REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA

Linking Demand Management with Production Planning

Elias Kirche, Janusz Zalewski

Florida Gulf Coast University, Ft. Myers, FL 33965-6565

Teresa Tharp

Argosy University, Sarasota, FL 34235

Keywords: Real-time planning, CORBA in manufacturing, Demand management.

Abstract: Several existing mechanisms for order processing, such as Available-to-Promise (ATP), Materials

Requirements Planning (MRP), or Capable-to-Promise (CTP), do not really include simultaneous capacity

and profitability considerations. One of the major issues in the incorporation of profitability analysis into

the order management system is the determination of relevant costs in the order cycle, and the real-time

access to production parameters (i.e., target quantities based on current cycle time) to be included in the

computation of planning and profitability. Our study attempts to provide insights into this novel area by

developing a Decision Support System (DSS) for demand management that integrates real-time information

generated by process control and monitoring systems into an optimization system for profitability analysis

in a distributed environment via CORBA (Common Object Request Broker Architecture). The model can

be incorporated into current enterprise resource planning (ERP) systems and dynamic use of real-time data

from various functional support technologies.

1 INTRODUCTION

The well-known Available-to-Promise (ATP)

mechanism is a powerful tool for order promising

and order date negotiation for many firms (Vollman,

Berry and Whybark 1997). ATP links manufacturing

and order management, thus synchronizing

production and sales/marketing activities.

Depending on the information technology used, ATP

implementation can simply use inventory position in

a single location or multiple locations. If the product

ordered is not currently available in any location,

customers may be promised delivery dates based on

when the product can be produced. In the typical

case, an additional materials requirements planning

(MRP) run with the added product demand can

determine a future availability date which then can

be used for order promising. However, as is well

known, MRP uses fixed lead times and does not

consider the current load at the shop level, and

therefore, does not necessarily provide accurate

promise dates.

A more contemporary approach to order

promising is to actually schedule the production in

the current manufacturing system in real-time

scheduling, through an Advanced Planning and

Scheduling (APS) software. This would result in a

more accurate, deliverable order promise date. Real-

time scheduling systems can manage instant priority

shifts when customer requirements or management

objectives change with resulting benefits of reduced

costs, reduced manufacturing cycle time, increased

throughput and better customer responsiveness

(Layden 1994). This concept is currently known as

Capable-to-Promise (CTP).

As far as CTP implementations exist in varying

degrees in practice, real-time CTP is yet to become

an integral part of supply chain management and

optimization. This is mainly due to the complexity

of exchanging information, in real time, between the

order management system, typically used by

customer service representatives, and the production

scheduling system, typically used by

schedulers/MRP controllers.

122

Kirche E., Zalewski J. and Tharp T. (2005).

REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA - Linking Demand Management with Production Planning.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 122-129

DOI: 10.5220/0002528301220129

Copyright

c

SciTePress

While all of the above mentioned approaches

are primarily concerned with the understanding of

existing process constraints and the balancing of the

flow of materials through the production process in

order to meet customer requirements, they do not

consistently utilize profitability analysis as an input

into order promising decisions. Clearly, a truly

effective order management approach should include

both capacity and profitability considerations. This

approach, in practice, is referred to as Profitable-to-

Promise (PTP). PTP is the ability to respond to a

customer order by determining how profitable it is to

accept this order. Successful PTP applications are

the ‘holy grail’ of electronic commerce for

manufacturers and the next avenue for many of the

supply chain management/optimization software

developers.

