COMBINING MANUAL HAPTIC PATH PLANNING OF

INDUSTRIAL ROBOTS WITH AUTOMATIC PATH SMOOTHING

Heinz W

¨

orn, Bj

¨

orn Hein, Detlef Mages

Institute for Process Control and Robotics (IPR), Universit

¨

at Karlsruhe (TH), Engler-Bunte-Ring 8,

76131 Karlsruhe, Germany,

Berend Denkena, Rene Apitz, Pawel Kowalski

Institute of Production Engineering and Machine Tools (IFW), Universit

¨

at Hannover, Schoenebecker Allee 2,

30823 Garbsen, Germany,

Niels Reimer

Tecnomatix GmbH, Richard-Reitzner-Allee 8, 85540 Haar (M

¨

unchen), Germany

Keywords:

robot programming, path smoothing, haptic manipulation, robot simulation, industrial robotics.

Abstract:

Nowadays, industrial robots are preferably programmed offline, i.e. without interference with the real cell

and running production processes. Usually a simulation tool is used to manually define individual locations

and to check the created raw path for possible collisions. Within this paper an approach is presented, that

combines a haptic input device by means of automated path smoothing. The quality of the generated path

can be significantly improved by subsequent automatic filtering. Removing redundant locations or modifying

intermediate ones increases the smoothness of the path. The semi-automatic programming paradigm with

haptic interaction is expected to lead to an improved workflow for robot offline programming.

1 INTRODUCTION

Today, offline robot paths are usually defined man-

ually, which is a time-consuming and error-prone

process, in particular with regard to the fact that in-

dustrial robots have up to six degrees of freedom. This

paper discusses an integration of means of virtual re-

ality and automated path smoothing.

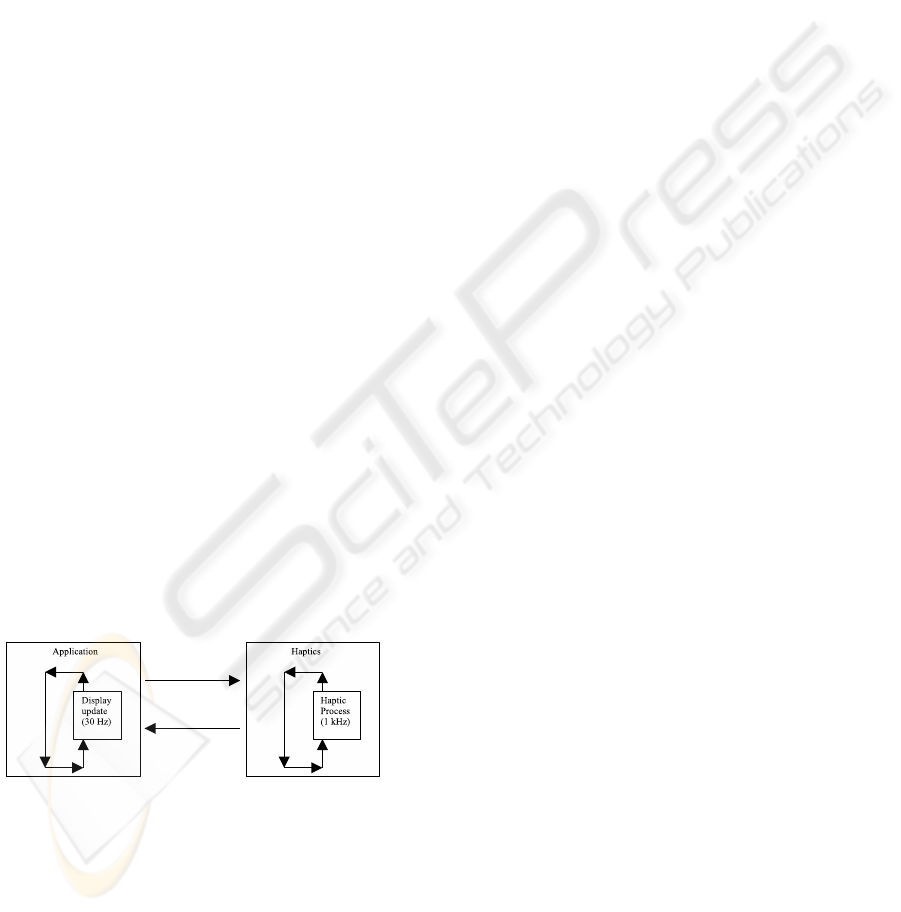

Figure 1: Coordination of haptics and the application

In robot simulation systems paths are traditionally

created with a mouse. First the robot is moved to the

desired start. This can normally be done by moving

the axes of the robot individually or by moving the

tool center point. Often a robot can reach one loca-

tion with different poses so the user must select one

via a configuration dialog. When the robot is in the

right position, the user adds a new point and places

it at the desired position. After that, the created path

is visually checked for collision-freeness. This cy-

cle is repeated until a collision-free path from start

to goal is generated. Due to the high number if iter-

ation steps, this process is time-consuming and very

monotone (repeating the same steps over and over) for

the user.

