RESISTANCE SPOT WELDING PROCESS IDENTIFICATION

AND INITIALIZATION BASED ON SELF-ORGANIZING MAPS

Heli Junno, Perttu Laurinen, Eija Haapalainen, Lauri Tuovinen, Juha Röning

ISG, Department of Electrical and Information Engineering,PO BOX 4500, 90014 University of Oulu, Finland

Dietmar Zettel, Daniel Sampaio, Norbert Link, Michael Peschl

Fachhochschule Karlsruhe, Institut für Innovation und Transfer, Moltkestr. 30, 76133 Karlsruhe, Germany

Keywords: Resistance spot welding, Se

lf-organizing maps, Process identification, Initialization parameters

Abstract: Resistance spot welding is used to join two or m

ore metal objects together, and the technique is in

widespread use in, for example, the automotive and electrical industries. This paper discusses both the

identification of different spot welding processes and the process initialization parameters leading to high-

quality welding joints. In this research, self-organizing maps (SOMs) were used, and optimal features for

the training parameters were sought. According to the results, processes can be classified by specific

features. When introducing new data to trained SOMs, the welding operator can visually identify similar

processes. After process identification, the most similar process is retrieved and a self-organizing map is

trained for this specific process. The initialization parameters leading to successful welds in that process can

thus be identified, which means that the manufacturers can use them to initialize their welding machines.

1 INTRODUCTION

Spot welding is used to join metal objects. It is

widely used, for example, more than 100 million

spots are produced daily in the European vehicle

industry (TWI). This study explains how SOMs

have been used to identify processes and to find the

initialization parameters leading to good results.

In this paper, the aim is to compare the

characte

ristics of a sample measured from a new

process to information gathered from existing

processes, to find a similar process and then to apply

the process parameters leading to high quality joints.

With this approach, the set-up time of new processes

can be significantly reduced.

The research in the field has concentrated on

esti

mating the quality of welding by using neural

networks and regression analysis. The studies have

utilized different features extracted from data. In

many studies the variation of resistance over time

has been used. Neural network and regression

models have been generated based on the dynamic

resistance pattern by, for example, (Aravinthan,

2001) and (Cho, 2002). Studies using other variables

include approaches involving neural networks with

tip force, the number of weld cycles, the weld

current and the upslope current (Ivezic, 1999).

In this paper, the term ‘process’ is used

diffe

rently compared to the previous studies on

process control of spot welding. In our study, the

welding machines, the material and the thickness of

the material can vary in different processes, but the

changes in current, electrode force or electrode wear

are thought to be internal to the process. In other

studies the term ‘process’ has been used to refer to

the internal changes, including differences in

electrode wear (Mintz, 1995). In other application

areas, such as the copper flash smelting process,

SOMs are used in process control but in these

studies, too, the emphasis has been on the internal

variations of processes (Vermasvuori, 2002).

2 DATA DESCRIPTION AND PRE-

PROCESSING

The data used in this study comprise measurements

of welding tests done at Stanzbiegetechnik (SBT).

The data set contained 5 test series (1107 welding

296

Junno H., Laurinen P., Haapalainen E., Tuovinen L., Röning J., Zettel D., Sampaio D., Link N. and Peschl M. (2004).

RESISTANCE SPOT WELDING PROCESS IDENTIFICATION AND INITIALIZATION BASED ON SELF-ORGANIZING MAPS.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 296-299

