KINEMATIC MODELING OF STEWART-GOUGH PLATFORMS

Pedro Cruz, Ricardo Ferreira

Institute for Systems and Robotics

Av. Rovisco Pais 1, 1049-001 Lisboa, Portugal

Jo

˜

ao Silva Sequeira

Instituto Superior T

´

ecnico

Institute for Systems and Robotics

Av. Rovisco Pais 1, 1049-001 Lisboa, Portugal

Keywords:

Parallel robots, Direct kinematics, Inverse kinematics.

Abstract:

This paper describes a method to solve the direct kinematics of a generic Stewart-Gough manipulators. The

method is formulated in terms of a search in the space of rigid body transformations. The underlying idea is

that the solutions of the direct kinematics can be obtained by moving the end-effector body according rotations

and translations and accounting for the rigidity conditions.

The paper presents simulation results for a 6-3 Stewart-Gough robot.

1 INTRODUCTION

This paper presents a method to solve the direct kine-

matics of Stewart-Gough robots. This work aims at

assessing the use of numerical algorithms for a real

time application to the control of such robots.

The use of parallel robots undergoes a renewed in-

terest nowadays due to the variety of possible practi-

cal applications. Parallel robot structures can be de-

signed which are specially tailored to handle heavy

loads with accurate positioning. Roughly, position-

ing errors in serial kinematic chains tends to propa-

gate additively throughout the chain links. This is not

the case with parallel manipulators, which are con-

sequently capable of performing positioning tasks to

a high degree of accuracy. Furthermore, the paral-

lel structure inherently distributes the forces/torques

by the actuators giving this class of robots high band-

width dynamic characteristics. Typical applications

include flight simulators, shaking tables (used in sim-

ulation of the effects of earthquakes in building struc-

tures), support structures for the accuracy position-

ing of instrumentation, medical instrumentation and

even entertainment devices (see for instance (Merlet,

2000)).

The generic Stewart-Gough platform is composed

of two rigid bodies connected through a number of

prismatic actuators as in a parallel arrangement of

kinematic chains. Usually six actuators are used,

pairing arbitrary points in the two bodies. The

linkages between the actuators and the bodies are

made through non-actuated universal or ball-in-socket

joints.

Figure 1 presents a Lego-based physical model of a

Stewart-Gough platform with six connecting rods of

fixed length in place of the linear actuators.