2 HAPTIC PATH GENERATION

Virtual reality covers perception by all human senses.

One of these senses is the sense of touch, i.e. haptics

(Burdea, 1996). Nowadays, the most popular fields

of application for this science are medicine and en-

gineering. Within the field of medical sciences, hap-

tics has been successfully used for training and sim-

ulation of surgeries (Cakmak and K

¨

uhnapel, 2000).

Within engineering applications, haptic devices have

been first used for modeling complex free-form ob-

jects, where virtual clay is used for designing (Fu-

jiki and Aoyama, 1999). Haptic devices can also be

used for programming machine tools (T

¨

onshoff et al.,

2001). Efforts have also been made to interact with

robots via haptic devices. These approaches, how-

ever, focus mainly on direct manipulation (Kesavadas

387

Wörn H., Hein B., Mages D., Denkena B., Apitz R., Kowalski P. and Reimer N. (2005).

COMBINING MANUAL HAPTIC PATH PLANNING OF INDUSTRIAL ROBOTS WITH AUTOMATIC PATH SMOOTHING.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 387-390

DOI: 10.5220/0001161903870390

Copyright

c

SciTePress

and Subramanium, 1998).

The Phantom device was originally developed at

MIT at the beginning of the 1990s (Massie and Salis-

bury, 1994). Presently, it is one of the most popular

and advanced haptic interfaces available on the mar-

ket. Working with the Phantom, the user holds a sty-

lus or a thimble-like end effector and can freely move

the device within its workspace, taking advantage of

six degrees of freedom (DOF). According to the pro-

grammed behavior, forces and torques are generated

to enable interaction with the virtual world. The up-

date rate in the force servo loop is about 1kHz to en-

sure haptic feedback quality. For lower update rates,

high-frequency discontinuities and hard surfaces be-

come either soft or unstable (Mark et al., 1996).

The goal of integrating haptic interaction into

the process of robot programming is an increase in

efficiency. This issue is especially important for

programming robot movements in narrow passages

where the collision probability is high. An additional

advantage is the possibility to move all axes simulta-

neously. This adapts the programming to real world

conditions and allows evaluating the process more ac-

curately.

The kinematics of the Phantom is not supposed to

reflect a robot. The user who operates the device is

able to control the tool center point (TCP) of a robot,

not its individual joints. Otherwise each robot model

would need a dedicated haptic device.

In contrary to the high update rates for haptic feed-

back quality, the frequency for sufficient visual feed-

back is below 30Hz. However, it is necessary to coor-

dinate these two tasks (figure 1) in order to assure sta-

ble and ergonomic working conditions. This concept

of two different update rates has been implemented

in the presented approach. The servo loop runs in-

dependently from the main application thread. The

current situation in the robot cell is sent regularly to

the servo thread to generate the forces accordingly. A

typical example for a force that is directed against the

movement initiated by the user is an occurring colli-

sion with an obstacle.

Apart from signaling collisions, the Phantom may

provide interaction with a robot cell in other cases as

well. Such cases include for example approaching an

obstacle, detecting disadvantageous movements, or

leaving the workspace. It can also be used for direct

input of points and paths as well as for selecting or

manipulating objects. At the present state of research,

a haptic device can be hardly considered to fully re-

place the contemporary methods of path input. One

of the most important reasons is the natural tremor of

human hand. However, this drawback can be dimin-

ished by employing smoothing algorithms.

3 SMOOTHING

The path smoothing algorithm presented here is based

on the method described in (Berchtold and Glavina,

1994) and tested in (Hein, 2003). Its input is a path

that is either generated by an automatic algorithm or

manually drafted e.g. by a haptic device. A path con-

sists usually of so called point to point (PTP) move-

ments. PTP means that all axes of the robot are moved

simultaneously along a straight line in the configu-

ration space of the robot. Start and end location of

a PTP movement are reached simultaneously. The

algorithm tries to erase points that are redundant in

two senses. First, collinear segments can be reduced

(remove the intermediate points) to one segment, see

section 3.1.1. Secondly, vertices that can safely be

deleted without harming the collision-freeness of the

path are considered redundant, see section 3.1.2.

