TESTBED EVALUATION OF NETWORKED CONTROL

SYSTEMS

George Hassapis, Spyridon Geronatsios and John Grigoriadis

Department of Electrical and Computer Engineering, Aristotle University, 54124 Thessaloniki, Greece

Keywords: Networked Control, Hardware in

the loop simulation, Profibus.

Abstract:

This work addresses the issue of performance evaluation of advanced control algorithms which

are going to be implemented on scalable industrial computer networks. The basic characteristic

of these implementations is that information concerning measurements from sensors, commands

to actuators and reference inputs is exchanged between the plant and the control system over a

real-time communication network. The need to evaluate the performance of such algorithm

implementations before commissioning them derives from the fact that the network-induced

delay during the exchange of the sensor-to-controller and controller-to-actuator data and the

possibility of loss of a data package during transmission may affect the algorithm performance.

One way of assessing this performance is by emulating the operation of the algorithm on a test-

bed. As test-bed is defined the facility that consists of a computer-based simulation of the plant

which is linked to the real communication network and actual control devices on which the

algorithm will be implemented. As there are many proprietary and open communication network

protocols and standards, unavoidably the test-bed has to be constructed for a specific protocol

and standard. In this work a test-bed based on the Profibus standard and its FMS protocol has

been realized. The purpose is the evaluation of a control algorithm which will run on one or

more controllers that will be inserted in an already operating networked control system. In order

to demonstrate the way of using a test-bed for evaluating the performance of a control algorithm

the study of the LQC control of a cement milling circuit is presented.

1 INTRODUCTION

The control systems that have their control loops

closed via a serial and common communication

channel are usually called Networked Control

Systems. They present certain advantages over the

traditional point-to-point architectures, such as

small volume of wiring, distribution of the

processing functions to many units, modularity, low

cost and quick and easy maintenance. However,

they introduce and some new problems arising from

the time varying delay that might appear during the

transmission of sensor and actuator related

measurement data and the possibility of loosing data

during one or more sampling periods. The control

algorithms are usually designed with the assumption

that measurements of the controlled variables can be

taken at sampling rates that are either steady or

varying within certain limits. Because of the

network-induced delays these limits might not be

always secured, something that may influence the

performance of the control algorithm. The same

problem of system stabilization may appear because

some packets of measured or command data not

only suffer transmission delay but even worse, they

can be lost during transmission and they will not

arrive by the time of control calculation.

Hence, the need arises to check the performance

of

control algorithms that have been designed with

conventional control theories, such as synchronized

control and non-delayed sensing and actuation when

they are implemented on networked control systems.

This performance is greatly influenced by the type

of the network and its traffic. So, there are networks

with communication protocols that minimize the

likelihood of having long packet delay or packet loss

and other that have predictable delay limits. As

networks of the second type seem to dominate the

industrial sector it would be wiser to invent ways of

assessing the performance of control algorithms that

116

Hassapis G., Geronatsios S. and Grigoriadis J. (2005).

TESTBED EVALUATION OF NETWORKED CONTROL SYSTEMS.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 116-123

DOI: 10.5220/0001178801160123

Copyright

c

SciTePress

will be implemented on such networked control

systems as reliably as possible. Believing that next

to the implementation of the algorithm in the real

field conditions is the hardware-in-the-loop

simulation of the algorithm, we propose in this work

a facility for assessing the performance of the

control algorithms which involves the actual

controllers and the network that will be used in the

industrial field and a computer simulation of the

controlled process. This facility is enhanced with

generators of network traffic, so that the controller

induced traffic added to generated traffic would

allow to study the behaviour of the controller under

varying traffic loads. The traffic load imposed by the

generator simulates the load inflicted on the network

by other control applications that the same network

is used for.

