IMPROVED METHOD FOR HIGHLY ACCURATE INTEGRATION

OF TRACK MOTIONS

Michael Kleinkes, Werner Neddermeyer and Michael Schnell

University of Applied Science in Gelsenkirchen

Neidenburger Str. 43, 45897 Gelsenkirchen

Keywords:

Industrial robots, 7

th

axis, linear track, offline programming, motion control, flexible automation.

Abstract:

Modern Robotics today deals with increasing requirements on the flexible automation. One of this is the usage

of linear tracks or even called 7

th

axis to extend the robots workspace. The inaccuracies of the linear track

deteriorate the accuracy, which is in constrast to highly accurate robot systems needed for modern applications.

To enhance the accuracy of the system consisting of robot and linear track, an identification of the non-

linearities of the linear track is necessary. This article introduces an optimisation of a method for highly

accurate integration of track motions where the profile of the linear track is identified by single coordinate

systems along the track, combined by a cubic spline interpolation. Resulting there is a continous description

of the track profile, depending on the current position of the robot on the linear track.

1 INTRODUCTION

Modern industrial robot applications become more

and more complex. The increasing demand on flex-

ibility and automation effects the need of high preci-

sion robot systems. One part of this robot systems are

external linear tracks, even called 7

th

axis, on which

the robot can be linear moved to extend its workspace.

In most of the cases this extension of the workspace

via linear track deteriorates the accuracy of the sys-

tem robot and track in significant number about sev-

eral millimeters or more. This alarming fact is not

compatible to the demands on the flexible automation

at all and additionally is neglected by scientists and

robot manufacturers at well.

In (6) there is one method presented, which makes it

possible to identify the inaccuracies of the linear track

and correct offline robot programs. For this, the linear

track is measured at n positions where a correspond-

ing track coordinate system is calculated. The number

of positions on the linear track where the single track

coordinate systems are calculated - following called

sampling points - are determined by a frequency scan

of the linear track. To get a continous description of

the linear track these track systems are combined by

a cubic spline interpolation. By this it is possible to

get a correction frame for each arbitrary position on

the linear track. This paper sets up on the first arti-

Figure 1: Track coordinate systems.

cle about highly accurate integration of track motions

and presents optimisations in the fields of frequency

check and spline correction and fulfils parts of the fu-

ture prospects of this article.

2 TRACK PROFILE FREQUENCY

CHECK

For the identification of the track motion one rigid

object is needed, which is to measure at different

positions on the linear track, by an 3D-coordinate

measurement device. Basing on the fact that the

rigid object is not deformed after moving from one

469

Kleinkes M., Neddermeyer W. and Schnell M. (2006).

IMPROVED METHOD FOR HIGHLY ACCURATE INTEGRATION OF TRACK MOTIONS.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 469-473

DOI: 10.5220/0001203504690473

Copyright

c

SciTePress

position to the next position on the linear track, the

positional changings of some measurement points on

the rigid object are only caused by the linear track.

The very high reapeatability of modern industrial

robots makes it possible to use the robot as such a

rigid object. The inaccuracy in moving to one point

repeatedly is in most of the cases more then 10 times

less than the inaccuracies caused by the linear track.

In (7) there is an overview about the absolute and

repeat accuracy of the used robot.

One important step in the process of identifying

the linear track is the determination of the needed

number of sampling points on the track. This value

is depending on the maximum error which has to be

identified and varies with each individual linear track.

A special procedure developed before is here used

again and is in certain ways optimised. For this,

the robot is moved along the linear track with its

Tool-Center-Point (TCP) in one constant position.

During the robots movement it is measured by

the external measurement system in a continious

measurement mode. This creates measurement data

from a theoretical straight line movement disturbed

by the inaccuracies of the linear track on the one

hand, the robots own vibrations and the measurement

inaccuracies on the other hand.

So if we sperate the theoretical path from the mea-

surement results we get:

h

k

=

p

∆x

2

+ ∆y

2

+ ∆z

2

− s

k

(1)

with

s

k

= k · v · dt , k = 0, 1, . . . , N − 1 (2)

Taking this function h

k

we make the discrete fourier

transform on it and get the spectrum of the non-

linearities of the track. One special aspect not con-

sidered before is the spectral leakage effect of time

delimited functions. Considering the finite number of

measurement values taken in a finite time intervall,

the number of the discrete function values of h

k

is

N − 1 as can be seen in (1). In respect to this, there

is a convolution with the spectrum of the rectengular

function in the frequency domain.