The algorithm smooths the path by inserting and

deleting vertices at promising locations. In the fol-

lowing text the notion “sharp vertex” is used, which

is a vertex that has a small angle defined by its ad-

jacent segments. The input data for the algorithm is

a (rough) path in configuration space that has to be

collision-free. All robot poses along the path in con-

figuration space must result in a collision-free situa-

tion in work space. (Mages et al., 2004; Schwarzer

et al., 2004)

3.1 Components of the algorithm

3.1.1 Linear redundant points

Linear redundant points can be identified by the angle

between two neighboring segments. A location p

i

is

chosen by the algorithm. If the angle between seg-

ment

p

i−1

p

i

and p

i

p

i+1

is π, the two segments can

be combined by removing the central point (see figure

2). No collision checks are necessary in this case.

3.1.2 Redundant points at vertices

S

S

S

S

S

S

Start

S

S

S

S

Result

Figure 2: Removal of redundant points on a linear segment

A vertex can be deleted if the collision-freeness of

the resulting path is still guaranteed. The vertex p

i

can

be deleted if the segment

p

i−1

p

i+1

is collision-free.

This can be accomplished if the smoothing oper-

ation described in 3.1.3 is executed with parameter

t

end

= 1. Then only one segment has to be checked

ICINCO 2005 - ROBOTICS AND AUTOMATION

388

S

S

S

S

Start

S

S

S

S

p

3

S

S

S

p

4

Figure 3: Removal of redundant points on a path. Special

case with t

end

= 1 (see 3.1.3). Candidate p

3

fails and p

4

succeeds.

for each vertex. This method combined with the

method from section 3.1.1 represent already a run-

ning smoothing algorithm that needs very few colli-

sion checks. This can be helpful when dealing with

complex scenes where collision checking is computa-

tionally expensive.

3.1.3 Cutting off sharp vertices

For sharp vertices it is desirable to increase the angle

between their two segments. To accomplish this, ad-

ditional points can be inserted at each of the segments

that are adjacent to the sharp vertex. Considering a

vertex p

i

two points p

i,1

and p

i,2

are inserted. The

new edge

p

i,1

p

i,2

must be checked for collision. If

a collision occurs, t is increased. Parameter t speci-

fies the number of steps made by this strategy starting

with t = 0.

p

i,1

(t) = p

i

+

p

i−1

− p

i

2

t

p

i,2

(t) = p

i

+

p

i+1

− p

i

2

t

This strategy terminates when

p

i

p

i,{1|2}

(t)

< ǫ

or t ≥ t

end

. The variables ǫ and t

end

are pa-

rameters of the algorithm. In the worst case (i.e.

when no solution can be found for the current ver-

tex) min

log

2

min(|p

i+1

−p

i

|,|p

i−1

−p

i

|

ǫ

, t

end

col-

lision checks for segments have to be calculated.

The methods described in section 3.1.1 and 3.1.2

are special cases of this smoothing operation. For sec-

tion 3.1.2 the parameter t

end

= 1 and for section 3.1.1

t

end

= 1 ∧ ∠(p

i−1

, p

i

, p

i+1

) = π.

S

S

S

Start

S

S

S

S

S

t = 0

S

S

S

S

S

t = 1

S

S

S

S

t = 2

Figure 4: Cutting sharp vertices by introducing an addi-

tional segment. In step t = 0 and t = 1 the new segment

collides. In step t = 2 a feasible segment is found.

3.1.4 Choosing a location for improvement

A location best suited for optimization is chosen by

a heuristics function. This function should evalu-

ate the highest priority for a location that is linear

redundant. Sharp vertices are unfavorable, so they

should be assigned a high priority for changing. The

heuristics function h(i) =

|p

i−1

−p

i

|+|p

i

−p

i+1

|

|p

i−1

−p

i+1

|

as-

signs p

i

a higher value if the angle between the seg-

ments

p

i−1

p

i

and p

i

p

i+1

is sharp or equal to π. If

∠(p

i−1

, p

i

, p

i+1

) = π then h(i) is set to ∞. The

heuristic value is used to order the candidates. The

improvement operation is used at each location that is

chosen by h. First the special cases described in 3 are

checked followed by the phase according to 3.1.3 if

t

end

and ǫ allow it.

3.2 Termination

The termination of the algorithm is trivial if all seg-

ments except a straight line from start to goal can be

erased, but in each new step a vertex may be added to

the path, see 3.1.3. To circumvent an infinite iteration

a quality measure allows terminating the algorithm.

As a quality measure the sum of angles between sub-

sequent segments is used. If several steps do not lead

to an improvement of the whole path, the smoothing

can be considered finished.

4 TEST CASES AND RESULTS

For tests of the described approach a robot cell has

been designed. To demonstrate the algorithms the

cell is kept as simple as possible. The only objects

are a robot and an obstacle. Three paths have been

proposed as the input for the smoothing algorithm: a

linear one, a rectangular one and one in shape of an

arc. Each of them has been generated using the haptic

device. When a specified distance from the previous

point is exceeded a new point is created.

Line Rectangle Arc

Figure 5: Test cases. Top row: raw input path from haptics.

