STRUCTURED INFORMATION PROCESSING FOR

SELF-OPTIMIZING MECHATRONIC SYSTEMS

∗

Thorsten Hestermeyer, Oliver Oberschelp

University of Paderborn, Mechatronic Laboratory Paderborn, Pohlweg 98, 33098 Paderborn, Germany

Holger Giese

University of Paderborn, Software Engineering Group, Warburger Strae 100, 33098 Paderborn, Germany

Keywords:

Self-Optimization, Mechatronics, Software Technology, Control Engineering, Artificial Intelligence, Recon-

figuration, Safety-Critical Systems.

Abstract:

Self-optimizing mechatronic systems are based on intrinsic controller systems whose complexity by far ex-

ceeds that of currently available systems. In addition to procedures taken from artificial intelligence, proce-

dures for a reconfiguration by means of appropriate design methods have to be integrated to fully implement

self-optimization features. Special importance falls to a networking of such complex controller systems for the

support of collaborative and emergent self-optimization. One main challenge lies in the safety-critical nature

of the systems that requires the resulting software along with the technical system to show a predictably cor-

rect behavior in spite of networking, reconfiguration, and integration of procedures from artificial intelligence.

The paper presents a concept for structuring and designing reconfigurable controller systems.

1 INTRODUCTION

Due to an increasing functionality of software-based

controller systems in recent mechatronic systems the

complexity of the information processing and thus the

number of errors increases accordingly. Further in-

creasing complexity is bound to result in a distinct

increase in the number of these problems unless they

are countered by a clear structuring of the systems to

be effected by an appropriate software support and au-

tomatized verification procedures.

This statement is even more true in the case of

cognitive abilities going to be integrated into fu-

ture systems where variable environmental conditions

and changes in their own behavior are accounted for

by self-optimization in the information processing.

Here a reconfiguration of control components is of

great importance. The safety-critical nature of self-

optimizing systems (Storey, 1996) causes the prob-

lems of ”classical” mechatronic systems to be by far

exceeded by additional complexity and possible dan-

gers resulting from interlinking reconfigurable sub-

∗

This work was developed in the course of the ”Col-

laborative Research Center 614 - Self-Optimizing Concepts

and Structures in Mechanical Engineering” - University of

Paderborn, and was published on its behalf and funded by

the Deutsche Forschungsgemeinschaft.

systems and integrating procedures taken from arti-

ficial intelligence. In the process it is compulsory to

employ adequate design methods and tools.

2 OPERATOR-CONTROLLER

MODULE (OCM)

The information-processing unit of a mechatronic

system has to perform a multitude of functions: con-

trol code working in quasi-continuous mode controls

motions in the plant, error-analysis software monitors

the plant in view of occurring malfunctions, adapta-

tion algorithms adapt the control to altered environ-

mental conditions, different systems are interlinked,

to name but a few of these functions.

