarGP, meaning a general practitioner in the

car). It is created by Init method, at the start of the

simulation. The AC waits at parking place near the

hospital until an order appears, and it also moves to

this place if no more patients are waiting for

treatment.

The parking place, the hospital, as well as all of

the houses have assigned its position sensor on the

track which indicates a stop position of the car serving

this place. In case of two-lane tracks, the sensor is

assigned only to one half of the track with proper

traffic direction. Each time the car approaches the

sensor, SensorCheck method starts to control further

simulation run.

2.1 Shortest Path Achievement Tree

Shortest path problem between vertices in the

weighted directed graph, shortest path tree,

bidirectional search etc. are widely described in the

literature (Wikipedia, 2009). Dijkstra's Shortest Path

algorithm enables to find the shortest paths between

nodes in a graph, which may a.o. stand for road

network. It was published in the year 1959. The

problem is defined for simple graphs without cycles,

negative weights, multigraphs, or loops. For

problems similar to the described one, the negative

weights are not needed, but the other properties will

occur with high probability. The structure of Bellman

Ford's algorithm and Dijkstra's algorithm is very

Ambulance Car Logistics using Shortest Path Achievement Tree in Plant Simulation

215

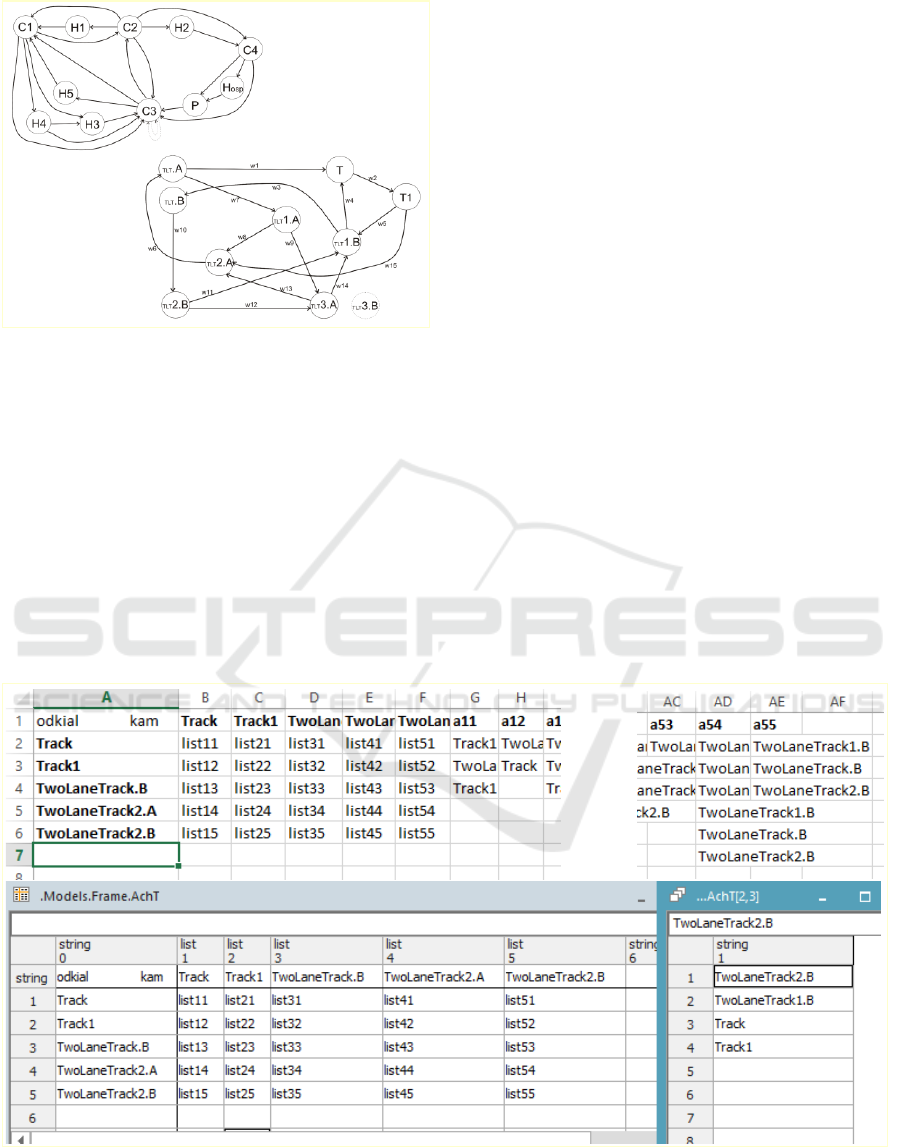

Figure 2: Two graphs created according to the model of the

tracks network.

similar. While Dijkstra takes into account only the

immediate neighbours of a node (breadth first),

Bellman looks into each edge in every iteration (depth

first search). Many different, enriched algorithms are

available for graphs with widened properties.

Given a graph G = (V, E) and a source vertex u,

the shortest distance from u to every other vertex v in

V could be found e.g. by Dijkstra’s algorithm, but in

the test case some tracks need to enable move in both

traffic directions. For this reason, creation of the

graph from the model’s routes network must take it

into consideration, as can be seen in the top part of

Fig. 2. The nodes consist of the position sensors near

the houses, the parking place and the hospital, and of

connectors of the routes. The edges represent the

routes with directions. The routes length are specified

during creation of the model. Positions of the houses

on the routes are specified in the TableFile Adresy,

which enables to compute the routes parts lengths.

One can prepare the shortest path achievement

tree from any place on the route specified by a sensor

