FUZZY CONTROL FOR FABRICS DRYING ON AN INDUCTION

HEATED ROTATING CYLINDER:

Experimental results

Sergio Pérez, Zulay Niño

Departamento de Ingeniería Química, Facultad de Ingeniería, Universidad de Carabobo, Valencia, Venezuela

Normand Thérien, Arthur D. Broadbent

Departement de Génie Chimique, Faculte de Génie, Université de Sherbrooke, Sherbrooke, Québec, Canada

Keywords: Textile contact drying, Fuzzy logic control, Heating by induction

Abstract: The removal of water from materials in textile industry and pulp and paper industries requires a high-energy

consumption, increasing significantly the operating costs. Nevertheless, electromagnetic induction heating is

an alternative with considerable potential for the thermal treatment of materials. Specifically, heating the

surface of a metallic cylinder by electromagnetic induction has opened up a range of applications for

continuos heating, pre-drying and drying of fibrous web. Otherwise, these news electrotechnologies with

industrial applications have to be used under controlled operational conditions. The past few years

witnessed a rapid growth in the use of fuzzy logic controllers for the control of processes, which are

complex and ill defined. These control systems are inspired by the approximate reasoning capabilities of the

process operator. The purpose of this paper is to improve and apply an digital control structure on the basis

of fuzzy logic technique for the textile drying using a rotational cylinder heated by electromagnetic

induction, manipulating the power supply to the inductors to control the exit humidity of the web. The

proposed fuzzy logic controller was tested experimentally in a dryer pilot-scale plant and the results show

the capability of the controller to reach the set point initially fixed at 20 g water/100 g dry fabric. Once

reached the set point, continuing the trial, steps changes of the web-cylinder contact surface and the set

point were done and the results shows the capacity of the proposed fuzzy logic controller in both

perturbations.

1 INTRODUCTION

Energy saving and product quality are among the

main concerns in industry today. It is well known

that the removal of water from materials in the

textile and pulp and paper industries requires a high-

energy consumption, significantly increasing the

operating costs. Many attemps have been made to

minimize energy cost. Nevertheless, the available

new technologies, such as infrared (Dhib, 1994;

Slitine, 1994), micro-wave and radio-frequency

(Cross et al., 1982; Jones, 1992) allow a more

efficient use of energy with a better product

quality. Among these techniques, the electro-

technology processes using infrared, microwave, and

radio frequency has proven to be effective in the

drying of fabrics. Among electro-technologies,

electromagnetic induction is worth mentioning. As

described by Tokuden (1995), this process utilizes a

metal cylinder heated by electromagnetic induction.

The induced energy is transmitted directly to the

fabric or fibrous material to be dried, and can be

regulated by manipulating the power supply to an

electro magnetic inductor (Perez et al., 2001).

The past few years have witnessed a rapid

gr

owth in the use of fuzzy logic controllers for the

control of processes that are complex and ill defined.

These control systems, inspired by the approximate

reasoning capability of humans under conditions of

uncertainty, consist of linguistic if-then rules. For

any reasonably complex chemical process, the

number of rules required to ensure adequate control

may be extremely large. In this paper, a fuzzy

controller based on the strategy proposed by Takagi

and Sugeno (Passino et al., 1998) was developed to

control the exit humidity of the web for a continuous

textile drying process, using the power supply to the

electrical inductors as the manipulated variable.

334

Pérez S., Niño Z., Thérien N. and D. Broadbent A. (2004).

FUZZY CONTROL FOR FABRICS DRYING ON AN INDUCTION HEATED ROTATING CYLINDER: Experimental results.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 334-337

DOI: 10.5220/0001140303340337

Copyright

c

SciTePress

2 EXPERIMENTAL SETUP

The experimental unit consist of an a small-scale

dryer by contact rotating cylinder heated by

electromagnetic induction. The external and internal

diameters of the cylinder are 457 mm and 448 mm,

respectively, and the width 358 mm. Three inductors

placed over the entire cylinder width are used to heat

the cylinder. The possibles manipulated variables in

the experimental unit are: the electrical power

supply; the rotational speed of the cylinder; and the

position of the movable roller that allows

adjustement of the surface area of the web in contact

with the heated cylinder.

