A VISUAL SERVOING ARCHITECTURE USING PREDICTIVE

CONTROL FOR A PUMA560 ROBOT

Paulo Ferreira

Escola Superior de Tecnologia de Setúbal, Estefanilha, 2914-508

João C. Pinto

Instituto Superior Técnico, Av. Rovisco Pais, 1096 Lisboa, Portugal

Keywords: robotic manipulators, predictive control, vision, modelling, simulation.

Abstract: A control system for a six degrees freedom Puma robot using a Visual Servoing architecture is presented.

Two different predictive controllers, GPC and MPC, are used. A comparison between these two ones and

the classical PI controller is performed. In this system the camera is placed on the robot’s end-effector and

the goal is to control the robot pose to follow a target. A control law based on features extracted from

camera images is used. Simulation results show that the strategy works well and that visual servoing

predictive control is faster than a PI control

.

1 INTRODUCTION

The controller has a crucial role in the visual

servoing system performance. Most of the developed

works in visual servoing systems do not take into

account the dynamics of the manipulator.

The term Model Predictive Control (MPC)

includes a very wide range of control techniques

which make an explicit use of a process model to

obtain the control signal by minimizing an objective

function (

Camacho 98). The MPC is formulated

almost often in a state space form conceived for

multivariable constrained control, Generalized

Predictive Control (GPC), which was first

introduced in 1987 (Clarke et al., 1987), is primarily

suited for single variable and the model is presented

in a polynomial form. Model Predictive control has

been adopted in industry as an effective way of

dealing with multivariable constrained control

problems (Lee and Cooley 1997). A work developed

in the field of visual servoing used a predictive

controller in small displacements (Gangloff, 98).

Other work compares a GPC with respect to a PID

and a feedforward controller in a pan-tilt camera

(Croust, 99).

To carry out this work it was created a toolbox

that allows incorporating vision in the Puma control

architecture. Its great versatility, allowing the easy

interconnection of different types of controllers,

becomes this type of tools very advantageous. The

Puma 560 model and the used 2D visual servoing

architecture can be found in (Ferreira 2003). In this

paper the results of a set of experiences in the area of

the modelling, identification and control of a visual

servoing system for a Puma 560 are presented.

This paper is organised as follows: Section 2

introduces the principles of Predictive Control (GPC

and MPC) and the identification of the Puma

ARMAX model. The experimental settings and the

results for a PI, a GPC and a MPC controller are

given in section 3. Section 4 concludes the paper and

section 5 suggests the continuity of this work.

2 PREDICTIVE CONTROL

2.1 Generalized Predictive Control

The basic idea of GPC is to calculate a sequence of

future control signals in such a way that it minimizes

a cost function defined over a prediction horizon

(E.F.Camacho 1998).

The system model can be presented in the ARMAX

form (Camacho 98):

475

Ferreira P. and C. Pinto J. (2004).

A VISUAL SERVOING ARCHITECTURE USING PREDICTIVE CONTROL FOR A PUMA560 ROBOT.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 475-478

DOI: 10.5220/0001147204750478

Copyright

c

SciTePress

1

1

11

1

)()(

)()()()(

−

−

−−

−

+−=

z

tzC

TtuzBtyzA

e

ξ

(1)

Where A(z

-1

), B(z

-1

) and C(z

-1

) are the matrix

parameters of transfer function H(z). To compute the

output predictions is necessary to know the system

model that must be controlled (Fig. 1).

