EMBEDDED ROBOTIC CONTROL TECHNOLOGIES AND ITS

APPLICATIONS IN AUTOMATED PROGRAMMERS

Ganwen Zeng, Kelly Hirsch

Data I/O Corporation,, 10525 Willows Road NE, Redmond, WA 98052, USA

Keywords: Device Programming, Robotics, Motion control, Fuzzy control, Firmware, Embedded Software, Hardware.

Abstract: The paper presents a synthesis of the problematic and actual solutions to the implementation of robotic

programmer control functionality using DSP controllers. Considerable technology shift occurred during the

recently decade in device programming industry. The advent of high performance DSP motion controllers

opens new possibilities for the development of high performance distributed intelligence device-

programming automation systems. The idea of implementing a unique, flexible robotic motion control

structure can significantly improve controllability of the robotic programming systems. High-level motion

command languages are used to setup and to control the robotic motors. A Fuzzy control algorithm has been

introduced to guarantee the motion control performance in an automated programmer.

1 INTRODUCTION

Automated programming systems available today

are able to fully automate device programming and

to fully integrate programming testing, device

handling, and labelling programmable devices. It

improves the productivity, quality and flexibility of

a semiconductor production process.

High performance motor motion control

precision and high level of integration is

continuously increasing, and the clear trend is

towards completely integrated intelligent

programming system. This paper describes an

embedded intelligent programming automation

system that uses a Motorola free scale 32-bit

architecture MPC8xx PowerPC embedded processor

as a host machine. The fuzzy control has been

designed for a robotic motion control subsystems

using the Motorola 32-bit architecture 68376 digital

signal processor (DSP), and the high speed robotic

motion digital control system has been realised.

The system hardware is implemented using the

MPC8xx PowerPC and Motorola 68376 DSP. The

control task of the system, except programming

devices, includes the following components:

(i) Robotic task space configuration

(ii) Robotic head home probing

(iii) Head dynamic motion control

(iv) Programming device picking control

(v) Programming device placing control

(vi) Device feeding tape control

(vii) Belt transportation motion control

A high level of integration of system firmware

and embedded software has been proposed on

different real-time operating systems (RTOS) for

modern programming automation. Control software

can be developed to utilize DSP pulse width

modulation (PWM) and quadrature decoding

capabilities of the 68376’s TPU (Timer Processor

Unit). Source Code can be also developed to make

use of the processor’s TouCAN (Controller Area

Network) and QADC (Queued Analog to Digital

Converter) modules. The embedded software is

realized in C++ language with Object Oriented

Programming techniques (OOP). Main advantages

of this choice are the easy software maintenance and

reutilization, as well as its uniformity in terms of

internal organisation compared with the system

hardware module architecture. A fuzzy control

algorithm is designed for precision motion control.