One of the major issues in the incorporation of

profitability analysis into the order management

system is to determine which costs are relevant, and

to have real-time access of production parameter

(i.e., current cycle time) to be included in the

calculation of planning and profitability. Our study

attempts to provide insights into this novel area by

developing a Decision Support System (DSS) for

demand management that integrates real-time

information generated by process control and

monitoring systems into an optimization system for

profitability analysis in a distributed environment

via CORBA, Common Object Request Broker

Architecture (Bolton 2002). The model can be

incorporated into current enterprise resource

planning (ERP) systems and dynamically use-real

time data from various functional support

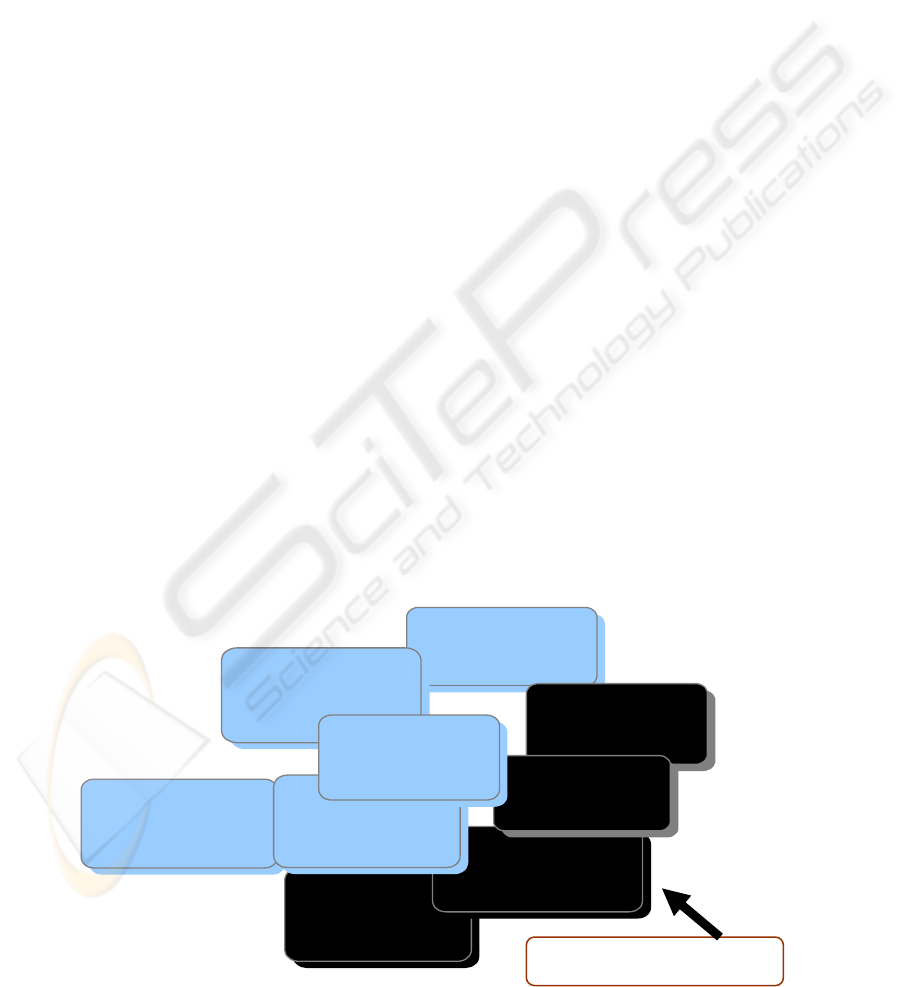

technologies as indicated in Figure 1.

2 THE DECISION SUPPORT

SYSTEM FOR DEMAND

MANAGEMENT

Many manufacturing environments use MRP,

material resource planning (MRPII) or ERP systems

for medium term planning. Such systems divide the

planning horizon into discrete time buckets and

require a medium term production plan for several

future time buckets, which is used to provide due

dates and release dates for detailed production

scheduling. Previous attempt to address an effective

sales and operations planning (S&OP) strategy to

react to changes in the demand has been difficult,

since there has been a lack of real-time information

concerning system status (Ovacsik and Uzsoy 1994).

However, the advent of computerized

information systems capable of tracking job and

machine status in real time has changed this

situation, and real-time performance measurement is

the next frontier of operational excellence. In many

of the process industries, information is generated in

real time by process control computers. In discrete

parts manufacture, computer systems for the entry

and distribution of data, such as video display units

and bar code scanners, are placed at various

locations on the shop floor, to record information

concerning the location and status of jobs and

resources, and to display this information for control

purposes. Feedback can be generated from several or

all work centers to track jobs and update their

progress. This technology is comparatively cheap

and very effective in many businesses and

manufacturing applications (Castillo 2001; Singh

2002).

Order

Fulfillment

Purchasin

g

Purchasing

Proces

s

Contr

ol

Proces

s

Contr

ol

Deman

d

Managemen

t

Demand

Management

MES

MES

Inventor

y

Managemen

t

Inventory

Management

MR

P

MRP

Plannin

g

Planning

Schedulin

g

Scheduling

Model Scope & Linkage

Figure 1: Model Interface with Enterprise Resource Systems (ERP)

REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA: Linking Demand Management with Production

Planning

123

Real-time data are commonly used to improve

estimated values of processing parameters, such as

processing time or worker performance (Steele et al.