So:

H(f

n

) =

Z

∞

−∞

h(s)e

−j2πf

n

s

ds ∗ G(rect

n

) (3)

and

G(rect

n

) = T

p

· si(πfT

p

) , T

p

=

1

f

n

(4)

This convolusion causes new spectral components

which are not included in the measured signal

whereby the original spectrum can not be analysed

properly. The solution for this problem is finding a

adequate window function, where the leakage effect

is lower, so that the important spectral components

can be detected properly.

The appropriate window function, a bartlett window

was found in some special analyses and after some

experiments in comparing different window functions

on the measurement values the discrete fourier trans-

form gets now an improved spectrum of the linear

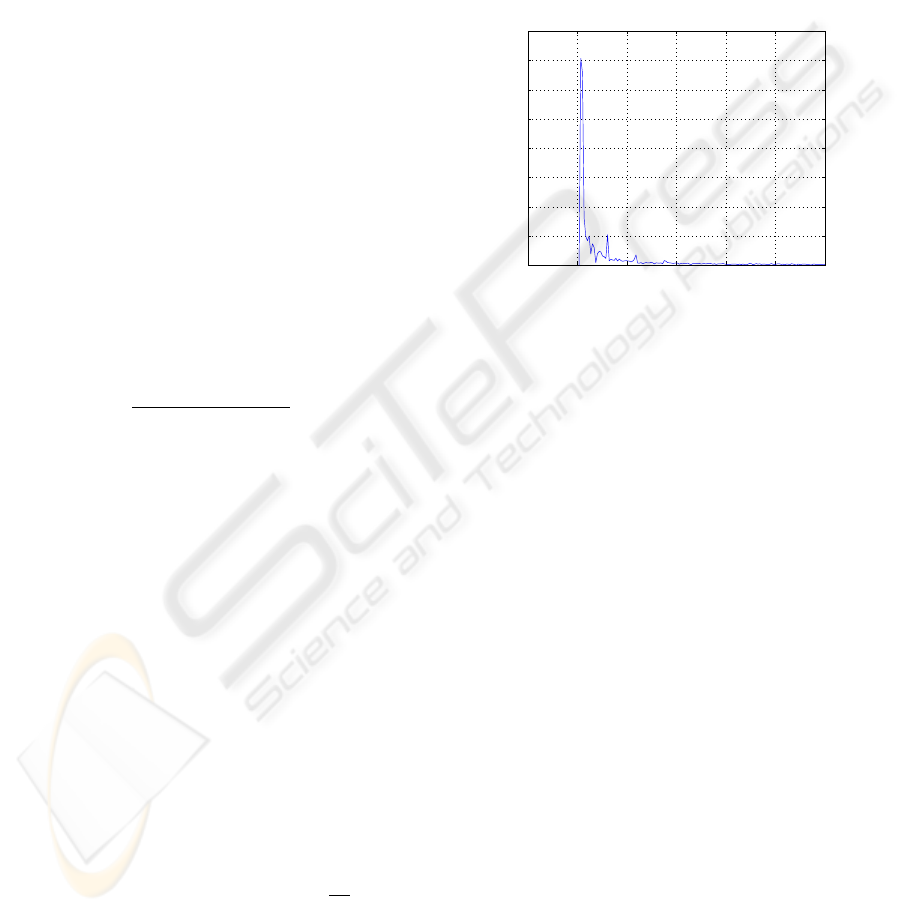

track scan depicted in figure 2:

−0.005 0 0.005 0.01 0.015 0.02 0.025

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

spectrum of h(t) with bartlett window

frequency [1/mm]

amplitude [mm]

Figure 2: Spectrum of the track scan.

Due to the windowing three different frequency peaks

can be seen clearly. The first peak with an amplitude

of 0.7 mm at a frequency of 0.0003/mm represents the

maximum error caused by the track which was mea-

sured and as you can see it is at the lowest frequency.

