INFORMATION SYSTEMS SUPPORT

FOR MANUFACTURING PROCESSES

The standard S95 perspective

Patrícia Macedo

Centro de Engenharia Organizacional, INESC Inovação, R Alves Redol, 9, 1000-029 Lisboa, Portugal

Escola Superior de Tecnologia de Setúbal, IPS, Setúbal, Portugal

Pedro Sinogas

Centro de Engenharia Organizacional, INESC Inovação, R Alves Redol, 9, 1000-029 Lisboa, Portugal

Departamento de Engenharia Informática, Instituto Superior Técnico, UTL, Lisboa, Portugal

José Tribolet

Centro de Engenharia Organizacional, INESC Inovação, R Alves Redol, 9, 1000-029 Lisboa, Portugal

Departamento de Engenharia Informática, Instituto Superior Técnico, UTL, Lisboa, Portugal

Keywords: Manufacturing Enterprises, Enterprise Resource Planning, Manufacturing Execution Systems.

Abstract: Manufacturing Execution Systems and Enterprise Resource Planning Systems support the

Manufacturing Enterprise. The two families of systems have been developed independently, so

they have grown without a scope or a strictly defined border. The feature overlapping between

them raises relevant issues in the integration with control systems. This paper analyzes how

different types of manufacturing processes are supported by ERP and MES, and how the standard

developed by ISA: S95 defines the scope of each system. This standard also provides the

separation of production from non-production processes. A paper mill enterprise case study is

presented, where the business processes are identified and a system framework is proposed in

accordance with the S95 hierarchy function model.

1 INTRODUCTION

Manufacturing Execution Systems and Enterprise

Resource Planning Systems exist to support the

manufacturing enterprise. As these two families of

systems have been developed independently, they

have grown without a scope or a strictly defined

border.

MES systems were developed to support the

production processes and have been extended to

support quality control, warehouse and order

management. ERP systems began supporting

corporate activities such as finances, sales and

distribution and then extended their scope to support

quality control and production tracking. The

overlapping features of production planning and

quality control between both systems raises relevant

issues in their integration with control systems of the

plant-floor (Mark2000). This integration is required

for systems to be able to completely support the

value chain of manufacturing enterprises.

This context allows three possible scenarios:

• MES products evolve to support everything.

• ERP systems grow to support manufacturing.

• MES and ERP are integrated in order to keep

the strong points of each one.

As the last option preserves the know-how from

within each system, it implies a clear definition of

the scope, boundaries and information flows

between them.

552

Macedo P., Sinogas P. and Tribolet J. (2004).

INFORMATION SYSTEMS SUPPORT FOR MANUFACTURING PROCESSES - The standard S95 perspective.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 552-555

DOI: 10.5220/0002644805520555

Copyright

c

SciTePress

Instrument Automation and System Association

formed a committee of system vendors to develop

S95: Enterprise-Control System Integration

Standard (S952000). This standard provides means

to represent how ERP and MES are structured

inside the Enterprise Architecture.

This paper analyzes how different types of

manufacturing processes are supported by MES and

ERP systems. To better illustrate these ideas a

system framework is proposed in accordance with

the S95 hierarchy function model for a paper mill

enterprise.