Timing information is presented which shows how

the robotic shaft torque functions could be

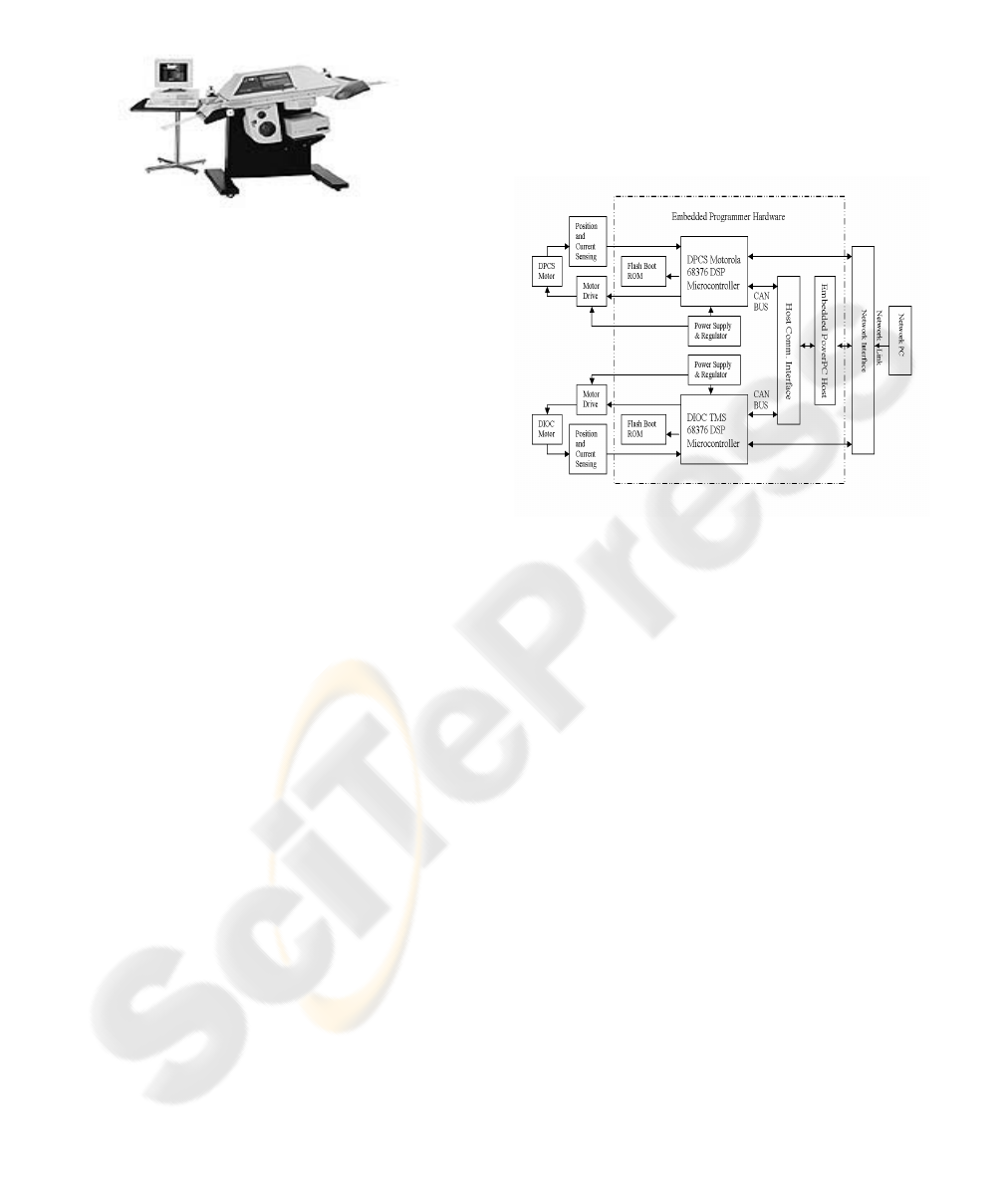

implemented. One use case of the designed

embedded robotic control technologies could be the

DATA I/O ProMaster 3000 automated programming

system (see Figure 1). The ProMaster 3000 has been

designed by DATA I/O for flexibility. Pick-and-

place heads can rotate devices, so programming and

labelling proceed without interruption regardless of

device orientation in the tubes. A high-density,

thermal printer quickly prints and applies device

279

Zeng G. and Hirsch K. (2005).

EMBEDDED ROBOTIC CONTROL TECHNOLOGIES AND ITS APPLICATIONS IN AUTOMATED PROGRAMMERS.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 279-283

Copyright

c

SciTePress

labels, available in a wide variety of materials and

sizes, in one swift and precise operation.

Figure 1: ProMaster 3s000 automation system

2 CONTROL SYSTEM

DESCRIPTION

The control system of a general robotic programmer

is composed of one host commander and two main

motion control subsystems DPCS (Device

Positioning Control System) and DIOC (Device

Input Output Control System). The DPCS is

composed by 5 control units of robotic task space

configuration, robotic head home probing, head

dynamic motion control, device picking control and

device placing control. The DIOC is composed by

two control units of device feeding tape control and

device transportation belt motion control.