The other two peaks at 0.003/mm and 0.006/mm are

caused by the robots vibration and by the measure-

ment system.

To get the needed number of sampling points for an

identification of the linear track the new spectrum of

the windowed function is used, considering the sam-

pling theorem. With this new results the number of

sampling points can be reduced by 25%.

3 POSITIONING ERRORS DUE

TO SPLINE LINEARISATION

The benefit of the interpolation of the identified track

coordinate systems via cubic splines is a continous

description of the linear track in 6 dimensions

(x, y, z, α, β, γ). As already mentioned the single

track coordinate systems are identified in the sam-

pling positions depending on the frequency spectrum

after the continous track scan. So what we get after

calculating the track coordinate systems is:

T

R

i

W

= f

i

(α(l

i

), β(l

i

), γ(l

i

), t

x

(l

i

), t

y

(l

i

), t

z

(l

i

))

(5)

ICINCO 2006 - ROBOTICS AND AUTOMATION

470

Figure 3: Track coordinate systems in sampling points.

This T

R

i

W

is depending on the sampling point position

i. Now we make use of the cubic spline interpolation

method and connect the discrete pairs of varieties

(α

i

, l

i

), (β

i

, l

i

), etc. with smooth and also smooth in

the first derivate functions, so that we can create track

coordinate systems on every arbitrary position on the

linear track.

T

R

W

(l) = f

i

(α(l), β(l), γ(l), t

x

(l), t

y

(l), t

z

(l)) (6)

Figure 4: Track coordinate systems arbitrary.

Using the continous description of the linear track

one robot programm can be modified and every

single position can be corrected considering its

corresponding linear track value. This method works

quite good for programs in which the robot moves

to static points. One crucial situation are linear

movements, because for this the robot uses two

programmed points and moves along the straight path

between these two points. The ability to correct the

first and the last point of this linear movement causes

that the robot moves at the start and end position

of its movement quite right, considering the errors

given through the linear track. But whats about all

the positions between the start and end point? Lets

make a small example:

The two positions p

1

and p

2

as shown in figure 5 are

S (x)

i

Lineartrackposition[mm]

Position[mm]

p

1

p

2

Figure 5: Programmed points between sampling positions.

programmed on a linear track position between two

sampling points. Between this two sampling points

there is the interpolation cubic spline function S

i

(x).

Assuming that the robot moves from the point p

1

to

the point p

2

it will calculate a straight line movement

using the new corrected positions for p

1

and p

2

. This

calculation will effect that during the movement no

correction can be processed because the splines are

not directly integrated into the positional control of

the robot. Mathematically the linearisation can be

described as follows:

Taking the general equation for cubic spline in

the range from one sampling position to the next:

S

i

(x) = a

i

+ b

i

(x − x

i

) + c

i

(x − x

i

)

2

+ d

i

(x − x

i

)

3

(7)

in the intervall I = [x

i

, x

i+1

]. To find one spline

function in the given interval there are four different

parameters to identify (a

i

...d

i

). Due to the side

conditions of the cubic spline interpolation there are

for each unknown spline four different equations to

find the four unknown parameters. As shown in (5) it

is possible to transform this set of equations to a set

of equation only depending on one parameter c

i

so

that:

d

i

=

1

3(x

i+1

− x

i

)

c

i−1

− c

i

(8)

b

i

=

y

i+1

− y

i

x

i+1

− x

i

−

x

i+1

− x

i

3

(c

i+1

+ 2c

i

) (9)

and

a

i

= y

i

(10)

with x

n

as x-coordinate in the sampling points and

therefore as linear track value at this positions and

y

n

as the corresponding y-coordinate of the single

dimension (x, y, z, α, β, γ). The remaining c

i

-values

IMPROVED METHOD FOR HIGHLY ACCURATE INTEGRATION OF TRACK MOTIONS

471

can be calculated through a linear equation using a

tridiagonal, symmetric and positive Matrix:

~c =

~

A

−1

· ~a (11)

with

~

A =

2(h

0

+ h

1

) h

1

0 0 0

h

1

2(h

1

+ h

2

) h

2

0 0

0 h

2

2(h

2

+ h

3

) h

3

0

0

.

.

.

.

.

.

.

.

.