2 MANUFACTURING PROCESSES

As business processes are the activities performed

within the business during which the state of

resources changes and which describe how work is

done, it is possible to define manufacturing

processes as business processes that transform

physical resources. ANSI/ISA classifies

manufacturing processes as discrete, continuous and

batch. This allows classifying manufacturing

processes according to resource type and their

relationship with time, as present on

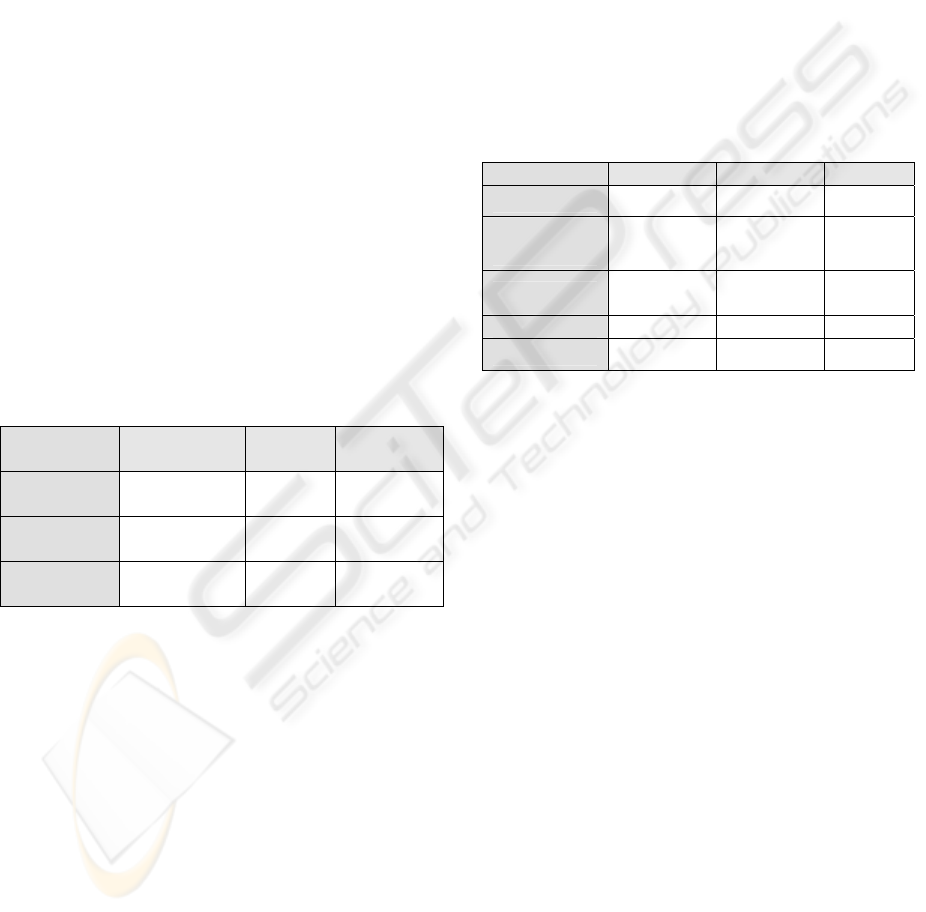

Table 1

Table 1: Manufacturing types

Manufacturing

Process

Time

Characteristic

Type of

Input

Type of

Output

Discrete Discrete Time

Finite

Discrete

Finite

Discrete

Process

Continuous

Continuous

Time

Flow Flow

Process Batch

Interval of

Time

Finite not

discrete

Finite not

discrete

Discrete Manufacturing Processes are of two

types: Assembling: Several items are aggregated to

build one finished product (i.e. Auto Industry) and

Disassembling: Product is split in several sub-

products (i.e. Paper sheet production).

Manufacturing Batch Processes are based on a

recipe that is executed during a finite period of time,

consuming and producing finite quantities of

products, called lots (i.e. Pharmaceuticals Industry).

Continuous Manufacturing Processes

transform continuous input resources into

continuous output resources (i.e. Steel and Pulp

Industries).

There are industrial cases where the production

chain process is based on the aggregation of several

types of manufacturing processes. Production can be

composed by a continuous process followed by a

disassembling discrete process for cutting and an

assembling discrete process for packing, as in the

paper industry (Schroder1993).

3 MES AND ERP SYSTEMS

Systems to support quality and production planning

have to handle the different characteristics of each

manufacturing type described. The differences on

Manufacturing Processes that have influences in the

definition of applications are resumed on table 1.

Product identification is based on item number

for Discrete Process, lot number for Batch Process

and based on time interval or time instant on

Continuous.

Table 2: System features / manufacturing types

Discrete Continuous Batch

Identification Item Time Lot

Production

Planning entity

Bill of

Material

Rate Recipe Recipe

Quantities

Numbers of

items

Recipe Ratio

Based

Volume

or Weight

Quality Item based Time based Lot based

Trace Item based Flow based Lot based

The identification type influences quality

management, planning process and traceability

implementations, as all these processes have to

manipulate the product entity.

3.1 Overlapping features

The identification of the overlapping features

between MES and ERP systems is presented in

Table 3 where business activities are defined

according to the value chain model (Porter1985).

Inbound Logistics include activities of

planning, receiving and storing raw material,which

are usually supported by ERP systems.

Manufacturing aggregates activities of planning

and execution. It is the core capability of MES.

Quality control activity is usually well

supported by MES systems. ERP systems’ planning

is usually based on Bill Material or Recipe entities

that do not cover all Industries Operations

requirements.

Outbound Logistics as Inbound Logistics are

well supported by MES and ERP systems on storage

management, planning and execution of delivery

activities.