Synchronous communications can rely on the bus

Ethernet and TCP/IP protocol. Asynchronous

Communications between the host commander and

the control subsystems can be based on the TouCAN

bus or Motorola 68376 Com Ports to guarantee the

space loop closure for the main axes of the robotic

control system.

In the multiple robotic axis configurations of the

programmer automation system, the design is to

consider more and more distributed intelligence

control structures. This means the use of single-axis

intelligent DSP motion controllers for both DPCS

and DIOC which can handle local robotic axis

control function independently from the host

MPC8xx PowerPC. In the ProMaster 3000 use case

applications where the robotic motion handler and

device transportation belt controller are equipped

with different motor control technologies, the use of

one single command language simplifies the

complexity of the integration of control elements in

the system. Based on these considerations, we are

going to discuss the implementation of the basic

digital motor fuzzy control functionality, including

real-time operating kernel, PWM generating units,

current and motor torque control, speed/position

control, and fuzzy control algorithm.

2.1 Motor DSP Motion Control

Hardware

The complete system consists of DC servo motors,

the motor control circuit, programmer processor, and

Network PC station as represented in Figure 2.

Figure 2: Block diagram of the control system of

automated programmer

The Motorola 68376 DSP is the shaft control

processor and carries out all the motion control and

torque current loop functions. The embedded motion

control software is stored on an external 16-bit Flash

bootrom and is automatically loaded into the DSP’s

internal program RAM on power-up. The DSP boot

firmware copies the program from the Flash memory

to the internal RAM, initialises all data variables

(look up tables, etc.), configures the DSP’s QADC

modules, and setups the PWM registers, and

performs self-diagnostic functions.

The second part of the embedded control

software contains the motion fuzzy control

algorithms, which are loaded at the end of the

initialisation phase. The shaft control algorithm can

be timed via the interrupt pin on the DSP.