The surface area of the web in contact with the

cylinder is adjusted by means of two rollers one

which is movable. The maximun and minimun

surface between the movable roller and the fixed

roller are 1618 cm

2

y 472 cm

2

, respectively.

The temperature inside the cylinder wall are

measured by three T-type thermocouples placed at

different depths in the wall. A contact thermocouple

J-type is placed at the inlet drying section to measure

the cylinder temperature at this fixed point.

The data acquisition and control are done by a

Hewlett-Packard interface (HP-4848) and a HP

VECTRA micro-computer,

which allow for on-line

measurements of the fabric humidity at the entrance

and exit of the dryer using a radio frequency-

humidity sensor. An optical pyrometer senses the

temperature of the fabric at the exit.

3 FUZZY LOGIC CONTROLLER

The development of a Fuzzy Logic Controller (FLC)

involves appropriate definitions of the input and

output variables, a number of linguistic terms and

their membership functions, the rules base, the

inference mechanism, and a defuzzification method.

The proposed controller, has two inputs

variables: the error (e) and the error velocity (v). The

two inputs (e and v) are used in the FLC to obtain a

value of the output variable, the power supply to the

inductors.

For each input variable, the error and the error

velocity, were adopted five fuzzy linguistic

attributes, so that there were 25 possible fuzzy

states, each which implied one defined control

action. These rules are of the folowing type: if the

error is negative high (NH) and the error velocity is

negative low (NL), then the response of the output

is high energy increasing (HEI). The Table 1 show

these fuzzy states and the decision matrix.