to any other place. Another possibility (as can be seen

in the bottom part of Fig. 2) is to create the graph in

which nodes represent the tracks. The paper suggests

that the shortest path achievement tree (based on the

route length) received from the graph is prepared in

an Excel file. The creation of the tree is out of the

scope of the paper, but e.g. Kurdel & Sebestyénová

(2013) described routing optimization for ATM cash

replenishment for ATM‘s places received from

Google maps of town Bratislava and its surroundings.

To illustrate the achievement tree of the presented

model, a part of it is given in the top part of Fig. 3,

where rows specify starting tracks and columns

specify destination tracks.

Using a method ReadExcel, this data is imported

into Plant Simulation table and lists, as can be seen in

the bottom part of Fig. 3. The table at the left contains

lists representing branches of the tree, and an example

list at the right contains tracks names and traffic

Figure 3: Shortest path achievement tree: at the top, in Excel file (as input file to the model); at the bottom, after being read

into Plant Simulation table and lists (list23 is one branch of the tree - from TwoLaneTrack.B to Track1).

Two loops (in light gray)

TwoLaneTrack3 with its

traffic directions are not

necessary in top graph.

The node

representing the

TwoLaneTrack3.B

(TLT3.B) is not

necessary, as this

direction of the

track is not used.

…

CHIRA 2019 - 3rd International Conference on Computer-Human Interaction Research and Applications

216

directions (A/B). These lists will be used to control

the car driving to its destination (which may be one

of the houses / the hospital / the parking place) during

the simulation.

3 PATIENTS REQUIREMENTS,

TREATMENT AND

HOSPITALISATION

The Patient class is derived from Entity type mobile

unit (MU) from the Class library. The house instances

are derived from the House class created in

UserObjects category in Plant Simulation Class

library. As both classes and instances are named

objects in Plant Simulation software, the users must

take care to properly distinguish between them.

The model works with two sub-classes of patients.

While some of them can be served by care at home

(sub-class Pat), another part needs to be transported

to the hospital, after a short treatment at home (sub-

class PatHosp). Distribution of instances of the sub-

classes is specified in Distrib TableFile of the main

frame of the model; in the simulated case about 40%

of the patients need transport to the hospital.

Figure 4: Sub-frame of one of the houses where patients

emerge (the class of the House, from which 5 instances will

be derived).