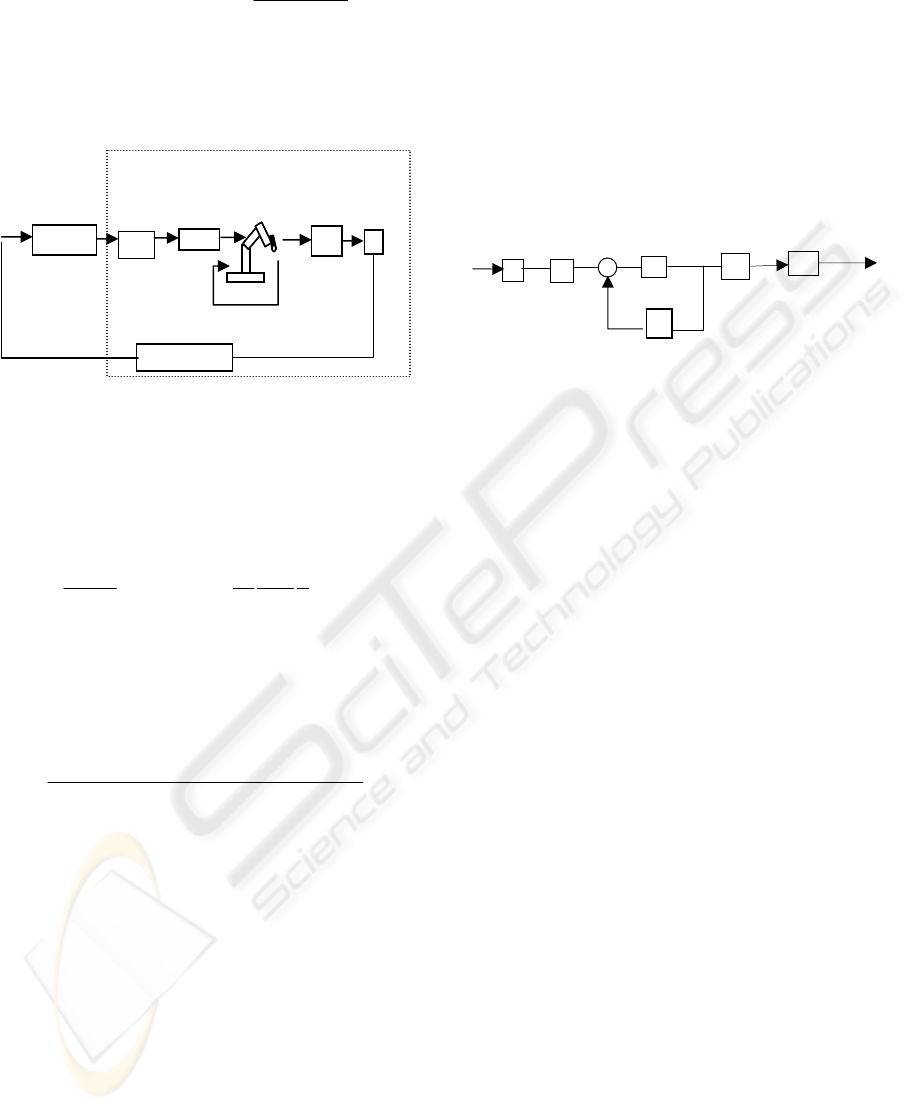

Figure 1: Manipulator system block diagram controlled by

vision

.

The parameters used by the GPC are obtained

from the configuration shown in figure 7 and the

transfer function is given by:

1

() 11

() ()

*( ) 2 1

a

cc

T

pz z

HZ JFzJ

pz z z

−

+

==

−

&

(2)

The parameters of this function are used in

predictive controller implementation.

The robot model is obtained by identifying each

of the joints dynamics to obtain a six order linear

model:

0

1

1

2

2

3

3

4

4

5

5

6

0

1

1

2

2

3

3

4

4

5

5

)(

azazazazazaZ

bzbzbzbzbzb

ZF

i

++++++

+++++

=

−−−−−−

−−−−−

System Identification .In the identification procedure

is used a PRBS as input signal. A prediction error

method (PEM) was used to identify the Robot

dynamics. The noise model C(z

1

) of order 1 was

selected. In this approach the identification of H(Z)

(Fig.1) is performed around a reference condition.