2001), but rarely used for demand management and

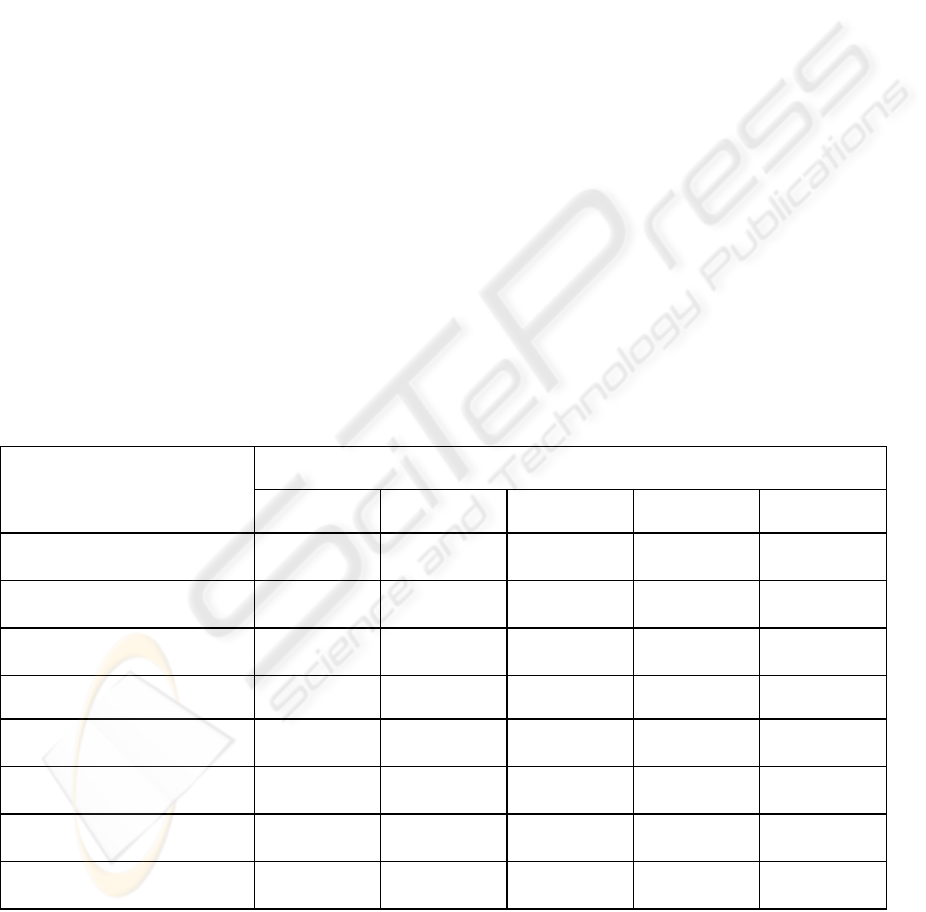

profitability analysis. In this study, we apply a DSS

for distributed environment utilizing CORBA to

interface with production, sales and financial

application technologies as shown in Figure 2.

The operational system continuously tracks

processing time at work centers and uploads

information to an operational data server,

performing immediate computations and display of

the production target based on current cycle time.

With instantaneous network access for monitoring

and reporting, it broadcasts production information

in real time to the entire factory floor. Concurrently,

the financial server maintains current cost and price

information on raw material, work center costs,

inventory, and other pertinent accounting data. An

advanced planning system (MIMI®, from Aspen

Technology Inc.) containing an optimizer module

(CPLEX) downloads on demand up-to-date

information from both operational and financial

servers via CORBA for evaluation and allocation of

resources to meet customer order request in the most

efficient manner.

The request can be made from various levels at

the organization but the primary use is in the support

sales for demand management to increase

profitability. The goal of the real-time system is to

dynamically integrate end-to-end processes across

the organization (key partners, suppliers and

customers) to respond with speed to customer

changes and market requirements. The real-time

CORBA framework enables employees to view

current process capability and load on the system

and provide immediate information to customers.