Figure 1: A Stewart-Gough platform model constructed us-

ing Lego

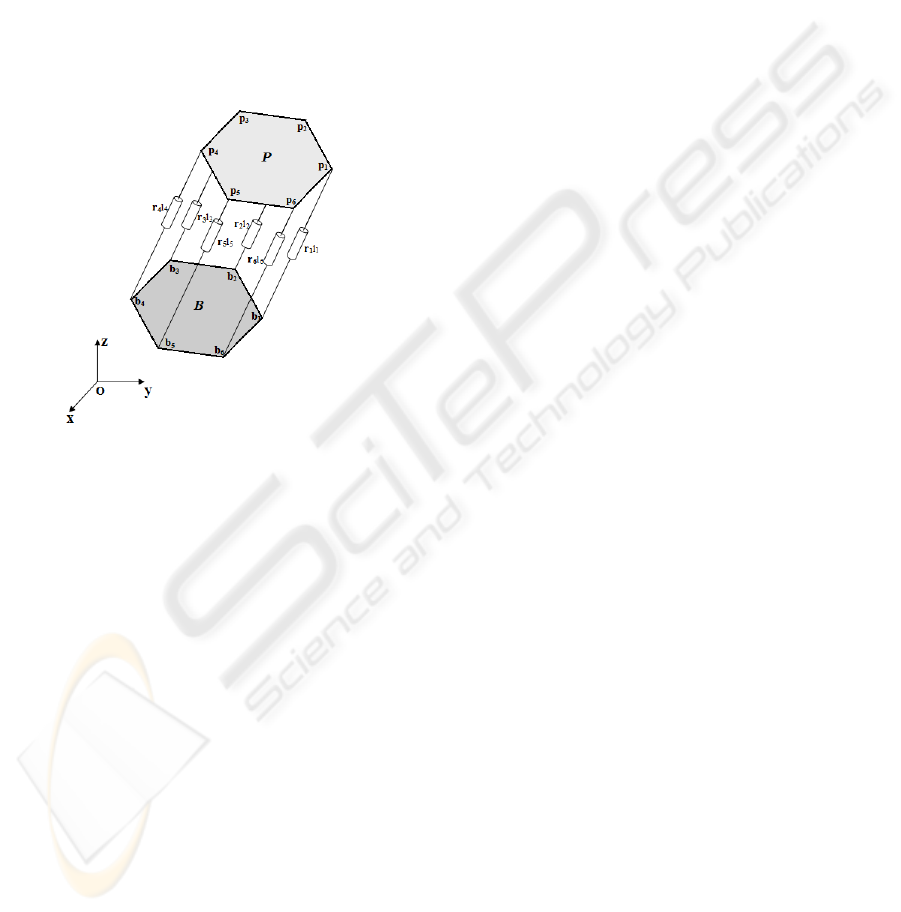

Figure 2 illustrates the terminology used in the paper.

The two bodies are denoted by B and P and the linear

actuators connect them at the anchor points denoted

by {b

1

,...,b

6

} and {p

1

,...,p

6

}, respectively in B

and P . For the sake of simplicity, the polygonal line

joining the b

i

points and the polygonal line joining

the p

i

points, are assumed to form simple polygons.

In the sequel B is assumed to be rigidly connected

93

Cruz P., Ferreira R. and Silva Sequeira J. (2005).

KINEMATIC MODELING OF STEWART-GOUGH PLATFORMS.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 93-99

DOI: 10.5220/0001189900930099

Copyright

c

SciTePress

to the ground, as the base of the robot. The body

P moves according to the joint values and the kine-

matic constraints. The actuator lengths are denoted

by l

i

,i=1,...,6. The i-th actuator connects the

points b

i

and p

i

and has length l

i

.

Unlike serial manipulators, the direct kinematics of

generic parallel manipulators can not be easily writ-

ten in closed form. Numerical methods are often used

to determine the position and attitude of the P body

from the set of joint variables (the lengths of the actu-

ators).

Figure 2: A generic Stewart-Gough platform

The direct kinematics of a generic Stewart-Gough

platform has often multiple solutions. For instance,

the general Stewart-Gough platform can have 40 real

solutions, (Dietmaier, 1998). Practical applications of

direct kinematics, e.g, in robot control architectures,

often require a one to one correspondence between

subsets in the spaces of joint variables and positions

and attitudes. Therefore, a relevant aspect in the study

of the kinematics of parallel robots is related with the

ability of the kinematics solution methods to converge

to a particular solution.

Various approaches to the computation of the kine-

matics of Stewart-Gough robots have been presented

in the literature. In (Jakobovi

´

c and Budin, 2002) the

direct kinematics problem is addressed by solving six

optimization problems, one for each actuator. Algo-

rithms like Powell’s method, Hooke-Jeeves’, steep-

est descent with constant update steps and Fletcher-

Powell’s were used to solve those problems. The di-

rect kinematics is also addressed as an optimization

problem in (Hopkins, 2002), solved using a Newton-

Raphson method. The work in (Hopkins, 2002) is

integrated in a control architecture. A hybrid strat-

egy using neural networks and Newton-Raphson tech-

niques is proposed in (Parikh and Lam, 2005). In this

strategy the neural network stage is used to obtain the

initial estimate for the Newton-Raphson method. Dy-

namic modeling, a fundamental aspect for high per-

formance control, has been addressed in (Khalil and

S., 2004).

This paper presents an algorithm that describes the

motion of the P body as a rigid body transforma-

tion, i.e., through rotations and translations. Newton’s

method is used to compute the rigid body transforma-

tion matrix that corresponds to the desired solution

of the direct kinematics of Stewart-Gough platforms.

