GENERAL ENGINEERING DATA MODEL IN SPECIAL PURPOSE

MACHINE ENGINEERING

Zhiliang Qi, Christian Sch

¨

afer

Software and Systems Engineering for Production Automation (CR/APA3), Robert Bosch GmbH

Robert-Bosch-Strasse 2, D-71701 Schwieberdingen, Germany

Peter Klemm

Institute for Control Engineering of Machine Tools and Manufacturing Units, University Stuttgart

Seidenstrasse 36, D-70174 Stuttgart, Germany

Keywords:

Modeling, Mechatronic systems, Optimization.

Abstract:

A main problem in todays engineering of special purpose machines is the reuse and the consistency of en-

gineering data across the whole development process. This paper presents an approach how to manage and

share data in the entire development process in the field of special purpose machine engineering. The first

part gives a short overview of the current problems by using software tools in engineering and the engineering

requirements. In the second part the current data models used in special purpose machine engineering are

analyzed. The third part provides the General Engineering Data Model (GED) as a new concept to share and

reuse the engineering data from each engineering phase and to improve the development activity. At the end

this paper gives also an evaluation on benefits and contribution of this GED.

1 INTRODUCTION

The fast evolution of software technology in recent

years offers new potential for engineering. Engineer-

ing is done more efficient and with better results using

engineering tools. This reduces the development cost

by 15-30% and shortens the production cycle time by

30-60%. The product quality is improved by 20-50%

(Rembold et al., 1994).

Yet this approach concentrates only on applying

and improving stand-alone engineering tools. Today

the focus has moved from stand-alone engineering

tools towards a coupled net of engineering tools. In

a next step to improve the engineering with respect to

time, cost and quality, interdisciplinary data exchange

is the key issue (Westk

¨

amper, 2002; EPLAN, 2005;

VDI, 2003).

In the field of special purpose machine engineer-

ing numerous and various stand-alone software tools

are used in the machine development. Each software

tool provides support for a special engineering phase

e.g. planning, design, application programming, man-

ufacturing etc. In many engineering phases even more

than one software tool is applied (Starke, 2001; Cio-

coiu et al., 2001).

Each software tool resolves one or more engineer-

ing tasks based on the necessary information. The

engineering result of one phase is needed as input-

information to resolve engineering tasks in other

phases (Welp et al., 2001). On the other hand, a set of

information is accessed from several tasks. The avail-

ability of these information is important to improve

the engineering process flow. Therefore the data ex-

change between the engineering phases is one of the

main challenges (Germer et al., 2001).

Product development in engineering is a contin-

uous work and conventionally divided into several

phases which are executed one after the other or paral-

lel in some case. Today most of the software tools and

their data models are independent from each other.

Each of them presents itself as an isolated application

and is used within one engineering tool. The same

machine is modelled in each software tool and inter-

preted differently (Keil and Schmidt, 2001). They

have also their individual document format to store

data. All of this makes the data management and

data exchange between the engineering phases diffi-

cult (Germer et al., 2001).

1.1 Requirements on engineering

data model

The engineering tasks become more complex from

day to day. To improve the engineering quality and to

shorten the developing time, software tools and their

data models face the new requirements from engineer-

348

Qi Z., Schäfer C. and Klemm P. (2005).

GENERAL ENGINEERING DATA MODEL IN SPECIAL PURPOSE MACHINE ENGINEERING.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 348-354

DOI: 10.5220/0001170203480354

Copyright

c

SciTePress

ing:

1.

Availability of the engineering data across multiple

engineering phases

A machine will be developed step by step through

the following phases: planning, mechanical design,

electric/electronic design until programming. The

engineering in each phase produces new data based

on the data of earlier engineering phases. The avail-

ability of data from earlier phases is essential to

continue the engineering sucessfully.

2.

Reuse of the phase-independent engineering data in

each phase

In the field of special purpose machine develop-

ment, engineers take advantage of standard ma-

chine components. A component in one machine

can also be used in other machines. Reusing these

standard components and their data reduces cost

and shortens developing time.

3.

Redundance-free and coherent data modelling

This means that the same data should appear only

once in the data model. This facilitates the change

management and data update.

4.