Fig. 4 presents a sub-frame of one of the houses

where sometimes someone gets ill, which is

represented by a Source type icon called GetIll. If

someone gets ill in the house, ReqTreatmet method

starts the AC moving to the house if the AC is free. If

the AC is not free, e.g. moving to another patient or

waiting to the end of the treatment provided to the

patient by the GP, etc., the new requirement data is

stored in a WaitingList TableFile. The next patient to

be served will be read from the WaitingList file in

FIFO order, after finishing the previous patient

treatment, or after the transport of the patient to the

hospital.

When the AC stops at the house, the patient in the

house frame moves from the source to a station

entitled GP, which represents the general

practitioner‘s work in the house. If the treatment at

home is sufficient, after some random treatment time

the patient (Pat) moves to a drain icon entitled

Recovery and ceases to exist in the model. If the

patient needs further hospitalization, the AC will

transport him/her (PatHosp) to the hospital. To

accomplish this, the patient moves to a

TransferStation entitled ToHospital after a short

random treatment time. The TransferStation

ToHospital enables boarding the patient on the AC.

In both cases, the movement of the patient out of the

GP station starts a Ready method in the House frame.

The method writes some statistics data into an in-

memory database (will be described latter).

Another TransferStation entitled TransToH in the

model’s main frame enables transport of the patient

from the AC to the hospital. The hospital is created as

a Store type object from the Plant Simulation Class

library. A random hospitalization time is specified for

arriving patient. After this time, the patient moves

from the hospital to a Drain type object entitled

Healthy by means of the method OutOfH in the

model’s main frame and ceases to exist in the model.

This method also writes some data into the database.

4 DATABASE

Tecnomatix Plant Simulation object ODBC enables

to import data from an ODBC database on a server,

e.g. to read parameters of the model to be created and

re-export the changed data back into the database.

Data exchange with an SQL database is also enabled

using SQLite object from the Class library. The object

SQLite uses a database which can be stored in a file

on the local hard disc, but also in main memory. In

that case, a string “:in memory:“ is specified instead

of the file pathname. In Plant Simulation software,

writing/reading data into/from in-memory SQLite

database is faster than writing/reading them into/from

the TableFile object.

As previously mentioned, some of the methods

write data into the SQLite database. The presented

use-case works with only one DB table entitled

Pacienti with 4 columns: MUType, MUName,

StartTime, and EndTime. The first two are texts, the

last two are reals. MUType is a primary key.

After the elapse of 1 month simulation time

(specified in EventController as 31:00:00:00

Ambulance Car Logistics using Shortest Path Achievement Tree in Plant Simulation

217

Figure 5: The ambulance car statistics (left), the patients statistics (centre), the hospital statistics (right).

[dd:hh:mm:ss]), a method koniecSim reads the data

from the DB into a TableFile Vysl and subsequently

writes the data into an Excel file for further analysis.

The next lines present a part from the code of the

method reading data from SQLite:

var sql,sql2:string

var r:integer

sql := "CREATE TABLE IF NOT EXISTS

Pacienti (MUType TEXT PRIMARY KEY,

MUName TEXT, StartTime REAL, EndTime

REAL)"

sql2 := "SELECT * FROM Pacienti"

PSSQLite.open

PSSQLite.exec(sql)

PSSQLite.prepare(sql2)

r := 1

while PSSQLite.step

Vysl[1,r]:=PSSQLite.getColumnString(0)

Vysl[2,r]:=PSSQLite.getColumnString(1)

Vysl[3,r] := PSSQLite.getColumnReal(2)

Vysl[4,r] := PSSQLite.getColumnReal(3)

r += 1

end

PSSQLite.close

Vysl.writeExcelFile("E:\PlantSim\Pacien

ti.xls")

Last line instruction writes data into an Excel file.

4.1 Resource Statistics

The AC statistics can be seen at the left side of Fig. 5.

