PREDICTIVE CONTROL FOR MODERN INDUSTRIAL ROBOTS

Algorithms and their applications

Květoslav Belda, Josef Böhm

Department of Adaptive Systems

Institute of Information Theory and Automation, Academy of Sciences of the Czech Republic

Pod vodárenskou věží 4, 182 08 Prague 8 – Libeň, Czech Republic

Pavel Píša

Department of Control Engineering

Faculty of Electrical Engineering, Czech Technical University in Prague

Karlovo nám. 13, 121 35 Prague 2, Czech Republic

Keywords: Predictive control, Redundant manipulators, Robotics, Steady-state error problem.

Abstract: Industrial robots comprise substantial parts of machine tools and manipulators in production lines. Their

present development stagnates in their control. Traditional approaches, e.g. NC (numerical control) systems

combined with PID/PSD structures, provide control of the tool drives as separate units only, but not solve

the control from view of the whole machine system. On the other hand, in control theory, there are a lot of

approaches, in which the information on tool dynamics and kinematic relations can be involved. The main

contribution of this paper is to introduce various utilization and modifications (not only control tasks) of one

such approach – model-base predictive control. The control is being developed for modern industrial robots

based on parallel configurations. The modifications of predictive algorithm are substantiated by real

laboratory experiments. The paper concerns with basic control design and its possibilities to remove

positional steady-state error. Quadraticaly-optimal trajectory planning is outlined in it.

1 INTRODUCTION

Industrial robots comprise substantial parts of ma-

chine tools and manipulators in production lines.

Their present development stagnates in their control,

which should ensure not only high accuracy, but also

economical and safe operation.

Traditional approaches, e.g. Numerical Control

systems (NC

systems) combined with PID/PSD stru-

ctures, provide control of the robots only from view

of their drives considered as separate units. It means

that whole robotic system is taken into account

as a set of drives and their relations. These relations

are given by mechanical constrains arising from real

robot structure – real mechanism. In those appro-

aches, the relations are considered only as distur-

bances acting to individual drives. This concept

yields no possibilities for further increase of opera-

tional accuracy and load capacity.

Modern control approaches can involve the most

of properties of whole robotic system through its

mathematical model. It is obtained by virtue of ma-

thematical-physical analysis or some numerical

identification method. Such control approaches are

generally called model-based approaches. They can

design, just by use of the mathematical model,

corresponding and energetically reasonable control

actions.

One of modern model-based approaches is multi-

step Predictive control (Ordys and Clarke 1993). It is

applicable in new developed industrial robots (e.g.

Neugebauer, ed., 2002), which are based on redun-

dantly actuated parallel structures. They represent

multi-input multi-output systems and their redundant

actuation solving the problem of workspace

singularities (Belda et al. 2003) deter mines different

number of their inputs and outputs.

In use of parallel robots, model-based control

can be fully utilized, for more complicacy of the

robot structure. Control based on model can better

distribute the input energy in the structure. Example

of two parallel structures is shown in Figure 1.

3

Belda K., Böhm J. and Píša P. (2005).

PREDICTIVE CONTROL FOR MODERN INDUSTRIAL ROBOTS - Algorithms and their applications.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 3-10

DOI: 10.5220/0001155800030010

Copyright

c

SciTePress

drive3

y

x

drive1 drive2

drive4 drive3

y

x

drive1 drive2

drive4

drive1

drive4

z

drive3

x

drive2

drive1

drive4

z

drive3

x

drive2

‘Crosshead’ ‘Sliding Star’

Figure 1: Planar parallel robots: horizontal and vertical

Although the parallelism is appeared in robotics

in the sixties - Stewart platform in 1965 (Tsai,

1999), their wider development started in the nine-

ties (Neugebauer, ed., 2002). The parallel robots are

promising way, how to significantly improve accu-

racy, speed and stiffness of machine tools. They can

be simply understood as movable truss constructions

or as movable work platforms supported by a set

of parallel arms (Tsai, 1999).

The main contribution of this paper is to demon-

strate various utilization and modifications (not only

control tasks) of predictive control; if it can achieve

acceptable dynamic control errors and solve steady-

state error problem. The theoretical results imple-

mented in algorithms are substantiated by real

laboratory experiments with redundant parallel

structure ‘Sliding Star’ (Figure 1, 3).