2.2 Motion Control Structure

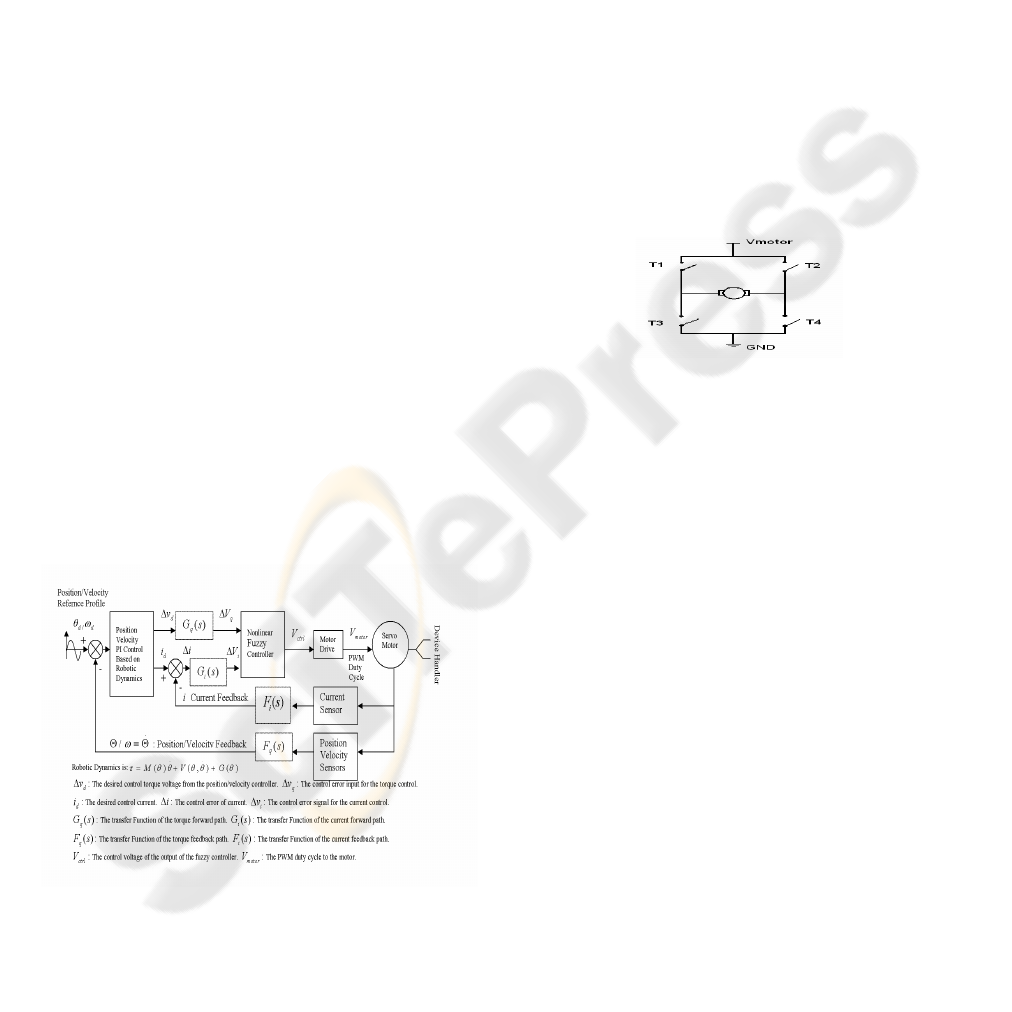

Figure 3 below illustrates a speed and torque control

scheme of DC motor for the motion control of the

device handler in a programmer robotic system with

an independent maximum current limit setting. The

quadrature decoding unit of the 69376’s TPU

samples the motor position and velocity, 68376’s

QADC analog-to-digital converter module samples

the motor currents. The feedback of motor current

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

280

and motor position/velocity sensing allows for

closed loop control of motor speeds. The outer

position and Proportional plus Integral (PI) velocity

control loop, based on the following robotic

dynamics, calculates the desired voltage control

error of the torque

d

V∆

, and the desired current of

the torque demand

d

i

, which is the reference input

for the current control loop.

)(),()(

θϑθθθτ

GVM ++=

…… (1)

Where

)(

θ

M

represents the mass matrix of the

distributed robotic joint,

),(

ϑθ

V

is the Coriolis

term of the robotic system,

)(

θ

G

is the gravity term

of the robotic system.

θ

is the angular position of

motor,

ϑ

is the angular velocity of the motor,

θ

is

the angular acceleration of the motor.

The desired voltage control error of the current

i

V∆

and the desired voltage control error of the

torque

q

V∆

are fed into the nonlinear fuzzy

controller. The nonlinear fuzzy control algorithm

implemented on the DSP calculates the desired

control voltage input

ctrl

V

for the motor. The DSP

scales and then generates PWM using the 68376’s

TPU from the

ctrl

V

, The velocity control is achieved

through varying the voltage across the terminals of a

motor by the Pulse Width Modulation that is the

continuous fast switching of motor voltage. By

varying the duty cycle from 0% to 100%, the

effective voltage across a motor can be established

from a set input of PMW duty cycle (

motor

V

). The

PWM duty cycle

motor

V

is fed into the motor drive

to drive the DC servo motor.

Figure 3: Motion control structure

Pulse Width Modulation (PWM) has both

bipolar and unipolar topologies, in the motion

control structure the bipolar PWM is used, which

switching voltage between a positive and a negative

set voltage (

motor

V

). In a bipolar a net positive

voltage across the motor can be achieved for a

positive duty cycle greater than 50%. This will drive

the motor forward, provided that generated torque is

greater than load torque. In the opposite case, if the

net voltage across the motor is negative, the motor

will be driven in reverse, provided that generated

torque is greater than load torque. If the duty cycle is

maintained at 50% the motor will remain stationary,

provided there is no load torque applied. PWM is

implemented in the motor drive circuit by the use of

an H-bridge. A simplified H-bridge configuration is

shown in Figure 4. By varying switch states, the

motor can be placed in the following states:

(i) Driving forward (T1 on, T4 on)

(ii) Driving in reverse (T2 on, T3 on)

(iii) Braked to ground (T3 on, T4 on)

(iv) Braked to

motor

V

(T1 on, T2 on)

(v) Neutral/ Floating (all switches off)

Bipolar switching only makes use of states II and I.