The instance name of AC object in the model is

CarGP:1, as only one AC is used in the use-case. The

AC‘s whole time of existence (1 month) is divided to

coloured parts of column chart according to: Order

empty part of time (representing the driving part of

time of AC without any patient), Order occupied part

of time (representing the driving part of time of AC

with any patient transported to the hospital),

Unplanned part of time (used to represent treatment

part of time, when the AC is waiting near the house),

Home driving and Ready parts of time, when the AC

actually has no order, i.e. no patient is waiting for

treatment (the AC then drives to the parking place

near the hospital and waits for an order, being ready

to serve).

The Patient statistics are represented in the central

part of Fig. 5. Two sub-classes of the Patient class are

used in the use-case, so statistics of the time usage are

given for the patients from the class Pat (needing only

treatment at home) and for patients from the class

PatHosp (that also need to be transported to the

hospital).

In case of the patients needing hospitalization, the

biggest part of existence time of these patients in the

model is the hospitalization part of the time.

Treatment and Waiting time of these patients are

smaller. The smallest part of the time is the transport

time of these patients. This is influenced also by the

fact that the shortest paths to the hospital are in most

of the cases shorter in presented use-case than the

shortest paths from any house to another house, where

often the change of the traffic direction is needed,

although houses may be on the same track. The

presented very simple tracks network was used to

show the usefulness of similar models, that could also

be created e.g. for optimisation of logistics between

manufacturers, sub-providers, warehouses, and

customers. For the patients cared for only at home,

there are only two slopes in the graph representing the

waiting and treatment time of these patients.

Resource statistics for the hospital can be seen at

the right side of Fig. 5. The number of the patients in

the hospital from start to end of simulation is

represented by the curve named inHospital. The

second curve named released gives the growing

number of released patients from the hospital during

the month.

CHIRA 2019 - 3rd International Conference on Computer-Human Interaction Research and Applications