2 MODEL-BASED APPROACH

The model-based approaches use the model as prior

information (feed-forward). It enables to predict

future behavior of a controlled system. Considering

future requirements and behavior, the input energy

can be optimized (Ordys and Clarke, 1993).

The models can be expressed in different forms.

In case of multi-input multi-output structures

(MIMO systems), as robots are, the model is useful

expressed by state-space formulation. State-space

model more clearly expresses the relations among

inputs and outputs and their coupling.

2.1 Composition of the Robot Model

Generally, the robot is a multibody system. Its

model is represented by pure equations of motion.

They are composed mostly from Lagrange’s

equations (e.g. Stejskal and Valášek, 1996). Then

the mathematical model described the real system

is given by a set of differential equations (1)

uyyyy )(),( gf +=

(1)

where input vector u can represent only forces,

caused by torques on drives in case of horizontal

configuration

τ

Fu

=

(2)

or these forces enlarged by gravitational forces

in case of vertical configuration

τ

FFu +−=

g

(3)

The equations (2) and (3) serve for final

determination of real control actions – force effects

required from drives. Furthermore, this arrangement

provides the equality

0yy =),(

f for arbitrary y from

range of definition and zero time derivatives

0y

=

in spite of presence of gravitational forces, which are

added to inputs (equation (3)).

The function

),( yy

f produces that the equation

(1) is nonlinear for state

TT

],[],[

21

xxyyX ==

.

One of ways to cope with nonlinearity is to use some

kind of linearization. In the following subsection,

one linearizing technique is introduced.

2.2 Exact Linearization

The subsection 2.2 deals with the linearization based

on differences. Against standard linearization using

partial derivatives, the resultant form is usable not

only in the working point, but also in its wider

neighbourhood.

The nonlinearity in the equation (1) can be

linearized as follows (Valášek and Steinbauer, 1999)

yyyyyyyy

),(),(),(

21

aa +=f

(4)

and transformed in state-space form

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

=

⎥

⎦

⎤

⎢

⎣

⎡

=

2

1

21

),(

)(

x

x

aa

10

yy

y

Xf

f

(5)

Provided that the nonlinear function

),( yy

f

and point

TT

],[],[

21

xxyyX ==

are given; X

belongs to the range of definition of the function;

zero elements in X are substituted by suitable

nonzero number

0→

κ

to prevent zero division.

Furthermore, two types of state variables are

assumed: generally outputs x

1

= y and their time

derivatives x

2

= y

; i.e.

TTT

xxxx ]],,[],,,[[],[],[

2221121121

""

=== xxyyX

(6)

ICINCO 2005 - ROBOTICS AND AUTOMATION

4

Finally, the assumption from previous section

has to be also fulfilled for arbitrary y and zero

y

]

2

arbitrary,

1

[)(),( 0xxXX0Xfyy =====

rrr

f

(7)

Then the decomposition indicated by equation

(4) can be reached. Its algorithm starts from second

state variables x

2

(i.e. according to the equation (6):

order is

{x

21

,

x

22

,

···,

x

11

,

x

12

,

···}

i.e.

{21,

22,

···,

11,

12,

···}) (8)

The order is given by amount of the information

included in the function f(X) and assumption (7).

The indicated order of selection will considerably

simplify decomposition, as it will be shown later.

In view of previous assumptions, the exact

linearization-decomposition is expressed as follows:

++∆

∆

∆

+∆

∆

∆

= "

DD

12

12

11

11

.

)(

.

)(

)( x

x

x

x

ff

Xf

"

DD

+−

−

∆

+−

−

∆

+ )0(

)0.(

)(

)0(

)0.(

)(

22

22

21

21

x

x

x

x

ff

(9)

(Note: The dots before variables in denominators

mark division ‘element by element’; division of all

elements of differences by scalar ∆

xij

.)

In detail, the equation (9) is written that way

=)(Xf

···

.