The decision to employ CORBA is based on its

importance in complex control systems (Sanz and

Alonso 2001) and the integration capabilities it

offers for real-time and embedded systems (Sanz

2003). The CORBA open system has vast resource

scalability and potentially can serve an unlimited

number of players and virtually any number of

manufacturing processes and partners in the

production environment. It provides an integrated

view of the production process for an efficient

demand management. Other benefits include

continuous availability, business integration,

resources availability on demand, and worldwide

accessibility.

Figure 2: Process Description – Distributed Service

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

124

The optimizing server uses a mixed integer

program (MIP) to plan order and optimize resource

allocation to maximize profits as orders arrive in

each period. Orders are for different products,

quantities and for a specific due date. If the order is

unfeasible for the current production period (that is,

cannot be produced without delaying a previously

accepted order) it will have to be renegotiated with

the customer (in real time) for a later due date or a

reduced order that can fit in current production.

The optimizer accesses current production

parameters from the operational server to plan and

schedule accepted orders for the next production

horizon. Typically in productions systems,

unforeseen events such as unscheduled down times,

production losses, change orders, bottleneck

constraints, and other issues make difficult the

synchronization of planning and scheduling of work

centers. However, the integration and enterprise

visibility created by the real-time demand

management system will tune resourses and balance

workloads to maximize production efficiency and

adapt to dynamically changing environment.

3 CASE STUDY

The manufacturing environment consists of a firm

that has limited production capacity geared to

produce multiple product lines. Products within

each line are processed in batches of varying sizes

according to the demand load. Production

comprises of a sequence of activities with processing

times that may change with load and manufacturing

conditions such as unscheduled downtime. The

production activities are of two types:

1) a sequence of activities common to all product

lines, and

2) a sequence of activities specific to each

product line. Each product line includes several

variations (of finished goods).

The common activities precede the product line-

specific activities and take place in the Common

Part Cell (CPC). The final assembly cells (P

i

C),

where i sub-index denotes the product line, are

specific to product line and product lines assume

different identities only after product line-specific

activities are performed in their respective final

assembly cells. Any accumulation of inventory

(WIP) between the common and product line-

specific activities comprise of a homogeneous

intermediate product (Common Part – CP). This

production environment is depicted in Figure 3 and

is similar to those used in other studies (O’Brien

1996; Umble et al. 2001).

Production takes place under a demand-pull

system, i.e., a customer order initiates production

activity - the processing of raw material (RM) and

subsequent processing at the common and product

line-specific cells. If there is excess work in process

(WIP) inventory (of the CP), no production activity

is initiated in the CPC; the required CP quantity is

transferred to the specific product line-cell. We

assume that there were no delays for moving parts

and/or raw materials among cells. If there is

sufficient finished goods inventory to cover an order

request, production is not initiated. Inventory exists

because one batch (or multiple batches) may be

greater than the order quantity, and the units

produced in excess of order quantity are placed in

stock. The capacity utilization level for each cell is

set as suggested in (Yang and Jacobs 1999).

RM

Common

PartCell

(CPC)

P1 Workcell

(P1C)

P2 Workcell

(P2C)

P3 Workcell

(P3C)

P4 Workcell

(P4C)

Part B

Common

Part (CP)

Inventory

P1 Inventory

P2 Inventory

P3 Inventory

P4 Inventory

Figure 3: Manufacturing Process Flow

REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA: Linking Demand Management with Production

Planning

125

The manufacturing time and cost parameters are

downloaded on demand in an advanced planning

system, MIMI®, Manager for Interactive Modular

Interface, Version 5.0 (from Aspen Technology,

Inc), which is utilized to optimize the production

scheduling. Reports can be generated for current

demand load, production sequence and profits.

4 PRODUCTION PARAMETERS

The production environment is for a supply chain

composed of several suppliers of raw material

serving a single plant and materials are delivered

assuming instantaneous lead-time. Within the plant,

there are several overhead activities to support

production, engineering, purchasing and marketing

operations. Order arrival rates (λ) and order size (q)

are set relative to an average capacity of the

Common Part Cell (CPC) to produce the common

part (CP), making the CPC cell the production

bottleneck by design. Yang and Jacobs (1999)

suggested a capacity utilization rate of 72% per

period without set time. In this research, we

designed the run time capacity (practical capacity)

for all work cells at 6 hours per period.

