A HYBRID DECISION SUPPORT SYSTEM

The joint use of Simulation, Coloured Petri Nets and Expert System

Fabiano A. Hennemann, Ricardo J. Rabelo, José E. R. Cury

DAS - UFSC, P O Box 476, 88040-900 – Florianópolis – SC, Brazil

José V. Canto dos Santos, Arthur T. Gómez

PIPCA – UNISINOS, P O Box 275, 93022-000 – São Leopoldo – RS, Brazil

Keywords: Decision Support Systems, Simulation, Coloured Petri Nets, Expert System.

Abstract: This works aim to propose a Hybrid Decision Support System (HDSS), based in Simulation and Coloured

Petri Nets as modelling techniques of manufacture processes, and an Expert System to assist in its use. The

HDSS provides a friendly interface for the user that, after selecting input parameters, gets a series of data

about the manufacturing process that will assist in the evaluation of its performance as answer. To validate

the proposal, some particular scenes have been tested, with the objective of elaborate a set of proposals for

improving the performance of productive systems, evaluating the impacts from the change on model

parameters and providing a better understanding about the systems considered. The HDSS makes possible

for managers, without knowledge of modelling techniques, manipulate data and interact with the models.

The developed prototype is generic for applying on general manufacturing processes, making it possible to

use it for any industrial plant, since that the input parameters of the model are adequately fitted.

1 INTRODUCTION

The companies must constantly improve its

manufacture processes and its methodologies of

work. For this, becomes necessary the improvement

of the productive process, looking for the reduction

of lead times, costs of production, improvement of

the quality, among others. However, this objective is

very difficult to reach. One of the causes is the lack

of good computational systems that assist managers

in the evaluation of the company and the posterior

decisions. The existence of a tool to support decision

that interacts with a model of the manufacture

process could benefit these companies to analyze the

performance of its processes, to establish schedules

of execution with precision, to relate the operations

and to plan the resources necessary in the

manufacture process of each product type. In

literature, the development of systems based on

some specific approaches is found, with its results

presenting, of course, inherent limitations to the used

techniques. This work presents a Hybrid Decision

Support System that combines the potentialities of

some excellent approaches, aiming at to improve the

quality of the diagnosis and the decisions to be done.

The techniques integrated in this work are

Simulation, Coloured Petri Nets and Expert

Systems.

In this work the shoes matrices production

segm

ent was chosen to evaluate and to validate the

proposal. Its processes can be considered as flow

shop type (Askin & Standridge, 1993), with great

variability and average production, as described in

(Groover, 2001). The research aims, in short, to

study the productive processes in manufacture

environments, with the objective to supply

theoretical subsidies through tools and

documentation, in order to assist administrative

resolutions. The choice of modelling techniques,

whose contributions interact with the processes

managers, through a HDSS, as suggested in (Piesik

& Weglarz, 1999) and (O'Reilly & Lilegdon, 1999)

is a appropriate strategy in this context. The article is

organized as follows: Section 2 presents the

Identified Problems; Section 3 shows the proposed

model and aspects related to the implementation; in

Section 4 the results and the structural validation

with CPNs are shown; and finally, Section 5

presents the conclusions.

251

A. Hennemann F., J. Rabelo R., E. R. Cury J., V. Canto dos Santos J. and T. Gómez A. (2005).

A HYBRID DECISION SUPPORT SYSTEM - The joint use of Simulation, Coloured Petri Nets and Expert System.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 251-254

Copyright

c

SciTePress

2 IDENTIFIED PROBLEMS

During the mapping of the process operations and in

interviews made with managers of productive

processes, some problems had been identified. These

problems are listed below.

• The products manufacture sequence are

frequently unregistered, making difficult the

visualization, understanding and analysis of the

process.;

• There are few estimates of necessary

manufacture times. The stated periods are supplied

to the customer based on the experience of the

managers;

• Trustworthy estimative about the use of

available resources does not exist;

• Absence of a tool to analyze impacts from

investments in new resources;

• Extensive amount of rework.

3 PROPOSED SYSTEM

The structure of the proposed system is based on the

problems that had been highlighted by the managers

and in the possible results that each modelling

technique can produce. The HDSS interacts directly

with the simulation model developed with a

Simulator. The use of CPNs complements the

available data on the manufacture process and

analyzes the properties of this model in structural

terms, validating it. Because the simulator and the

CPN generate an enormous amount of information,

the manager is assisted by the module of

intelligence, represented for an Expert System, who

assists in the data interpretation. Figure 1 shows the

basic architecture of the proposed system. Each part

of the system is described below.

Figure 1: Basic architecture of the proposed system.

3.1 User Interface

This module is divided in two parts called:

Managing Module - Data entry and Managing

Module - Results. Using the User Interface, the

manager selects and modifies the desired

parameters, before executing the Simulation. After,

these parameters are saved on text files in the

Repository of Data and the Simulation begins.

Concluded this stage, the results are shown to the

user and stored again in the Repository. This module

was developed using Delphi as programming

language.