)]([)]([

···)(

).(

)]([)]([

21

21

23

,

22

,0,

13

,

12

,

1123

,

22

,

21

,

13

,

12

,

11

1111

1111

0,0,0,

13

,

12

,

11

0,0,0,

13

,

12

,

11

+

−

+

+−

−

−

=

x

x

xx

xx

T

xxxxx

T

xxxxxx

r

r

T

xx

r

x

T

xxx

ff

ff

(10)

The individual fractions of the equation (10) are

columns of the coefficients of the matrices

),( yya

1

and

),(

2

yya

with following internal structures

0yya =),(

1

,

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

%#

"

22

2

21

2

12

2

11

2

2

aa

aa

a

(11)

The first column group (matrix

),(

1

yya

)

contains only zeros due to differences being also

zeros - the vector function equals zeros for zero time

derivatives; see equation (6) – e.g. numerator of the

first column of

),(

1

yya

is

0ff =− )]0,0,0,,,([)]0,0,0,,,([

131211131211

T

r

T

xxxxxx

(12)

2.3 Discrete State-Space Formulation

Let the linear (or linearized) differential equation

or the system of differential equations with separate

the highest derivation on left side are assumed

uyyyyyyyyyfy )(),(),(),( g++==

21

aa

(13)

Then, its continuous state-space form is written as

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

+=

)(

;;

1

21

2

1

x

0

B

aa

10

A

x

x

X

uBXAX

g

CC

CC

[]

21

ccC

XCy

=

=

C

C

(14)

For real-time control the system (14) has to be

discretized, because continuous realization is not

feasible. The reason is that the model of the robot

needs certain time for its own composition and real

control systems are usually realized discretely.

The discretization of the model has to be realized

also in finite time. Therefore, the conventional

discretization technique (Šulc, 1999)

)()()1(

)(

kdekek

k

k

C

k

CC

uBXX

AA

∫

+

−+

+=+

δδ

δ

τδδδ

τ

(15)

is provided by finite expansion of exponential

function

)( ⋅

e .

Finally, then the discrete state-space model is

written as follows

)(

)(

)(

)(

)1( k

k

k

k

k uB

X

X

C

A

y

X +

=

=+

(16)

This model (16) is initial form for further

explanation of design of predictive algorithm.

3 PREDICTIVE CONTROL

Generalized Predictive Control is a multi-step con-

trol (Ordys and Clarke, 1993) as well as a similar

approach – Linear Quadratic Control (Phillips and

Nagle, 1995). It offers more powerful control actions

than standard PID controllers and therefore it gains

significant and widespread application in industrial

process control. Its basic formulation can be

adapted, without difficult modifications, for multi-

input multi-output (MIMO) systems.

The control is based on local optimization

of quadratic cost function (quadratic criterion)

()()

{}

+−−=

∑

+=

++++

N

Noj

jkjk

T

jkjk

k

J

1

)()()()(

wyQwy

y

{}

∑

=

−+−+

+

Nu

j

jk

T

jk

1

)1()1(

uQu

u

(17)

The criterion is expressed in step k. N is a hori-

zon of optimization, No is a horizon of initial

insensitivity and Nu is a control horizon.

Q

y

and Q

u

are output and input penalizations and

y

(k+j)

and

u

(k+j −1)

are input and output values.

PREDICTIVE CONTROL FOR MODERN INDUSTRIAL ROBOTS - Algorithms and their applications

5

The predictive control combines together both

feed-forward part and feed-back part. The former,

feed-forward part is represented by prediction

via mathematical model of the controlled system

(parallel robot). It forms the dominant part of control

actions. The latter, feed-back, closed from measured

outputs, compensates some model inaccuracies

and certain bounded disturbances.

In spite of mentioned incontestable advantages of

predictive control, it can cause, in general point

of view, occurrence of steady-state errors. It is

happened not only when penalizations in quadratic

cost function are nonzero but also e.g. when

unmeasured disturbances occur.

It can be solved by modification of generalized

predictive algorithm, which will be explained

thereinafter.

3.1 Equations of Prediction

The prediction is fundamental part of the design.

It defines the character of the algorithm. Generally,

let us consider two types of algorithms:

• absolute algorithm (standard)

• incremental algorithm (modified standard)

Absolute algorithm generates directly values

of the control actions, their full (absolute) values.

The algorithm arises from the model (14) or (16)

without any changes. On the other hand, incremental

algorithm generates only increments of the control

actions. To obtain incremental/integrative character,

the integrator has to be added to the model of the system.

