FAULT MAINTENANCE IN EMBEDDED SYSTEMS

APPLICATIONS

Multiple Lift Control System as Safety Critical Embedded Application

Miroslav Sveda

Faculty of Information Technology, Brno University of Technology, Bozetechova 2, 61266 Brno, Czech Republic

Radimir Vrba

Faculty of Electrical Engineering & Communication, Brno University of Technology, Brno, Czech Republic

Keywords: Embedded system design, System architecture, Fault maintenance, Fail-stop safety model.

Abstract: This paper describes principles of a designed multiple lift control system based on a dedicated embedded

architecture. After reviewing dependable concepts used, the main attention is focused on the design of

hardware architecture, software, and communication services and protocols fitting the application

requirements. The multiple lift control system presents in this case a real-world solution of a safety critical

embedded system application. The design employs a fail-stop safety model and dedicated distributed

architecture to meet application requirements efficiently. The paper stresses those features that distinguish

the real project from a demonstration case study.

1 INTRODUCTION

Requirements on current embedded system

applications include both functional and non-

functional requirements on real-time behaviour and

safety properties (Leveson, 1984) that can be

formally specified and verified or, at least, properly

explored before they are designed in detail and

implemented. After reviewing utilized dependable

concepts, the main attention of this paper is focused

on hardware and software architecture of the

developed system, and on communication services

fitting the application domain.

2 DEPENDABILITY

The design of current embedded system applications

should consider not only functionality but also

dependability measures. Functionality means

services delivery in the form and time fitting

requirement specifications, where the service

specification is an agreed description of the expected

service. Functionality properties should be realized

efficiently and cost-effectively, so reachable

performance and maintainability of implementation

belong to the checked properties.

Dependability is that property of a system that

allows reliance to be justifiably placed on the service

it delivers. A failure occurs when the delivered

service deviates from the specified service.

Dependability measures consist of reliability,

availability, security, safety and survivability.

Availability is the ability to deliver shared service

under given conditions for a given time, which

means elimination of denial-of-service

vulnerabilities. Security is the ability to deliver

service under given conditions without unauthorized

disclosure or alteration of sensitive information.

Security attributes add requirements to detect and

avoid intentional faults.

Safety is the ability to deliver service under

given conditions with no catastrophic affects. Safety

attributes add requirements to detect and avoid

catastrophic failures. A failure occurs when the

delivered service deviates from the specified service.

An error is that part of the system state which is

liable to lead to failure. The cause of an error is a

fault. Failures can be classified according to

183

Sveda M. and Vrba R. (2006).

FAULT MAINTENANCE IN EMBEDDED SYSTEMS APPLICATIONS - Multiple Lift Control System as Safety Critical Embedded Application.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 183-186

DOI: 10.5220/0001202501830186

Copyright

c

SciTePress

consequences upon the environment of the system.

While for benign failures the consequences are of

the same order of magnitude (e.g. cost) as those of

the service delivered in the absence of failure, for

malign or catastrophic failures the consequences are

not comparable.

A fail-safe system attempts to limit the amount

of damage caused by a failure. No attempt is made

to satisfy the functional specifications except where

necessary to ensure safety. A fail-stop system never

performs an erroneous state transformation due to a

fault (Schneider, 1983). Instead, the system halts and

its state is irretrievably lost. The fail stop model,

originally developed for theoretical purposes,

appears as a simple and useful conception

supporting the implementation of some kinds of fail-

safe systems. Since any real solution can only

approximate the fail-stop behaviour and, moreover,

the halted system offers no services for its

environment, some fault-avoidance techniques must

support all such implementations.

3 APPLICATION

While a lift control system offers a classical example

used in literature for presenting principles of

requirements elicitation (Lamsweerde, 1998),

simulation (Knuth, 1969), formal specification

(Evans, 1994), validation (Valmari, 1987), design

verification (Cuellar et al., 1994), rapid prototyping

(Brink et al., 1993), and executable specification

(Hale, 1990), little attention is de-voted to

publishing the real world projects of this kind.

Nevertheless, such dedicated system, with a long

tradition of development, can demonstrate dedicated

solutions that have to conform to the strict

dependability requirements typical for safety-critical

applications.