These various tasks access the actuators of the

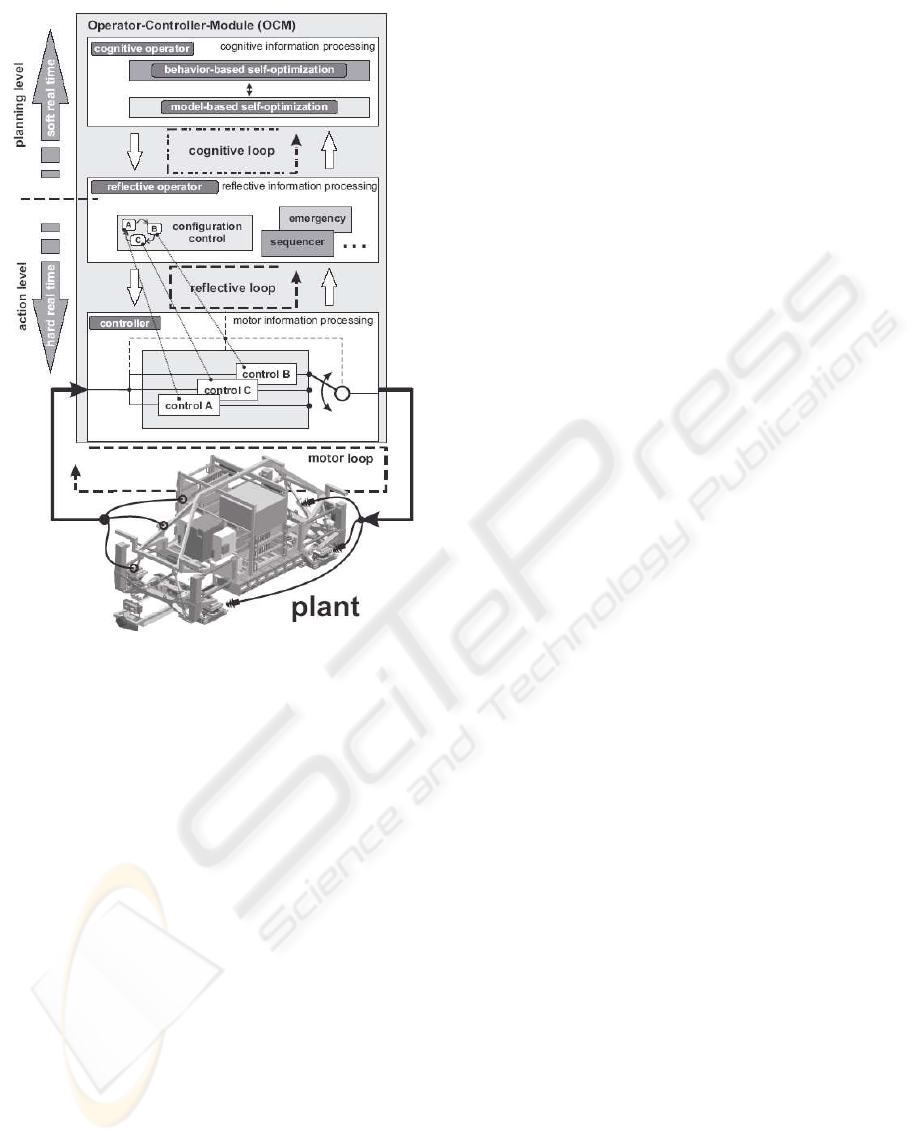

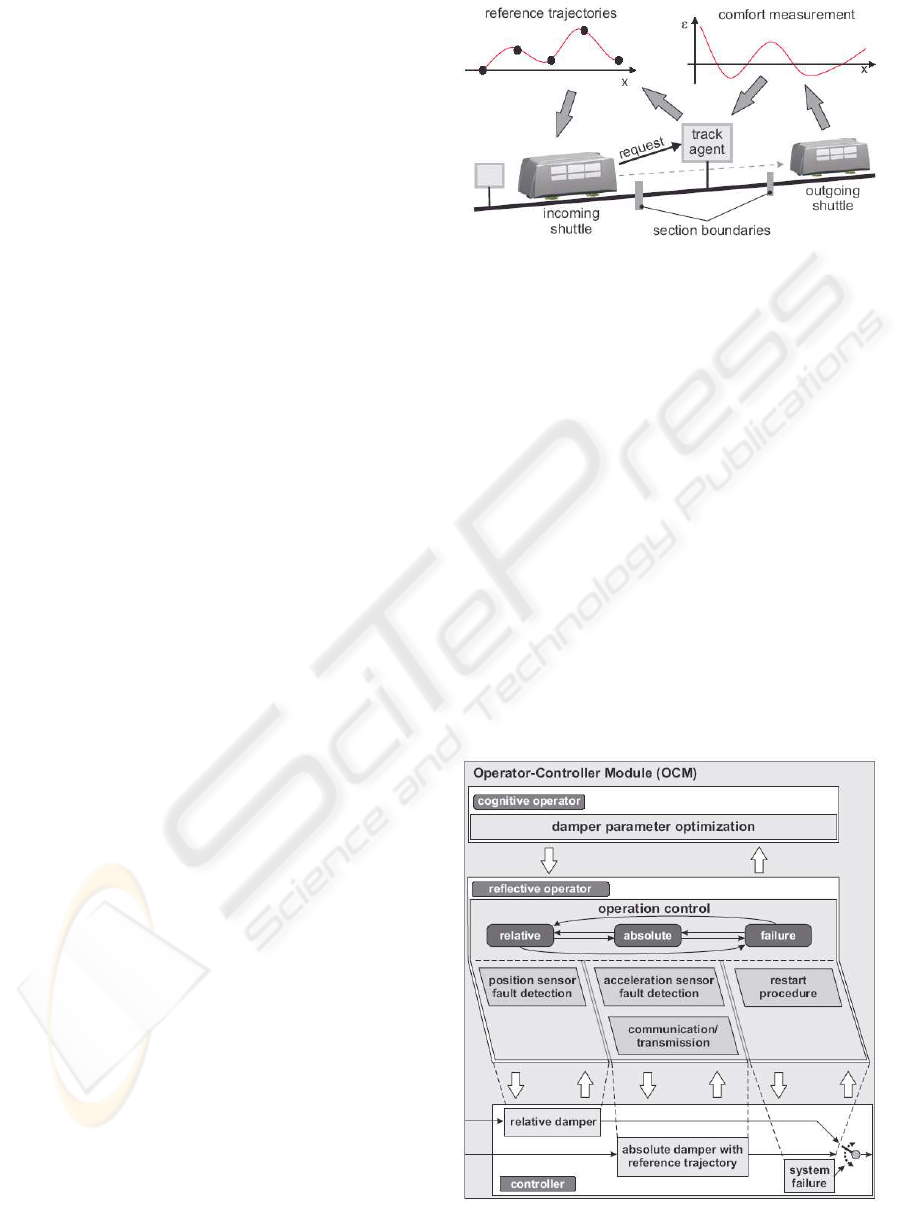

plant more or less directly. Fig. 1 proposes a new

structure of the information processing of a mecha-

tronic function module (MFM - cf. e.g. (Oberschelp

et al., 2002)) that resulted from practical experiences

and combines the approaches presented in (Naumann

and Rasche, 1998) and (Naumann, 2000) with con-

cepts from (Hestermeyer et al., 2001) and (Ober-

schelp et al., 2002). The OCM set-up orientates itself

by the kind of effect on the technical system:

230

Hestermeyer T., Oberschelp O. and Giese H. (2004).

STRUCTURED INFORMATION PROCESSING FOR SELF-OPTIMIZING MECHATRONIC SYSTEMS.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 230-237

DOI: 10.5220/0001138102300237

Copyright

c

SciTePress

Figure 1: OCM structure

1. On the lowest level of the OCM there is the con-

troller. This innermost loop processes measure-

ments and produces control signal. It directly ef-

fects the plant. It can therefore be called ”motor”

loop. Software processing on this level works in

a quasi-continuous mode, i.e., measured values are

read in, processed, and output continuously and un-

der hard real-time conditions. The controller can be

made up of several controllers, with the possibility

to switch between them. The switch is done in one

step; fade-over mechanisms and the like are again

integrated in a separate controller element (see Sec-

tion 3).