Since the robot is controlled in velocity and because

the dynamics depend almost from the first joints and

the displacement is small is possible to linearize the

system in turn of the position q. It was also

necessary to consider a diagonal inertia matrix.

Assuming those conditions, is possible to consider

that the Jacobian matrix is constant and therefore

H(Z). This procedure is valid at low velocities. This

means that the cross coupled terms are neglected.

2.2 A MPC Controller

In this approach the model used is in a space state

format. The model of the plant to be controlled is

described by the linear discrete-time difference

equations:

(1) () (),(0)

0

() ()

x

tAxtButxx

yt Cxt

+= + =

=

⎧

⎨

⎩

(3)

Where x(t) is the state, u(t) is the control input and

y(t) is the output.

Figure 2: State space scheme of the manipulator controlled

in velocity

In Fig. 2 is represented the scheme of a

manipulator controlled in velocity. The parameters

values of A

t

, B

t

and C

t

are obtained from the

prediction error method identification algorithm and

eq.3 is computed by the following definitions:

1

ttt

BBJ CCJAA

−

=

==

The algorithm of the predictive control is:

1. At time t predict the output from the system,

)/(

ˆ

tkty

+

, k=N

1

,N

1

+1,…,N

2

. These outputs

will depend on the future control signals,

)/(

ˆ

tjtu

+

, j=0,1,…,N

3

.

2. Choose a criterion based on these variables and

optimise with respect to

3

,...,1,0),/(

ˆ

Njtjtu

=

+

.

3. Apply

)/(

ˆ

)( ttutu

=

.

4. At time t+1 go to 1 and repeat.

3 EXPERIMENTAL PROCEDURE

3.1 System configuration

The implemented Visual Servoing package allows

the simulation of different kind of cameras. In this

particular case, it was chosen a Costar camera placed

in the end-effector and positioned according with o

z

axis. It was created a target of eight coplanar points

that will serve as control reference. The accuracy of

the camera

position control in the world coordinate

system was increased by the use of redundant

features (Hashimoto, 1998). The centre of the target

corresponds to the point with coordinates (0,0) and

J

c

∫

GPC

ZOH

Robot

velocity

control

ˆ

&

&

&

p

J

-1

q

&

∗

q

&

p∆

*p

&

F(Z)

Vision (Z

-1

)

H(Z)

A

t

*p

&

p

&

∫

C

t

J

-1

J

B

t

±

ICINCO 2004 - ROBOTICS AND AUTOMATION

476

the remaining points are placed symmetrically in

relation to this point. The target pose is referenced to

the Robot base frame. In the case of servoing a

trajectory, the target is remained fixed and the

desired point is variable. As the primitive of the

target points is obtained it is possible to estimate the

operational coordinates of the camera position point.

3.2 2D visual servoing with PI control

In 2D Visual Servoing the image characteristics are

used to control the Robot. Images acquired by the

camera are function of the end effector’s position,

since the camera is fixed on the end effector of the

robot. They are compared with the corresponding

desired images. In the present case the image

characteristics are the centroids of the target points.

Fig. 3 represents the model simulation of the

implemented 2D visual servoing configuration. In

this case CT is a PI controller.

Figure 3: Model simulation of 2D visual servoing

3.3 Predictive Visual servoing

implementation.

In this approach our goal is also to control the

relative pose of the Robot in respect to the target.

The model corresponds to Fig.3 but substituting the

controller – in the first case is used a GPC and in

another is used a controller MPC. The target object

is composed of eight coplanar points. From the

projection of these points in the image frame, the

estimated pose of the object in the sensor frame is

computed (Gangloff 99). In both experiments all the

condition and characteristics of the robot are the

same. The goal is control the end effector from the

image error between a current image and desire

image.

3.4 Visual servoing control results

PI Controller .To eliminate the position error was

chosen a PI controller considering points in

operational coordinates:

p

i

= [0.35 –0.15 0.40 π 0 π]

T

p

d

= [0.45 –0.10 0.40 π 0 π]

T

The points p

i

and p

d

correspond to the Robot

position from which the images used to control the

robot are obtained.