Figure 4: A simplified H-bridge configuration

In order to sense small motor currents (less than

100mA), which can be difficult to be sensed in a

noisy environment such as brush noise due to the

make/break characteristic of brush commutation,

and torque ripple due to gearing effects; a custom

amplifier was built. That is properly scaled for the

expected motor currents, includes low-pass filtering

of sensed current before performing an A/D

conversion of the current feedback signal. The

second order active filter is used to reduce the

current feedback noise, which would otherwise be

amplified by the feedback circuit and cause

oscillations in motor speed.

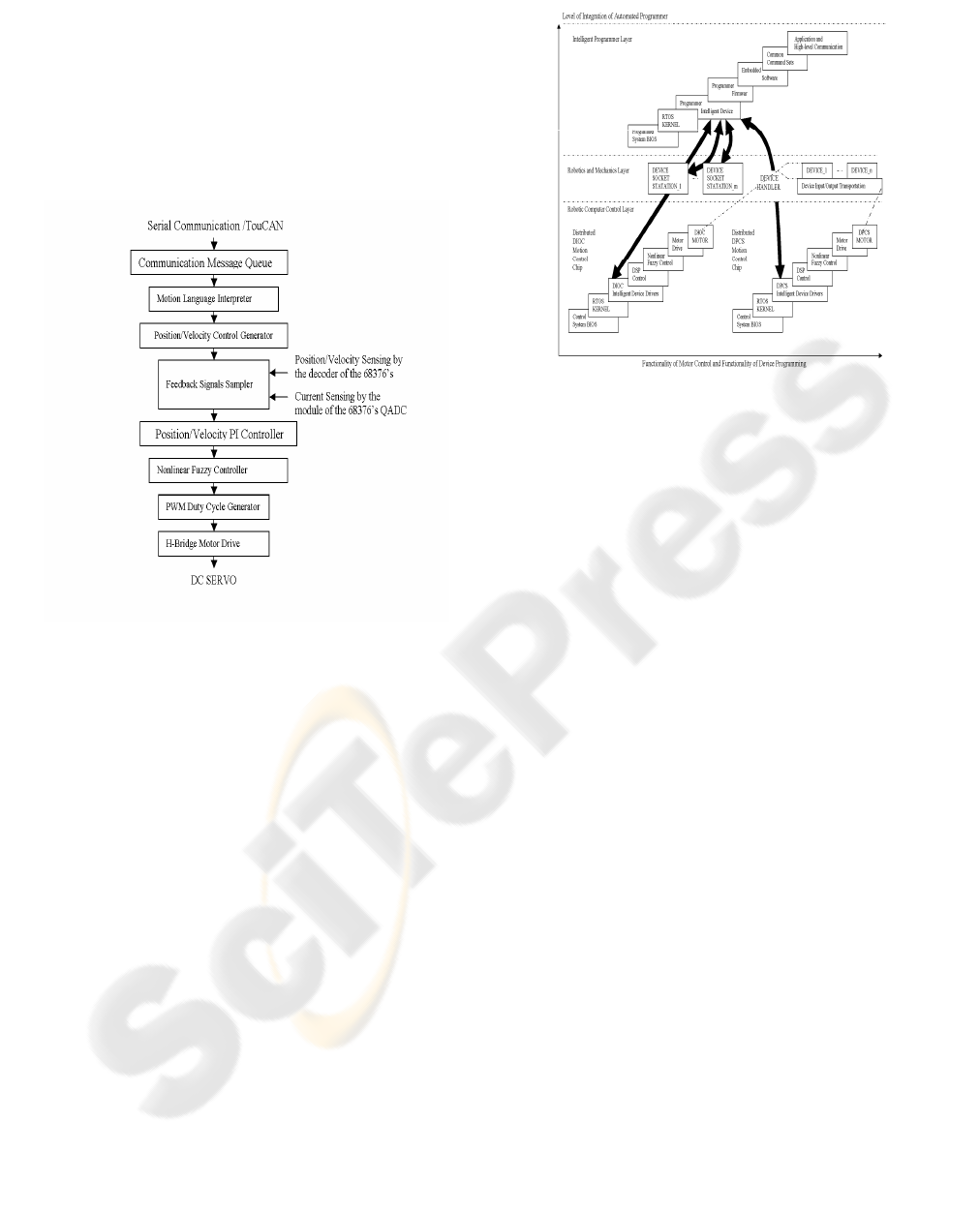

2.3 Motion Control Hierarchy

The robotic control system presented in this paper

will implement, through the above specified

hardware and the corresponding embedded software

modules, the hierarchical robotic motion control

architecture shown in Figure 5. The are four low-

level modules, i.e., the H-Bridge, PWM Generator,

Nonlinear Fuzzy Control and Position/Velocity PI

Control blocks, will implement the basic motor

control functionality. The high-level modules, i.e.,

the feedback Signals Measurement, Reference

EMBEDDED ROBOTIC CONTROL TECHNOLOGIES AND ITS APPLICATIONS IN AUTOMATED

PROGRAMMERS

281

Generator, Motion Language Definer and

Communication Message Queue blocks, will

implement the motion control functionality.

All these modules are interconnected within a

hierarchical model, the output of one module being

the input of the subsequent low-level module. All

the modules are fit into the Motorola 68376 DSP

micro-controller that would play the role of a

“Motion Control Chip”.

Figure 5: Motion control hierarchy

2.4 Integrated Intelligent

Programmer Control System

As discussed in the above Figure 2, both the DPCS

and the DIOC are designed as a distributed

intelligence control structure independently. This

means that the use of single-axis intelligent

controllers which handle the axis of the DPCS and

the axis of the DIOC independently from the

programmer host. This highly flexible solution for

the robotic programmer system, and easily

parameterised for the distributed control of the

motor and the programming of Devices, by uses of

single robotic command language and programmer

command language, it makes the programmer

system to run at non-specialist level. This demands a

completely integrated intelligent programmer (see

Figure 6), which covers the implementation of the

basic motor control functionality and the high-level