Extensibility of data structure

The requirements of engineering expand from day

to day. More and more new types of engineering

data will be created and processed. Corresponding

to these new requirements, engineering tools need

to be developed and integrated with new function-

alities. The current data structures of these software

tools must have the extensibility to respond to these

changes.

In the part 2 the different data models used in spe-

cial purpose machine engineering are analyzed. At

the end this paper presents the general engineering

data model and how to improve cooperation and com-

munication between engineering software tools.

In principle a special purpose machine is regarded

as mechatronic system within the whole engineering

process. At first, it is needed to understand the essen-

tial components of a mechatronic system and the data

processed in development.

1.2 Composition of mechatronic

systems

A mechatronic system consists of three subsystems:

a mechanical subsystem, an electronic subsystem and

a subsystem of information processing. The associ-

ation between the three subsystems is the spatial ar-

ragement and the functional interaction. The spatial

arrengement is determined by the mechanical design.

The functional interaction is mainly determined by

the information processing system (Isermann, 1999;

Welp et al., 2001; Pelz, 2001).

The mechanical subsystem provides support and

guidance. The electronic subsystem records the

measurement data from sensors and sends the con-

trol data to actuators. The subsystem of informa-

tion processing controls the manufacturing process

(K

¨

ubler, 2000).

The development of these three subsystems is the

main task within the whole engineering of the mecha-

tronic system. Normally, the life cycle of a mecha-

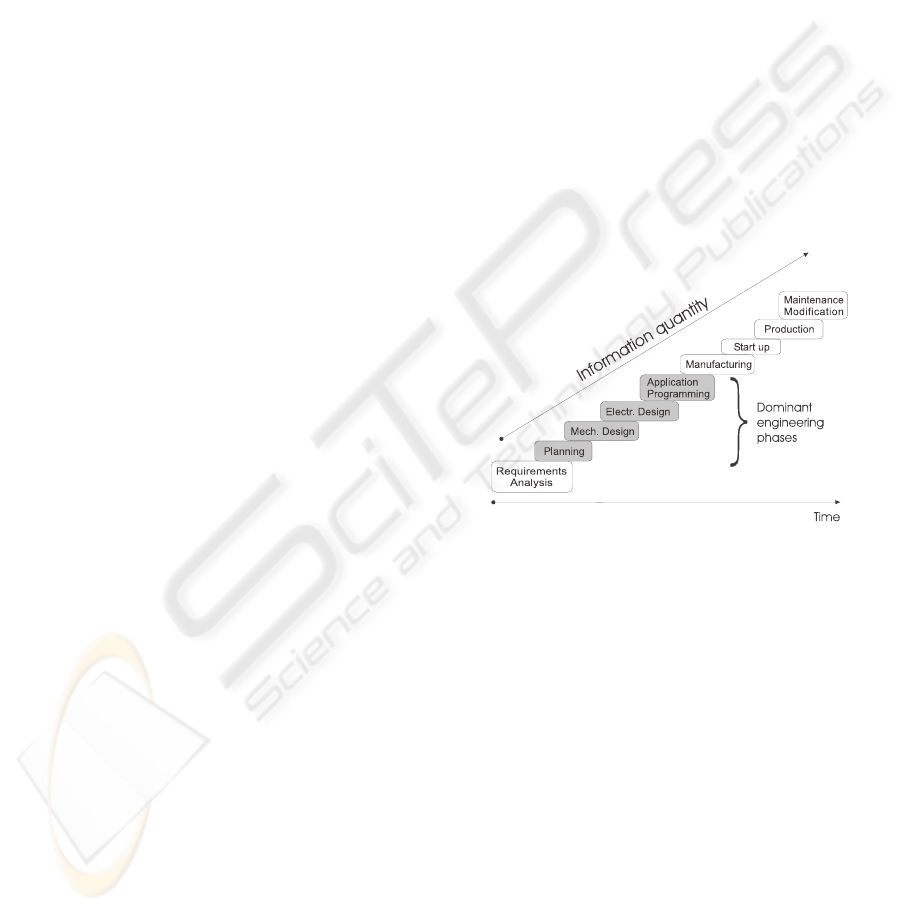

tronic system is subdivided into the following phases:

requirements analysis, planning, mechanical design,

electric/electronic design, application programming,

manufacturing, start up, production, maintenance and

modification as illustrated in figure 1.