The following lines show this addition

uyyyyyyyyyfy )(),(),(),( g++==

21

aa (18)

uduuduu

~

)(' ==→=

∫

tdt (19)

after insertion of equation (19) to (18), it is obtained

uyyyyfy

~

'''))',((''' g++==

21

aa

(20)

Then continuous state-space formulation is

u

0

0

x

x

x

10

0

0

010

x

x

x

~

][][

3

2

1

21

3

2

1

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

+

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

g

aa

(21)

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

+=

===

C

C

C

C

CC

B

0

B

A0

010

AX

x

x

x

uBXAX

~

;

][

~

;

~

3

2

1

~

~~

~

~

TT

ccC ]'',',[],,[];[

~

321

~

~

yyyxxxX0CCXCy ====

(22)

Extended state

X

~

is computed by state observer

(Anderson and Moore, 1979). This modified model

(22) has the same form as state-space model (14).

If it is discretized according to (15), then obtained

model is the same as (16). That form is generally

correct and it will be used in the following text also

for the modification (21) and (22).

Using considered discrete state-space form (16),

the equations of prediction are usually expressed as

)1(

)1(

)(

)(

)(

)(

1

1

)(

)(

)(

)(

)(

)(

)1(

)1(

−+

−+

−

−

+

+

+

+

+

+

+

+

+

+

+

+

=

=

=

=

Nk

Nk

k

k

k

k

N

N

k

k

k

k

N

N

Nk

Nk

k

k

Bu

Bu

CBu

Bu

Bu

Bu

A

A

C

C

X

X

X

X

A

A

A

A

C

C

y

X

y

X

"

"

%##

#

(23)

and in matrix notation, they are given that way

uGfy +=

()

k

N

X

CA

AC

f

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

= #

,

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

−

CB

0

B

B

AC

C

G #

"

%

"

#

1N

(24)

Vector

f represents free responds (u = 0) from time

instant k. The product

G

u compensates differences

of free responds from desired values within horizon

of optimization N (Ordys and Clarke, 1993).

3.2 Computation of Control Actions

The control actions are obtained by minimization

of quadratic criterion (17). It can be simply rewritten

to the following matrix product (Belda et al. 2002)

=

⎥

⎦

⎤

⎢

⎣

⎡

−

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

−

=

u

wy

Q0

0Q

Q0

0Q

uwy

u

y

u

y

],)[(

TT

k

J

JJ ×=

T

(25)

where y

is a vector composed according to (24)

(time step k+1, · · ·, k+N), w is a vector of desired

values, corresponding to vector

y

and u is a vector

of designed future inputs, again in discrete time

instants for the whole horizon (k, · · ·, N - 1).

The product (25) is more suitable form that can

be decomposed in two parts so-called square roots

of the criterion. From mathematical point of view

the minimization of square root is more straight-

forward.

If the square root of the criterion on the right side

is selected and expression of prediction (24)

is inserted in this square root, then the criterion is

given

⎥

⎦

⎤

⎢

⎣

⎡

−

−

⎥

⎦

⎤

⎢

⎣

⎡

=

⎥

⎦

⎤

⎢

⎣

⎡

−

⎥

⎦

⎤

⎢

⎣

⎡

=

0

fwQ

u

Q

GQ

u

wy

Q0

0Q

J

y

u

y

u

y )(

(26)

J is a column vector and its Euclidean norm equals

a cost of the square root of the criterion.

ICINCO 2005 - ROBOTICS AND AUTOMATION

6

The objective is to search for such u, which

minimizes the square root (26) i.e. the control u

minimizes the norm |J| of the criterion. In case of

square root (26), the minimization leads to a system

of algebraic equations with more rows than

columns – over-determined system:

0

0

fwQ

u

Q

GQ

y

u

y

=

⎥

⎦

⎤

⎢

⎣

⎡

−

−

⎥

⎦

⎤

⎢

⎣

⎡

)(

0buA =−

(27)

For optimization of the criterion, the orthogonal

triangular decomposition (Golub and Van, 1989;

Lawson and Hanson, 1974) is used. It reduces

excess rows of matrix A [(2·N·i)×(N·i)] and elements

of vector b [2·N·i] (i is a number of DOF) into upper

triangular matrix R and a vector c according

to the following scheme:

T

TT

Q

b

b

Qu

u

A

A

Q

/

=

=

cuR =

(28)

⇒

=

A u

b

=

R

1

0

u c

c

z

1

(29)

Vector c

z

is a lost vector, whose Euclidean norm

|c

z

| is equal value of square root √J (i.e. J = c

z

T

c

z

).