modules of the “Motion Control Chip” as shown in

Figure 5, and the implementation of programming

functionality through single programmer command

language.

Figure 6: An integrated intelligent programmer

The integrated intelligent programmer consists of

three layers of integration, i.e., the robotic computer

control layer, the robotics and mechanics layer, and

the intelligent programming layer. The motion

control functionality will be implemented in the

robotic computer control layer; and the device

programming functionality will be implemented in

the intelligent programming layer. The robotics and

mechanics layer will configure all the mechanical

requirements of the transportation of the device

input and output, the device picking and placing

handling, and the device sockets stations. There are

two distributed robotic control subsystems; i.e., the

distributed DIOC motion control chip and the

distributed DPCS motion control chip in an

integrated intelligent programmer. The intelligent

programming layer communicates with the device

sockets station in the robotics and mechanics layer

through the device programming interface, and it

communicates with each distributed motion control

chip in the robotic computer control layer through

host communication interface. The motion control

functionality covers the control system BIOS (Basic

Input Output System), RTOS kernel, intelligent

device drivers, DSP control, nonlinear Fuzzy

control, motor drives, and robotic joint motor. The

device programming functionality covers the

programmer BIOS, RTOS kernel, the intelligent

device drivers, the programmer firmware, the

embedded software, the common command sets, the

application and communication. The common

commands of non-specialist level allow an easy

implementation of a device programming

application in end-customer level using an integrated

intelligent programmer. This structure will eliminate

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

282

the need to write programming software for the final

user, it also eliminates the need of write DSP code

for robotic motion control. In such cases, the device

will be easily programmed though only setting

device specific parameters and giving non-specialist

common commands to the system. A set of common

language instruction can be defined from a final

user. The common command language syntax is a

mixture between simple memorics similar to

assembler and C language, for instance:

Devices:

DEV PROG; -- program device

DEV ERASE; -- erase device

DEV LOAD; -- load the content of a device

Etc.