DOI: 10.5220/0001128802960299

Copyright

c

SciTePress

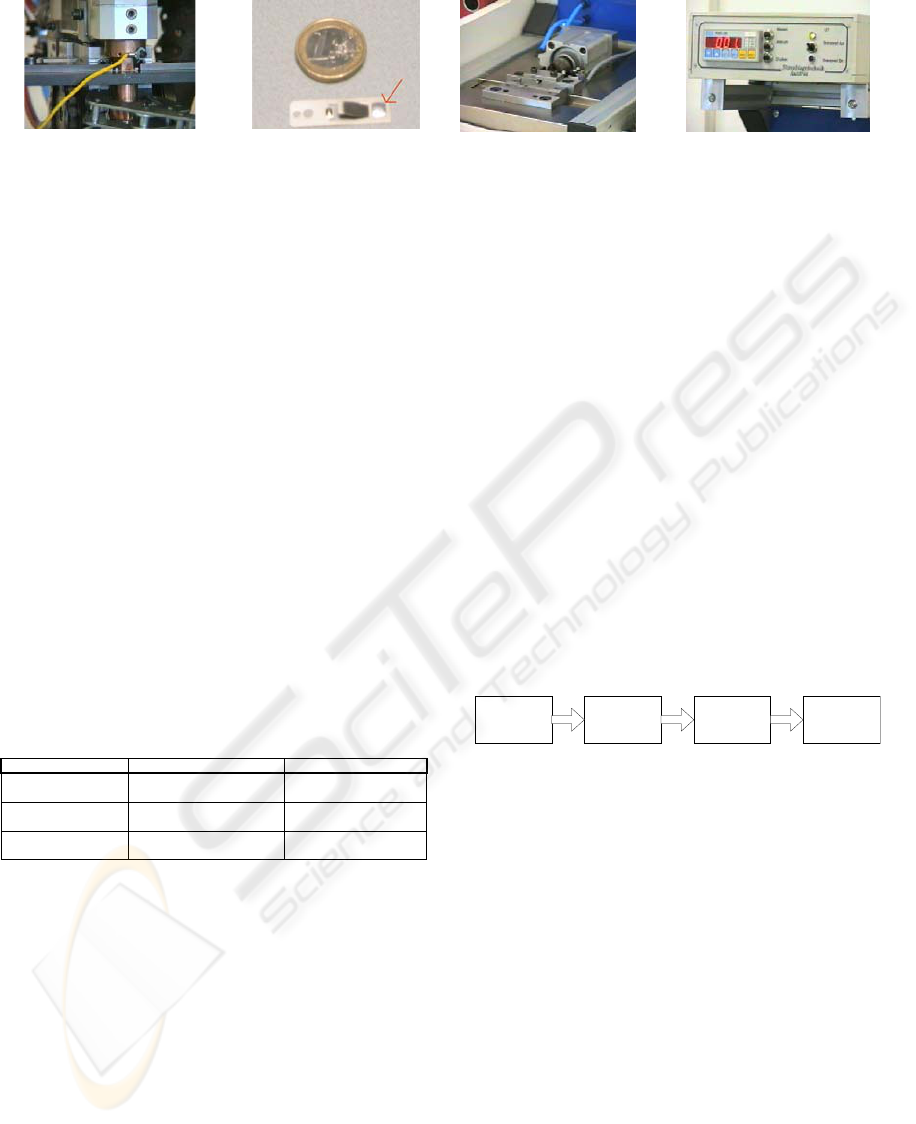

a)

b)

c)

d)

Figure 1: a) metal objects are joined using resistance spot welding, b) the welded part, c) the welding joint is torn apart in

a destructive test by a quality assurance device, d) tensile strength is shown on the screen of the quality assurance device.

experiments). The materials can be seen in Table 1.

The experiments were done by welding two metal

objects together and after that tearing the objects

apart in a destructive test (Figure 1). Each of the

observations contains measurements of current and

voltage signals recorded during and the tensile

strength of the spot measured after the welding.

The resistance curve, derived from the voltage

and current signals, contains the necessary

information for comparing the processes. Since it

was not feasible to train a SOM with all the data

points of a signal curve, suitable features were

extracted. Every resistance signal was divided into

ten parts of equal length, and their averages were

chosen as features. However, the whole feature set

was not used, but the number of features was

reduced to avoid cross-correlation and to eliminate

overlap. Furthermore, the data were divided into

training and test data sets, which consisted of 80 and

20 percent of the data, respectively.