Sales are composed by the activities of order

fulfilment, planning and invoicing which are

supported by both systems. When the order deliver

INFORMATION SYSTEMS SUPPORT FOR MANUFACTURING PROCESSES - THE STANDARD S95

PERSPECTIVE

553

dates have to be calculated to support production

planning, MES suite better.

Service aggregates the activities of receiving and

of processing a reclaim.

Support activities as Human Resources,

Procurement and Administration are better suited in

the scope of ERP systems.

Table 3: General Application Fit Comparison

Processes ERP MES

Plan

Receive

Inbound Logistics

Store

Plan

Execute

Manufacturing

Control Quality

Plan

Store products

Outbound

Logistics

Deliver

Promoting Sales and

Marketing

Selling

Receive Reclaims Service

Repair

Human Resources

Procurement

Administration

Fit Well Medium No

The coexistence of both systems in a coherent

and robust way is a challenge. The goal of the

ANSI/ISA standard is to define a model to integrate

these different systems solving the overlapping

problem.

4 ANSI/ISA S95 STANDARD

“The ANSI/ISA S95 standard – Control Systems

Integration provides standard models and

terminology for defining the interfaces between an

enterprise’s business systems and manufacturing

control systems”.

S95 was developed to provide a common model

of integration, a standard terminology to define

system requirements and integration between

different software vendors. S95 is based on three

models: Hierarchy Model, Functional Model and

Object Information Model. (S952000)

4.1 Support of different

Manufacturing types

The analysis of S95, lead to the following

differences in the models, when changing the

manufacturing process type.

Equipment Hierarchy Model

Discrete

: Production line and work cell are defined.

Continuous

: Products units are defined.

Batch

: Process cell and unit are defined.

Product Segment of the Information Model

Discrete

: defines operation as assembly steps

Continuous

: defines operation as unit-operations

Batch

: defines operation as same location operations

Process Segment on the Information Model

Identifies the capability that can be defined in

absolute or rate units.

The implementation of S95 guaranties that MES

and ERP are independent from the manufacturing

type, as layer 0, 1 and 2 systems, supports the

differences.