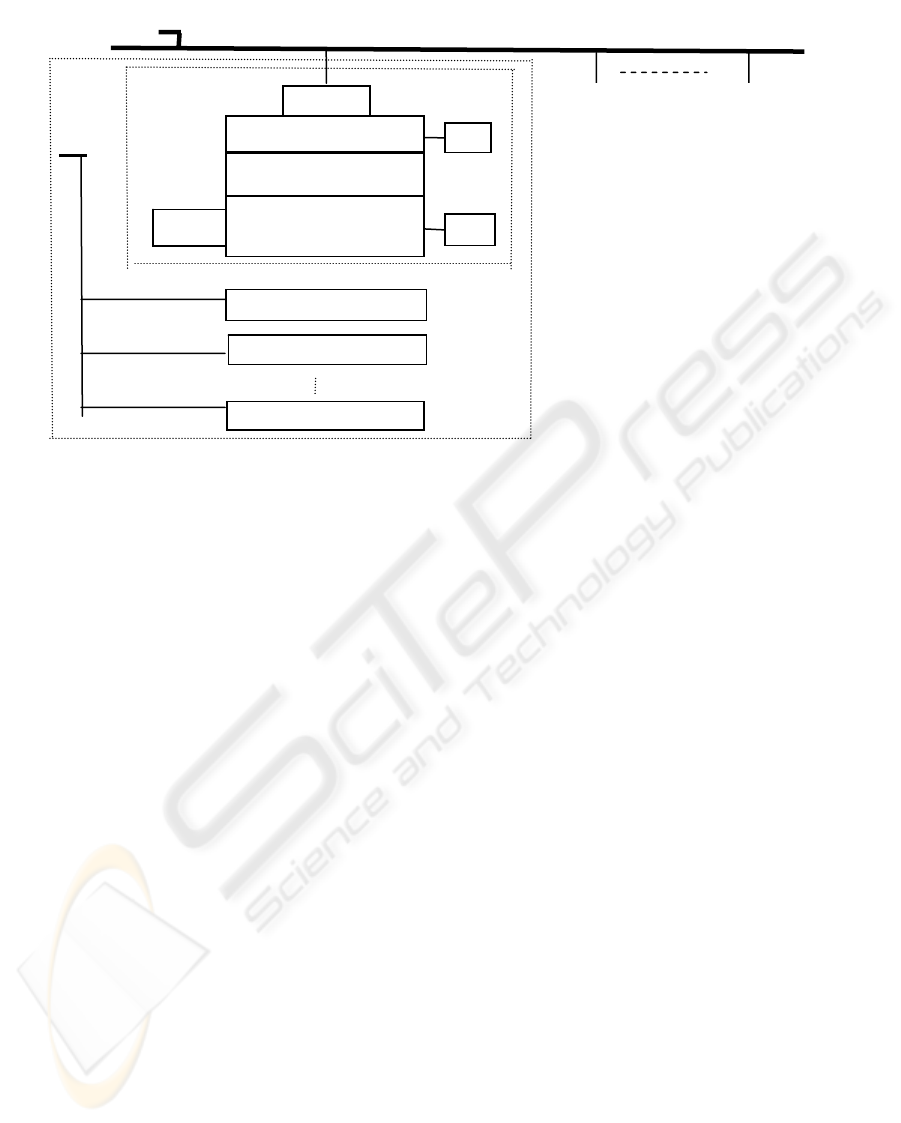

3.1 Architectural Specifications

The multiple lift control system governs the

operation of N identical lifts servicing an M-storey

building, see Figure 1. For this purpose, it interacts

with its environment in the following way. Every lift

cabin includes a control panel with one button for

each floor, an emergency button, a key-lock handler

for attendant-mode traffic, and a numerical display.

These inputs/outputs should respect human

physiological constants. Other inputs and outputs in

the lift cabin involve load sensor, door driver, door

position detector, and gate optical barrier, of course,

with individual timing. On each floor (except ground

and top with modified configuration for border line

Dispatcher

External Serial Bus

LIFT

CONTROLLER

2

LIFT

CONTROLLER

N

Shaft

Controller

Comm

WD

WD

Comm

Scheduling Processor

Two-port RAM

Drive Control

Processor

Floor Controller M

Floor Controller M

Lift Cabin Controller

LIFT

CONTROLLER

1

Diagnostics

Internal Serisal Bus

Comm: Communication Processor

WD: Watchdog Processor

Figure 1: Multiple lift control system architecture.