2. The controller is complemented by a reflective op-

erator in which monitoring and controlling rou-

tines are executed. The reflective operator does

not access the actuators of the system directly but

modifies the controller. In certain circumstances it

can also switch between different controller con-

figurations. The reflective operator operates very

much in an event-oriented manner. On this level,

though, there are also other quasi-continuous func-

tions, such as continuous adaptation algorithms or

so-called watchdogs. Because it is tightly linked to

the controller, the reflective operator has also to op-

erate under hard real-time constraints. The reflec-

tive operator, connecting element to the cognitive

level of the OCM, provides an interface between

those elements that are apt for real-time operation

resp. operating in soft real time and the controller.

It filters the incoming signals and inputs them to

the subordinated levels.

3. The topmost level of the OCM is occupied by the

cognitive operator. On this level the system can

gather information on itself and its environment by

applying various methods such as learning, use of

knowledge-based systems, model-based optimiza-

tion, and the like; it can employ them for improving

its own behavior. Moreover, one can think of other

cognitive functions. The present paper will confine

itself to local self-optimization. This optimizing in-

formation processing can roughly be divided into

model-based and behavior-based self-optimization.

Model-based optimization allows an optimization

that is predictive and decoupled in time from the

real system. The behavior-based optimization com-

prises functions for planning and evaluating the

current objectives (cf. (Oberschelp et al., 2002) and

(Hestermeyer and Oberschelp, 2003)). While both

the controller and the reflective operator are subject

to hard real-time constraints the cognitive operator

can also operate asynchronously to the real time.

Of course it has to respond within a certain time

limit; otherwise, due to altered environmental con-

ditions, self-optimization would not find utilizable

results. So the cognitive operator is subject to soft

real time.

To sum things up, one can detect two distinct levels

of separation: on the one hand, information process-

ing is divided into two loops affecting the system, one

directly and the other only indirectly. This division re-

flects the one that distinguishes between operator and

controller. On the other hand, one can distinguish be-

tween hard and soft real time constraints. This classi-

fication sets the cognitive operator apart from the re-

flective one and the controller. As the level of separa-

tion is chosen according to the task we propose three

separate elements.

3 RECONFIGURABLE BLOCK

DIAGRAMS

This section deals with the use of block-diagram rep-

resentation for the purpose of defining reconfigurable

systems that are the basis for structure-variable self-

optimizing systems. In general, block diagrams serve

for an abstract modelling of technical systems. In

STRUCTURED INFORMATION PROCESSING FOR SELF-OPTIMIZING MECHATRONIC SYSTEMS

231

many CAE tools they are the basis for an abstract

modelling. Block diagrams have their origin in con-

trol engineering where they serve the purpose of

graphically representing mathematical transfer func-

tions. As their name indicates, block diagrams are

composed of blocks. A block encapsulates a func-

tion or a behavior. In most cases this behavior is

described mathematically, e.g., as differential equa-

tions in a state-space representation of the dynamics.

Equally possible is a description by physical elements

such as in multibody system models. In this process

the mathematics is derived automatically by means

of automated transformation methods, such as New-

ton or Lagrange. Between the individual blocks there

are interconnections or links that can have the shape

of direct or non-direct links. With direct links data

are exchanged whereas non-directed ones often de-

scribe functional relations or physical links, such as

a link between mass and spring in multibody system

representation. Hierarchical block diagrams broaden

this approach by classifying several blocks into hier-

archies which may themselves comprise other hierar-

chies. This allows a structured design and reduces the

overall complexity of a block diagram:

Figure 2: Block diagrams in the CAE tools CAMeL and

MATLAB

Fig. 2 displays typical block diagrams developed

with the tools CAMeL and MATLAB. The respective

left-hand part of the windows shows the tree struc-

tures while the right-hand side displays the topology

of a level. The topology of hierarchical block dia-

grams can be displayed as a tree, with its leaves repre-

senting the behavior resp. the function and the nodes

describing the interconnections and the structure of

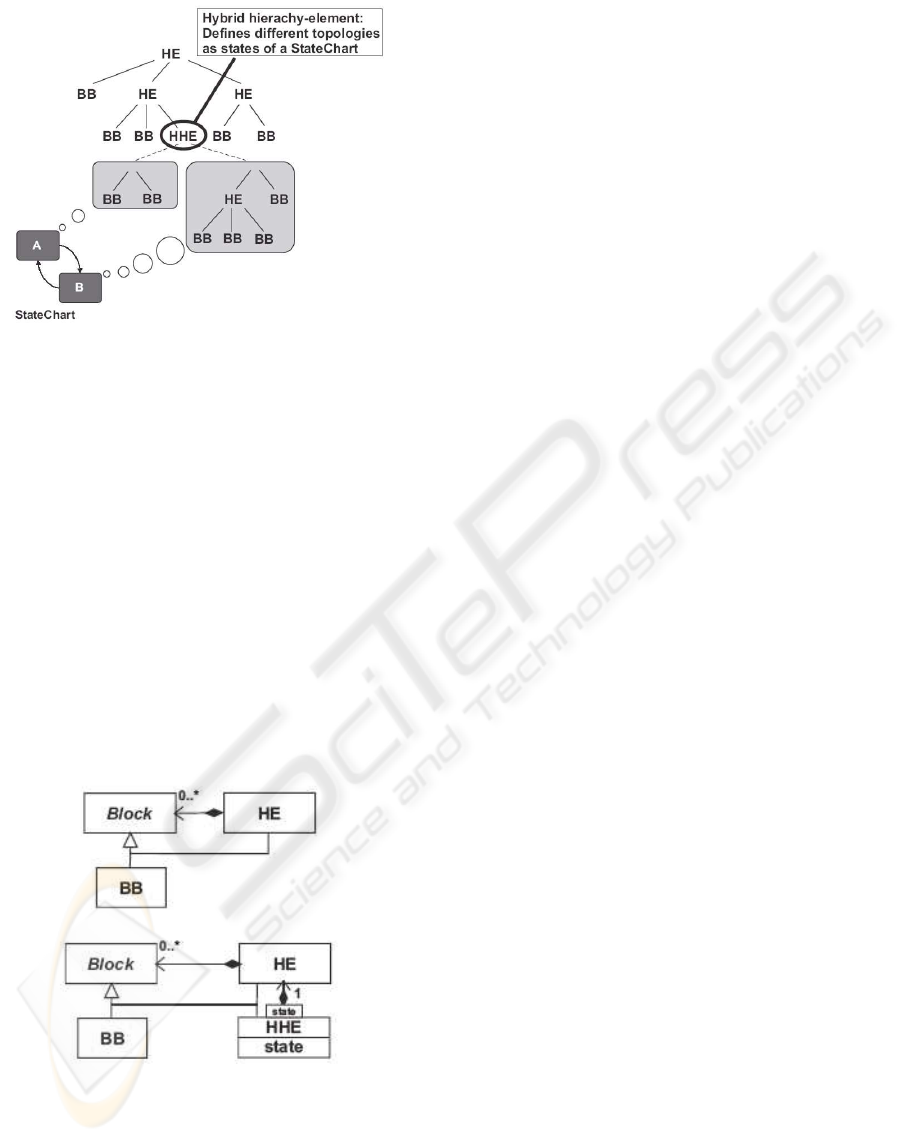

the system (Fig. 3):

The distinction between structure (hierarchy) and

function (block) can be used to derive an integrated

representation of reconfiguration from the classical

block diagrams described above. In our context, a

reconfiguration is a change in the structure resp. sub-

Figure 3: Hierarchical block diagrams

structure of a system. It alters the topology of the

system; functions are added and/or interlinked anew.

Under the assumption that all functional blocks us-

able in a defined configuration are set and defined, a

reconfiguration will alter only hierarchical elements:

Figure 4: Reconfiguration on the topological level

Alteration of only one part of the system corre-

sponds to a change of one part of the topological tree,

under the important boundary condition that the inter-

faces of the exchanged hierarchical elements be com-

patible. Fig. 4 displays this principle for an exchange

of a hierarchical element. The element and all subor-

dinated components are exchanged in the process.

The boundary conditions to an exchange of hier-

archical elements, assuming that all components to

be switched have to exist and all interfaces have to

be compatible, can now be employed for the defi-

nition of a new hierarchical element describing dif-

ferent topologies. A hierarchical element can com-

prise different configurations in the shape of topolo-

gies and inner interconnections that are valid at vary-

ing times. The superordinated hierarchy does not no-

tice the change in the topology of the subordinated hi-

erarchy because the latter is described outwardly only

by its interfaces:

If the different topologies are seen as states of the

subordinated hierarchical element it makes sense to

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

232

Figure 5: Hybrid hierarchical elements

control the change between the different topologies

by means of a state machine. With the help of State-

Charts (Harel, 1987) it is possible to specify all tran-

sition processes and to employ them as interfaces for

a reconfiguration. Combining a StateChart and a hi-

erarchical element leads to specific hybrid systems,

with the result of this combination of reconfigurable

hierarchical element and StateChart being named a

hybrid hierarchical element. A great advantage of

this approach lies in the fact that it includes as a spe-

cial case those classical, non-reconfigurable block di-

agrams, and this in the shape of a hybrid hierarchical

element with only one state. Thus it is possible to

design also reconfigurable systems according to well-

known methods:

Figure 6: Structure of the block interconnection without and

with reconfiguration

Fig. 6 visualizes the elements required for the in-

tegration model with and without reconfiguration as

well as their hierarchy by means of a UML class di-

agram (UML, 2003). In addition to the basic blocks

(BB) and the hierarchical elements (HE) in the model

without reconfiguration (Fig. 6, top) our integrated

model (Fig. 6, bottom) comprises also hybrid hierar-

chical elements (HHE). Basic blocks may e.g. be (hy-

brid) mathematical functions, but also inputs and out-

puts, especially interfaces to actuators and sensors. A

hierarchical element links any number of blocks of the

respective type and thus is a true likeness of the classi-

cal hierarchical block diagram. The additional hybrid

hierarchical elements with local, discrete states allow

also to employ one hierarchical element per state; this

makes possible an adequate representation of the re-

configuration of the block diagrams. Easy to oper-

ate, an HHE comprising only subordinated elements

of the HE and BB types that are limited to the case

of quasi-continuous elements resembles the usual ap-

proaches to the modelling of hybrid systems by means

of differential equations and automats (cf. (Henzinger

et al., 1995)). By offering the possibility to use such

HHE blocks several times over, the concept presented

outmatches other known approaches.