Each subsystem is developed within the corre-

sponding engineering phase. Additionally, each of

these phases can contain simulations to verify the

phase solution.

Figure 1: Phase definition in special purpose machine engi-

neering

In the past, the development of mechatronic sys-

tems has often been dominated by mechanical de-

sign. The design of software/electronic components

was added later. This has led to a poor development

approach (Isermann, 1996; Gausemeier et al., 2001).

Today the work flow is recursive and solutions from

earlier phases have to be taken into consideration per-

manently.

Software tools which are used in the phases of

planning, mechanical design, electric/electronic de-

sign and application programming deal with most of

the tasks in the entire engineering. They determine

also most of the engineering data. Other phases use

the engineering data from these four phases and make

rarely changes or replenishments. For this reason, the

discussion in the remaining sections will focus on the

engineering data models in these four phases.

GENERAL ENGINEERING DATA MODEL IN SPECIAL PURPOSE MACHINE ENGINEERING

349

2 AVAILABLE DATA MODELS

AND SOFTWARE TOOLS IN

SPECIAL PURPOSE MACHINE

ENGINEERING

The data models and corresponding engineering

phases are listed in figure 2.

Figure 2: Data models in special purpose machine engineer-

ing

2.1 Data models in planning phase

As illustrated in figure 3 using UML notation, the data

model in the planning phase is the functional model

derived from the function analysis. This data model

describes the hierarchically on one hand the functions

this machine provides, and on the other hand the se-

quence of operations in this machine.

A mechatronic system (see figure 3) is abstracted

and analyzed in this phase as a group of Functio-

nUnits which interact with each other. Each Func-

FunctionGroup

ActionInstance

FunctionUnit

Actuator

Connection

Relation

Input

Output

Signal

1

0..*

1

0..*

1

0..*

1

1

1

1 0..*

1

0..*

1

1

1

0..*

1

0..*

Figure 3: Functional data model in planning phase

tionUnit executes the predefined action when the

Input conditions are given. The execution result

serves as Input information for other FunctionUnits.

The FunctionUnits connect through their Inputs and

Outputs with each other. This map of Connections

defines the functional interactions within the system.

The order of ActionInstances describes the sequence

of machine operation.

One software tool used in this phase is eM-Planner

of Tecnomatix (Tecnomatix, 2005). This engineering

tool provides the ability to model and plan manufac-

turing processes for entire plants, lines and single op-

erations.

The functional analysis and functional data model

of this phase is the basis of mechanical, elec-

tric/electronic design and control application pro-

gramming. It can be changed according to the re-

quirements of coming phases.

2.2 Data models in mechanical

design

Data models in this phase are categorized into two

different ways:

Environment

Object

Hull

Section

Grippoint

Gripper

Frame

1

1

1

1

1

1

1 0..*

1

0..*

1 1

1

1..*

1

1..*

1

1

1

1..*

0..*

0..*

1

0..*

Figure 4: Geometric data model

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

350

• geometric structure: the geometric data models

are used in CAD software tools. They describe

the mechanical structure of a mechatronic system.

Figure 4 illustrates a geometrically oriented data

model (Uthoff, 1998; Rossmann, 1993). Multiple

Objects could be involved in one Environment.

One Object is separated in several Sections and

substructured into several Hulls. Each Hull rep-

resents a basic geometric body. All of them have

a Frame which describes their spatial position and

orientation. The connection between Gripper and

Grippoint defines the geometric binding of bodies.

• Multi body system: in these data models a mecha-

tronic system is regarded as a multi body system

(MBS) as illustrated in figure 5 (Otter, 1995; Reif,

1998; Sch

¨

afer and L

´

opez, 1999). Each subsystem

in an MBS has three basic components: Force,

Body and Joint. Force describes the general in-

put and output of the subsystem, as well as Body is

the geometric description. Joint defines the kine-

matic constrains and describes the interaction be-

tween the subsystems. This data model is used ba-

sically in the mechatronic simulation to analyze the

kinematic and kinetic characteristic. The definition

of the machine function, that has been carried out

in the planing phase, determines the kinematic mo-

tion.