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

184

positions) there are two buttons, one to request a lift

going upwards and the other for going downwards,

and moreover course lights, time interval display

and acoustic signalization with the same timing

requirements as mentioned above for the lift cabin

control panel. The position and speed of each lift is

measured and controlled by a lift drive. This group

of in-puts/outputs requires special attention because

of hard real-time limits.

The control system architecture stems from the

following conception. The external serial bus

interconnects N identical lift controllers and a

dispatcher station; in addition, each lift controller

embodies a dedicated distributed system with

internal serial bus connecting a shaft controller, M

floor controllers, and a cabin controller. The shaft

controller, which is a dedicated multiprocessor,

comprises one scheduling processor and one drive

control processor communicating through a common

memory, two communication processors enabling

access to external and internal serial buses, and two

simple watchdog processors.

3.2 Functional Specifications

The behaviour of each lift is directed by its

scheduling processor using both global master

directives, which consider orders from floors

provided through a floor controller and local orders

from the lift cabin provided through a cabin

controller -- the global master, elected among all

active scheduling processors during the initialization

phase -- obtains also information about orders from

all cabins to improve task allocation efficiency. For

each shaft controller, a scheduling processor and a

drive control processor share, in two-port RAM, data

structures describing the state (position, speed,

direction, load, and error status), list of orders to be

serviced including allowed time limits, and the next

serviced floor.

Possible traffic modes implement a self-service

administration with various N-lift scheduling

strategies and a separate lift self-service or attendant

management including also such special policies as

maintenance and fire brigade support. While the

scheduling processor communicates with the global

master and, accordingly, updates the orders from

floors, the drive control processor controls the lift

position and speed and updates the lift state and

cabin orders. The lift cabin controller serves the

control panel and the load sensors and manages the

door drive respecting the door position, the drive

moment, and the gate optical barrier. Finally, the

floor controller serves floor buttons, course lights,

acoustic signalization of arriving lift, and display

with approximate time interval to floor tending.

The multiple lift control system is designed to be

fully observable and controllable through its serial

buses. In a special 'off-line' mode, every processor

can upload or download through the incident serial

bus its local data and local inputs or outputs. That

feature administered by relevant modes of the

dispatcher and diagnostic station behaviour props

installation and repair of the control system. Both

above mentioned stations can also emulate dedicated

network analyzers and management terminals.

While the dispatcher station can monitor, test, or

supervise the whole interconnected system, the

portable diagnostic station implements equivalent

functions for the individual lift controller. Such

property promotes both an adaptation of service

strategies and regular system maintenance.

After power supply initiation and successful

power-up tests of all processors including memories,

peripheries, and internal connections, the

communication processors incident with the external

interconnection elect, according to the lowest

address on external serial bus, the current global

master, which is responsible to allocate service tasks

to the individual lifts. This allocation follows a

strategy either prescribed by the dispatcher station or

selected by the global master according to the traffic

type of building serviced, week and month or season

day, and day or night time. When the external serial

bus is disconnected, the scheduling will proceed

locally.

The software of scheduling processors stems

from a real-time executive with pre-emptive task

planning based on fix priorities. The supervisor task,

which is periodically activated by a timer,

implements initialization, mode selection, and

extraordinary events services. The scheduler task,

which can be activated by a message, realizes global

and local scheduling of lift services. Other auxiliary

tasks support accessing and updating the lift data

model based on above mentioned data structures. As

for the drive control processors, their dedicated

software in foreground/background format

guarantees very short response times for speed and

position drive control loops and transfers, without so

strict temporal limits, information between the lift

data model and the lift cabin or floor controllers. In

each shaft controller, the communication controllers

implement corresponding, special purpose protocols

and release the execution processors from

communication loads. The lift cabin and floor

controllers fulfil the above stated functions using

polling loops.

