HARDWARE INDEPENDENT ARCHITECTURE FOR

AUTONOMOUS COLABORATIVE AGENTS

Guillermo Glez. de Rivera, Ricardo Ribalda, Kostadin Koroutchev, José Colás, Javier Garrido

Escuela Politécnica Superior. Universidad Autónoma de Madrid. C/ Francisco Tomás y Valiente 11, Madrid, Spain

Keywords: Mobile robot, XML/RPC,

WebService, Wireless.

Abstract: We describe a modular mobile robot test system. This architecture allows easy inclusion of user hardware

and communication modules. A client-server, XML/RPC based approach makes the system easy to program

and neutral in respect to the operating system and the programming language used. The hardware modules

are included using a hardware independent protocol. This feature of the system makes it very flexible and

easy to use and reconfigure. The architecture by itself has support for many different communication

modalities.

1 INTRODUCTION

Nowadays there is a great demand of robotic

systems designed to solve complex tasks in fields as

manufacture, construction, transport, medicine and

others (Sybley 2002). Furthermore, in web-

controlled systems, robots play the role of a physical

mediator, enabling remote operators to acquire

information, explore, manipulate, communicate, and

establish long-range interactions with other persons

(Wang, 2004), (Wang, 2003).

During the development process of a robotic

project, two

different teams are involved, namely

hardware and software group. The two teams

interact each other in order to solve the problem. In

many cases, the communication between the teams

is not possible and therefore, each group limits its

activities to the basic function only. For example, a

frequent practice for the software team is to limit its

efforts to simulated environment.

This paper presents a flexible and generic

platform

that serves to the hardware designers as a

full operative open system, where they can include

easily their own devices (see also Glez. De Rivera

2002). The only requirement imposed on the devices

is to comply with relatively simple communication

protocol.

The final result is, on one side, a mobile robot

equi

pped with sensors, actuators and different

communication interfaces, and on the other side,

software that controls the robot’s sensors-actuators.

The communication interfaces allow robot-robot and

robot-control centre collaboration.

The software design includes as much drivers as

necessa

ry to handle the sensors and the actuators.

Also, the necessary communication protocols are

defined, having in mind a variety of physical

communication media.

Multiple network interfaces are included, which

allow the age

nt to choose the optimal media in each

particular application. For the end user of the

platform, the system looks like a "black box" with

which he interacts through simple XML-RPC calls.

XML-RPC (XML-RPC, 2000), (Dissanaike

2

004) allows a software running in different

environments to make operating system independent

procedure calls over TCP/IP. This makes possible to

use different hardware elements, as for example

sensors and actuators to be used from most

platform/programming languages. From the

programmer point of view, the whole robot is

converted into a simple set of RPC functions.

This paper describes the global architecture of

the platform and its bas

ic hardware structure.

Similar systems are described in (Golovinski, 2004),

(Hoopes, 2003) and (Navarro 2002). The system

described in this paper, using client-server paradigm,

XML/RPC and machine/language independent way

to introduce hardware/software modules in assumed

to be easier to program and reconfigure.

Using this architecture, a variety of peripheries,

as for exam

ple video camera, microphones, speakers

have been tested and are in test process.

459

Glez. de Rivera G., Ribalda R., Koroutchev K., Colás J. and Garrido J. (2005).

HARDWARE INDEPENDENT ARCHITECTURE FOR AUTONOMOUS COLABORATIVE AGENTS.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 459-462