3.2 Expert System

The Expert System is divided in two modules. The

first module assists in the definition of the data that

must be selected in the User Interface - Data Entry

and the second provides the interpretation of the

Results, shown in the Managing Module. This

function helps the manager in the interaction with

the User Interface and interpretation of the Results

that the HDSS presents. The Expert System was

developed in shell Expert Sinta.

3.3 Repository of Data

This module stores all the information supplied in

the User Interface Module, the results reached for

Simulator and CPNs, and all the data used by the

Simulator program. This repository also stores the

set of logs from all evaluated scenes. Beyond

serving for future evaluations, the objective of this

base is to make possible that the different scenes of

developed tests are compared, without necessity of a

new simulation. The files are MS Excel spread

sheets.

3.4 Simulator Module

With this module, through the selection of some

parameters, the manager gets the following results:

amount produced, daily production; WIP; graph with

the state of the entities; graph with utilization and

the state of the resources; graph of use and the state

of the production stages; relation of the resources

(humans and machines) that are being used in more

than 60% of the time; measurers with permanence

time in each sector and documentation with process

data. This module was constructed with the software

Promodel.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

252

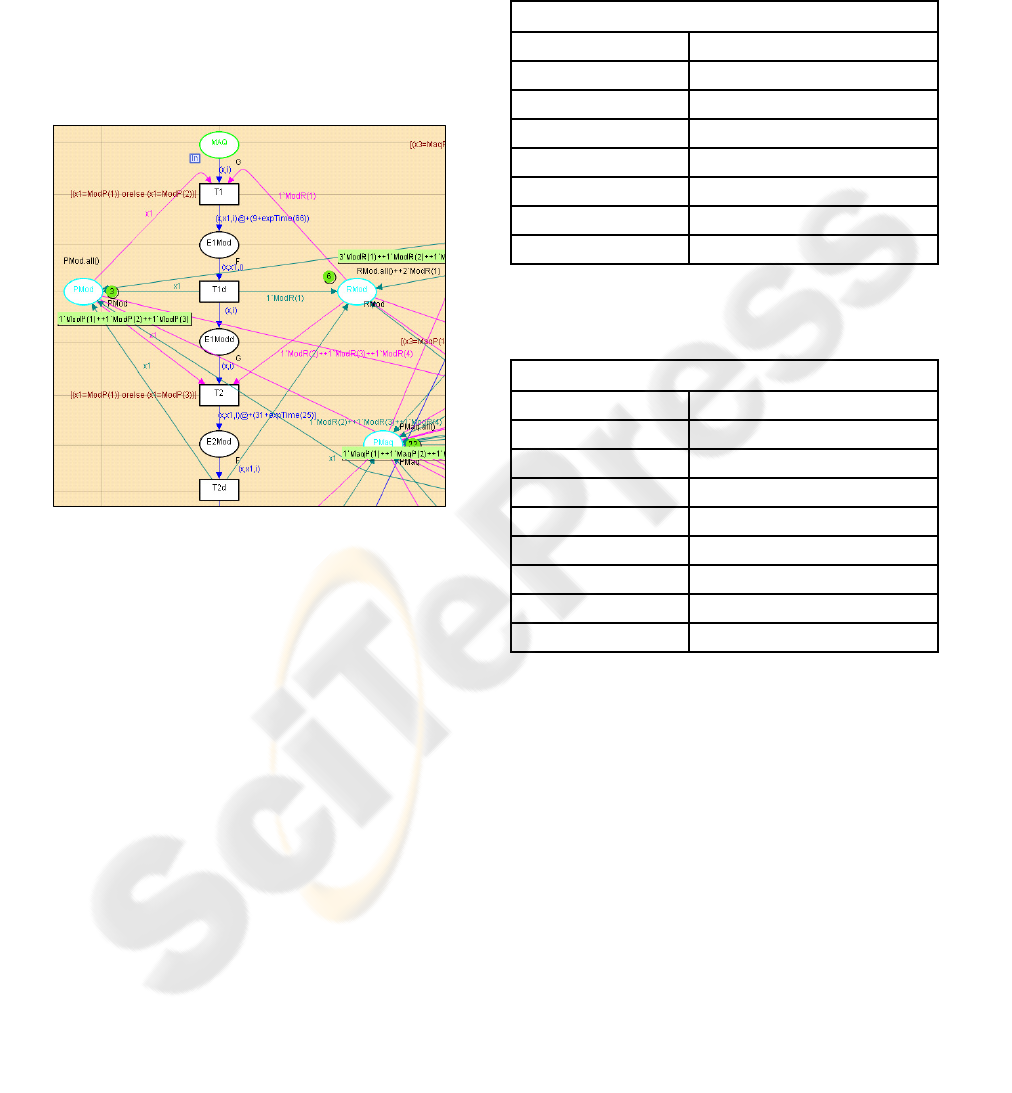

3.5 CPN Module

The CPN module was developed with top-down

approach (Jensen, 1996). Figure 2 shows a small

example of this net. The application of the CPN is

justified because that the majority of the systems are

complex, making traditional Petri Nets inadequate to

represent a model with large dimensions. The

deadlock property (Dicesare et alli, 1993) of the

physical system is verified. The model was

developed with software CPN Tools.