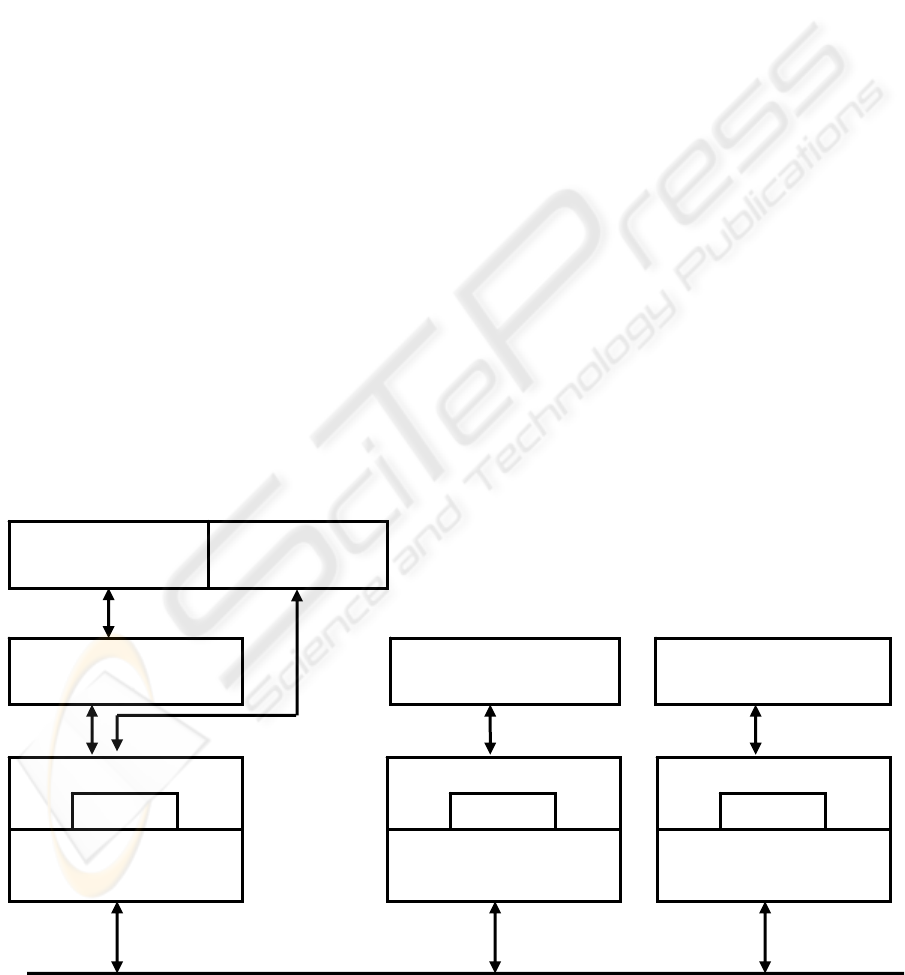

The proposed test facility consists of at least

three units. The first unit is a PC-based computer

station which hosts a process simulation package

such as MATLAB (Math Works, 1996), interfaces

and links to an industrial network, such as FMS

Profibus (DIN, 1992, Tovar, 1999a). It also has the

necessary software that allows the transfer of data

between the controllers and the process simulation

package. The second unit is a PC-based station of

the network which simulates the traffic load of the

control applications. The third unit is another PC-

based network station that implements the algorithm

that controls the simulated plant. This facility is

scalable and can be expanded to accommodate

additional network stations that will implement the

control of other variables of the simulated plant.

Although the FMS protocol has functions and

services that are more than those required for the

pure automatic control of process variables, this

protocol has been selected as the protocol of the

first attempt to build a test-bed because it can

include traffic that is related with the functions of

the supervisory and process operations control.

These functions are an integral part of the operation

of any industrial complex and in small plants using

different Profibus protocols for the pure automatic

control and the higher level functions increases the

development and running cost. Therefore, this test

bed may be used to evaluate a mixture of higher and

low level control operations and its use is mainly

addressed to the case of the small process plant.

In this work a realization of the above test-bed

concept has been made and is presented. In this

realization the proposed test facility has been

expanded to include a fourth station that monitors

the network operation and realizes the supervisory

and monitoring functions of the plant simulation.

How these facilities can be used to assess the

performance of an algorithm on a networked control

system is demonstrated by realizing the LQC

networked control of two loops of a cement milling

circuit with the FMS Profibus protocol. Various

network parameters are adjusted and the use of the

developed test-bed to evaluate the performance of

the considered LQC control algorithm was studied

under a specific network traffic. This demonstration

shows the possible use of the test-bed to checking

whether a control algorithm can be implemented in

an existing networked control system without

driving the system to instability. Also, it shows how

one can tune the network to accommodate the

insertion of the new algorithm.