4 OCM ARCHITECTURES WITH

RECONFIGURATION

Section 3 elaborated on a systematic extension of

classical block diagrams to a kind with reconfigurable

parts by means of discrete switches. In the following

we will explain how to apply these concepts to OCM

architectures. In addition to hierarchy, the systems

are characterized by the information flow occurring

with every configuration. Information between the

elements of the integration model can be transported

via event channels, discrete or quasi-continuous sig-

nal channels and has been omitted in the model for

reasons of space. Furthermore this information flow

brings about direct and bidirectional links between the

inputs and outputs of the blocks. In the design of self-

optimizing mechatronic systems by means of recon-

figurable block diagrams, an OCM corresponds to a

coherent number of unambiguously allocated blocks

in such a manner that the entire block structure cor-

responds to a tree made up of OCM. The arrange-

ment of the different parts of the OCM makes up a

well-structured architecture if and only if the follow-

ing rules apply:

• All BB- and HE blocks that have a direct effect on

an actuator of the OCM or of a subordinated OCM

via signals in the workflow - and just these - have

to be allocated to the controller of the OCM.

• Concerning the distinction into reflective operator

and cognitive operator, the rule must hold that the

cognitive operator can affect the reflective operator

only in an event-driven manner and that it cannot

STRUCTURED INFORMATION PROCESSING FOR SELF-OPTIMIZING MECHATRONIC SYSTEMS

233

affect the controller at all, the reflective operator

having to stay capable of acting at all times even

without assistance by an active cognitive operator.

This means that the reflective operator has to be ca-

pable of acting autonomously to the degree that his

behavior is sufficient to ensure the OCM to operate

safely.

• As regards the interconnections between the com-

ponents of the different OCM, the rule must hold

that controllers are linked only to controllers of the

superordinated and subordinated OCM and reac-

tive operators only to the reactive ones of the su-

perordinated reactive operator and the subordinated

reactive ones. A similar structure with the cognitive

operators is useful but not compulsory.

The above limitation to well-structured architec-

tures gives the guarantee that the decoupling between

controller and reflective operator as well as that be-

tween reflective and cognitive operator correspond to

the architecture presented in Section 2 and that the

cognitive blocks will have no unsupervised direct ac-

cess to the controller. If one wants to realize the

required interconnection structure by means of the

above-described classical block diagrams one will en-

counter the following problem: a hierarchical decom-

position of all levels of the system (controller, re-

flective operator, cognitive operator) results in several

overlapping trees that cannot be represented by a sin-

gle tree like the one displayed in Fig. 6. We have here

the same problem that occurs in the software domain

if only one hierarchical decomposition dimension is

allowed (Tarr et al., 1999). In order to avoid this prob-

lem one will have to admit a well-structured multiple

referencing

2

for each OCM so that every level can ad-

equately describe its partial hierarchy:

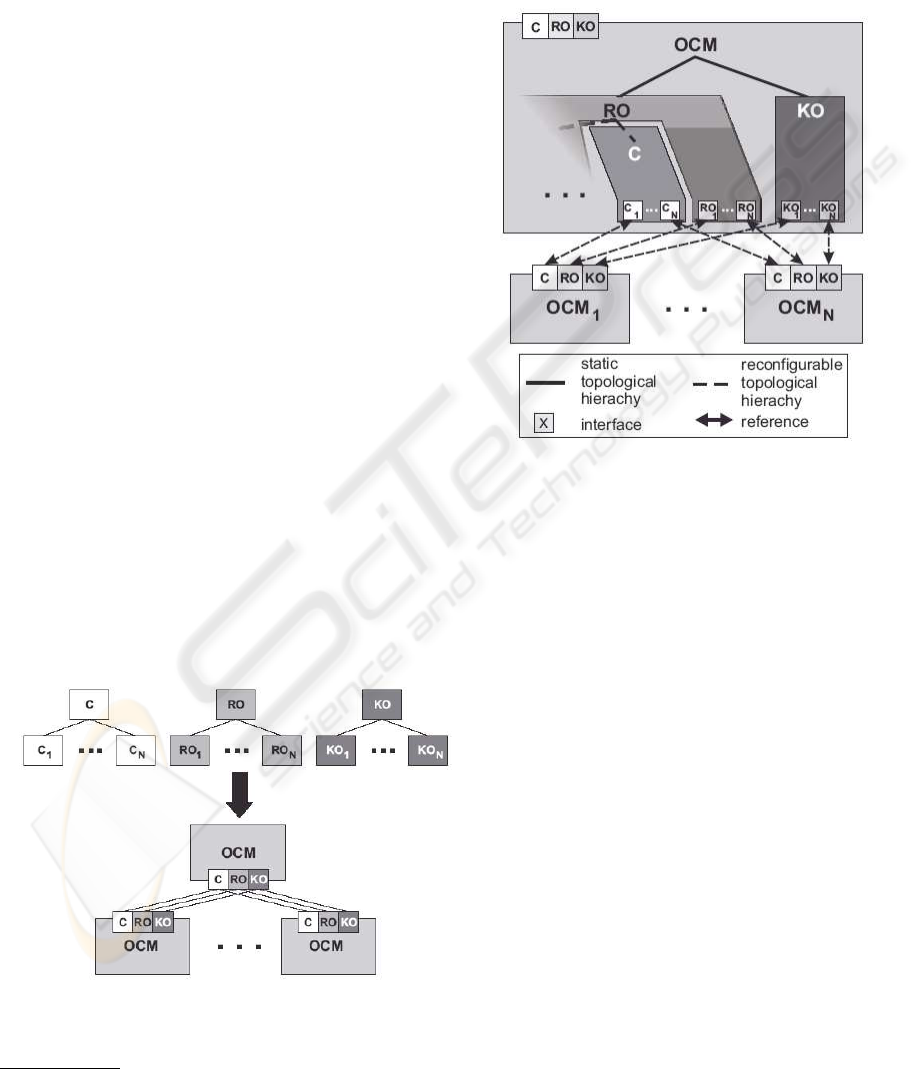

Figure 7: OCM with interfaces for all three levels

2

In contrast to the composition (”is contained”-relation).