218

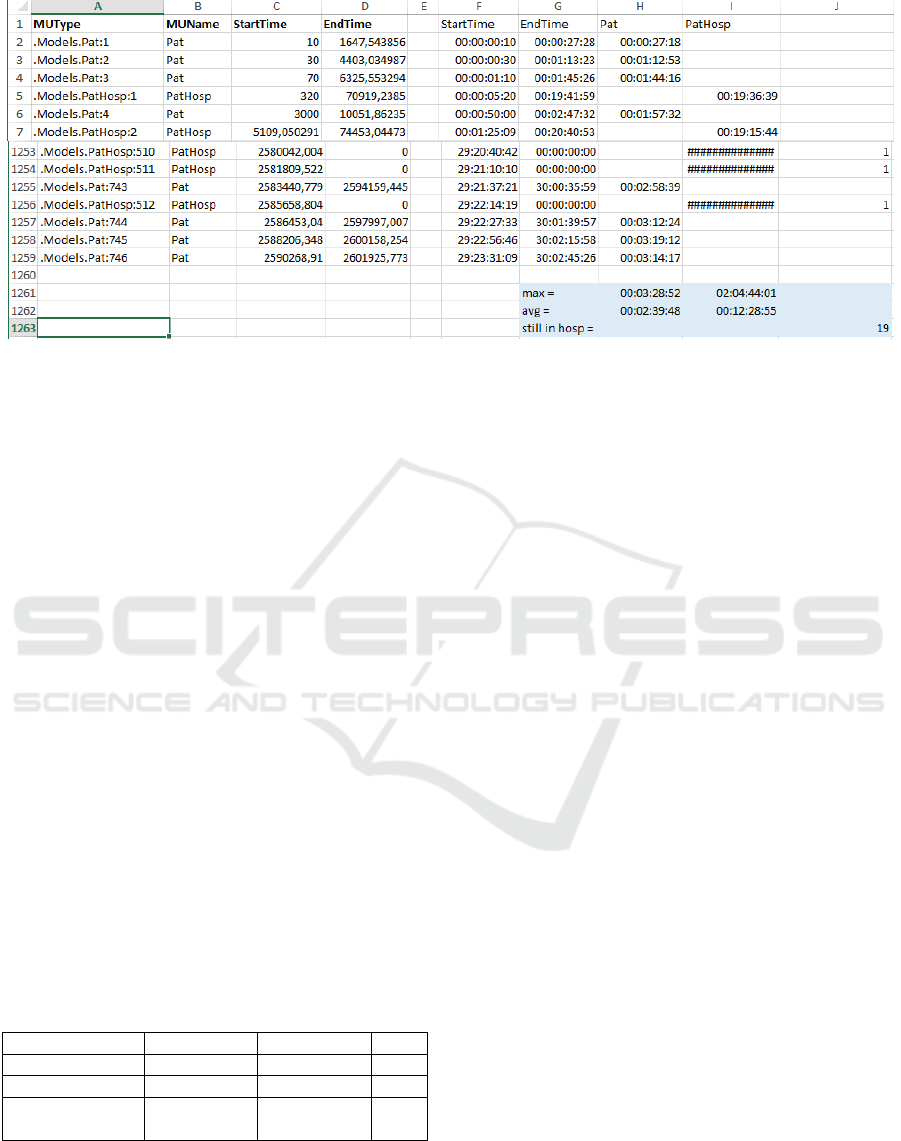

Figure 6: The time of existence of two types of patients in the model exported from SQLite to Excel file for further analysis

of retrieved data.

5 DATA ANALYSIS

The time of existence of two types of patients in the

model exported from SQLite to Excel file to further

analysis of data are given in Fig. 6. DB table columns

(two of type string, and two of type real) mentioned

in section 4 represent for each patient its instance

name, class name, and start/end times of his/her

appearance/disappearance in the model.

In many cases, it is better to transform time data

given in real format to time data given in time format

[dd:hh:mm:ss], which can be done by division by

86400. The existence time of the patient in the model

can be received by subtraction operation (EndTime -

StartTime). At the end of the simulation some of the

patients (instances of the PatHosp class) are still in

the hospital. The end time data for them equals to zero

(initial value), so a result of the subtraction is

negative. This can be used e.g. to obtain the number

of the patients still in the hospital (by a simple count).

In presented use-case there are 19 patients in the

hospital at the end of the simulation.

Table 1: Results from data analysis in the Excel file

exported from SQLite.

Pat

PatHosp

No

Max time

00:03:28:52

02:04:44:01

Avg time

00:02:39:48

00:12:28:55

Still in hospital

at end

19

The existence time of each patient consists of the

waiting, treatment, transport, and hospitalization

time. For illustration, maximum/average existence

time calculated for two categories of the patients are

given in Table 1.

6 CONCLUSIONS

Plant Simulation software and models created in it

can be useful in different ways. Running long time

simulation of some model, the user can retrieve a

sufficiently big amount of information and data, in

adequate degree similar to real world data because of

wide range possibilities to use random parameters in

the model. These data retrieved from simulation can

be further used to analysis and test of new design,

control, or decision strategies. Model of a simple

tracks network with an ambulance car is presented.

Some of the data received from the model simulation

is stored in SQLite in-memory database to be

exported for further analysis.

The model contains one ambulance car (AC)

waiting at parking place near the hospital until an

order for treatment appears and returning to this place

if there are no more patients waiting for treatment.

Shortest path achievement tree from any place on the

routes network to any other place is prepared before

the start of simulation run in a form of an Excel file.

This data is imported into Plant Simulation table and

lists and is then used to control the car moving over

to the destination during the simulation. Some of the

methods write data into SQLite database. After the

elapse of 1 month simulation time (running

approximately 12 s for this simple test case), the data

from the DB is read into a TableFile and subsequently

written into an Excel file for further analysis.

Ambulance Car Logistics using Shortest Path Achievement Tree in Plant Simulation

219

Results presented in the paper can be seen as part

of the project research. Creation of the routes network

model in Plant Simulation is planned (to be done in

future) using Google maps and GPS coordinates of

some important places. Influence of Blockchain on

the transportation industry is described in (Robinson,

2019). In further work, the authors plan to create a

distributed flexible manufacturing system model with

logistics. In such a task, intensive data exchange and

communication between distributed places will be

needed. BlockChain distributed database (Zigurat,

2019) connected to Plant Simulation model will

contain data on products, sub-parts, manufacturers,

sub-producers, customers, orders, etc. and this data

will become the subject of further sophisticated

analysis.