2 THE PROFIBUS INDUSTRIAL

NETWORK

Vendor-independent standardized networks for

control, supporting the open system concept, have

emerged over the last years. Profibus is one of the

available standards that have been approved by

CENELEC (EN, 1996). Numerous Profibus

installations have been reported. The Profibus MAC

protocol is a simplified version of the timed-token-

bus protocol (IEEE, 1985, Tovar and Vasques,

1999b). According to this protocol master stations of

the network get the bus access when a data object

called token is passed to them. During operation of

the network the station with the token transmits data

frames until it runs out of data frames or the time it

has held the token reaches a limit. Actually there are

two types of frames that are transmitted. The

synchronous and the asynchronous ones. The

synchronous ones correspond to critical data that

must be transmitted within the holding time of the

token. The Profibus protocol allows one

synchronous package per token holding time to be

transmitted and if time is left the asynchronous

transmission is initiated and is terminated even if

that requires the violation of the holding time limit

of the token.

The time delay of a message is defined as the

difference between the time when the source node

begins the process of sending a message and the

time when the destination node completes reception

of this message. This time delay must be less than

the target rotation time, a network timing parameter

that can be set by the user and expresses the time

elapsed between two consecutive receptions of the

token by the network station. A dominant part of the

TESTBED EVALUATION OF NETWORKED CONTROL SYSTEMS

117

message time delay is the slot time which defines the

maximum timing period that the sender of a package

must wait for the receiver response. If the sender

does not receive the response from the receiver

within this timing period the sender repeats the

transmission of the same package. By adjusting the

token rotation time (trt) and the slot time (tst) and

keeping all the other timing parameters of the

network at preset values is a first level tuning of the

network in order to cope with the satisfaction of

deadlines of tasks that have to be executed by the

network stations.

3 THE FMS TEST-BED

The diagram in Figure 1 shows pictorially the

architecture of the developed test-bed which consists

of four different stations. Each station plays a

specific role in the network and is loaded with

software that is appropriate for its role. The first

station is used for simulating the process to be

controlled as well as the sensors and the actuators of

the controlled plant. The second station simulates

the control functions that have already being using

the network. In fact, it generates network traffic

similar to the one that is expected to be produced by

the aggregated operation of all the other control

functions except the ones that we are going to

introduce. This traffic is exchanged with the first

station and is produced by a generator which can be

preset to send a number of packages the data size of

each package being determined statistically

according to the Poisson distribution.

When a master holds the token it may establish a

master-slave communication procedure with process

relevant devices, such as sensors and actuators for

exchanging data. Typically, the process relevant

devices are accessed through a slave network

interface whereas the distributed control algorithms

reside at master stations. The sampling and

activation of the sensors and actuators that are

related with the operation of the new control strategy

is carried out by the master station on which the new

control algorithm is running. Finally, the fourth

station is a monitoring station of the network

operation. By means of this station the various

timing parameters of the network can be measured

and the exchange of frames among the network

stations can be observed and recorded. Each station

is linked with the common data transmission

medium by the use of the Profibus interface card

PB-FM-1MS made by Softing (Softing, 2003) and

the necessary software on the host PC which

implements the levels 2 and 7 of the FMS protocol

of the Profibus standard. Data exchange between the

PC and the card takes place through a dual port

memory. The card configuration is carried out by the

Profibus window NT software which installs the

card driver and allows the user to set up the driver

parameters. The parameters are those that are related

with the network baud rate, the various network

parameters, such as token rotation time, slot time,

etc. In the first station where the plant dynamics are

simulated, the control systems simulation

environment of MATLAB is installed. It

communicates with custom-made application

Master Station 1

Process Simulation

Master Station 2

Aggregated Control

System

Master Station 3

New Controller

Profibus Bus

Monitoring system

Figure 1: The architecture of the test-bed

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

118

software in C which creates virtual objects of the

plant sensors and actuators and sends and receives

the output and input data to the plant model by

incorporating services of the application layer of the

FMS protocol. In Figure 2 the architecture of the

installed software is pictorially depicted.