To obtain unknown control actions u, only upper

part of the system (29) is need

11

1

1

)( cR

c

u

uR

T

=

=

(30)

Since a matrix R

1

is upper triangle, then the con-

trol u is given directly by back-run procedure.

The penalizations Qu and Qy (usually selected

as

Qy

=

diag(λ

y

),

λ

y

=1

and

Qu

=

diag(λ

u

), 〉〈∈ 1,0

u

λ

)

determines magnitude of the redistributed loss

in considered horizon of the prediction N.

The horizons Nu and No have not direct

utilization here. Control horizon Nu is usually equal

horizon of prediction N; lower values provide

equality of control actions at the end of optimization

horizon – useless for robot motion. Initial insen-

sitivity horizon No is also directly useless. It causes,

that control differences at the beginning of the hori-

zon N are not considered.

The different choice of ratio of penalization λ

u

/λ

y

together with horizon N enables to generate control

actions that the available drives were not fitfully

exerted. However, distributed changes of torques

are achieved with the cost of certain loss (error),

that theoretically equals value of the criterion.

3.3 Quadraticaly-Optimal Trajectories

As one interesting possibility, the predictive control

offers, due to its several horizons (N, No, Nu), planning

trajectories by record of outputs from simulation.

The task is defined as follows: let us have two points

– start and end, and at the same time, a path

(trajectory) is not conditioned, only end-point must

be achieved (Figure 2). In such case, we can use

predictive control with specific setting of the output

horizons N and No. If we set, that the horizon

maxNN

=

and kNNo

−

=

, where k is order of the

controlled system, then the quadratic criterion will

consider only last k differences among predicted

end-point and its reference value. Thus, the matrix G

and corresponding differences (w - f) in the criterion

(27), are reduced only on their last k rows and

elements respectively

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

−

−

=

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

−

⋅

⋅

−

−−

−

0

0

fw

fw

1

0

CB

0

.

CAB

.

.

.

1

CB

.

BCA

0

1

BCA

BCA

0

0

fw

10

1

01

G

#

#

#

#

"

"

"

"

"

"

"

#

#

#

N

kN

NN

kN

)(

)(

21

(31)

Lower unit matrix in (31) corresponds to dimen-

sion of input penalization. Such form, specifically

last k rows of matrix G and corresponding

differences (w – f), causes quadratic distribution

of energy to individual inputs (control actions)

within whole horizon Nmax.

If indicated procedure would be applied, then the

control process has no information, in which step

should stop. Difference of horizons N and No is still

the same. Information on stopping the control

process is given by horizon No.

Described sequence represents specific dead-

bead control spread within time. Thus, it is not

necessary to achieve end point during minimal

number of steps (= order of system) in control

process, but on the other hand (from reasons of

feasibility by drives) it is better to distribute the

input energy uniformly without rapid turns in some

wider horizon. Its length should arise from

technological requirements.

The sequence can be used only once under

condition, that the system is linear and horizon No is

a little bit lower than horizon N; i.e. value No gives

the length of horizon, on which the system should

stop after previous

)( No-maxN steps.

Figure 2: One example of planned trajectory

z

xx

end

star

t

PREDICTIVE CONTROL FOR MODERN INDUSTRIAL ROBOTS - Algorithms and their applications

7

In case of nonlinear systems, the sequence has

to be repeated with progressively shortened horizon N

min,minmax max, NN,-NNN 1,1: += "

(32)

where the value

minN is suitable selected,

not exceed number approx. 20 (k < Nmin < 20).

The higher numbers do not improve the process.

The repetition provides the changes of model during

planning of the trajectory according to real state

of the controlled system i.e. it respects nonlinearity

by changing of models in compliance with real

positions and velocities of the robot.