ACKNOWLEDGEMENTS

The authors are grateful to Scientific Grant Agency

of Slovak Republic and Slovak Academy of Sciences

for partial support of this work by projects VEGA

2/0167/16 and VEGA 2/0155/19.

REFERENCES

Bangsow, S, 2015, Manufacturing Simulation with Plant

Simulation and SimTalk- Usage and Programming

with Examples and Solutions, Springer-Verlag,

Berlin Heidelberg, viewed 10/12/2018

https://link.springer.com/content/pdf/10.1007%2F978-

3-319-19503-2.pdf

Blaga, F, Stanasel, I, Pop, A, Hule, V & Karczis, A, 2018,

´The use of modeling and simulation methods to

improve the performance of manufacture lines´ in

ModTech2018 IOP Conf. Series: Materials Science and

Engineering 400 (2018) 042006, viewed 20/2/2019

https://www.researchgate.net/publication/327731392_

The_use_of_modeling_and_simulation_methods_to_i

mprove_the_performance_of_manufacture_lines

Kurdel, P, Sebestyénová, J, 2011, ´Statecharts model and

heuristic scheduling of a production process´ in IEEE

INES 2011 - Budapest, pp. 309-314. ISBN 978-1-4244-

8955-8.

Kurdel, P, Sebestyénová, J, 2013, ´Routing optimization for

ATM cash replenishment´ in International Journal of

Computers, 2013, vol. 7, p. 135-144. ISSN 1998-4308.

Mes, M, RK, 2017, Simulation Modelling using Practical

Examples. A Plant Simulation Tutorial. University of

Twente, viewed 15/10/2018 https://www.utwente.nl

/en/bms/iebis/staff/mes/plantsimulation/tutorialplantsi

mulation13v20170726.pdf

Robinson, A, 2019, Blockchain Technology in Logistics,

viewed 10/4/2019 https://cerasis.com/blockchain/

Sebestyénová, J, Kurdel, P, 2019, ´Modelling,

Optimization, and Simulation of several First Aids in an

Area with Plant Simulation´ in 9th Int. Conf. on

Simulation and Modelling Methodologies,

Technologies and Applications SIMULTECH 2019,

Prague. INSTICC, in print.

Sebestyénová, J, Kurdel, P, 2014a, ´ Workflow for a multi-

agent system with voice user interfaces in a changing

environment´ in IEEE 12th International Symposium

on Applied Machine Intelligence and Informatics SAMI

2014, p. 117-122, ISSN 978-1-4799-3440-9.

Sebestyénová, J, Kurdel, P, 2014b, ´ Multimodal aspects of

communication and data storage and managing

systems´ in IEEE 18th International Conference on

Intelligent Engineering Systems INES 2014, p. 209-214,

ISBN 978-1-4799-4616-7.

Smith, JS, 2013, ´Survey on the use of simulation for

manufacturing system design and operation´ in Journal

of Manufacturing Systems 22(2), pp. 157-171, viewed

20/2/2019 http://dx.doi.org/10.1016/S0278-6125(03)

90013-6

Wikipedia, 2009, ´Shortest path problem´ in

https://en.wikipedia.org/wiki/Shortest_path_problem

Vavrík, V, Gregor, M & Grznár, P, 2017, ´Computer

simulation as a tool for the optimization of logistics

using automated guided vehicles´ in Procedia

Engineering 192, pp. 923-928.

Zigurat, 2019, ´Blockchain Success cases: Supply Chain

and Logistics´ in https://www.e-zigurat.com/

innovation-school/blog/blockchain-success-cases/ vie

wed 20/2/2019.

CHIRA 2019 - 3rd International Conference on Computer-Human Interaction Research and Applications

220