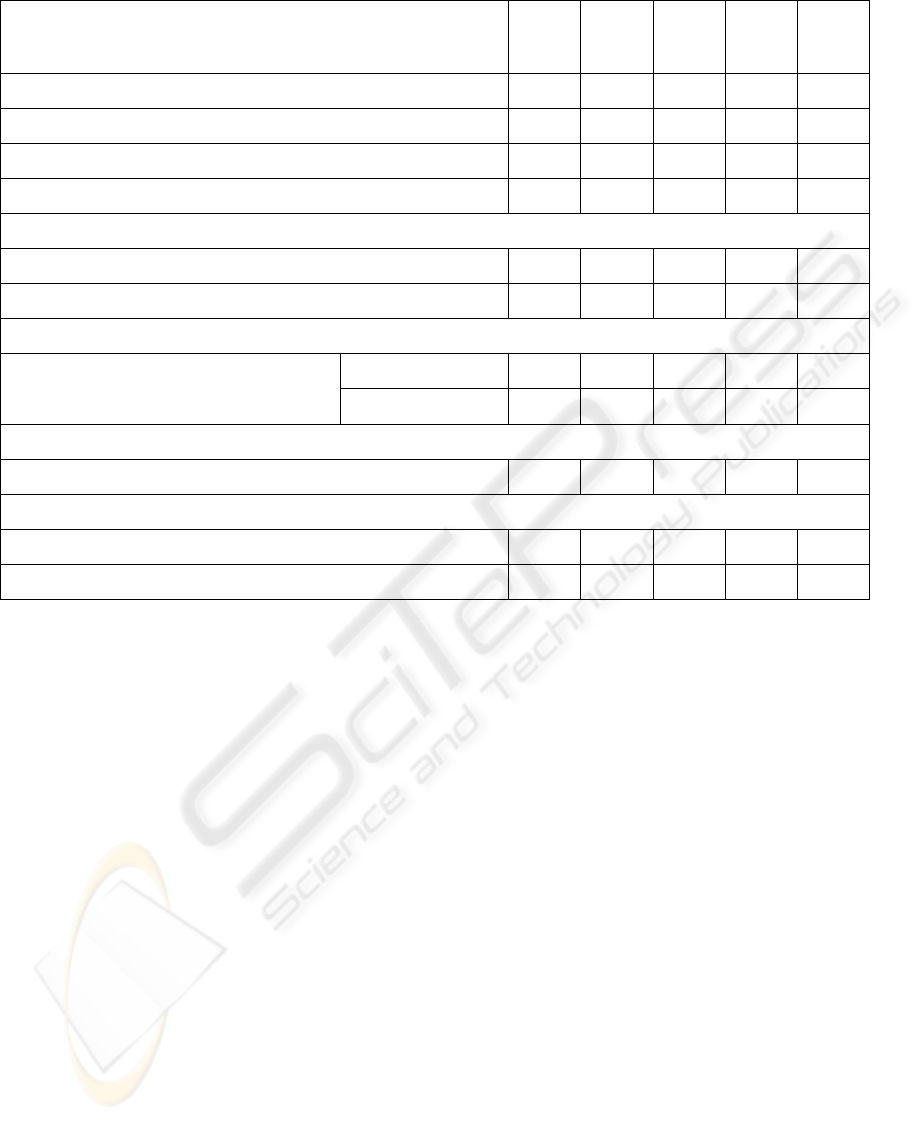

Table 1 indicates the parameters associated with

each cell and product type. Product P1 is made up

of two components - raw material A which is first

semi processed in CPC work center, and purchased

component B. Other products are made of only raw

material A, also processed in work center CPC.

Raw material A and purchased component B are

available from two suppliers, although the model in

the study allows for a flexible number of suppliers,

parts and components, and finished goods. These

parameters are stored in the operational server which

interfaces directly with plant floor machinery to

facilitate accurate, real-time data collection for better

business planning.

The system updates and stores all production

part numbers and desired quantities scheduled for

each period, so there is minimum operator

involvement. In addition to acquiring production

counts directly from production equipment, the

system updates current cycle time, inventory counts,

productivity and other production parameters. This

information, in addition to financial data stored in

the financial server, is uploaded to an APS via

CORBA for production optimization and profit

analysis on demand (as shown in Figure 2). The

financial data are displayed in Table 2.