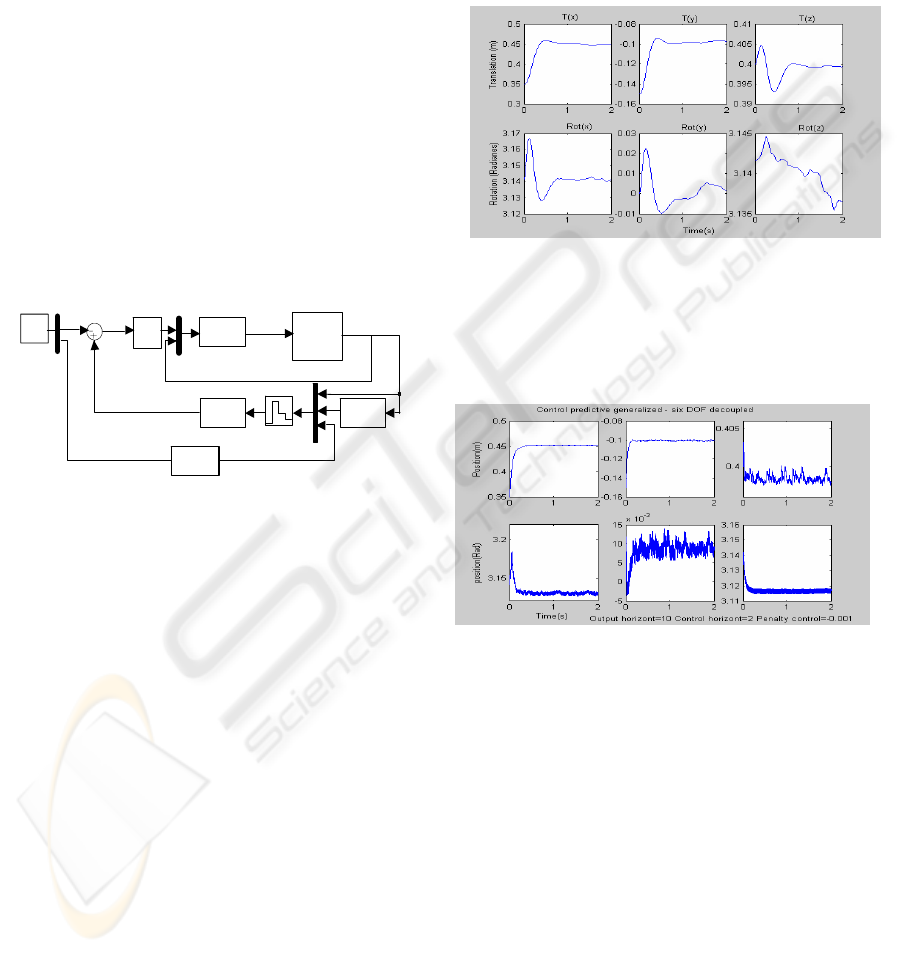

In Fig. 4 it can be observed the

translation and rotation of the end-effector around o

x

,

o

y

and o

z

axis.

Figure 4: Stabilization in a desire point using a PI.

Predictive GPC Visual servoing control. In this case

it was used a 2D visual servoing architecture with a

GPC controller. To compare the performance of this

system the same initial and desire position were

used.

Figure 5: Results of a 2D architecture using a GPC

controller.

When compared with the 2D visual servoing

with a PI controller it can be seen that the GPC has a

more linear trajectory and is faster for the same

displacement (more displacement around the x and y

axes). Figure 5 and 6 show that the rise time to PI is

around 0.6s while to the GPC and MPC are 0.1s and

0.2s.The settling time is 1s for the PI, 0.3s for the

GPC and 0.9s for the MPC.