DOI: 10.5220/0001185604590462

Copyright

c

SciTePress

2 ROBOT ARCHITECTURE

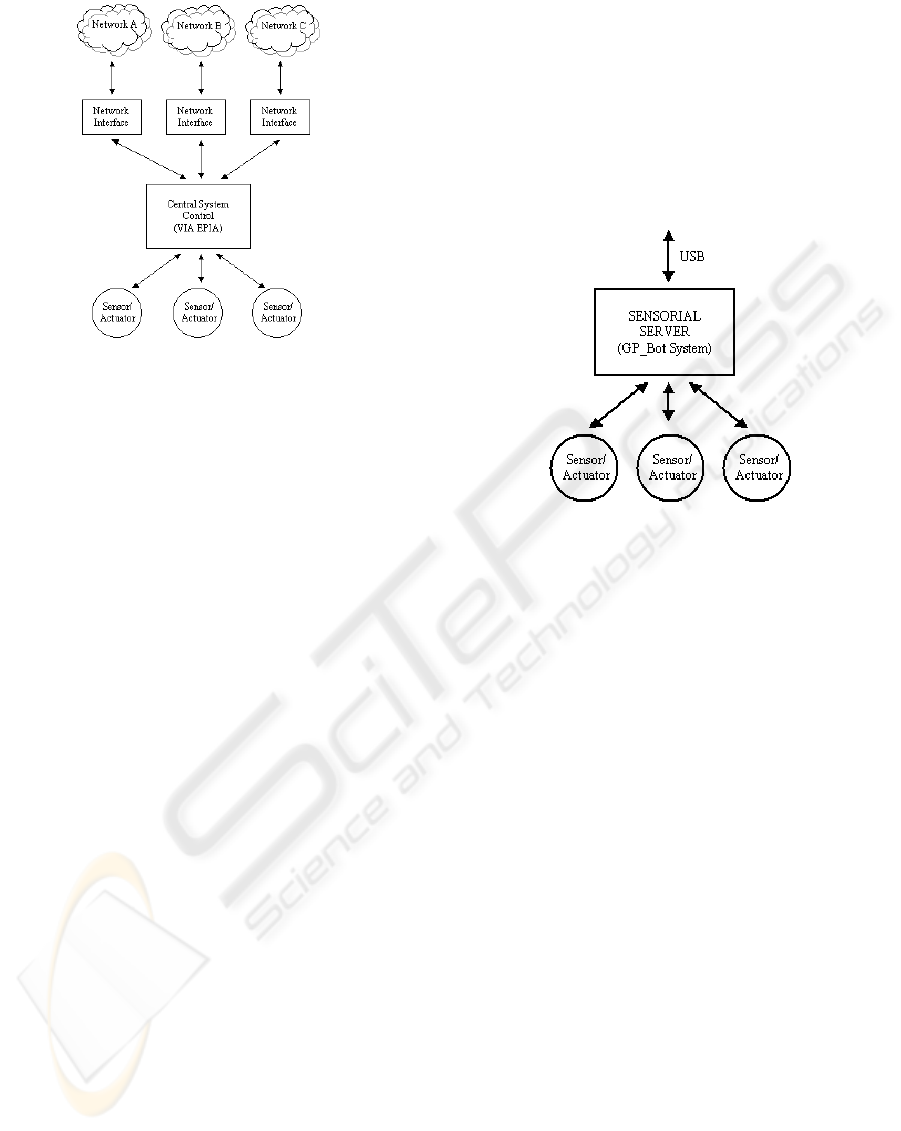

A scheme of the system is showed in Figure 1.

Basically, each robot acts as a server. A set of clients

can query and command the robots. The clients can

be installed in the robots itself. The communication

server-server or client-server, can be done using

Internet or another type of private network.

Figure 1: System architecture

If given client does not support some of the

conventional data physical transport media, the

platform allows to use a bridge.

The client can be any device that supports

TCP/IP, like PC, PDA, mobile telephone, embedded

system, etc.

Considering the robot as hardware architecture,

the robot is a mechanical structure with traction

system, set of sensors e.i. ultrasounds/infrared

proximity sensors, end-race switches, camcorder,

microphone, etc.. All components are controlled by

a microprocessor that also supports the external

communications.

It is important to point out the flexibility of the

hardware structure, derived from:

a) The simple way to add new devices. The designed

software platform allows changing or adding any

hardware element with USB connection.

b) The possibility of establishing a communication

with the robots by means of different physical

media. Due to the capacity of the robots to choose

the most suitable media for each situation and the

ability to use redundancy of the media, the reliability

of the communications is high.

c) The control and data acquisition is possible from

any devices that have Internet connection, suitable

client application and adequate permissions.