Simulation results are obtained from one special class

of Stewart-Gough platform 6-3/\

3

configuration (the

notation in (Merlet, 2000) is followed hereafter to de-

scribe the organisation of the actuators in the robot).

The direct kinematics problem is formalized as an

optimization problem and simulation results obtained

are presented.

The paper is organized as follows. Section 2 de-

scribes the direct kinematics problem (the inverse

kinematics is trivial) in the space of rigid body trans-

formations. Section 3 describes a set of simulation

experiments. Section 4 presents the conclusions of

the paper and ongoing work.

2 KINEMATICS MODELING

Table 1 details the notation used in the paper to for-

mulate the kinematics of the robot.

Table 1: Notation used in the paper

l

i

a scalar standing for the i-th

actuator length

p

i

=(p

x

i

,p

y

i

,p

z

i

) point in R

3

belonging to P

b

i

=(b

x

i

,b

y

i

,b

z

i

) point in R

3

belonging B

r

i

unit vector in R

3

¯p

i

the “usual” inclusion of p

i

in the projective space P

3

q

i

representation of point p

i

described in a local refer-

ence frame (see Figure 3)

Figure 3 illustrates relations between the coordi-

nate reference frames assigned to the rigid bodies that

form the robot.

Assuming the rigidity of the two bodies B and P ,

the kinematics of the robot is completely described by

the set of equations,

ICINCO 2005 - ROBOTICS AND AUTOMATION

94

Figure 3: Relations between reference frames

(p

x

i

− b

x

i

)

2

+(p

y

i

− b

y

i

)

2

+(p

z

i

− b

z

i

)

2

= l

2

i

,

i =1,...,6 (1)

meaning that, for any actuator, any achievable config-

uration must lie in a 2D ball embedded in R

3

.

Expanding the square terms in the lefthand side of

(1) the expression can be written as

¯p

T

i

C

i

(b

i

,l

i

) ¯p

i

=0,i=1,...,6 (2)

where C

i

is a matrix relating the i-th actuator and the

B body defined as

C

i

=

⎡

⎢

⎣

100 −b

x

i

010 −b

y

i

001 −b

z

i

−b

x

i

−b

y

i

−b

z

i

b

T

i

b

i

− l

2

i

⎤

⎥

⎦

(3)

The solution of the direct kinematics problem ex-

pressed by (2) can be obtained by moving the P body

in the 3D space. This amounts to finding the adequate

rotation and translation such that (2) has a solution.

Alternatively, this can also be seen as finding a new

reference frame where to describe the p

i

solutions of

(2), that is,

¯p

i

= T¯q

i

(4)

where ¯q

i

describes ¯p

i

in a local reference frame and

T ∈ SE(3) is the homogeneous transformation ma-

trix given by

T =

Rt

0 1

(5)

with R standing for a rotation matrix and t standing

for the displacement between the origins of the two

reference frames. Equation (2) can then be written as

¯q

T

i

T

T

C

i

(b

i

,l

i

) T¯q

i

=0

i =1,...,6 (6)

In addition, it is also necessary to ensure that the

structure of of the elements in T is preserved, namely

that R ∈ SO(3). Given the homogeneous structure of

(6) this condition can be relaxed to R ∈ O(3) yield-

ing the following 9 additional constraints,

R

T

R = I

3

⇐⇒ [

I0

] T

T

I

0

[

I0

] T

I

0

= I

3

⇐⇒ I

3×4

T

T

DTI

4×3

= I

3

All the 15 restrictions have the general form

g

i

(T)=a

i

T

T

T

C

i

Tb

i

− d

i

=0 (7)

and hence the solution of the forward kinematics

amounts to find a solution for a non-linear system of

15 equations and 12 unknowns.

Expression (7) is thus the formulation of the di-

rect kinematics problem in the space of homogeneous

transformations.