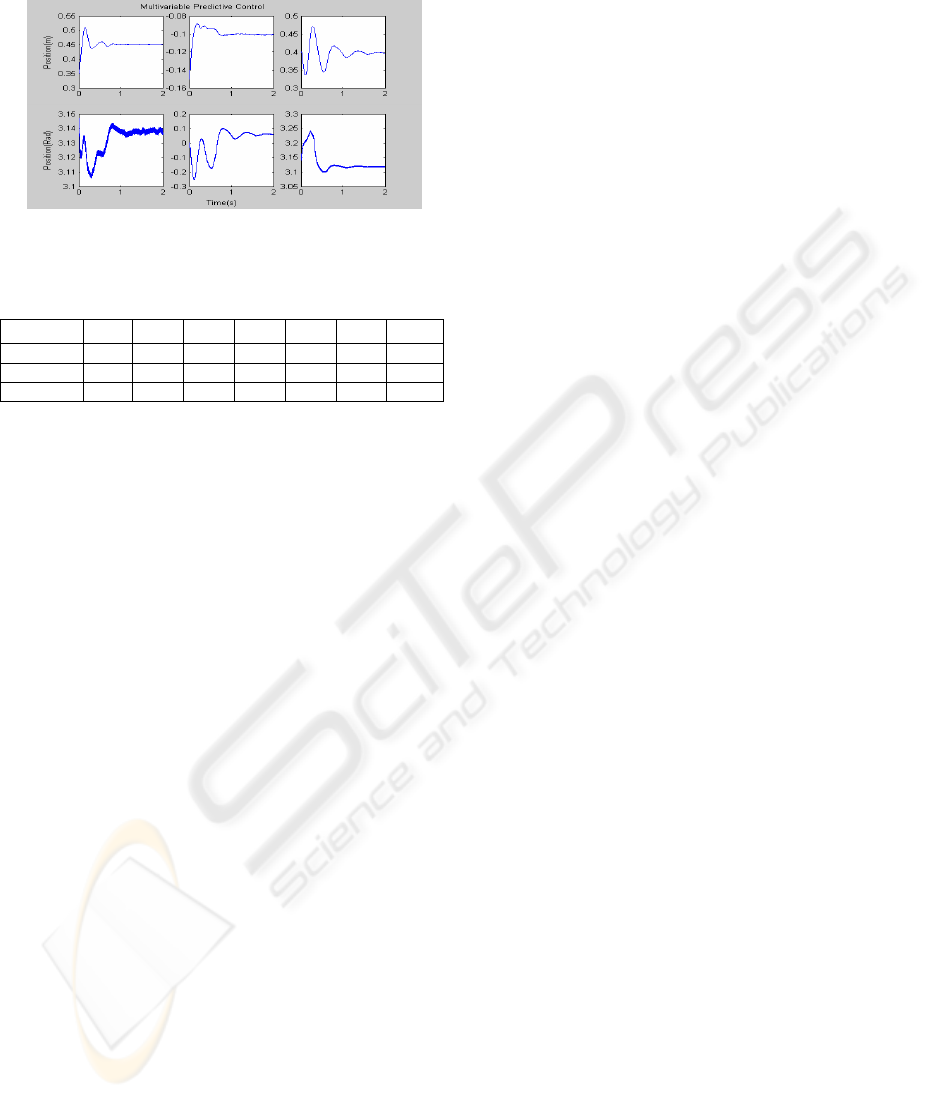

Predictive MPC Visual servoing control. In this case

it was used a MPC controller. To compare the

performance of this system the same initial and

desire position were used.

From Figure 6, it can be seen that the rise time

for the MPC is 0.3s. The result was not so good

ZOH

q

in q

out

Puma 560 +

control

J

r

v

J

+

−

S

CT

pd

d

p

,p

d

dp

P-P*

S

0

A VISUAL SERVOING ARCHITECTURE USING PREDICTIVE CONTROL FOR A PUMA560 ROBOT

477

mainly in turn of z and for rotation of the end-

effector.