Configuration:

STA NO 5; -- set the programming stations 5

SCOKET NO 8; -- set the socket number 8

Etc.

Motion:

ROBOT POS; -- set the robotic position profile mode

ROBOT SPD; -- set the robotic speed mode

HEAD HOME; -- set the end-effector home mode

Etc.

Even if such a language is very advanced and

simplifies all the device programming task of the

end user of the programmer. For a user-friendly

operation environment, we can build a completely

graphical development tools, accompanied by code

generators, thus eliminating the need to write the

code of these command sets. This user-friendly

application interfaces (GUI) can be easily built on a

ColdFusion application dynamic web server, the

designed ColdFusion Components (CFCs) in GUI

framework provide a way to encapsulate device

parameter data and device programming functions in

an object-like manner with inheritance. An end user

of an automated programmer can easily produce any

device programming supports only by clicking

button and filling parameters on Internet remotely or

a local computer.

3 CONCLUSION

In this automated intelligent programmer control

system, the position sensor is needed to measure the

motor angular position; the speed can be estimated

based on position information. The speed control

accuracy of the control system is up to 1/2000

maximum speed in the automations, measured in

LabVIEW 7.0 Professional Development System

(PDS).

Based on the nonlinear fuzzy control

technologies and intelligent integrated automation

strategies for an intelligent programmer application,

applied at embedded system firmware, embedded

software and hardware architecture, together with

advanced DSP micro-controller, this new control

system solution offers many advantages:

(i) Simple self-generation of device programming embedded

software in a user-friendly GUI framework using at non-specialist

level, i.e., software-less device support (no much programming

effort required)

(ii) Flexibility to remote users or local users for programming

device support, having the biggest simplicity of the system

configuration even for the complex programming services,

including consistence of all the components: system hardware,

BIOS, embedded system firmware, and embedded software, and

high-level user application of device programming.

(iii) Implementation of distributed motion control, including a

high accuracy speed digital control and current/torque control

(iv) The implementation of high robot performance in an

intelligent distribution structure, the development of the OOP

embedded software architecture encapsulating all controller

objects and programmer objects of the automated intelligent

system; and simplifying a sophisticated control model for

different robot applications with the utilization of the advantages

of DSP PWM.

(v) University, flexibility, high-performance of device

programming; non-specialists easy access to the intelligent

programmer system, and no need of debugging any embedded

software and hardware, are key features of the intelligent

integrated automated programmer.

REFERENCES

John J. Craig, 1989. Introduction to ROBOTICS

Mechanics and Control, Addison-Wesley Publishing

Company. New York, 2

nd

edition.

William A. Wolovich, 1987. Robotics: Basic Analysis and

Design, CBS College Publishing. New York.

Darley S., Melear C., 1996, An Introduction to the

MC68331 and MC68332, Motorola Inc.

Hassan K. Khalil, 1992. Nonlinear Systems, Macmillan

Publishing Company. New York.

L. A. Zedeh and K. Tanaka et al., 1975. Fuzzy Sets and

their Applications to cognitive and Decision

Processes, Academic Press.

SHIN, K. G. –MCKAY, N. D, 1985, Minimum-Time

Control of Robotics Manipulators with Geometric

Path Constraints. In AC-30 6, pp.531–541, IEEE of

Automatic Control.

SHIN, K. G, 1991. Trajectory Planning for Robot

Control: A Control System Perspective, Control and

Dynamic System Series, Advances in Robotics System,

Academic Press Inc.

EMBEDDED ROBOTIC CONTROL TECHNOLOGIES AND ITS APPLICATIONS IN AUTOMATED

PROGRAMMERS

283