In order to support multiple referencing every

OCM provides three separate interfaces C, RO, and

KO for controller, reflective operator, and cognitive

operator (cf. Fig. 7). Thus the required allocation

to block diagrams of the superordinated OCM can be

adequately described for the different levels:

Figure 8: OCM with reconfiguration

Fig. 8 illustrates how the three levels of controller,

reflective operator, and cognitive operator from Fig. 1

can be integrated in one single hierarchical block di-

agram. The different configurations of the controller

are mapped to individual trees. The reflective opera-

tor assumes the task of coordinating the switches be-

tween the different configurations of the controller.

The behavior of the reflective operator itself is de-

scribed by a state machine which, in addition to its

conditions and side effects, disposes of a reconfig-

urable structure of quasi-continuous blocks so that,

for instance, quasi-continuous blocks required for

purposes of diagnosis can be used in the reflective op-

erator if the need arises. In contrast to the tight inter-

lacing between controller and reflective operator, the

cognitive operator makes up a separate tree whose in-

terconnection with the reflective operator must be re-

stricted to event channels. Moreover, Fig. 8 illustrates

the way the three interfaces of the respective subordi-

nated OCM provided by every OCM are inserted into

the block diagram of the superordinated OCM. In the

domain of software components this can be described

by means of e.g. so-called plug-ins in the compo-

nent diagrams proposed for UML 2.0. Moreover, the

safety-critical nature of mechatronic systems postu-

lates that only reconfigurable block diagrams satis-

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

234

fying the demands on a well-structured architecture

and showing a predictably safe behavior are adequate.

This is why we have to consider not only if the archi-

tecture is well-structured but also if it has the follow-

ing properties:

1. A configuration is structurally correct if no uncon-

nected inputs or outputs exist. If this is not the

case continuous evaluation or missing events may

lead to undefined behavior. If all configurations re-

sulting from the combination of partial configura-

tions described by means of the individual states

of the hybrid hierarchical elements are structurally

correct, we speak of a statically correct reconfigu-

ration. If, however, only those configurations are

structurally correct that can be reached by interac-

tion of the system, the term is dynamically correct

reconfiguration.

2. The continuous control described by the workflow

must have the necessary stability with all possi-

ble configurations and every possible transition be-

tween them.

3. The real-time behavior of the reactive operators,

coupled via events and discrete signals and includ-

ing the emergency behavior (fail safe and/or fail

operational), has to operate correctly, i.e., it has to

fulfill necessary safety regulations and give proof

of its being free of deadlocks.

While problem (1) can essentially be solved by

means of a suitable component architecture compris-

ing discrete and continuous elements, the problems

(2) and (3) are hardly solvable in general. Making

use of the specific constraints to mechatronic systems

we were able to find a preliminary solution to prob-

lem (3) by means of a compositional model-checking

(Giese et al., 2003). For problem (2) we are currently

examining procedures of fade-over (V

¨

ocking, 2003)

and approaches to a model-checking of hybrid sys-

tems, above all.

5 APPLICATION EXAMPLE

In order to demonstrate the concepts expounded

above this section presents the control structure of an

active suspension system for railway vehicles.

Modern railway systems have to compete with

individual transport with regard to comfort, flexibility

and cost. A research group which accepts the

challenge is the ”Neue Bahntechnik Paderborn”.

The project has been initiated and worked upon by

several departments of the University of Paderborn

and the Heinz Nixdorf Institute. The objective of

this group is the development of a transport system

that is faster, cheaper and more comfortable than

other transport systems. In order to achieve this

goal, the project group has conceived a concept

based on an individual logistics system with small

shuttles transporting goods and people according to

the individual demand. Apparently, such a concept

cannot be realized with conventional trains. A new

kind of railway vehicle is required: The combination

of modern chassis technology with active steering

and tracking, an active suspension system and a

new linear motor similar to that of the Transrapid

yields the ”Railcab”, a small shuttle ideally suited for

individual transport on rails (Hestermeyer, 2003).