In this work, the quality criterion was given as

tensile strength, and the distribution of quality

varied. For example, the quality limit for SBT 1 was

160 N, while for SBT 3 it was 550N.

Table 1: The materials used

Test series Base material Contact material

SBT 1, SBT 2 0.18mm Stainless steel Silver nickel

0.5x0.9mm

2

SBT 3, SBT 4 (Time

variation)

0.18mm Nickel-Beryllium

Stainless steel

Silver nickel

0.5x0.9mm

2

SBT 5 0.18mm Nickel-Beryllium Silver nickel

0.7x1.5x2.3mm

3

3 METHOD

The self-organizing map is a method that visualizes

high-dimensional data in a two-dimensional space.

This is done by keeping the topologic and metric

relations of the two-dimensional space as close as

possible to the relations of the initial space.

The SOM is usually formed of neurons on a

regular low-dimensional grid. The neurons are

model vectors m

i

=[m

i1

, m

i2

, … , m

in

], where n is the

dimension of the input space. The training is done

iteratively by choosing a data sample x and finding

the closest model vector m

c

(best-matching unit).

When the best-matching unit is found, it and its

closest neighbors are updated with the equation

m

i

(t+1) = m

i

(t) + α(t)h

ci

(t)(x(t) - m

i

(t)),

where α(t) is the learning rate factor and h

ci

(t) is the

neighborhood kernel centered on the winner unit c.

In this study, the SOM Toolbox, a function package

for Matlab implementing the Self-Organizing Map

algorithm, was used (HUT). For more information

on SOMs, (Kohonen) is recommended.

4 RESULTS

The study was divided into two phases: process

identification and search for initialization

parameters. The features selected were generally the

same in both cases, but the effect of welding time

was ignored when searching for the initialization

parameters, because it was the same inside process.

A strategy for deploying the results is presented

in Figure 2 and a case study of the implementation is

presented in the following chapters.

1) SOM

containing all

the processes

2) Process

identification

4) Return

parameters

leading to good

quality

3) SOM formed

for the states of

an individual

process

Figure 2: Steps for deploying the results.

4.1 Process identification

Figure 3a) shows a trained SOM. The division into 5

regions can be seen from the U-matrix. Now, the

division given by the SOM is researched in more

detail, because it is not yet certain that the different

regions in the map contain information from

different processes.

In Figure 3b), the spots of the 5 test series are

labeled with the numbers 1-5. These labels are

assigned to the map elements representing the curves

belonging to the corresponding cluster. From Figure

3b), it can be seen that all the regions visible in the

U-matrix contain only different processes. However,

the division in the lower part of the map only points

out the differences inside the processes 1 and 2,

which are thought to be similar processes and it is

therefore not considered as an important division.