0

0 0 0 h

n−2

2(h

n−2

+ h

n−1

)

(12)

using

h

i

= x

i+1

− x

i

(13)

and

~a =

3

y

2

−y

1

h

1

− 3

y

1

−y

0

h

0

− h

0

c

0

3

y

3

−y

2

h

2

− 3

y

2

−y

1

h

1

.

.

.

3

y

n

−y

n−1

h

n−1

− 3

y

n−1

−y

n−2

h

n−2

− h

n−1

c

n

(14)

Basing on this the prefactor d

1

of a spline between

two arbitrary points can be calculated:

d

1

=

6

15h

3

[(y

1

− y

0

) − 2(y

2

− y

1

) + (y

3

− y

2

)]

(15)

Special mathematical simulations have shown that

the greatest deviation from a straight line between

two points on the spline and the spline function itself

is when the cubic part and therefore the prefactor d

i

of the corresponding spline is zero. Basing on the

symmetry in (15) this is the case for y

2

= y

1

and

(y

1

− y

0

) − (y

3

− y

2

) = 0. Given this conditions the

maximal deviation is:

∆s = S

i

b

i

2c

i

+ x

i

− y

1

(16)

With practical meanings this is on a linear track with

an inaccuracy of 0,5 mm in the heigth of its two

rails an ∆s-value of 0.325mm. That means, that if it

would be possible to correct the robots position dur-

ing the movement, the postioning of the TCP would

be 0.325 mm better than without. Methods of correct-

ing the robots TCP-motion dynamically during the

movement were analysed and we expect to obtain ∆s-

values greater than 0.5mm.

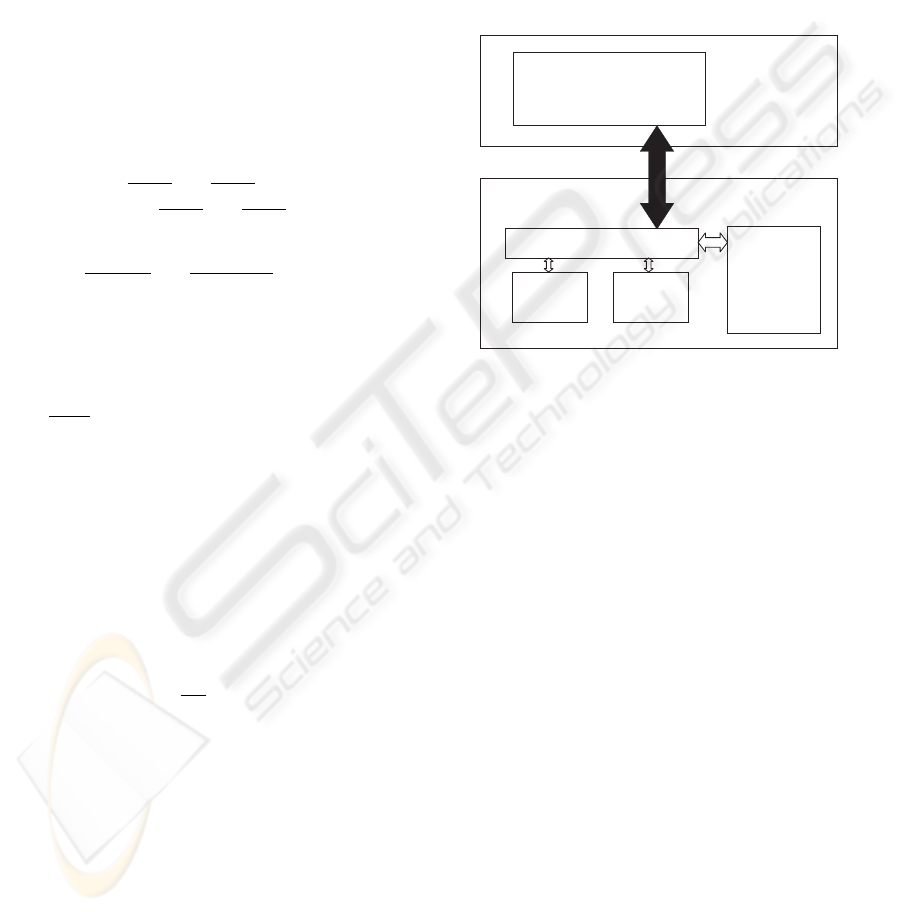

4 ROBOT INTERFACE

Due to a new robot interface it is possible to use an

uniform interface for variable sensor applications. For

this the used sensors are not connected to the robot

control via external interfaces but directly integrated

in the robots programming language. This is done

through a modular built program which is working on

the robot control an which is supporting special func-

tions for the user.