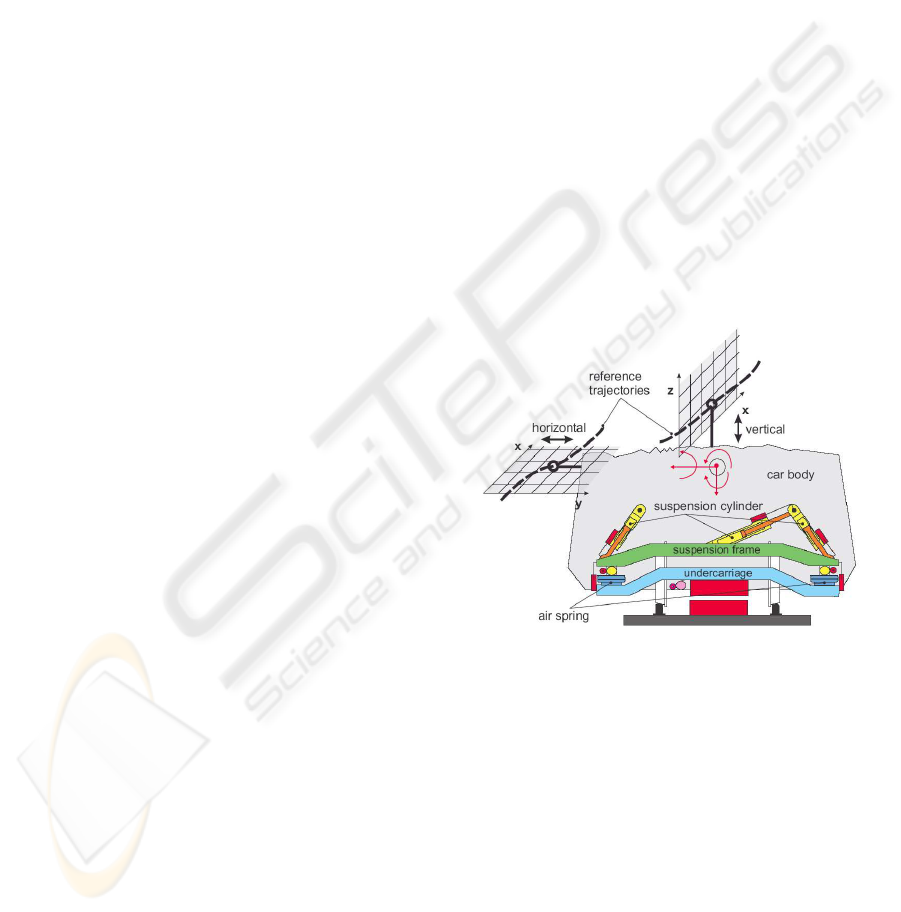

The active suspension system completely dis-

penses with shock absorbers in the secondary spring

system. Car body and chassis are connected only

by air springs. Damping is realized by an active

damping system with 10 hydraulic cylinders. These

actuators can also be used for tilting the shuttle in

the curves. Fig. 9 shows the main scheme of the

suspension module. The three ”vertical” cylinders are

mirrored on the rear of the vehicle. For the sake of

simplicity, the four longitudinal cylinders are omitted.

Figure 9: Reference trajectory for an active suspension sys-

tem

The classical control algorithm of an active suspen-

sion system uses acceleration measurements to deter-

mine the absolute velocity of the car body and dis-

placement measurements to determine the distance

between track and car body (relative position of the

car body). The relative position of the car body

and its first time derivative can be used to create

pseudo spring and damper forces by creating addi-

tional airspring displacements proportional to the de-

sired forces. The damper force created by this first

derivative is equivalent to damping forces generated

by passive dampers in so far as it is caused by relative

motion between the car body and the chassis. It thus

tries to suppress the relative motion and will hence-

STRUCTURED INFORMATION PROCESSING FOR SELF-OPTIMIZING MECHATRONIC SYSTEMS

235

forth be called ”relative damping”. The absolute car

body velocity - derived from acceleration measure-

ments by integration - forms a virtual damper attached

to a so-called ”sky hook”, which suppresses the abso-

lute movement of the car body. This damping will be

called ”absolute damping”.

As far as the damping of the resonance poles in the

car-body frequency response is concerned, both types

of damping are equivalent. However, time responses

of systems with identical damping of the car-body

eigenfrequency can differ significantly with different

shares of relative or absolute damping, respectively.

The reasons for this behavior are easy to understand

if one takes into account the extremes:

A system with a large portion of absolute damping

tries to prevent any movement of the car-body. As

any movement is perceived to be uncomfortable,

such a system is highly comfortable. However,

as the absolute damping suppresses the car-body

movement, a vehicle with large absolute damping is

not able to move up a slope or go around a curve -

after all, this requires vertical or lateral movement of

the car-body, respectively.

Systems with relative damping, on the other hand,

try to suppress the relative motion between car body

and chassis and thus between car body and track.

Taken to extremes, this means that the car body

follows the rail exactly, exciting the car body and

deteriorating the comfort. Therefore, systems with

relative dampers have poorer than those with absolute

damping. In return, they work in all situations.

One good way to overcome the difficulties of the

absolute damping is to introduce a reference trajec-

tory the car body is supposed to follow. The body

is thus not attached to the sky but to this trajectory

(Fig. 9 depicts this trajectory separately for the x/y-

and the x/z plane). This approach is in a way a

compromise between absolute and relative damping.

In a first approach the trajectory could be the ideal-

ized railway track. With increasing capability of ac-

tive displacement, however, the reference track can

change in order to compensate for unnecessary accel-

erations when entering a curve, etc. (M

¨

unch et al.,

2004) show how a multi-agent optimization can be

used to optimize the reference track using different

shuttles as probes.

Fig. 10 shows the set-up of the optimization system

envisioned in (M

¨

unch et al., 2004). After dividing

the track into sections, an agent network is allocated

to the track. One track agent is allocated to each

section. It collects data about its respective section

and communicates with shuttles that run along. The

track agent transmits the actual reference trajectory

to a shuttle that wants to enter its section. After

completing the section the shuttle answers with a

performance rating, which is used by the track agent

Figure 10: Multi-agent optimization of the reference trajec-

tory

to optimize the trajectory.

The absolute damping with a self-optimizing track

reference presents a fine way to build the active

suspension control. However, there is a risk of

transmission failure of the reference trajectory, which

whould lead to a malfunction. The solution to this

problem is a reconfiguration of the system, changing

from the absolute damping to relative damping with

onboard sensors in case of a failed transmission of

the reference data. The presented software structure

in combination with the hybrid state charts is an

excellent means to implement the software in a

well-structured and clear way (see also (Burmester

et al., 2004)).