2.1 Solution by Newton’s method

To obtain a solution of (7) the g

i

(T) is expanded in

Taylor series, retaining only the first order terms,

g

i

(T + H)=g

i

(T)+

(∇g

i

)

T

T

vec (H)+O( vec(H)

2

) (8)

where ∇ denotes the gradient, vec denotes the vector

operator that stacks the columns of H to form a vector

and

∇g

i

|

T

= vec(C

i

Tb

i

a

i

T

+ C

i

T

Ta

i

b

i

T

) (9)

Note that not all entries of T are variables, so 4 entries

of the gradient vector need be removed.

Discarding the terms of higher order results in a

linear system of 15 equations, compactly written as

g(T + H) ≈ g(T)+ Jg|

T

vec(H) (10)

where Jg|

T

=[∇g

1

|

T

,...,∇g

15

|

T

]

T

denotes the

jacobian matrix of g which depends on the current

value of the argument being searched, that is the rigid

body transformation T.

The solution of the direct kinematics problems in

this space of transformations is obtained when a mo-

tion in this space, expressed by the Jacobian matrix,

KINEMATIC MODELING OF STEWART-GOUGH PLATFORMS

95

verifies the constraints (7), that is, g(T + H)=0,

which yields the system

Jg|

T

vec(H)=−g(T) (11)

Expression (11) indicates that, starting at some ini-

tial configuration the motion of the P body to T + H

results in an approximate for the solution of the sys-

tem (recall that the higher order terms in (8) were dis-

carded). By repeating this process for the obtained

approximate solution the sequence of transformation

converges to the solution of the direct kinematics.

Note that the Jacobian is overdetermined and thus a

pseudo-inverse must be used.

3 SIMULATION RESULTS

This section presents simulation experiments that il-

lustrate the solution of the direct kinematics of a 6-3

/\

3

robot using the proposed algorithm. In all sim-

ulations the initial transformation matrix is

T

initial

=

⎡

⎢

⎣

1000

0100

0011

0001

⎤

⎥

⎦

3.1 Experiment 1

Table 2 presents the values used as initial conditions

by the algorithm. For this experiment, the actuator

values were set at l

1

=2, l

2

=2, l

3

=2.5, l

4

=2.5,

l

5

=2and l

6

=2.

Table 2: Experiment 1: Initial values

Act. l

i

p

i

b

i

r

i

(0.7500 (0.5000 (0.2236

1 1.1180 -0.4330 -0.8660 0.3873

1.0000) 0.0000) 0.8944)

(0.7500 (1.0000 (-0.2236

2 1.1180 -0.4330 0.0000 -0.3873

1.0000) 0.0000) 0.8944)

(0.0000 (0.5000 (-0.4472

3 1.1180 0.8660 0.8660 -0.0000

1.0000) 0.0000) 0.8944)

(0.0000 (-0.5000 (0.4472

4 1.1180 0.8660 0.8660 -0.0000

1.0000) 0.0000) 0.8944)

(-0.7500 (-1.0000 (0.2236

5 1.1180 -0.4330 0.0000 -0.3873

1.0000) 0.0000) 0.8944)

(-0.7500 (-0.5000 (-0.2236

6 1.1180 -0.4330 -0.8660 0.3873

1.0000) 0.0000) 0.8944)