4 NETWORKED CONTROL OF A

CEMENT PLANT

Next, how the developed test-bed has been used to

evaluate the performance of the networked control

of two critical parameters of a cement plant will be

demonstrated. The considered control functions are

implemented on an existing Profibus network which

is supposed to be used for the control of other

variables of the same or other processes of a plant.

The insertion of these two new functions inflicts

additional traffic to the existing network and for this

reason both the influence of this traffic on the

stability and performance of the already running

functions has to be evaluated and the performance of

the new algorithms need also to be checked for

compliance with the control specifications. In fact,

one can assume that there are already known limits

for the existing control functions on their execution

deadlines. This will allow us to impose range limits

on the network tuning parameters the values of

which will be determined in a way that satisfies the

deadlines of the new network control functions.

In this work this assumption is made and the

performance of the considered plant is evaluated for

various network loads that the operation of the

existing control functions might inflict on the

network. First, a brief description of the control

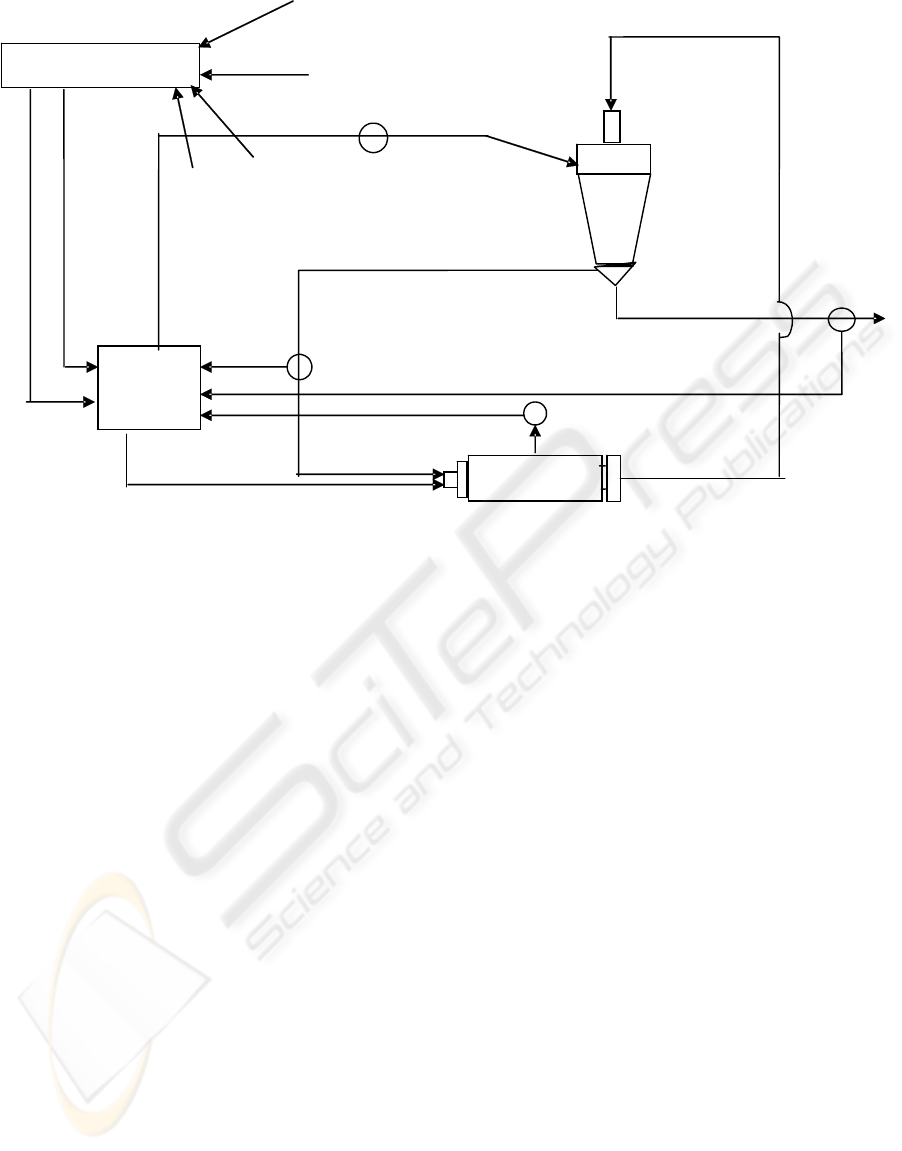

problem of the cement plant is presented. The basic

process unit in the production of cement is the

cement milling circuit. Such units are fed with raw

material which after being ground is introduced into

a high efficiency classifier and separated into two

classes.