The system has a set of predefined control

primitives to facilitate to the user low level operation

as for example, to advance straight, left or right, to

take and send a video frame, and similar.

The aim of the platform is to offer to the final

user a hardware solution for implementing any

application or algorithm. The platform offers to the

user a real hardware system that he can manage as

call functions to an especial software library.

These functions are defined in any part of the

code and the arguments of then will be for example

the robot IP address, identifying the physical

communication media chosen, or any parameter to

select a determinate sensor system predefined in the

robot.

2.1 Physical structure

The chassis is formed with aluminium profiles

forming rigid enough structure that allow fixing of

all necessary elements.

The traction mechanism was chosen to be a

system of rubber wheels, two driving rubber wheels

and a third rubber "crazy" wheel.

Each driving wheel is connected to a powerful

step motor that allows fine control of the robot

position.

In order to obtain that fine control and to release

the main controller from this time-consuming task,

the motors are handled by dedicated microprocessor

(PMD 2002) and run their own specially designed

Linux driver. The access to this driver is made by

means of USB protocol.

2.2 Central control system

The central control system is based on the well-

known PC architecture. The motherboard is a VIA

EPIA M10000 (VIA 2000), based on the

microprocessor Via C3/EDEN and running under

Linux operating system.

The communications are implemented using large

number of network elements, such as Ethernet,

wireless, parallel and serial ports, USB, bluetooth,

GSM/GPRS and radio in the band of 433MHz or

868MHz. Wireless is designed as principal

connection mode, because is the one that better

adjusts most of the necessities. The other methods

have been included in order to improve and

generalize the system as well as to add

communication redundancy.

The internal connections of different elements,

such as sensors or actuators, use exclusively USB

ports, because this interface is supported by the most

of peripheral devices. USB devices are low cost and

they do not need any additional power source.

A block diagram of the control structure can be

observed in Figure 2.

ICINCO 2005 - ROBOTICS AND AUTOMATION

460

Figure 2: Block diagram of control structure

2.3 Robot state manager

This hardware element is mounted on the structure

of the robot and allows independent real-time

monitoring of the robot’s state, as for example the

current communication physical media, the state and

values of the connected sensors, the battery state,

power consumption of different modules, etc.

The state manager is implemented using the

GP_Bot Platform (Glez. de Rivera, 2002) connected

to the mainboard by serial port. Data are displayed

in a 128x64 graphic LCD screen (Ampire AG-

12864EYIQY-00). Screen menus are accessed by

means of a button set.

2.4 Sensorial server

A platform based just on PC is not flexible enough

for all propose as Input/Output processing. So we

developed a method to upgrade it introducing

external elements in a simple and standard way. The

external element, normally, will be composed by a

control element with sensors/actuators. In some

cases a specific sensor needs more attention of the

CPU. In these cases small autonomous control

systems, named sensorial servers (SS), are designed.

The SS are based on a microcontroller that attends

the sensor-effectors demands without occupying the

central unit (Figure 3).

In order to standardize the operation of the

sensorial servers, a communication protocol with the

central control has been defined.

In each one of these servers, an application that

attend demands of the central control is running. The

connection between the control central and the

server is made trough an USB port.

Most of the sensors/actuators are designed for

working using serial communications like RS232,

but in the other hand, a normal PC have just up to 4

serial ports. To solve this we propose that the RS232

communication goes over a USB communication

using USB UARTS. They support speeds up to 3M

bauds, what is enough for most applications. Also,

because they work through USB interface, up to 127

sensorial servers can be connected for each USB

port.

Figure 3: Block diagram of the sensorial server

In general, there are two ways to connect SS:

developing a protocol for each particular SS or

developing a standard SS protocol. If we choose the

former way, the hardware expert will have to

develop a driver and its interface. The later method

gives clear advantages in the development process

and makes the programs more simple and uniform.