MBS

InertialSystem

Interact

Joint

Part

Body

Sensor

Frame

Force

Member

Connect

1

1

0..*

1

0..*

0..1

2

1

0..*

2

0..*

2

0..*

Figure 5: Data model of multi body system

2.3 Data models in electric design

Electric design in special purpose machine engineer-

ing is different from electric design in modul develop-

ment. The configuration of BUSSystems, the assign-

ment of system components (FunctionUnits) to the

BUSSystem and the design of the electrical cabling

between system components and BUSMember are in

the focus.

FunctionGroup

BUSMember

FunctionUnit

BUSSystem

Equipment

IOChanal

IOPin

IOModul

Input

Output

1..*

0..1

1

1..*

8, 16

1..*

0..1

1

0..*

0..*

1..*

0..*

Figure 6: Data model in electric design

Figure 6 illustrates a part of the model that de-

scribes the data processed in electric design.

On the left hand side the functional equipment hi-

erarchy is shown as defined in planning phase. On

the right hand side is the hierarchy of Bus-system.

The Association between Input/Output and IOPin

describes the electrical cabling.

2.4 Data models in control

application programming

FunctionObject

EquipmentObject

ElecResource ControlModulER

ControlModulFG

ControlObject

ControlProgram

SensorActor

FunctionGroup

FunctionUnit ControlModulFU

Machine

UserIO

0..*

0..*

0..*

0..*

0..*0..*

0..*

0..*

0..*

Figure 7: Data model in control application programming

Figure 7 gives a data model in control application

programming (Brandl, 1999; Lutz, 1999). This data

model is separated into two hierarchies. On the left

side is the functional equipment hierarchy as defined

in planning phase, and on the right side the hierar-

chy of the control program. Each FunctionGroup

and FunctionUnit in the functional hierarchy has a

related ControlObject in the hierarchy of the control

program. The data planned in functional analysis, e.g.

sensors/actuators and input/output are also needed for

the control programs and the control modules.

GENERAL ENGINEERING DATA MODEL IN SPECIAL PURPOSE MACHINE ENGINEERING

351

2.5 Evaluation of the data models

As discussed in the sections before, each data model

is used specifically in one engineering phase and

processes the phase-specific data. These data models

contain not only phase-specific data but also common

data. For example, the definition of input and output

in the functional analysis in the planning phase is used

in mechatronic simulation and control programming.

However the common data are not shared between the

models of the different engineering phases or the dif-

ferent engineering tools respectively. The data can not

be reused. The new requirements 1, 2 and 3 from en-

gineering as listed in the part 1.1 are not satisfied in

these data models.

3 CONCEPT OF THE GENERAL

ENGINEERING DATA MODEL

The idea of the General Engineering Data Model

(GED) is that all software tools in all engineering

phases use only one single data model. All of them

share the same data from this general data model.

These software tools access this single data model and

retrieve the necessary data from it and store the phase

result back into this data model.

For example, the software tool in the planning

phase creates and stores the functional hierarchy of

a mechatronic system in the GED. The software tool

in mechanical design can accept this functional hi-

erarchy and build the model for multi body system.

This means that the functional model from planning

phase is reused for modelling in the kinematic simu-

lation. The software tool in control application pro-

gramming can use this functional hierarchy directly

to facilitate the design of control program. The later

phases can change and update the data coming from

earlier phases straightforward.

Figure 8 illustrates the position of the General En-

gineering Data Model in special purpose machine en-

gineering. In this case, the software tools do not have

Figure 8: Position of GED in special purpose machine en-

gineering

proprietary data bases. They use the GED to share

data. The data exchange between the software tools is

executed through the GED.

3.1 Structure of the General

Engineering Data Model

Figure 9 shows the basic data structure of the GED

using UML notation. The main data of engineering

are abstracted and separately modelled in SystemU-

nit. It contains the shared data of multiple engineer-

ing phases. The mechanical binding is modelled in

DynamicInterface, and the electrical binding is sep-

arately modelled in ControlInterface. SystemUnit

and its sub-hierarchy build the backbone of the GED.