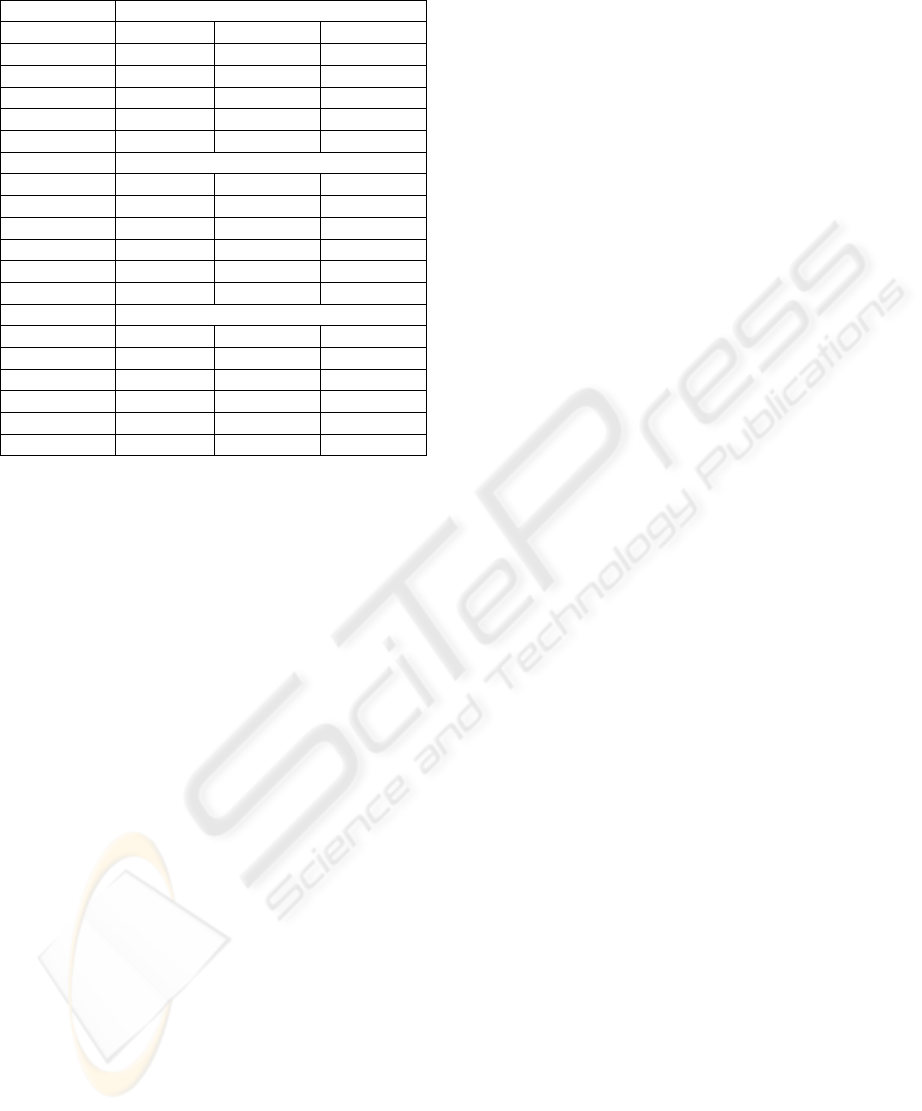

Table 1: Labels defined for the inputs variables

Error velocity

NH NL ZERO PL PH

NH LEI HEI HEI HEI HEI

NL HED STOP LEI LEI HEI

ZERO LED STOP STOP STOP LEI

PL HEI STOP LED LED HED

Error

PH LED HED HED HED HED

The control action implied by each rule was then

invoked in proportion to the compatibility of the

measured fuzzy state with the antecedent of the

relevant fuzzy rule; this later operation was done by

determining the membership value of the

instantaneous error value and the velocity error. For

this particular controller, the so-called Π-function

(Yamakawa, 1992) has been used.

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

+

=

n

W

bx

x

)(2

1

1

)(

µ

(1)

The Table 2 present the parameters values for the

membership functions defined for the inputs and

output variables.

In the inference step the elements of the output

fuzzy set become activated. In this work this is made

according to the folowing process: the elements of

the input fuzzy sets having µ function greater than

zero are paired one element of the error (e) variable

set to one element of the error velocity (v), making

all posibles combinations. Looking at the rules,

defined previously, to each pair corresponds an

element of output the fuzzy set.

The truth value of this output element will be

calculated using the inference method named sum-

product. If any one of the output fuzzy set elements

is activated more than once, its final µ function value

will be the sum of alls the activated µ

functions of

this element.

FUZZY CONTROL OF FABRICS DRYING ON AN INDUCTION HEATED ROTATING CYLINDER: Experimental

results

335

Table 2: Parameters for the memberships functions

Error membership funtion

Fuzzy State b W n

NH -3 3 8

NL -1 1 4

ZERO 0 0.5 2

PL 1 1.5 4

PH 3 2 8

Error velocity membership funtion

Fuzzy State b W n

NH -10 4 8

NL -4 2 4

ZERO 0 1 2

PL 4 2 4

PH 10 4 8

Power supply membership funtion

Fuzzy State b W n

HEI -3 3 8

LEI -1 1 4

STOP 0 0.5 2

LED 1 1 4

HED 3 3 8

In the defuzzification stage a numerical final output

value is obtained through the center-average

defuzzification method.

4 EXPERIMENTAL RESULTS

The objective of this stage is to implement the

proposed Fuzzy Logic Controller using the pilot-

plant cylinder dryer so as to control the exit web

humidity by actuating the power supplied to the

inductors.

The trial initially involved manual operating

conditions leading to a preliminary decrease in web

humidity during drying by using a cylinder

rotational speed of 1.7 rev/min., a power supply of

2.42 kW and the maximun degree of web-cylinder

surface contact (1618 cm

2

). This startup step for the

process takes about 26 min. Figure 1 shows the

operational variables measured on line during the

complete trial: the cylinder temperature and the web

humidity at the inlet of the drying section, the

temperature of the fabric at the exit of the drying

section, and the cylinder rotational speed. Once

steady–state conditions were achieved, the process

was changed to automatic mode and a set point for

the exit web humidity fixed at 20 g water/100 g dry

fabric. From this moment on, the process is under

the Fuzzy Logic Controller action.