Figure 6: Results of a 2D architecture using a MPC

controller .

Table 1: r.m.s. values for the control algorithm

SSR

T

x

T

y

T

z

θ

x

θ

y

θ

z

error

PI 2.50 2.40 1.20 2.20 0.30 0.47 1.51

GPC 2.14 0,81 0.22 1.84 0.22 0.02 0.87

MPC 1.36 0.67 3.01 0.76 6.3 6.21 3.04

Table 1 presents the computer errors for each

algorithm which reveals the best performance for the

GPC.

4 CONCLUSIONS

A vision control system for a six degrees of freedom

robot was studied.

A prediction error method was used to identify the

Robot dynamics and implement a predictive control

algorithm ( MPC and GPC).

The controllers (PI, GPC and MPC) were used to

control the robot in a 2D visual servoing

architecture.

The three different algorithms always converge to

the desired position. In general we can conclude that

in visual servoing is obvious the good performance

of both predictive controllers.

The examples show also that the 2D algorithm

associated with the studied controllers allow to

control larger displacements than those referred in

(Gangloff 99).

From the analysis of r.m.s error presented in Table 1

we can conclude the better performance of the GPC.

In spite of better MPC results for the translation in

the xy plane when compared to the GPC, the global

error is worse. These results can still eventually be

improved through a refinement of the controllers

parameters and of the identification procedure. In the

visual servoing trajectory is obvious the good

perfomance of this approach. The identification

procedure has a great influence on the results.

The evaluation of the graphical trajectories and the

computed errors allow finally concluding that the

GPC vision control algorithm leads to the best

performance.

5 FUTURE WORKS

In future works, another kind of controllers such as

intelligent, neural and fuzzy will be used. Other

algorithms to estimate the joints coordinates should

be tested. These algorithms will be applied to the

real robot in visual servoing path planning.

Furthermore others target (no coplanars) and other

visual features should be tested.

ACKNOWLEDGEMENTS

This work is partially supported by the “Programa de

Financiamento Plurianual de Unidades de I&D

(POCTI), do Quadro Comunitário de Apoio III” by

program FEDER and by the FCT project

POCTI/EME/39946/2001.

REFERENCES

Bemporad, A. and M. Morari 1999. Robust Model

Predictive Control: A Survey. Automatic Control

Laboratory, Swiss Federal Institute of

Technology(ETH) Physikstrass

Camacho, E. F. and C. Bordons 1999. Model Predictive

Control. Springer Berlin

Clarke, D.W., C.Mohtafi, and P.S.Tuffs. Generalized

Predictive Control-Part I. The Basic Algorithm,

Automatica, Vol.23, Nº2, pp.137-148

Corke, P. 1996. Visual Control of Robots. Willey

Corke, P. 1994. A Search for Consensus Among Model

Parameters Reported for the Puma 560 In Proc. IEEE

Int. Conf.. Robotics and Automation, pages 1608-1613,

San Diego.

Ferreira, P. e Caldas, P. (2003). 3D and 2D Visual

servoing Architectures for a PUMA 560 Robot, in

Proceedings of the 7

th

IFAC Symposium on Robot

Control, September 1-3, , pp 193-198.

Gangloff, J. 1999. Asservissements visuel rapides D’ un

Robot manipulateur à six degrés de liberté. Thèse de

Doutorat de L’ Université Louis Pasteur.

Lee, J.H,. and B. Cooley-Recent advances in model

predictive control.In:Chemical Process Control,

Vol.93, no. 316. pp201-216b. AIChe Syposium Series

– American Institute of Chemical Engineers.

Mezouar, Y. and F. Chaumette 2001. Images Interpolation

for Image- Based control Under Large Displacements.

Proceedings of the European Control Conference, pp.

2904-2909

.

ICINCO 2004 - ROBOTICS AND AUTOMATION

478