The geometric data are separated from SystemUnit

because they can be modelled and assigned otherwise.

For example, the body of a cylinder could be assigned

with its piston together as a component. In this case it

will be used and referenced from the kinematic simu-

lation. Just the same cylinder body could be also as-

signed with its fixing plate together as a group. Multi-

body-systems-analysis takes advantage of this assign-

ment to analyse the kinetic characteristic.

The structure of FunctionHierarchy is the same

as illustrated in figure 3 in planning phase. The struc-

ture of ControlModuleHierarchy and its assignment

to a FunctionHierarchy are also the same as fig-

ure 7. The engineering data in FunctionUnit are ab-

stracted in SystemUnit and ControlInterface. Each

FunctionUnit has a reference on an appropriate Sys-

temUnit. A program module accesses the definition

of input/output and sensor/actuator indirectly through

FunctionUnit to SystemUnit in this case.

The modelling of the dynamic characteristic is

wrapped in MKSHierarchy.

3.2 Evaluation of the General

Engineering Data Model

The General Engineering Data Model connects the

software tools used in the engineering of special pur-

pose machines.

The advantage of this new approach is a smaller

number of interfaces. Each tools needs only a sin-

gle interface to the GED. The earlier implementation

of proprietary interfaces for the direct data exchange

between the software tools is not neccesary anymore.

The number of interfaces for the data exchange re-

duces from n(n-1) to n, in which n is the number of

software tools.

Another advantage is a better quality of the engi-

neering data. The GED allows all software tools to

store and access their engineering data. The change

of data in one software tool directly updates the data

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

352

ControlModuleHierarchy

MKSHierarchy

FunctionHierarchy

DynamicInterface

ControlInterface

ControlProgram

Subsystem

FunctionGroup

UnitModule

GroupModule

FunctionUnit

Geometric

SystemUnits

SystemUnit

Cell

Body

Part

GED

Interaction

CInput

Connection

MOutput

COutput

MInput

Figure 9: Compositions/Aggregations in the General Engi-

neering Data Model (not shown are e.g. class hierarchy)

status of the other software tools. The data is consis-

tent and up-to-date.

According to the requirements in 1.1,

1. The data in the GED is available across all en-

gineering phases, from planning, mechanical and

electrical design, control application programming

and so on.

2. The GED separates the engineering data from the

phase-specific hierarchy and allows the software

tools to share the phase-independent engineering

data.

3. The data in the GED is redundance-free. This im-

proves the data change management.

4. The GED can be extended. It allows to integrate

data of new software tools because the data are cou-

pled through references.

A prototypical implementation of the GED has

been used for the engineering of an assembly cell at

Bosch. The GED has been used to cauple software

tools for cell-planning and for cell-programming.

Due to the GED the first of the five steps (modeling,

configuration, module test, program completion and

integration test) in the programming of the cell is gen-

erated automatically. It shortes the development time

by more than 20%, and therefore, the engineering cost

is reduced.

Moreover, the data has always been kept up-to-date

and coordination effort within the engineering team

has been significantly reduced. The improvement has

been estimated to a 20% reduction in development

time and a 25% better data quality.

4 CONCLUSION

The development of special purpose machines is a

continuous and recursive process. It is divided into

several engineering phases. The software tools and

their data models currently used in each phase are in-

dependent from each other. It is difficult to exchange

the data between these phases and to keep the data

consistent. Engineering needs a new concept to im-

prove the cooperation of these software tools.

The GED summarizes the data processed in each

engineering phase and builds a data base for all en-

gineering phases. It connects the software tools and

makes the engineering process smooth. Through the

separation of engineering data from its phase-specific

system hierarchy, all of the phase-neutral data is cen-

trally managed. The GED retains the phase-specific

system hierarchies, which refer to engineering data.

This avoids the data redundance and improves the

data availability across the entire engineering process.

REFERENCES

Brandl, T. (1999). Anlageninformationssystem - Informa-

tionsmodell und Erstellungsystematik. Jost Jetter Ver-

lag, Heimsheim.