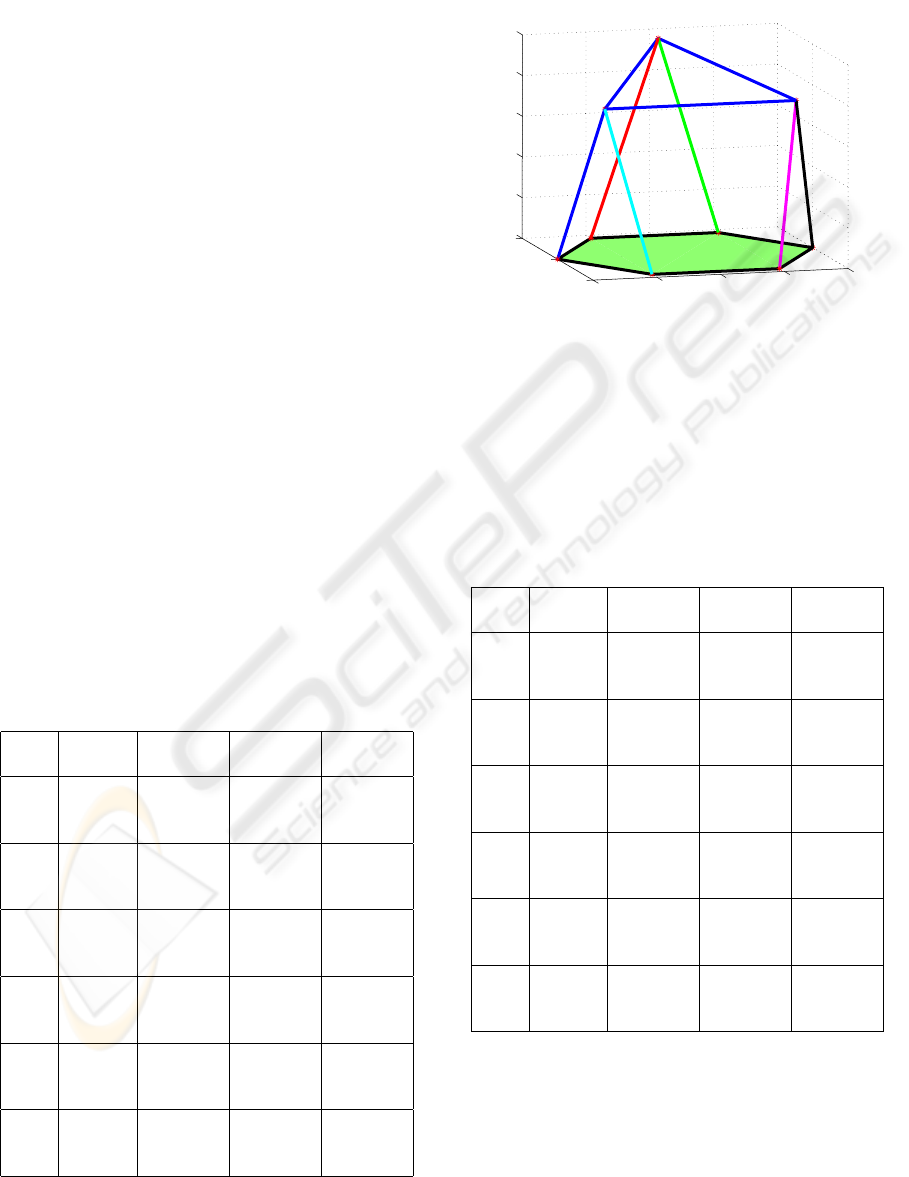

Figure 4 displays the robot at the final configuration

obtained.

−1

−0.5

0

0.5

1

−1

0

1

0

0.5

1

1.5

2

2.5

X

Y

Z

b

1

b

2

b

3

b

4

b

5

b

6

p

1

=p

2

p

3

=p

4

p

5

=p

6

r

1

l

1

r

2

l

2

r

3

l

3

r

4

l

4

r

5

l

5

r

6

l

6

Figure 4: Experiment 1: Final configuration

The algorithm was stopped after 5 iterations, with

a final absolute error of 7.5675 × 10

−11

. Table 3 dis-

plays the lengths of the actuator rods, along with the

corresponding positions of the connecting points in

the P body.

Table 3: Experiment 1: final results

Act. l

i

p

i

b

i

r

i

(0.7500 (0.5000 (0.1250

1 2.0000 -0.4330 -0.8660 0.2165

1.9365) 0.0000) 0.9682)

(0.7500 (1.0000 (-0.1250

2 2.0000 -0.4330 0.0000 -0.2165

1.9365) 0.0000) 0.9682)

(0.0000 (0.5000 (-0.2000

3 2.5000 0.7614 0.8660 -0.0419

2.4473) 0.0000) 0.9789)

(0.0000 (-0.5000 (0.2000

4 2.5000 0.7614 0.8660 -0.0419

2.4473) 0.0000) 0.9789)

(-0.7500 (-1.0000 (0.1250

5 2.0000 -0.4330 0.0000 -0.2165

1.9365) 0.0000) 0.9682)

(-0.7500 (-0.5000 (-0.1250

6 2.0000 -0.4330 -0.8660 0.2165

1.9365) 0.0000) 0.9682)

The key point in this experiment is the fast conver-

gence of the algorithm. Figure 5 illustrates, in loga-

rithmic scale, the evolution of the absolute error.