Figure 11: OCM of the active suspension system

ICINCO 2004 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

236

Fig. 11 shows the operator-controller module

for the active suspension system. Three different

controllers can be selected: the controllers ”rela-

tive damper” and ”absolute damper with reference

trajectory” implement the concepts detailed above.

If underlying modules or the sensor-fault detectors

signal a system failure, the active suspension will be

shut off and the controller ”system failure” selected.

The controller choices are reflected in the reflective

operator. Each controller has a part in the reflective

operator dedicated especially to itself. The displace-

ment sensors as well as the acceleration sensors

each have their own fault detection systems, testing

plausibility and computing parity equations. The con-

troller ”absolute damper with reference trajectory”

requires additionally a communication/transmission

part that contacts the stationary agents and receives

the respective track reference trajectory from it. The

necessary procedure to start the suspension system

after a system failure is part of the reflective operator

dedicated to the controller ”system failure”.

Along with the reference trajectory, it is of course

also possible to optimize the controller parameters

themselves. This is done in the cognitive operator

”damper parameter optimization”. An example of the

implementation and the necessary software to recon-

figure the controllers for a hydraulic system can be

found in (Hestermeyer et al., 2004).

6 CONCLUSION

A consistent structuring of the controlling informa-

tion processing of mechatronic systems makes man-

ageable the whole range of complex systems up to

self-optimizing systems. Extension of classical de-

sign views, such as block diagrams, allows integration

of conventional design and analysis methods and per-

mits the designer to stick to his familiar views. The

next step will be the prototypical realization of a mod-

elling tool of reconfigurable systems according to the

concept presented. Already implemented OCM on

other platforms will subsequently be transferred into

it. This will allow us to verify and refine our concept.

REFERENCES

Burmester, S., Giese, H., and Oberschelp, O. (2004). Hy-

brid uml components for the design of complex self-

optimizing mechatronic systems. In 1st International

Conference on Informatics in Control, Automation

and Robotics (ICINCO), Setubal, Portugal.

Giese, H., Tichy, M., Burmester, S., Sch

¨

afer, W., and Flake,

S. (2003). Towards the compositional verification of

real-time uml designs. In European Software Engi-

neering Conference (ESEC), Helsinki, Finland. ACM

Press.

Harel, D. (1987). Statecharts: A visual formalism for com-

plex systems. Science of Computer Programming,

8(3):231–274.

Henzinger, T. A., Ho, P.-H., and Wong-Toi, H. (1995).

Hytech: The next generation. In 16th IEEE Real-Time

Symposium, Pisa, Italy. IEEE Computer Press.

Hestermeyer, T. (2003). railcab - an integrative system

for the 21st century. Urban Tranport International,

(50):24–25.

Hestermeyer, T., Becker, M., and Neuendorf, N.

(2001). Nichtlineare ABC-Regelungen mit Operator-

Controller-Struktur, abgestimmt auf F

¨

uhrung und

St

¨

orung der Straße. Essen. Haus der Technik.

Hestermeyer, T., M

¨

unch, E., and Sch

¨

afer, E. (2004). Model-

based online parameter optimization. In 3rd IFAC

Symposium on Mechatronic Systems, Sydney, Aus-

tralia. IFAC.

Hestermeyer, T. and Oberschelp, O. (2003). Selbst-

optimierende Fahrzeugregelung - Verhaltensbasierte

Adaption. In Gausemeier, J., L

¨

uckel, J., and Wal-

laschek, J., editors, Intelligente Mechatronische Sys-

teme, Paderborn. HNI-Verlag.

M

¨

unch, E., Hestermeyer, T., Oberschelp, O., Scheideler,

P., and Schmidt, A. (2004). Distributed optimization

of reference trajectories for active suspension with

multi-agent systems. In European Simulation Mul-

ticonference 2004 - Networked Simulations and Sim-

ulated Networks, pages 343–350, Magdeburg, Ger-

many. SCS.

Naumann, R. (2000). Modellierung und Verarbeitung ver-

netzter intelligenter mechatronischer Systeme. PhD

thesis, MLaP, University of Paderborn.

Naumann, R. and Rasche, R. (1998). Description and simu-

lation of hybrid mechatronic systems. In International

Workshop on Hybrid Systems: Computation and Con-

trol, Berkeley, CA.

Oberschelp, O., Hestermeyer, T., Kleinjohann, B., and

Kleinjohann, L. (2002). Design of self-optimizing

agent-based controllers. In CfP Workshop 2002 -

Agent-Based Simulation 3, Passau.

Storey, N. (1996). Safety-Critical Computer Systems.

Addison-Wesley, MA/Menlo Park, CA. Reading.

Tarr, P., Ossher, H., Harrison, W., and Sutton, S. M. (1999).

N degrees of separation: Multi-dimensional separa-

tion of concerns. In 1999 International Conference

on Software Engineering, pages 107–119, Los Ange-

les, CA.

UML (2003). UML 2.0 Superstructure Specification. Object

Management Group. Document ptc/03-08-02.

V

¨

ocking, H. (2003). Multirate-Verfahren und Umschalt-

strategien f

¨

ur verteilte Reglersysteme. Diplom-thesis,

MLaP, University of Paderborn.

STRUCTURED INFORMATION PROCESSING FOR SELF-OPTIMIZING MECHATRONIC SYSTEMS

237