4 LABORATORY EXPERIMENTS

RESULTS AND CONCLUSIONS

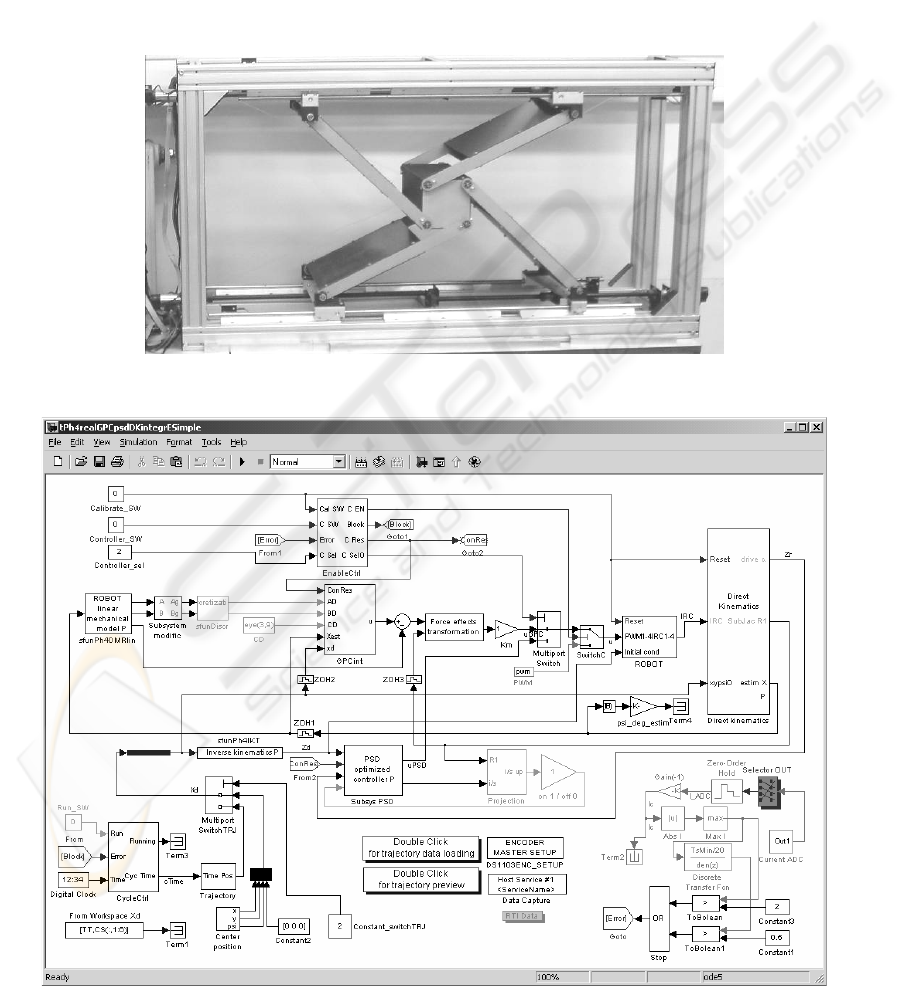

For laboratory tests, robot ‘Sliding Star’ was used.