In first stage of the process control, as shown in

Figure 2, an important increase of the power

supplied to the inductors is observed generating an

immediate increase in the cylinder temperature, and

consequently a fabric with a low exit humidity.

From these conditions of over-drying, a reduction of

the power is observed. In this early stage, the web

humidity oscillates around the set point of 20 g

water/100 g dry fabric and the controller takes

approximately 45 min. to control the exit web

humidity to the set point.

Once the set point value is attained, a step

perturbation was made changing the position of the

movable roller, decreasing the contact web-cylinder

surface. From this second stage of the trial, there is

an immediate increase of the web humidity

following a reduction in the area of web-cylinder

contact (or reduction of the drying time).

The fuzzy logic controller responds by increasing

the power supplied to the inductors but the same

previous oscillatory dynamic of the exit web

humidity is observed tending towards the set point.

In the last stage of the trial, a set point change was

made, changing the value from 20 to 10 g water/100

g dry fabric. Figure 6 shows the dynamic reponses,

for the controlled and manipulated variables and as

in the previous stages, the web humidity tends

towards the new set point

.

5 CONCLUSIONS

A Fuzzy Logic Controller was used with success to

control a complex process, like the drying of a fabric

by contact with a rotating cylinder heated by

electromagnetic induction. The performance of the

controller was tested using a pilot scale dryer and a

stable reponse was observed when the process was

perturbed with changes in the operational conditions

and in the set point for the exit web humidity.

REFERENCES

Dhib, R., 1994. Modelisation, simulation et côntrole

numérique d’un procédé de séchage par rayonnement

infrarouge, Thèse de doctorat, Université de

Sherbrooke, QC.

Jones, P.L. 1992. Electromagnetic wave energy in drying

process. In drying 92, A.S. Mujumdar, Ed. Elsevier,

Amsterdam, pp. 115-136.

Passino K.M., S. Yurkovich. 1998. Fuzzy Control,

Addison-Wesley Longman Inc., Menlo Park,

California.

Pérez S., N. Thérien and A.D. Broadbent. 2001. Modelling

the continuous drying of a thin sheet of fibres on a

cylinder heated by electric induction. Can. J. Chem.

Eng. 79, 977-989.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

336

Slitine, M.D., 1994. Identification et commande en temps

réel d’un procédé de séchage par radiation infrarouge,

thèse de doctorat, Université de Sherbrooke, QC.

Yamakawa, T., 1992. A fuzzy logic controller. J.

Biotechnol. 7, 1-32

0

20

40

60

80

100

120

140

160

180

200

0 20 40 60 80 100 120 140 160 180 200

Time (min.)

Web Humidity (g water/100 dry fabric) and Temperatures (C)

0,00

0,20

0,40

0,60

0,80

1,00

1,20

1,40

1,60

1,80

2,00

Cylinder rotational speed (rev/min.)

Exit temperature of the fabric

Temperature of the cylindre

at the inlet drying section

Cylinder rotational speed

Inlet web humidity

Figure 1: Operational variables during the trial.

0

10

20

30

40

50

60

70

80

90

100

0 20 40 60 80 100 120 140 160 180 200

Time (min.)

Web Humidity (g water/100 g dry web)

0

1

2

3

4

5

6

7

8

9

10

Power supply (kW)

Power supply to inductors

M ovable roller position

Exit web

hum idity

W eb Humidity Set point

Figure 2: Variables manipulated, controled and perturbations during the trial.

FUZZY CONTROL OF FABRICS DRYING ON AN INDUCTION HEATED ROTATING CYLINDER: Experimental

results

337