Products

CP P1 P2 P3 P4

Manufacturing cell for

specific products

CPC P1C P2C P3C P4C

Mean run time per unit

(hours)

0.25 0.25 0.25 0.25 0.25

Batch size (units)

4 4 4 4 4

Setup time (hours) 0.5 0.333 0.333 0.25 0.25

Number of procurement

transactions per order

0 3 2 1 1

Max run time in each cell

(hours)

6 6 6 6 6

Max time for setups in each

cell (hours)

3 2 2 1.5 1.5

Total capacity in each cell

per period (hours)

9 8 8 7.5 7.5

Table 1: Production Parameters

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

126

Product

CP

P1 P2 P3

P4

Order cost per unit (average order size = 6) - 14.29

9.52

4.76

4.76

Batch cost per unit 6.25

4.17

4.17

3.13

3.13

Unit cost 2.92

2.08

1.67

0.83

0.83

sub-total 1

9.17

20.54

15.36

8.72

8.72

CP cost 9.17

9.17

9.17

9.17

sub-total 2

9.17

29.70

24.52

17.89

17.89

Raw material A

30.00

30.00

30.00

30.00

30.00

Cost of purchased material

Component B - 10.00

- - -

Total Manufacturing Costs (TMC) 39.17

69.70

54.52

47.89

47.89

Price ~(200 % over TMC) - 130.00

110.00

95.00

90.00

Inventory costs 0.01

0.05

0.05

0.05

0.05

5 SIMULATION ANALYSIS

According to Pritsker (1986), simulation models

must be verified and validated before relying on

their results. He states that verification is the

process of establishing that the computer program

executes as intended, whereas validation is the

process of establishing that a desired accuracy or

correspondence exists between the simulation model

and the real system. A pilot study is simulated to

provide parameter boundaries for a more

comprehensive experiment, evaluate the proposed

model formulations, and provide understanding of

how the model behaves in a real application.

We first validate and verify results of the

simulation through an illustrative example. The

models used in this experiment were verified by

testing them as a whole and in subsections. For

example, each manufacturing cells were completely

evaluated individually to match orders and cost

considerations.

The orders were traced from suppliers to

production timing, bottleneck influence of other

activities, inventory quantities generated by the

order and conformance to due date restrictions. All

costs incurred during the production cycle were also

verified to correspond to each specific activity.

Through debugging, refining, and redesigning, all

models were completely verified. As a result, it has

been concluded with confidence that all models are

performing as intended.

Validation is the process of establishing that the

desired accuracy or correspondence exists between

the simulation model and the real system being

simulated. The performance criterion in this

validation process is the general knowledge and

logical intuition of how the system should behave.

For example, in the stage of randomly generated

product orders, a specific number and type of orders

was generated for specific due dates and quantities.

This ensures that these products are the only inputs

and expected outputs of the system. Table 3

indicates a typical order set to be operationalized by

the model.

Table 2: Product Cost and Pricing

REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA: Linking Demand Management with Production