We restrict the parameters of interface calls to

several primitive types, as integers and strings in

order to make the interface as simple as possible.

One of the reasons to do so is because at least some

of the functions of the interface have to be

implemented in hardware.

The communications with SS appear to the

central unit as a set of function calls. In each

functions a set of input and output arguments are

defined.

One important condition of these protocols is the

reflection activity; that means that the protocol have

to list all the defined functions supported by the SS.

With this capacity, when a new SS is connected to

the main control, this control or any client connected

to the robot trough the net, can know and use them.

In the basic robot architecture a set of predefined

SS, based on the previous mentioned GP_Bot

platform is included.

Due to the open design of the platform, any user

can include any kind of new sensor, directly o

trough a microprocessor based server with the only

condition of to be adapted to the previous declared

protocol.

HARDWARE INDEPENDENT ARCHITECTURE FOR AUTONOMOUS COLABORATIVE AGENTS

461

2.5 Speech synthesis and recognition

The robot’s architecture includes a set of

microphone and speaker, as speech system sensor

for two main reasons:

As a remote speech server, to record and transmit

sounds produced in the robot’s surroundings and to

reproduce speech messages received trough the net.

As an element for advanced research in the area

of human computer interfaces, to recognize human

speech orders, and to synthesize robot speech

answers.

3 CONCLUSIONS

As final result of this work a set of robots has been

designed. One of them is showed in the Fig. 4a &

4b, has the following characteristics:

a) Main control: mainboard VIA EPIA M10000

b) Sensorial servers: GP_Bot platform

c) Network interfaces: Wireless, Ethernet, USB

d) Two stepping motors (SST58D3820 model),

controlled by a motor processor (PDM).

e) Four Infrared sensor (Sharp GPD2D12).

f) Two Ultrasound sensor (SRF04).

We have developed new drivers for other types of

sensors as pyrometers, wet sensors or gas sensors.

Figure 4a: Image of the robot

Figure 4b: Image of the robot without top

REFERENCES

Dissanaike S.; P. Wijkman and M. Wijkman, 2004.

Utilizing XML-RPC or SOAP on an embedded system,

Proc. 24th International Conference on Distributed

Computing Systems Workshops, pp438–440.

Glez. de Rivera G. et al.. 2002. GP_BOT: Plataforma

Hardware para la enseñanza de Robótica en Ing.

Informática. In (TAEE'02). pp67-70. UPGC.

Golovinski A., Yim M., Zhang Y., Eldershaw C., Duff D.,

2004. PolyBot and PolyKinetic System: A modulR

Robotic Platform for education, International

Conference on Robotic & Automation.

Hoopes D., Davis T., Norman K., Helps R., 2003, An

Autonomous Mobile Robot development platform for

teaching a graduate level mechatronics course. 33

rd

ASEE/IEEE Frontiers in Education Conference.

Navarro L., et al., 2002. Millibots. The development of a

framework and algorithms for a distributed

heterogeneous robot team. In IEEE Robotic and

Automation Magazine, vol 2, no 4, pp 31-40.

PDM-MC3410 Pilot Motion Processor

Sibley G.T., Rahimi M.H., Sukhatme G.S., 2002.

Robomote : a tiny mobile robot platform for large-

scale ad-hocsensor networks. IEEE, Robotics and

Automation. ICRA’02, pp 1143-1148.

VIA Technologies Inc,

http://www.viavpsd.com/product/

Wang D.; X. Ma and X. Dai, 2004. Web-based robotic

control system with flexible framework. Proc. ICRA

'04. IEEE International Conference on Robotics and

Automation, Volume: 4, pp:3351-3356.

Wang X.; M. Moallem and R.V. Patel. 2003. An Internet-

based distributed multiple-telerobot system. IEEE

Transactions on Systems, Man and Cybernetics, Part

A, Vol:33, Issue: 5, Sept. 2003, pp:627 – 634.

XML-RPC

http://www.xmlrpc.com/

ICINCO 2005 - ROBOTICS AND AUTOMATION

462