The solution for the optimal rigid body transforma-

tion is given by the matrix

ICINCO 2005 - ROBOTICS AND AUTOMATION

96

1 1.5 2 2.5 3 3.5 4 4.5 5

10

−12

10

−10

10

−8

10

−6

10

−4

10

−2

10

0

10

2

Temporal evolution of the absolute error in logarithmic scale

Absolute Error in logarithmic scale [m]

Iteration

Figure 5: Experiment 1: Temporal evolution of the

quadratic error

T

final

=

⎡

⎢

⎣

1.0000 0.0000 0.0000 0.0000

0.0000 0.9195 −0.3932 −0.0349

0.0000 0.3932 0.9195 2.1067

0.0000 0.0000 0.0000 1.0000

⎤

⎥

⎦

3.2 Experiment 2

Table 4 presents the values used as initial conditions

by the algorithm for this second experiment. The goal

values for the actuators were set at l

1,...,6

=2.

Table 4: Experiment 2: Initial values

Act. l

i

p

i

b

i

r

i

(0.0000 (0.5000 (-0.2425

1 2.0615 0.8660 -0.8660 0.8402

1.0000) 0.0000) 0.4851)

(0.0000 (1.0000 (-0.6030

2 1.6583 0.8660 0.0000 0.5222

1.0000) 0.0000) 0.6030)

(0.7500 (0.5000 (0.1508

3 1.6583 -0.4330 0.8660 -0.7833

1.0000) 0.0000) 0.6030)

(0.7500 (-0.5000 (0.6063

4 2.0615 -0.4330 0.8660 -0.6301

1.0000) 0.0000) 0.4851)

(-0.7500 (-1.0000 (0.2236

5 1.1180 -0.4330 0.0000 -0.3873

1.0000) 0.0000) 0.8944)

(-0.7500 (-0.5000 (-0.2236

6 1.1180 -0.4330 -0.8660 0.3873

1.0000) 0.0000) 0.8944)

The final robot configuration obtained from this

simulation is presented in Figure 6.

−1

−0.5

0

0.5

1

−1

−0.5

0

0.5

1

0

0.5

1

1.5

2

X

Y

Z

b

1

b

2

b

3

b

4

b

5

b

6

p

1

=p

2

p

3

=p

4

p

5

=p

6

r

1

l

1

r

2

l

2

r

3

l

3

r

6

l

6

r

4

l

4

r

5

l

5

Figure 6: Experiment 2: Final configuration

The algorithm was stopped after 20 iterations, with

a final absolute error of 2.0054 × 10

−8

. Table 5 dis-

plays the lengths of the actuator rods, along with the

corresponding positions of the connecting points in

the P body.

Table 5: Experiment 2: Final values

Act. l

i

p

i

b

i

r

i

(-0.8017 (0.5000 (-0.6509

1 2.0000 0.4629 -0.8660 0.6644

0.7346) 0.0000) 0.3673)

(-0.8017 (1.0000 (-0.9009

2 2.0000 0.4629 0.0000 0.2314

0.7346) 0.0000) 0.3673)

(0.0000 (0.5000 (-0.2500

3 2.0000 0.8660 0.8660 0.0000

1.9365) 0.0000) 0.9682)

(0.0000 (-0.5000 (0.2500

4 2.0000 0.8660 0.8660 0.0000

1.9365) 0.0000) 0.9682)

(-0.7500 (-1.0000 (0.1250

5 2.0000 -0.4330 0.0000 -0.2165

1.9365) 0.0000) 0.9682)

(-0.7500 (-0.5000 (-0.1250

6 2.0000 -0.4330 -0.8660 0.2165

1.9365) 0.0000) 0.9682)

As in the previous experiment, the algorithm con-

verges in an acceptable number of iterations. Figure

7 shows the temporal evolution of the error.