Planning

127

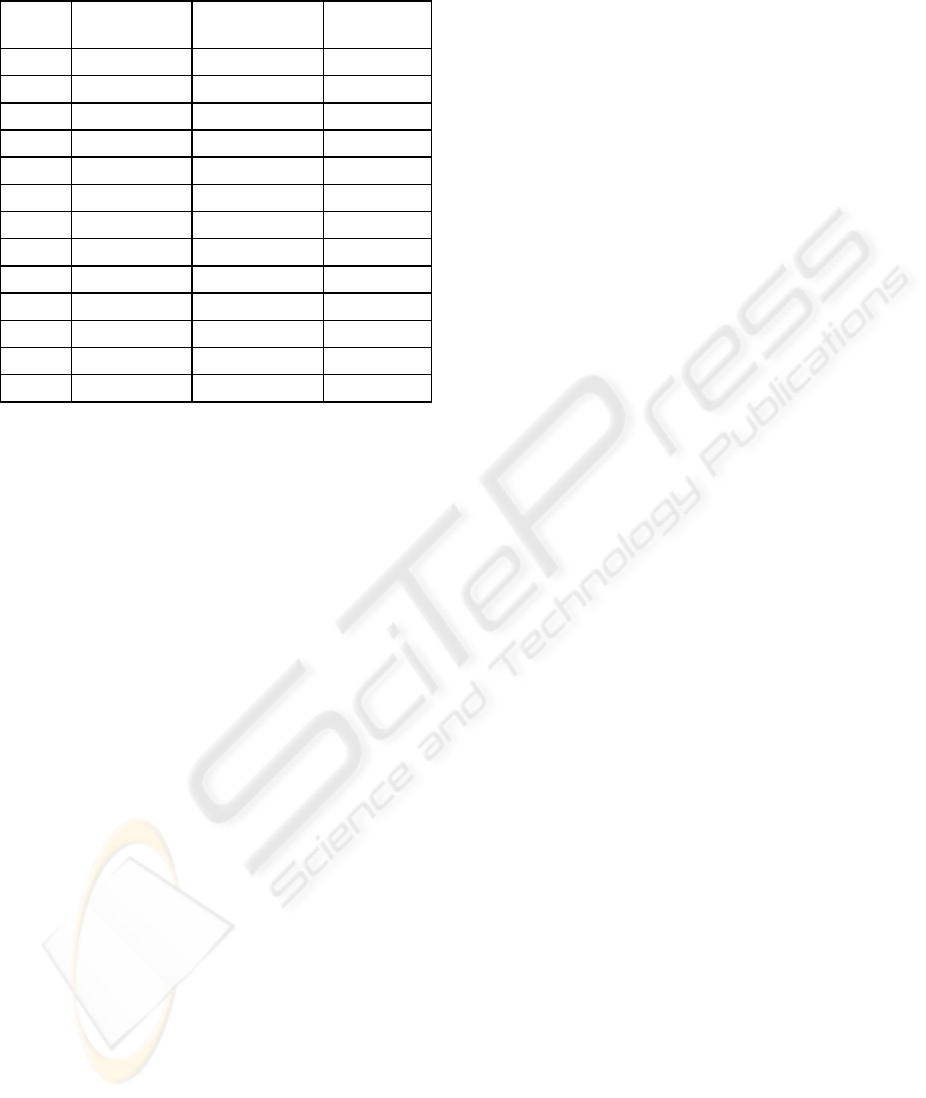

Table 3: Demand Information

Part #

PO # Delivery

date

Order

quantity

Order

date

P1 10 1/15/04 14 1/13/04

P1 11 1/24/04 11 1/13/04

P2 12 1/26/04 15 1/13/04

P3 12 1/17/04 17 1/14/04

P2 14 1/29/04 5 1/14/04

P1 15 1/20/04 6 1/15/04

P3 16 1/29/04 5 1/15/04

P4 17 1/30/04 9 1/16/04

P4 18 1/29/04 19 1/16/04

P3 19 1/27/04 3 1/16/04

P4 21 1/22/04 9 1/16/04

Order management applications interface with

the user in sales through the demand information

(Table 3), which is stored in the financial server. It

can be accessed via CORBA by the salesperson for

order confirmation and input of the new orders.

After a new order is entered into the table, the user

can run the optimizer (APS) to update and confirm

the feasibility of the order. If the order can produce

a capacity feasible schedule, the information is

stored in the financial server and the profitability of

the order can by be generated as indicated in data

presented in Table 4.

Table 4: Profit Analysis

PO # Order

quantity

Order date

Profit

10 14

1/13/2004

11 11

1/13/2004

12 15

1/13/2004 2401.60

13 17

1/14/2004

14 5

1/14/2004 3434.00

15 6

1/15/2004

16 5

1/15/2004 4184.98

17 9

1/16/2004

18 19

1/16/2004

19 3

1/16/2004

20 9

1/16/2004 5778.32

The production schedule and profitability analysis is

possible because the APS accesses real-time data

from the financial and the operational servers via

CORBA to generate reports. The APS, when

producing the updated schedule, will also generate

several reports to support production in the shop-

floor (Table 5), and other required accounting

transactions to meet the new customer order. Table

6 indicates the required purchasing order to be

placed with vendors to maintain a feasible schedule

and guarantee the contractual delivery date with the

customer. The purchasing requirements can be

electronically sent to vendor via CORBA and stored

in the financial server for later retrieval.

Table 5: Production Scheduling.

Production period Part # P1 Part # P2 Part # P3 Part #P4 Part # CP

1/15/2004 16 0 4

0 20

1/24/2004 0 0 4

0 4

1/26/2004 0 0 12 0 12

1/17/2004 0 0 0

4 4

1/29/2004 0 0 0

0 0

1/20/2004 4 0 0

0 4

1/29/2004 0 0 0

0 0

1/30/2004 12 0 0

8 20

1/29/2004 0 0 0

0 0

1/27/2004 0 0 0

0 0

1/22/2004 0 0 0

0 0

1/29/2004 0 16 0

0 16

1/26/2004 0 0 0

0 0

1/27/2004 0 4 8

0 12

2/04/2004 0 0 0

16 16

2/01/2004 0 0 0

12 12

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

128

Table 6: Purchasing Orders.