The identification of different processes with this

RESISTANCE SPOT WELDING PROCESS IDENTIFICATION AND INITIALIZATION BASED ON

SELF-ORGANIZING MAPS

297

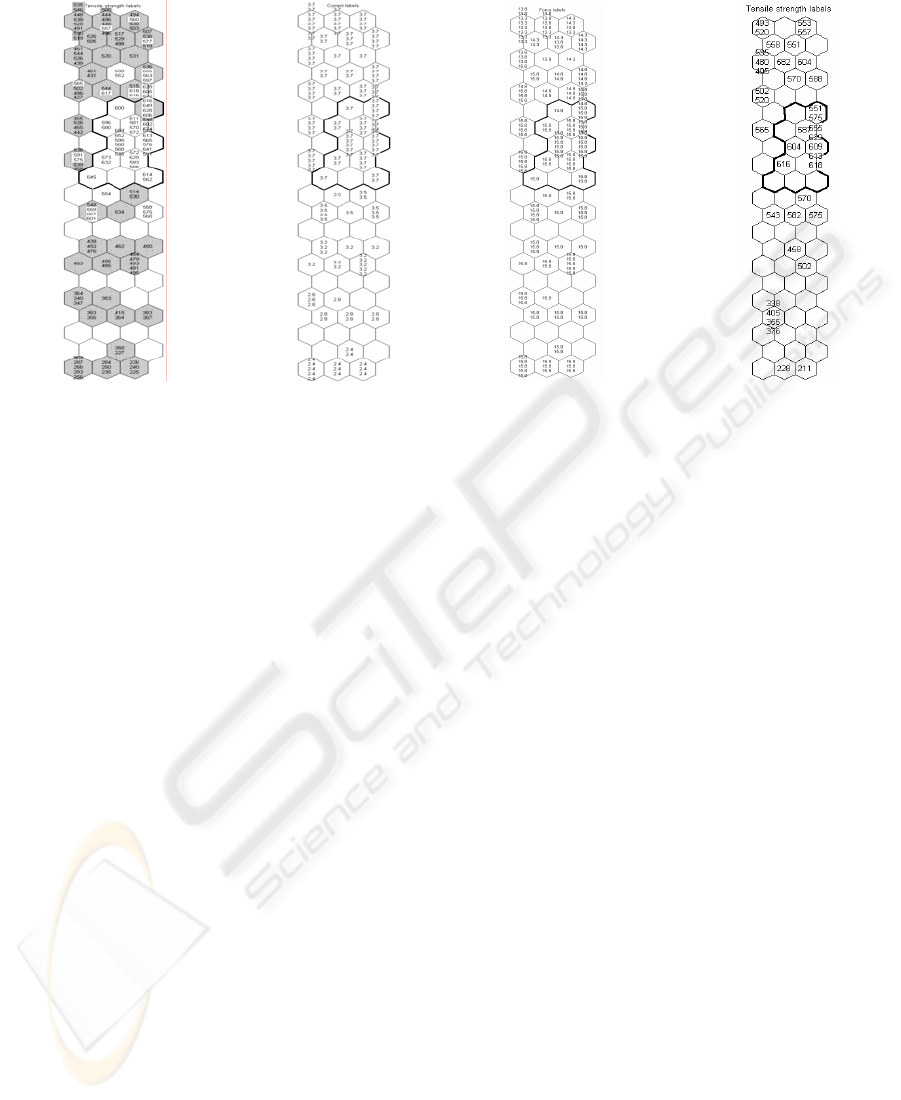

a) b) c)

Figure 3: a) The SOM for all the test series from SBT when the means with the least cross-correlations of ten equally long

parts and welding time were used as features. The following abbreviation is used: r = resistance. The numbers 1,…,10 refer

to the means of the respective tenths of the signal. b) The labels for the map shown in a). c) The labels for the testing set.

method seems to be straightforward, but to be more

confident, the test set can be introduced into the

map. The Figure 3c) shows the corresponding labels.

All the welding experiments of the test set are

located in the correct regions. This allows the

operator to identify manually the most similar

process from a database of existing processes on the

basis of welding experiments conducted on the

process of the user.

4.2 Search for initialization

parameters

After identifying the most similar process, the search

for the suitable initialization parameters for that

particular process can be started. In this paper, the

results for process number 3 are presented in greater

detail. The actual SOM trained with the data from

the SBT process number 3 is not shown, but Figure

4 shows the labels related to the map. In the Figure

4a) the quality values of the welding spots shown as

labeled, b) and c) the pre-set values used by the

welding machine.

A welding spot is classified as successful if its

tensile strength is more than 550N. From Figure 4a)

it can be seen that, in the middle right part of the

map, all the welds are of high quality. The low

quality welds are shown as grey areas, while the

high-quality welds are shown as white. The area that

consists only high-quality welds is marked by a

black line

1

. The figures b) and c) show that the

parameters of the welding machine in that area are:

current=3.7 and force=15.8. In fact, all the spots

welded by a combination of those values are there

2

.

With this knowledge, it can be assumed that the

correct parameters to be used with the welding

machine are the current value of 3.7 and the force

value of 15.8. These assumptions can be tested with

the test data. In Figure 4d), the tensile strengths for

the testing data are shown labeled. For every weld

from the testing set, the best-matching unit from

SOM is identified, and the corresponding tensile

strength is used as a label. Because in Figure 4d), the

successful tests are located inside the successful area

that was formed in the training phase, the parameters

can be considered good enough. Therefore, the

parameters can be delivered to the manufacturer,

who can use them to initialize his welding machines.