FAULT MAINTENANCE IN EMBEDDED SYSTEMS APPLICATIONS - Multiple Lift Control System as Safety Critical

Embedded Application

185

3.3 Fault Maintenance Concepts

The methods used accomplish the fault management

in the form of (a) hazardous state reachability

control and (b) hazardous state maintenance. In safe

states, the lift cabins are fixed at any floors. The

system is allowed to reach any hazardous state when

all relevant processors successfully passed the start-

up checks of inputs and monitored outputs and of

appropriate communication status. The hazardous

state maintenance includes operational checks and,

for shaft controller, the fail-stop support by two

watchdog processors performing consistency

checking for both execution processors. To comply

with safety-critical conception, all critical inputs and

monitored outputs are doubled and compared; when

the relevant signals differ, the respective lift is either

forced (in case of need with the help of an substitute

drive if the shaft controller is disconnected) to reach

the nearest floor and to stay blocked, or (in the case

of maintenance or fire brigade support) its services

are partially restricted. The basic safety hard core

includes mechanical, emergency brakes.

Because permanent blocking or too frequently

repeated blocking is inappropriate, the final

implementation must employ also fault avoidance

techniques. The other reason for the fault avoidance

application stems from the fact that only

approximated fail-stop implementation is possible.

Moreover, the above described configurations create

only skeleton carrying common fault-tolerant

techniques see e.g. (Maxion et al., 1987). In short,

while auxiliary hardware components maintain

supply-voltage levels, input signals filtering, and

timing, the software techniques, namely time

redundancy or skip-frame strategy, deal with non-

critical inputs and outputs.

4 CONCLUSIONS

The multiple lift control system presents a real-

world solution of a safety critical embedded

application employing the introduced fail-stop safety

model and dedicated distributed architecture. The

specification and design of the multiple lift control

system, ordered and supported by a lift

manufacturer, were completed a couple of years ago.

For other than technical reasons the project was

cancelled before full implementation of the target

system and preparation of production stages. What

appears as an advantage in this not too optimistic

state of affairs is the fact that this situation enabled

to publish such details of the project that could not

be disclosed in the opposite case.

ACKNOWLEDGEMENTS

The research has been supported by the Czech

Ministry of Education in the frame of MSM

0021630503 Research Intention MIKROSYN: New

Trends in Microelectronic Systems and Nano-

technologies, and by the Grant Agency of the Czech

Republic through the grants GACR 102/05/0723: A

Framework for Formal Specifications and

Prototyping of Information System’s Network

Applications and GACR 102/05/0467: Architectures

of Embedded Systems Networks.

REFERENCES

Brink K., Huijsman R., van Katwijk J.: SEAL: A Simple

Language for Prototyping Action-Event

Specifications. Microprocessing and Micro-

programming, Vol. 38 (1993) 87-95.

Cuéllar J., Wildgruber I., Barnard D.: Combining the

Design of Industrial Systems with Effective

Verification Techniques. In: Naftalin M., Denvir T.,

and Bertran M. (Eds.): FME'94: Industrial Benefit of

Formal Methods, LNCS 873, Springer-Verlag, Berlin

(1994) 639-658.

Evans A.S.: Specifying & Verifying Concurrent Systems

Using Z. In: Naftalin M., Denvir T., and Bertran M.

(Eds.): FME'94: Industrial Benefit of Formal Methods,

LNCS 873, Springer-Verlag, Berlin (1994) 366-380.

Hale R.: Using Temporal Logic for Prototyping: The

Design of a Lift Controller. In: Zedan H.S.M. (Ed.)

Real-Time Systems, Theory and Applications, North-

Holland, Amsterdam (1990) 81-118.

Knuth D.E.: The Art of Computer Programming: Basic

Algorithms (Vol. 1), Addison-Wesley, London (1969).

van Lamsweerde A.: Inferring Declarative Requirements

Specifications from Operational Scenarios. Trans. on

Software Engineering, Vol. 24 (1998) 1089-1114.

Leveson N.G.: Software Safety in Computer-Controlled

Systems. IEEE Computer, February (1984) 48-55.

Maxion R. A., Siewiorek D. P., Elkind S. A.: Techniques

and Architectures for Fault-Tolerant Computing. Ann.

Rev. Comput. Sci., No. 2 (1987) 469-520.

Schneider F.B.: Fail-Stop Processors. COMPCON'83

SPRING, Digest of Papers 26th IEEE CS Int. Conf.

(1983) 66-70.

Valmari A.: Reachability Analysis-Based Validation of

Embedded Systems. Microprocessing and Micro-

programming, Vol. 21 (1987) 393-404.

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

186