Realtimecore

Robot

Position

Control,

I/Os

Interfaceprogram

Sensors,

Drivers

Object

Libraries

Usercore

Robot

Programming

Language

Figure 6: Robot interface for dynamic correction.

Using this new robot interface it is possible to send

correction signals to the robot which are processed

exactly in the interpolation rate of the robot. This al-

lows to modify the TCP position with such a high time

rate that the spline correction can be nearly perfectly

used.

5 MEASUREMENT SYSTEM

The used measurement system for the needed mea-

surement tasks like continous scan of one track mo-

tion, determining the particular track coordinate sys-

tems or identifying of the robots accuracy is repre-

sented by a Leica Laser Tracker LTD800 (figure 7).

With this measurement device it is possible to do

touchless measurements of 3-dimensional points in a

range up to 80 meters. The measurement uncertainty

of a coordinate is given by 10µm + 5µm/m with a

possible maximum measurement rate of 3000 points

per second.

Using the world’s most accurate absolute distance

meter (25µmm within 40m) and two built-in preci-

sion encoders for horizontal and vertikal angle mea-

surements, it is a highly accurate measurement sys-

tem and common in measurement tasks for aircraft

and automobile industries.

ICINCO 2006 - ROBOTICS AND AUTOMATION

472

Figure 7: Leica LTD800 Laser Tracker.

6 CONCLUSION

The dynamic correction of the robot during its move-

ment is the basis for an optimal usage of the spline

interpolation. In the first step (6) there was only a cor-

rection of single points and as can be seen, this has an

disadvantage at controlled movements between two

points.

With the improved method for highly integration of

track motions this problem is solved and any move-

ment can be corrected. Even the offline correction

of robot programs is not needed anymore because the

robot gets the corrections in the interpolation cycle of

the motion control.

A future prospect will be the implementation of the

spline correction in the new interface modul and

therefore the correction of arbitrary movements.

REFERENCES

Bachman, G., Narici, L., Beckenstein, E. (2002). Fourier

and wavelet analysis. Springer, New York.

Bracewell, R. (2000). The fourier transform and its appli-

cations. McGraw-Hill, Boston.

Convay, J. and Smith, D. (2003). On quaternions and octo-

nions. A K Peters, Massachusetts.

Dautray, R. (2000). Mathematical analysis and numerical

methods for science and technology. Springer, Lon-

don.

Engeln-Mllges, G., Niederdrenk, K. and Wodicka, R.

Numerik-Algorithmen. Springer, Berlin.

Kleinkes, M., Lilienthal, A., Neddermeyer, W. Highly Ac-

curate Integraion of Track Motions. ICINCO Proceed-

ings 2005, Barcelona.

Kleinkes, M., Lilienthal, A., Winkler, W. Static and dy-

namic accuracy and process ability tests for industrial

robots. WMSCI Proceedings 2005, Orlando.

Maas, H. G. (1997). Dynamic photogrammetric calibra-

tion of industrial robots, spie’s 42 annual meeting, san

diego. In Videometrics V, SPIE proceedings Series Vol.

3174.

Nitschke, H. (2002). Zur Bestimmung geometrischer Pa-

rameter von Industrierobotern. Bayrische Akademie

der Wissenschaften, Dissertation, TU Munich.

Press, W. H., Teukolsky, S. A., Vetterling, W. T., and Flan-

nery, B. F. (1989). Numerical Recipes in C. Cam-

bridge University Press.

Ramanathan, J. (1998). Methods of Applied Fourier Analy-

sis. Birkhuser, Boston.

Spong, Mark W., Vidyasagar, M. (1989). Robot dynamics

and control. John Wiley and Sons, New York.

IMPROVED METHOD FOR HIGHLY ACCURATE INTEGRATION OF TRACK MOTIONS

473