Ciocoiu, M., Nau, D. S., and Gruninger, M. (2001). On-

tologies for integrating engineering applications. In

Transaction of the ASME, Journal of Computing and

Information Science in Engineering, volume 1, pages

12–22.

EPLAN (2005). Reibungsloser Informationsfluss zwischen

allen Abteilungen bringt Ihr Engineering auf Erfol-

gsspur. Technical report, EPLAN Software and Ser-

vice.

Gausemeier, J., Flath, M., and Mohringer, S. (2001). Con-

ceptual design of mechatronic systems supported by

semi-formal specification. In Proceedings of the

IEEE/ASME international Conference on Advanced

Intelligent Mechatronics, pages 888–892, Como,

Italy.

Germer, C., Hansen, U., Franke, H.-J., and B

¨

uttgenbach,

S. (2001). Produkentwicklung mit neuen technolo-

gien - mechatronik vs. mikrosystemtechnik. In 4.

GENERAL ENGINEERING DATA MODEL IN SPECIAL PURPOSE MACHINE ENGINEERING

353

VDI Mechatronik Tagung 2001 Innovative Produkten-

twicklungem, pages 19–36.

Isermann, R. (1996). Modeling and design methology

for mechatronic systems. In IEEE/ASME Trans. on

Mechatronics, volume 1 of 1, pages 16–28.

Isermann, R. (1999). Mechatronsche Systeme. Springer-

Verlag Berlin.

Keil, A. and Schmidt, M. (2001). Modellierung

und simulation elektromechanischer systeme durch

werkzeugkopplung. In 4. VDI Mechatronik Tagung

2001 Innovative Produktentwicklungem, pages 112–

126.

K

¨

ubler, R. (2000). Modulare Modellierung und Simulation

mechatronischer Systeme. VDI-Verlag D

¨

usseldorf.

Lutz, R. (1999). Softwaretechnik f

¨

ur maschinennahe

Steuerungsfunktionen bei Fertigungseinrichtungen.

Jost Jetter Verlag, Heimsheim.

Otter, M. (1995). Objektorientierte Modellierung mechatro-

nischer Systeme am Beispiel geregelter Roboter. VDI-

Verlag, D

¨

usseldorf.

Pelz, G. (2001). Modellierung und Simulation mechatron-

ischer Systems. H

¨

uthig Verlag Heidelberg.

Reif, T. (1998). Zur objektorientierten Modellierung aktiver

Mehrk

¨

orpersysteme. VDI-Verlag D

¨

usseldorf.

Rembold, U., Nnaji, B. O., and Storr, A. (1994). CIM: Com-

puteranwendung in der Produktion. Addison-Wesley.

Rossmann, J. (1993). Echtzeitf

¨

ahige, kollisionsvermeidende

Bahnplanung f

¨

ur Mehrrobotersysteme. Universit

¨

at

Dortmund.

Sch

¨

afer, C. and L

´

opez, O. (1999). An Object-oriented robot

model and its integration into flexible manufacturing

system. In I. Imam, Editor, Mulitple Approaches to

Inteligent Systems. Springer.

Starke, G. (2001). Virtual reality und simulation als integri-

erte werkzeuge f

¨

ur die entwicklung mechatronischer

systeme. In 4. VDI Mechatronik Tagung 2001 Innov-

ative Produktentwicklungem, pages 1–17.

Tecnomatix (2005). eM-Planner: Planning, Analyzing and

Managing Manufacturing Process. Technical report,

http://www.tecnomatix.de/.

Uthoff, J. (1998). Offenes, modulares System zur zellenori-

entierten Robotersimulation. VDI-Verlag D

¨

usseldorf.

VDI (2003). Digitale Planung bringt Sicherheit. Technical

report, VDI.

Welp, E. G., Lippold, C., and Bludau, C. (2001). Ein system

zur objektorientierten modellierung mechatronischer

produktkonzepte (modcode). In 4. VDI Mechatronik

Tagung 2001 Innovative Produktentwicklungen, pages

93–112.

Westk

¨

amper, E. (2002). Die digitale fabrik - interview

mit engelbert westk

¨

amper: Intelligente maschinen

m

¨

ussen kommunizieren und sich selbst organisieren.

Technical report, Siemens: Pictures of the Future.

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

354