Bottom row: smoothed paths

As can be seen in figures 5 and 6, the created path is

not smooth. In consequence, it takes longer to move

COMBINING MANUAL HAPTIC PATH PLANNING OF INDUSTRIAL ROBOTS WITH AUTOMATIC PATH

SMOOTHING

389

a robot along such a path. The time for moving along

a path is a good measure for path quality as it is the

most crucial factor in production.

Manual Haptic

Smooth

Figure 6: Complex test case. Manual: Path was generated

using a mouse. Haptic: Path was generated using the Phan-

tom device. Smooth: Path from Haptic that was smoothed.

In table 1 the time the robot needs to move with

PTP motions along the result path is displayed. The

table shows the time before smoothing (haptic), after

smoothing with t

end

= 1 and t

end

= ∞.

The time needed for programming the movement

is important. In the complex scene the programming

using a mouse in a professional robot simulation ap-

plication took the authors about 150s. In contrast to

that, defining the path with a haptic device took only

15s. The subsequent run of the smoothing algorithm

took 75s, which is very long due to the slow distance

calculation used as a basis for the collision check on

segments in this test. In this example the time bene-

fit of the approach is about 70%. The smoothing can

take place in the background, so only 10% is actual

user interaction.

Table 1: Results of tests with smoothing manual haptic gen-

erated paths. A simple interpolator is used. Only the accel-

eration and the maximum speed of the robot are considered.

Test haptic t

end

= 1 t

end

= ∞

Line 12.11s 2.35s 2.35s

Rectangle

19.03s 4.43s 3.73s

Arc

16.09s 5.07s 4.38s

Complex

26.48s 5.32s 5.29s

5 CONCLUSION AND OUTLOOK

The presented paper targets new methods in robot

offline programming by integrating haptic input and

output. One important factor is path quality. By

using e.g. a Phantom device, many points can be

created easily that define the desired collision-free

path. Though, these paths are not well-suited to be

used directly. It is desirable to remove the redundant

points. The smoothing algorithm described here in-

creases path quality. At the present state only the geo-

metric path is considered. To evaluate the impact on

the process of manual path planning, a survey with

users of simulation systems is planned.

REFERENCES

Berchtold, S. and Glavina, B. (1994). Kosten-Nutzen-

optimale Verbesserung kollisionsfreier Roboterbewe-

gungen mittels Polygon-Manipulation. In 10. Fachge-

spr

¨

ach Autonome mobile Systeme.

Burdea, G. (1996). Force and Touch Feedback for Virtual

Reality. John Wiley & Sons, New York.

Cakmak, H. and K

¨

uhnapel, U. (2000). Animation and

Simualtion Techniques for VR-Tranining Systems in

Endoscopic Surgery. In EGCS 2000, Eurographics

Workshop on Animation and Simulation, pages 173–

185.

Fujiki, H. and Aoyama, H. (1999). Development of virtual

clay modeling system. In 32nd CIRP International

Seminar on Manufacturing Systems, New Supporting

Tools for Designing Products and Production Systems,

pages 91–97.

Hein, B. (2003). Automatische offline Programmierung von

Industrierobotern in der virtuellen Welt. PhD thesis,

Universit

¨

at Karlsruhe(TH).

Kesavadas, T. and Subramanium, H.(1998). Flexible virtual

tools for programming robotic finishing operations. In

Industrial Robot, volume 25, pages 268–275.

Mages, D., Hein, B., and W

¨

orn, H. (2004). An-

gen

¨

aherte Abstandstransformation vom Arbeitsraum

in den Konfigurationsraum von Robotern mit serieller

Kinematik. In Proceedings Robotik 2004, M

¨

unchen.

Mark, W. R., Randolph, S. C., Finch, M., Verth, J. M. V.,

and Taylor, R. M. (1996). Adding Force Feedback

to Graphics Systems: Issues and Solutions. In SIG-

GRAPH 96 Conference Proceedings, pages 447–452.

Massie, T. and Salisbury, J. (1994). The Phantom haptic

interface: a device for probing virtual objects. In Pro-

ceedings of the ASME Witner Annual Meeting.

Schwarzer, F., Saha, M., and Latombe, J. C. (2004). Exact

Collision Checking of Robot Paths. In Boissonnat, J.,

Burdick, J., Goldberg, K., and Hutchinson, S., editors,

Algorithmic Foundations of Robotics V, pages 25–41.

Springer Tracts in Advanced Robotics.

T

¨

onshoff, H., B

¨

oß, V., and Rackow, N. (2001). Virtual Real-

ity for NC-Programming. In ICPE, 10th International

Conference on Precision Engineering, Initiatives of

Precision Engineering at the Beginning of the Mille-

nium.

ICINCO 2005 - ROBOTICS AND AUTOMATION

390