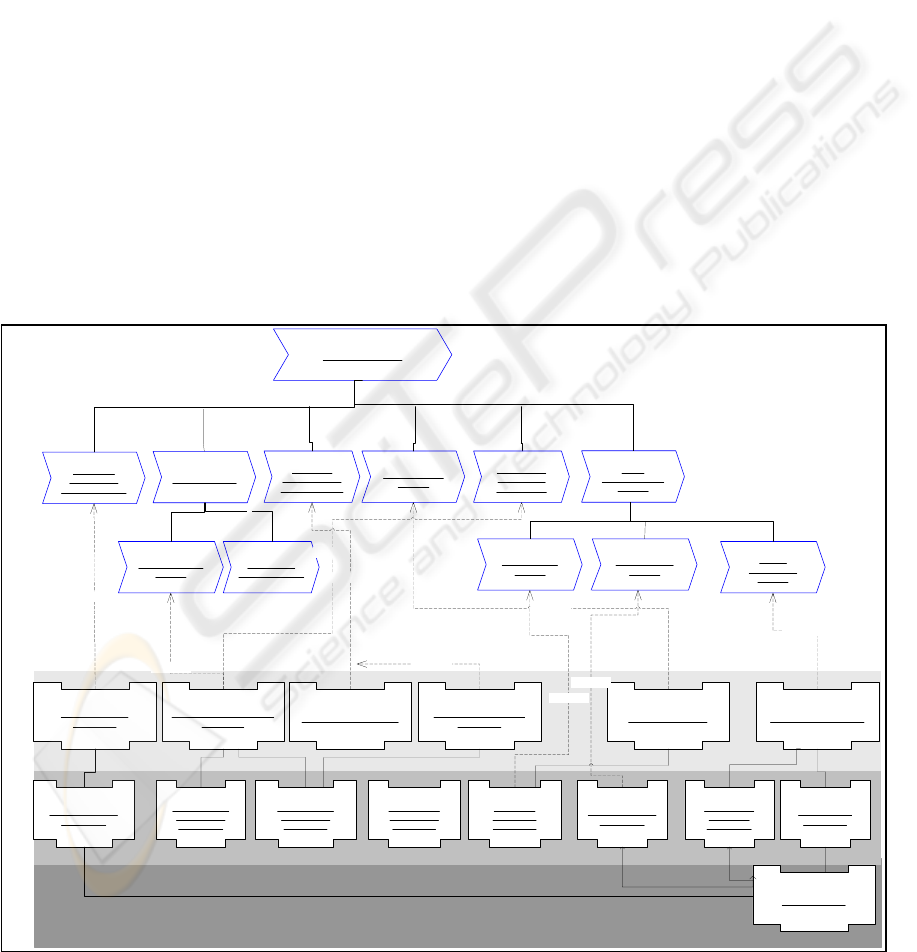

5 CASE STUDY

Paper Mill Enterprise Processes were analyzed in

order to propose a system framework in accordance

with the S95 hierarchy function model. The paper

production process was selected as it provides a

scenario where continuous, discrete and batch

processes are used in the same production chain.

The following methodology was applied to build

the framework in figure 3:

1. Business process modelling of a Paper Mill.

2. Identify the features of ERP and MES, and

which business process they support.

3. Follow S95 Hierarchy Functional Model to

identify the activities of each level.

4. From S95 Functional Model identify the

processes that should be supported by level 3

and by level 4 systems.

5. From point 3 and 4 infer which MES or ERP

component should support each process.

In the diagram MES was split into components

considering the activities defined on hierarchy

functional model of S95.

ICEIS 2004 - INFORMATION SYSTEMS ANALYSIS AND SPECIFICATION

554

6 CONCLUSION AND FUTURE

WORK

“A major business challenge for large enterprises is

to achieve the proper level of decentralization that is

to assign responsibility and decision making to the

appropriate organization level” (NIST1999).

S95’s hierarchy models provide a powerful tool

to build a manufacturing enterprise system

framework where the decentralization concept is

applied on the Information Systems Architecture.

Although the standard defines an object

information model, it only provides a functional

approach. This leads to a lack of clear definition

between functions and objects entities and hardens

its application when following a business process

oriented methodology.

An issue under research is how the information

entities could be defined to guarantee the

information integrity across system components and

from levels 2 throw level 4.

REFERENCES

(NIST1999) Ed Barkmeyer et al, 1999, NIST Response to

MES OMG Request for Information, NIST.

(Mark2000) Adams Mark e al, 2000, ERP;MES;APS;

Quality Management: How should we put these pieces

together?, PIMA 32nd Annual Information Systems

Conference.

(Porter1985) Michael Porter, 1985, Competitive

Advantage, New York: Free Press.

(Schroder1993) Roger G. Schoroder, 1993, Operations

Management, Decision Making in the Operation

Function, McGraw-Hill International Editions, 4

th

Ed.

(S952000) ANSI/ISA-95.00.01-2000, 2000, Enterprise-

Control System Integration, Part 1: Models and

Terminology, ISA, North Carolina.

(Vasconcelos2001) A. Vasconcelos, A. Caeteano, J.

Neves, P. Sinogas, R. Mendes, J. Tribolet, 2001, A

Framework for Modelling Strategy, Business Processes

and Information Systems, EDOC, Seattle.

Figure 1: Paper Production Process-System using CEO framework (Vasconcelos2001)

«process»

Bussiness

Administration:

support process

«process»

Paper Manufacturing

«process»

Sell Paper: core

Process

«process»

Distribuition

:support process

«process»

Logistic:process

«process»

Paper

Production:core

process

«process»

Storage: support

process

«process

»

Raw Material

Procurment:

core Process

«process»

Equipment

maintenance

:support process

«process»

Planning; core

process

«process»

Execution:core

process

«process»

Quality

Control:core

process

0

«system»

Control Systems

«system»

ERP: Human Resources

component

«system»

ERP financial:component

«system»

ERP: Quality component

«system»

ERP:Maintenance

component

«system»

ERP :Material Management

Componen

«supports»

«supports»

«supports»

«system»

ERP:Sell component

«supports»

«supports»

«supports»

«supports»

LEVEL 4

LEVEL 2

LEVEL 3

«system»

MES: Dispatching

Component

«system»

MES:Tracking

component

«system»

MES:detail

Scheduling

component

«system»

MES:Resource

Management

component

«system»

MES:definition

Management

Component

«supports»

«supports»

«system»

MES:Maintenance

Component

«system»

MES: Quality

Assurance

Component

«system»

MES:Process

Management

component

INFORMATION SYSTEMS SUPPORT FOR MANUFACTURING PROCESSES - THE STANDARD S95

PERSPECTIVE

555