The tailings (refused part) are fed back into the

milling circuit while the finished product (accepted

part) exits the milling circuit. In the schematic

diagram of Figure 3 the milling circuit principle is

shown (Magni, 1999). The classification of the

material is driven by the rotational speed and by the

air flow rate of the classifier. The load in the milling

circuit depends on the input feed (fresh feed plus

tailings flow rate) and on the product flow rate that

depends in a non-linear way on the load in the

milling circuit and the hardness of the material.

There is a different upper limit of the load for each

hardness value which leads to circuit instability,

while keeping the load at a low level will result in

the fast wear of the mill internal equipment.

Figure 2: Software architecture of the Profibus stations

COMMUNICATION

SOFTWARE

NEW CONTROL

ALGORITHM

AGGREGATED

CONTROL

AGGREGATED

CONTROL

MATLAB

FMS Protocol

Drive

r

PB-FM-1MS card

FMS Protocol

Drive

r

PB-FM-1M card

FMS Protocol

Drive

r

PB-FM-1MS card

TESTBED EVALUATION OF NETWORKED CONTROL SYSTEMS

119

Figure 3: the milling circuit

A multivariable control technique, based on Linear

Quadratic Control (LQC) theory, has been

introduced (

Van Breusegen, 1996) to deal with the

instability problem. With this technique two

outputs, namely the product flow rate (y

r

) and the

load (z) are simultaneously controlled by using the

two available inputs, that is the feed flow rate (u)

and the classifier speed (v). For the implementation

of the LQC algorithm on the networked control

system the second master station was programmed

to perform this algorithm. In the first master station

the plant dynamics without the LQC control were

simulated in the MATLAB environment. During this

simulation the solution of the differential equations

is carried out at every sampling instant and then the

data of the controlled variables y

r

and z are read by

the second master, when this second master holds

the token. Also, within the same token holding time

the LQC computations are executed by using the

received data and the computed corrections for the

manipulated variables u and v are sent to the first

station where they are sampled in a similar way.

Then the token is passed to the third station which

generates data packages of sizes that are randomly

selected according to the Poisson distribution. These

packages are also read, enhanced by the data of the

cement plant and retransmitted over the network.

There are certain known deadlines for sending and

receiving data from the plant simulation, equal to the

sampling rate of each algorithm. To meet these

deadlines for a known network baud rate, the timing

parameter of the maximum token rotation time (trt)

and the slot time (tsl) have been preset. Also the

maximum retry limit (max_retry_limit) is set to

three. If, however these figures are not correct or

there are bursts of heavy traffic in the network,

sensor measurements and controlled variables

updates might not occur within the deadlines. This

might drive the controlled variables to deviations

from the desired transient and steady state

specifications.

By obtaining a recording of the variations

of the considered variables of y

r

and z over a horizon of

sampling instants at various traffic loads, possible

instabilities and deviations from the desired transient and

steady state specifications may be traced down. Then, new

tuning parameters may be tried.

5 TEST-BED EVALUATION

A number of experiments were conducted to show

the effect of different values of network timing

parameters

on the performance of the networked control

of the cement plant under varying network loads. The

study was conducted under three different loads, namely

for 5, 50 and 100 packages. The size of each package

varied from 0-510 bytes, randomly defined by the Poisson

distribution. The experiments were conducted for two sets

of trt and tsl values, that is for tsl=3.5msec and trt=10msec

and tsl=3.5msec and trt=2msec. In order to compare the

obtained test-bed results with the ideally expected

Speed

Product

Mill

Load Mill

Feeding

Multivariable

Control

Classifier

-

Supervisory Level

Tailings

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

120

responses, the curves in Figure 4 are given. They have

been obtained from the MATLAB simulation of the

networked control of the cement plant.