It represents vertical planar parallel configuration

with different levels of potential energies (i.e. gra-

vitational force has to be considered) and redundant

actuation. The aim of the experiments was control

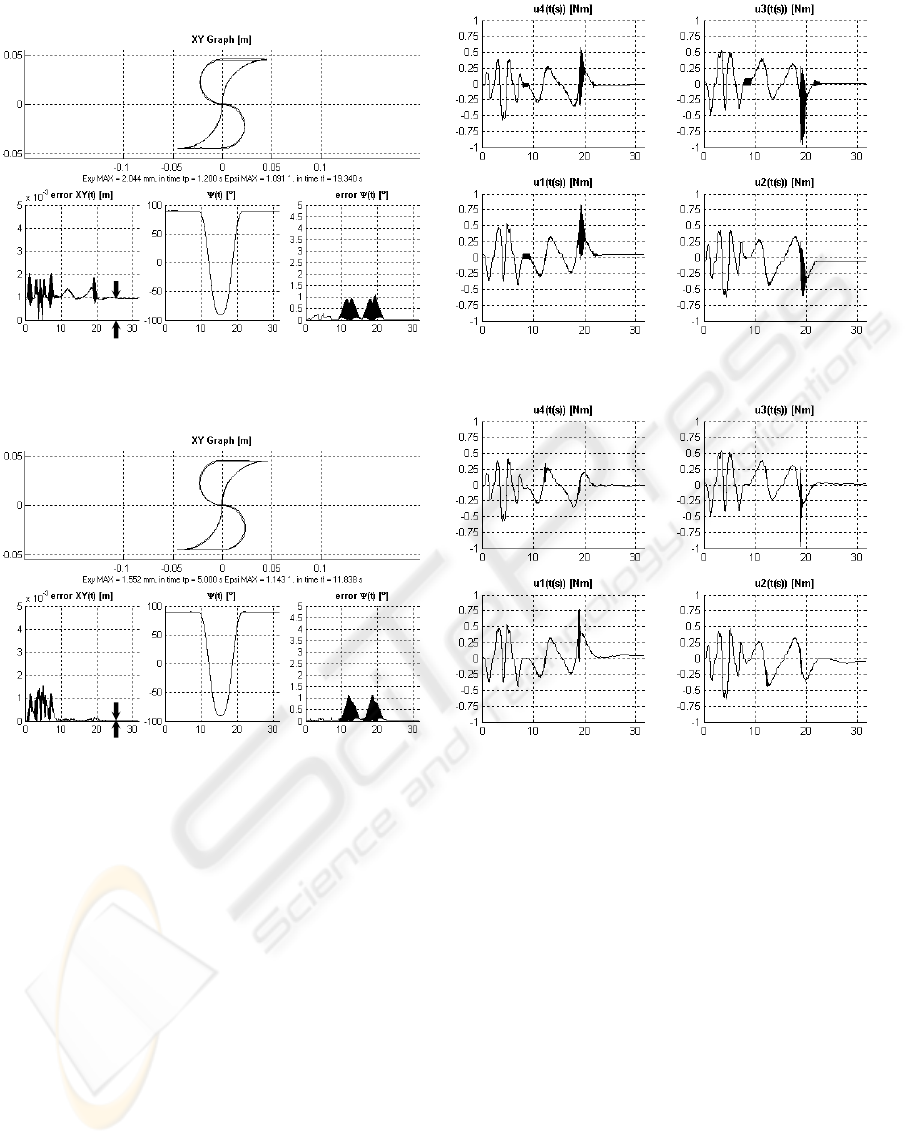

based on described predictive algorithms (control

circuit in Figure 4) fulfilling a given trajectory (time

histories of control process Figure 5 and 6).

Figure 3: Lab model of parallel robot ‘Sliding Star’

Figure 4: Control scheme for predictive control and PSD controller for comparison (discrete form of PID)

ICINCO 2005 - ROBOTICS AND AUTOMATION

8

Figure 5: Absolute GPC – Steady state error is evident (ts = 0.02s; N = 10, Nu = 10, No = 0,

λ

u

= 1e-6)

Figure 6: Incremental GPC – Steady state error converges to zero (ts = 0.02s; N = 10, Nu = 9, No = 1, ∆

λ

u

= 1e-6)

The control circuit (Figure 4) is composed

in MATLAB-Simulink environment, where the pre-

dictive control algorithm itself was realized as cap-

sulized C-coded s-function in Simulink block (Belda

et al. 2004). This control circuit (Simulink scheme),

after its compilation and uploading to digital signal

processor, was used for real time tests of control

on laboratory model of parallel robot ‘Sliding Star’

(Figure 3). The robot model has three degrees

of freedom (movement in direction x and z and

rotation

ψ

around perpendicular axis y), but it is

redundantly actuated by fourth rotational DC motors

with gearings and motion screws. The screws

provide transformation of rotation of the motors

to straight-line motion.

The circuit contains not only the block of con-

troller and block representing robot interface, but

also other necessary blocks as blocks of generating

trajectory, model composition, discretization, kine-

matical transformations, measurement of current,

safety logical blocks etc.

The Figures 5 and 6 well present the difference

of the results of real control process with different

predictive algorithms.

In the upper parts of figure left sides, the testing

trajectory (shape ,S’) is shown. In lower parts, there

are consecutively time histories of position error,

desired rotation (besides rectilinear motion the robot

performs also rotation), and just error of rotation.

On right sides of the figures, there are times

histories of foursomes control actions – real values

of torques on appropriate drives.