5 CONCLUSIONS

The study was divided into two different phases:

process identification and search for initialization

parameters. According to the results, the different

processes could be identified on the basis of the

features extracted from the signal curves. Also,

processes close to each other could be differentiated.

Furthermore, after identifying the most similar

process, the initialization parameters leading to high-

quality welds could be found inside that process.

The authors will continue to explore the usage of

more extensive data sets and to address in more

detail the questions that arose during the study.

Answers will be sought to the following questions:

Can the method of setting up the welding parameters

be automated? Can the initialization parameters be

1

There is one node in the upper right part of the

successful area with one unsuccessful test, but a closer

analysis shows it to have been formed when the force had

a value of 14.8.

2

There is also another region where the current value of

3.7 and the force value of 15.8 co-occur. However, in that

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

298

region the welding help parameter, which does not show

in the maps, was not applied.

a) b) c

)

d)

Figure 4: The labels for the map trained for SBT3, a) tensile strength, b) pre-set current values, c) pre-set force values. d)

Tensile strength labels for the testing set.

delivered to the manufacturer if there are also

unsuccessful welds in the successful area? And is it

possible to differentiate between processes without

taking the effect of time into account?

ACKNOWLEDGEMENTS

We would like to express our gratitude to our

colleagues at Fachochschule Karlsruhe, Institut für

Innovation und Transfer, in Stanzbiegetechnik, in

Harms + Wende GmbH & Co.KG and in Technax

for providing the data set and the expertise needed at

the different steps of the research project.

Furthermore, this study has been carried out with

financial support from the Commission of the

European Communities, specific RTD programme

“Competitive and Sustainable Growth”, G1ST-CT-

2002-50245, “SIOUX” (Intelligent System for

Dynamic Online Quality Control of Spot Welding

Processes for Cross(X)-Sectoral Applications”). It

does not necessarily reflect the views of the

Commission and in no way anticipates the

Commission’s future policy in this area.

REFERENCES

Aravinthan, A., Sivayoganathan, K., Al-Dabass, D.,

Balendran, V., 2001. A neural network system for spot

weld strength prediction, UKSIM2001, Conf. Proc. of

the UK Simulation Society, Pages: 156-160.

Cho, Y., Rhee, S., 2002. Primary Circuit Dynamic

Resistance Monitoring and its Application on Quality

Estimation during Resistance Spot Welding, Welding

Researcher, Pages 104-111.

Fachochschule Karlsruhe,

http://www.fh-karlsruhe.de/, the

homepage of the university, referenced 10.2.2004.

Harms+Wende, Web site of Harms&Wende

http://www.harms-wende.de/. Referenced: 10.2.2004.

HUT, Helsinki University of Technology,

http://www.cis.hut.fi/projects/somtoolbox/, referenced

10.2.2004.

Ivezic, N., Alien, J. D., Jr., Zacharia, T., 1999. Neural

network-based resistance spot welding control and

quality prediction, Intelligent Processing and

Manufacturing of Materials, IPMM '99. Proceedings

of the Second International Conference on, Pages: 989

–994.

Kohonen, T., 1997. Self-organizing maps, Springer-

Verlag, 2

nd

edition.

Mintz, D., Wen, J.T., 1995. Process monitoring and

control for robotic resistive welding, Proceedings of

the 4th IEEE Conference on Control Applications,

Pages: 1126 –1127

Stanzbiegetechnik, SBT,

http://www.stanzbiegetechnik.at,

referenced 10.2.2004.

Technax,

http://www.technaxindustrie.com/, referenced

10.2.2004.

TWI World Centre for Materials Joining Technology,

information available at their homepage:

http://www.twi.co.uk/j32k/protected/band_3/kssaw001

.html

, referenced 10.2.2004.

Vermasvuori, M., Enden, P., Haavisto, S., Jamsa-Jounela,

S.-L., 2002. The use of Kohonen self-organizing maps

in process monitoring, Proceedings of IEEE

International Symposium Intelligent Systems, Pages:

2- 7 vol.3.

RESISTANCE SPOT WELDING PROCESS IDENTIFICATION AND INITIALIZATION BASED ON

SELF-ORGANIZING MAPS

299