For this experiment, the matrix that corresponds to

the solution of the optimal rigid body transformation

is

KINEMATIC MODELING OF STEWART-GOUGH PLATFORMS

97

0 5 10 15 20

10

−8

10

−6

10

−4

10

−2

10

0

10

2

10

4

Temporal evolution of the absolute error in logarithmic scale

Absolute Error in logarithmic scale [m]

Iteration

Figure 7: Experiment 2: Temporal evolution of the

quadratic error

T

final

=

⎡

⎢

⎣

0.5000 −0.3285 −0.8013 −0.5172

0.8660 0.1897 0.4626 0.2986

0.0000 −0.9253 0.3793 1.5358

0.0000 0.0000 0.0000 1.0000

⎤

⎥

⎦

3.3 Experiment 3

The 6 − 3

/\

3

structure considered in the experi-

ments is known to have 16 real solutions. In general,

these solutions differ significantly from each other.

Therefore, when targeting control applications it is

important to determine the sensitivity of a particular

solution to the initial condition. This is illustrated by

comparing this experiment with experiment 2.

In this experiment the values for the actuator are

set identical to those in experiment 2 but with the ini-

tial position of the P body slightly changed. Table 6

displays the data for this experiment.

Figure 8 illustrates the final configuration of the ro-

bot which is clearly different from that obtained in

experiment 2.

The algorithm was stopped after 4 iterations, with a

final absolute error of 1.052 × 10

−7

. Table 7 displays

final data obtained in this experiment.

Figure 9 shows the time evolution, in logarithmic

scale, of the error.

For this experiment, optimal rigid body transforma-

tion matrix is given by

T

final

=

⎡

⎢

⎣

1.0000 0.0000 0.0000 0.0000

0.0000 1.0000 0.0000 0.0000

0.0000 0.0000 1.0000 1.9365

0.0000 0.0000 0.0000 1.0000

⎤

⎥

⎦

Table 6: Experiment 3: Initial values

Act. l

i

p

i

b

i

r

i

(0.7500 (0.5000 (0.2236

1 1.1180 -0.4330 -0.8660 0.3873

1.0000) 0.0000) 0.8944)

(0.7500 (1.0000 (-0.2236

2 1.1180 -0.4330 0.0000 -0.3873

1.0000) 0.0000) 0.8944)

(0.0000 (0.5000 (-0.4472

3 1.1180 0.8660 0.8660 -0.0000

1.0000) 0.0000) 0.8944)

(0.0000 (-0.5000 (0.4472

4 1.1180 0.8660 0.8660 -0.0000

1.0000) 0.0000) 0.8944)

(-0.7500 (-1.0000 (0.2236

5 1.1180 -0.4330 0.0000 -0.3873

1.0000) 0.0000) 0.8944)

(-0.7500 (-0.5000 (-0.2236

6 1.1180 -0.4330 -0.8660 0.3873

1.0000) 0.0000) 0.8944)

4 CONCLUSIONS

The paper presents a solution for the direct kinemat-

ics of a Stewart-Gough robot supported on a Newton

method for the search of a rigid body transformation

that places the moving body (the P body in the termi-

nology used in the paper) in a configuration compati-

ble with the desired actuator lengths. The experimen-

tal results show fast convergence to the solution.

4.1 Ongoing work

Experiments 2 and 3 show the importance of the

initial conditions to the final solution. Future work

includes the analysis of solutions sensitivity to initial

conditions.

High performance applications, namely those re-

quiring the manipulation of heavy loads at large band-

widths, require the knowledge of the dynamics model

in order to design the adequate control strategy.