The Figure 6 shows the improvement of control

process, when the incremental modification of pre-

dictive algorithm is used. Indicated error in position

in steady-state (let us say undesirable offset) is

evident in Figure 5. On the other hand, the error

in Figure 6 converges to zero.

error

error

PREDICTIVE CONTROL FOR MODERN INDUSTRIAL ROBOTS - Algorithms and their applications

9

0 1 2 3 4

-0.2

-0.1

0

0.1

0.2

time [s]

ex = xd-x [m]

0 1 2 3 4

-0.2

-0.1

0

0.1

0.2

time [s]

ey = yd-y [m]

01234

0

0.1

0.2

time [s]

exy = sqrt(e

2

)[m]

0 1 2 3 4

-20

-10

0

10

20

time [s]

error = psid-psi [°]

0 1 2 3 4

-0.2

-0.1

0

0.1

0.2

time [s]

ex = xd-x [m]

0 1 2 3 4

-0.2

-0.1

0

0.1

0.2

time [s]

ey = yd-y [m]

01234

0

0.1

0.2

time [s]

exy = sqrt(e

2

)[m]

0 1 2 3 4

-20

-10

0

10

20

time [s]

error = psid-psi [°]

Figure 7: Time histories of differences at quadratically-optimal trajectory planning for trajectory in Figure 8

-0.1 -0.05 0 0.05 0.1

-0.1

-0.05

0

0.05

0.1

-0.1 -0.05 0 0.05 0.1

-0.1

-0.05

0

0.05

0.1

Figure 8: Really planned trajectory for ‘Sliding Star’

On the basis of shown results (representative

selection only) model-based control can be effective.

It can achieve acceptable control errors. Model-based

control can also meet some additional requirements

not only from control point of view. One of examples

can be quadratically-optimal trajectory planning (exam-

ple in Figures 7 and 8) described in subsection 3.2.

The presented simple trajectory planning is basic

idea, which can solve avoidance of obstacles not

only in robot workspace.

ACKNOWLEDGEMENTS

The authors appreciate the kind support by the Grant

Agency of the Czech Republic:

●

grant (101/03/0602, 2003/05), “Redundant drives

and measurement for hybrid machine tools”

and

●

grant (102/05/0271, 2005/07), “Methods of Predic-

tive Control, Algorithms and Implementation”.

REFERENCES

Anderson, B.D.O. and Moore, J. B. (1979). Optimal

Filtering, Prentice-Hall, Inc.

Belda, K., 2002. Control of Redundant Parallel Structures

of Robotic Systems, Dissertation, Czech Technical

University in Prague.

Belda, K., Böhm, J., and Valášek, M., 2003. State-Space

Generalized Predictive Control for Redundant Parallel

Robots. Mechanics Based Design of Structures and Ma-

chines, Marcel Dekker, Vol. 31, No. 3, pp. 413 - 432.

Belda, K., Böhm, J., Píša, P., Valášek, M. (kbweb © 2004)

GPC pages: http://www.utia.cas.cz/AS/belda/.

Golub, H., G. and Van, Ch., F., L., 1989. Matrix Compu-

tations, The Johns Hopkins Univ. Press.

Lawson, Ch. and Hanson, R., 1974. Solving Least Square

Problems, Prentice-Hall, Inc., New York.

Neugebauer, R.

ed., 2002. Development Methods and Application

Experience of Parallel Kinematics, Reports from the IWU

Vol. 16, ISBN 3-928921-76-2, IWU Chemnitz.

Ordys, A. and Clarke, D., 1993, A State - Space Des-

cription for GPC Controllers. Int. J. Systems SCI.,

Vol. 24, No. 9, pp. 1727 - 1744.

Phillips, L., and Nagle, T., 1995. Digital Control Systems

Analysis and Design, Prentice Hall, New Jersey.

Sciavicco, L. and Siciliano, B., 1996. Modeling and

Control of Robot Manipulators, The Mc-Graw Hill

Companies, Inc., New York.

Stejskal, V. and Valášek, M. 1996. Kinematics and Dyna-

mics of Machinery, Marcel Dekker, New York.

Šulc, B., 1999. Theory of automatic control. Script

of the Czech Technical University, Prague (in Czech).

Tsai, L.-W., 1999. Robot analysis, The Mechanics of Se-

rial and Parallel Manipulators, John Wiley & sons,

Inc., New York.

Valášek, M. and Steinbauer, P., 1999. Nonlinear Control

of Multibody Systems, Euromech, pp. 437-444, Lisabon.

ICINCO 2005 - ROBOTICS AND AUTOMATION

10