Part# Vendor Delivery date Order

quantity

A SUP1 1 20

A SUP1 2 4

A SUP1 3 12

A SUP1 4 4

A SUP1 6 4

A SUP1 8 20

A SUP1 12 16

A SUP1 14 12

A SUP1 15 16

A SUP1 16 12

B SUP2 1 16

B SUP2 6 4

B SUP2 8 12

6 CONCLUSION

In order to remain competitive in the global market,

companies need to establish a well connected supply

chain to synchronize production and order decisions

in through information technology.

This study introduced an application of a

decision support model with CORBA for

synchronized sales and operations planning in a

multi-stage manufacturing environment. Our

objective was to gain insights into how real-time

order management decisions could be used to

maximize profitability while ensuring that the firm

has adequate resources to satisfy the demand. The

model interfaces in real time with enterprise-wide

planning systems to directly access financial and

plant floor machinery data for better business

planning.

The model presented considers availability and

cost of supply chain resources (including raw

material, work-in-process, finished goods inventory

and production and distribution capabilities) and

allocates these scarce resources to incoming orders

to maximize profitability. It suggests that the

synchronization of resource utilization across the

supply chain and the real-time cost of resource

information provided by the CORBA environment

can lead to more reliable order commitment and

increased profitability. By synchronizing the

organization’s cycle times with those of key

suppliers and customers, the company can order and

produce the exact quantity at the right time. The

heightened visibility and accuracy bring about more

streamlined process and greater adaptability to

changing customer requirements.

The added benefits of the real-time model

includes increased customer relationships through

fast and reliable deliveries, lower operation costs

(buying and producing only what is needed at the

right time), and increased flexibility in order

management.

REFERENCES

Bolton, F., 2002. Pure CORBA: A Code Intensive

Premium Reference, Sams Publ., Indianapolis, Ind.

Castillo, I., C. Roberts, 2001. “Real-time control and

scheduling for multi-purpose batch plants”. Computers

and Industrial Engineering, Vol. 41, pp. 211-225

Layden, J., 1994. “Real-time factory floor scheduling

enhances responsiveness”, Industrial Engineer, Vol.

26, No. 11, p. 20

O’Brien, J., K. Sivaramakrishnan, 1996. “Coordinating

order processing and production scheduling”. J. of

Management Accounting Res., Vol. 8, pp. 151-170

Ovacik, I, R. Uzsoy, 1994. “Exploiting shop floor status

information to schedule complex job shops”. Journal

of Manufacturing Systems, Vol. 13, No. 2, pp. 73-84

Pritsker, A.A.B., 1986. Introduction to Simulation and

SLAM II, Halstead Press

Sanz, R., 2003. “A CORBA-based Architecture for

Strategic Process Control”. Annual Reviews in

Control, Vol. 27, pp. 15-22

Sanz, R., M. Alonso, 2001. “CORBA for Control

Systems”. Annual Reviews in Control, Vol. 25, pp.

169-181

Singh, R., G. Gilbreath, 2002. “A real-time information

systems for multivariate statistical process control”.

International Journal of Production Economics, Vol.

75, pp. 161-172

Steele, J., Y. Son, R. Wysk, 2001. “Resource modeling for

the integration of the manufacturing enterprise”.

Journal of Manufacturing Systems, Vol. 19, No. 6, p.

407

Umble, M., E. Umble, L Deylen, 2001. “Integrating

enterprise resource planning and theory of

constraints.” Production & Inventory Management J.,

2nd Quarter, pp. 43 – 48

Vollmann, T.E., W.L. Berry, C. Whybark, 1997.

Manufacturing Planning and Control Systems,

Irwin/McGraw-Hill.

Yang, K.K., F.R. Jacobs, 1999. “Replanning the master

production schedule for capacity-constrained job

shop”. Decision Sciences, Vol. 30, No. 3, pp. 719-748

REAL-TIME SALES & OPERATIONS PLANNING WITH CORBA: Linking Demand Management with Production

Planning

129