For a large class of applications, e.g., shaking tables

for seismic simulations, the typical frequency band

goes from 0 up to 20-40 Hz (the typical bandwidth

of a real earthquake). Despite the heavy loads consid-

ered in such applications, the bandwith requirements

do not impose detailed knowledge on the dynamics

of the robot. Thus, the use of control schemes us-

ing direct and inverse kinematics solutions obtained

by methods such as the one proposed in this paper are

acceptable.

For the experiments in Section 3, the algorithm

requires less than 20 ms to reach a solution within

the aforementioned errors (Matlab implementation).

ICINCO 2005 - ROBOTICS AND AUTOMATION

98

−1

−0.5

0

0.5

1

−1

−0.5

0

0.5

1

0

0.5

1

1.5

2

X

Y

Z

b

2

b

1

b

3

b

4

b

5

b

6

p

1

=p

2

p

3

=p

4

p

5

=p

6

r

1

l

1

r

2

l

2

r

3

l

3

r

4

l

4

r

5

l

5

r

6

l

6

Figure 8: Experiment 3: Final Robot Solution

1 1.5 2 2.5 3 3.5 4

10

−7

10

−6

10

−5

10

−4

10

−3

10

−2

10

−1

10

0

10

1

Temporal evolution of the absolute error in logarithmic scale

Absolute Error in logarithmic scale [m]

Iteration

Figure 9: Experiment 3: Temporal evolution of the

quadratic error

Therefore, the upper bound on the bandwith is es-

timated at about 25 Hz (assuming that 20 ms cor-

responds to the sample time), this being compatible

with real time control of a shaking table.

Figure 10 illustrates the control strategy under eval-

uation for the shaking table problem. Instead of hav-

ing the inverse kinematics defining the trajectories for

each actuator, this scheme includes both the direct and

inverse kinematics in the control loop. The advantage

of this procedure is that any modeling errors, e.g.,

those due to inaccurate positioning of the actuators

anchor points in the B and P bodies, are compensated

by the control loop.

ACKNOWLEDGEMENTS

This work was supported Programa Operacional So-

ciedade de Informac¸

˜

ao (POSI) in the frame of QCA

III.

Table 7: Experiment 3: Final values

Act. l

i

p

i

b

i

r

i

(0.7500 (0.5000 (0.1250

1 2.0000 -0.4330 -0.8660 0.2165

1.9365) 0.0000) 0.9682)

(0.7500 (1.0000 (-0.1250

2 2.0000 -0.4330 0.0000 -0.2165

1.9365) 0.0000) 0.9682)

(-0.0000 (0.5000 (-0.2500

3 2.0000 0.8660 0.8660 -0.0000

1.9365) 0.0000) 0.9682)

(-0.0000 (-0.5000 (0.2500

4 2.0000 0.8660 0.8660 -0.0000

1.9365) 0.0000) 0.9682)

(-0.7500 (-1.0000 (0.1250

5 2.0000 -0.4330 0.0000 -0.2165

1.9365) 0.0000) 0.9682)

(-0.7500 (-0.5000 (-0.1250

6 2.0000 -0.4330 -0.8660 0.2165

1.9365) 0.0000) 0.9682)

Figure 10: Control architecture

REFERENCES

Dietmaier, P. (1998). The stewart-gough platform of gen-

eral geometry can have 40 real postures. Advances in

Robot Kinematics: Analysis and Control, pages 1–10.

Hopkins, Brian R., W. I. R. L. (2002). Modified 6-psu

platform. Industrial Robot: An International Journal,

29(5):443–451.

Jakobovi

´

c, D. and Budin, L. (2002). Forward kinemat-

ics of a stewart parallel mechanism. pages 149–154.

Opatija, May 26-28.

Khalil, W. and S., G. (2004). Inverse and direct dynamic

modeling of gough-stewart robots. IEEE Trans. on

Robotics, 20(4):754–762.

Merlet, J. (2000). Parallel Robots. Kluwer Academic.

Parikh, P. and Lam, S. (2005). A hybrid strategy to solve the

forward kinematics problem in parallel manipulators.

IEEE Transactions on Robotics, 21(1):18–25.

KINEMATIC MODELING OF STEWART-GOUGH PLATFORMS

99