Figure 2: Part of a CPN model

4 RESULTS

Using the collected data of the current process, tests

with HDSS has been carried through. The results of

these tests for the production of matrices are

presented in Table 1. The space limitation imposes

the results shown of a one type of matrix (PUS).

(The amount of results is extensive and related to

several products.) Considering that the reached

results represents the real behavior of the process,

some pointers have been used to mark the

elaboration of alternative scenes of improvements,

focused in the reduction of production time and

increase of productive capacity.

4.1 Scene 1

In Table 1 is shown the resources with the bigger

percentage of use in the productive plant. Because

the majority of these are human resources, more

people training to execute the corresponding stages

were suggested. For such, the resources indicated in

Table 1 had been duplicates and the new results are

presented in Table 2.

Table 1: Current scene

PUS (Model)

Amount Production 32

PUS/Day 1,15

WIP 83

Busiest Resources P1Mod, P2Mod,P3Mod

Busiest Resources P1Maq,P2Maq,P3Maq,P4Maq

In Operation 59,25%

Blocked 26,60%

Wait for Resources 14,13%

Table 2: Scene 1.

PUS (Model)

Amount Production 50

PUS/Day 1,73

WIP 88

Busiest Resources P1Mod, P2Mod,P3Mod,R1Mod

Busiest Resources R4Mod, P1Maq,P2Maq,P3Maq

Busiest Resources P4Maq,P22Maq

In Operation 60,77%

Blocked 25,08%

Wait for Resources 14,13%

The most significant differences between the

current scene and the scene 1 are listed below:

• Increase 56% productivity of matrices PUS;

• Machine resources appear with index of use

above 60%;

It was concluded that scene 1 introduces

improvements to the current scene, mainly in

relation to the significant addition of production in

the matrices.

4.2 Scene 2

Aiming improve the data found in scene 1, the

changes shown in Table 3 will be carried through

using the HDSS. These changes are based on the

resources that had presented the biggest percentage

of use. Comparing the results of this scene with the

A HYBRID DECISION SUPPORT SYSTEM - The joint use of Simulation, Coloured Petri Nets and Expert System

253

current scene, in Table 4, the following ones can be

detached as main alterations:

• Increase of productivity of more than 100% of

matrices of type PUS;

• The time of production product PUS falls

significantly;

• The values of products in operation, blocked

and waiting resources had remained essencially the

same.

Table 3: Changes in Scene 1

Previous Resources Modified Resources

1 P1Mod 3 P1Mod

1 P2Mod 3 P2Mod

1 P3Mod 3 P3Mod

1 P1Maq 3 P1Maq

1 P2Maq 3 P2Maq

1 P3Maq 3 P3Maq

1 P4Maq 3 P4Maq

1 P22Maq 2 P22Maq

3 R1Mod 5 R1Mod

1 R4Mod 2 R4Mod

5 CONCLUSION

In this work was presented a hybrid decision support

system, using the main properties of the techniques

Table 4: Scene 2

of Simulation and CPNs, with an Expert System for

aid in its use. With the survey of the necessities and

diagnosis, the construction of a generic model of the

manufacture plant was possible, leading to a higher

reliability and quality in the decisions to be taken.

The used techniques were adequate and had

corresponded to the objectives established. The

Simulation was efficient to improve the performance

of the considered system. The CPNs has been

adequate for structural analysis of the model and, in

the tests presented, shown the structural validity of

the scenes.

REFERENCES

Dicesare, F., Harhalakis, G., Proth, J., Silva, M.,

Vernadat, K., Practice of Petri Nets in Manufacturing.

Chapman e Hall, 1993.

Groover, M. P., Automation Production Systems and

Computer-Integrated Manufacturing. 2 ed., 2001.

Jensen, K., Coloured Petri Nets - Basic Concepts,

Analysis Methods and Pratical Use, vol. 1. 2 ed., 1996.

O'Reilly, J. and Lilegdon, W., “Introduction to

FACTOR/AIM,” Proceedings of the 1999 Winter

Simulation Conference, vol. 1, pp. 201 -- 207,

December 1999.

Piesik, P. and Weglarz, J., “Multicriteria Decision

Support for Flexible Manufacturing Systems Using an

Interactive Method,” 7th IEEE International

Conference on Emerging Technologies and Factory

Automation, vol. 1, pp. 733--734, October 1999.

PUS (Model and Matrix)

Amount Production 71

PUS/Day 2,42

WIP 97

Busiest Resources P1Mod, P2Mod,P3Mod,R1Mod

Busiest Resources R2Mod, R4Mod,P1Maq,P2Maq

Busiest Resources P3Maq,P4Maq,P6Maq,P7Maq

Busiest Resources P8Maq,P9Maq,P10Maq,P13Maq

In Operation 57,90%

Blocked 28,24%

Wait for Resources 13,85%

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

254