The test-bed

results for a network load of 50 frames, trt=10msec

and tsl=3.5msec are presented in Figure 5

. The results

for the same network load and tsl value but for trt=2msec

are presented in Figure 6.

0 1 2 3 4 5 6

0

50

100

150

200

250

300

350

400

450

time(sec)

metavlites

yf

yr

z

Figure 4: MATLAB Simulation of the LQC control of the cement plant

Figure 5: Plant response from the test-bed implementation of the LQC control of the cement plant for g=50, tsl=3.5msec

and trt=10msec

0 1 2 3 4 5 6

0

50

100

150

200

250

300

350

400

450

time(sec)

metavlites

yf

yr

z

TESTBED EVALUATION OF NETWORKED CONTROL SYSTEMS

121

0 2 4 6 8 10 12 14 16 18

0

50

100

150

200

250

300

350

400

450

time(sec)

metavlites

yf

yr

z

Figure 6: Plant response from the test-bed implementation of the LQC control of the cement plant for g=50, tsl=3.5msec

and trt=2msec

From the curves of Figures 4, 5 and 6 one can

conclude that the network delay has a small negative

influence on the settling time of the plant variables

when the trt =10msec. The settling time of the

product flow rate (y

r

) and the mill load (z) is around

3 and 1.8 time units respectively. These times are

very close to those predicted by the MATLAB

simulation. On the contrary, at trt=2msec the

difference from the simulation is significant, being

around 8 time units for the product flow and 5 time

units for the load. This is quite an expected behavior

as at small token rotation times the possibility of not

completing the sampling of the sensors and the

computation of the algorithm is quite high.

Therefore, according to the Profibus operation the

computations will be concluded by violating the trt

time. Consecutive violations added up over the time

will result to omit one or more computations at

certain sampling times, a condition that is known to

lead to a deterioration on the loop performance and

instability. However, problems of instability are not

monitored for the considered network load.

Although, one verifies practically what is most

likely to expect, the use of the test-bed can provide

to him additional quantitative information for the

responses of the networked control system Then, on

the basis of this information one can take decisions

for the trt and tsl values which can satisfy the

performance of the new control system without

affecting the performance of the already existing

control functions.

6 CONCLUSIONS

A test-bed with four master stations for evaluating

the performance of designed networked control

algorithms of physical processes has been developed

and its correct operation has been tested. The

network protocol implemented by the test-bed is the

FMS Profibus protocol. The conducted tests

involved the quantitative comparison of the

responses of the product flow rate and load of a

milling circuit of a cement plant to different network

data loads. They can be attributed to the use of the

network for other control operations in addition to

those of the cement plant. The comparison has

disclosed that as it was expected, the network delay

at small token rotation times influences the response

and especially the settling time. The use of the test-

bed can provide the necessary quantitative

information which will allow somebody to trade off

the network loading with more control functions at

the expense of performance degradation.

REFERENCES

DIN 19245, 1992. The Profibus standard part I and II,

translated from German, Profibus Nutzerorganisation

E.V.

EN 50170, 1996. General purpose field communication

system, CENELEC.

IEEE standard 802.4, 1985. Token passing bus access

method and physical layer specification.

ICINCO 2005 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

122

Math Works, 1996. Matlab Control Systems Τoolbox,

User’s Guide, Version 5.

Magni, G. Bastin, and Vincent Wertz, 1999. Multivariable

Nonlinear Predictive Control of Cement Mills, IEEE

Transactions on Control Systems Technology. vol. 7,

no 4, pp. 502- 508.

Softing Gmb, 2003. Profiboard User’s manual.

Tovar E. and Vasques F., 1999a. Real-time Fieldbus

communications using Profibus networks, IEEE

Trans. Indust.,,Electron., vol.46, pp.1241-1251.

Tovar E. and Vasques F., 1999b. Cycle time properties of

the PROFIBUS timed-token protocol, Computer

Communications, vol. 22, pp. 1206-1216.

Van Breusegen V, Chen L., Bastin G., Wertz V.,

Werbrouck V., and de Pierpont C., 1996. An

industrial application of multivariable linear quadratic

control to a cement mill circuit, IEEE Trans. Ind.

Applicat., vol.32, pp. 670-677.

TESTBED EVALUATION OF NETWORKED CONTROL SYSTEMS

123