HEAT-AND-POWER PROCESSES OPTIMIZATION BY MEANS

OF MODEL-BASED SIMULATION

Dmitry Antropov

JSC, Etalon MCS“, Kazan, Russia

Rosica Ivanova, Renat Sadykov

Kazan State Architectural Building University, Kazan, Russia

Sergey Yeryomin, Rauf Kafiatullin

PO “Kazenergo“, Kazan, Russia

Keywords: Intelligent systems in education, system integration, intelligent laboratory-scale plant.

Abstract: A firmware was developed for simulation of heat-mass transfer processes in power equipment such as steam

or water boilers and dryers. Hardware of this pilot plant is based on modern microprocessors control

devices. Software rests on specially developed mathematical models. The functions and structure of the

model of fully automated boiler and dryer control system (B-DCS) are described in detail. One of the

variants of implementation of B-DCS on the example of the dryer unit for drying bioactive products is

considered. The analysis of the optimality criterion problem and selection of the optimal control structure

are reviewed using Pontryagin’s maximum principle. The objective of optimization is to reduce

expenditures of operational process.

1 INTRODUCTION

The depletion of the resources of extensive

development of economy makes critical the issues of

the development of intensive process technologies

and their introduction in the industry. In the rapidly

developing technologies these challenges can be

competitively met only by methods of computerized

mathematical modelling which reduces the amount

and time of R&D required and enhances its quality.

The realization of these advantages in the

computerized automated design and control systems,

scientific research requires the unity of

mathematical, algorithmic, informational and

software support for various processes and tasks in

power engineering, chemical technology and

biotechnology. This unity should be based on the

generalizing mathematical models (MM) covering

the basic aspects of the development of the intensive

process technologies. However, in common practice

highly specialized MMs of empirical character

down to regressive ones are in use owing to the fact

that the conventional, more universal MMs do not

adequately incorporate such features of the

intensive process tecnologies as multi component

structure and lability of the process agents, low

process observability and reproducibility, intensity

and coherency of various features of the happening

phenomena, interference of process technology

stages.

We have designed a model of a fully automated

boiler and dryer control system (B-DCS) based on

the microprocessor data acquisition and control

devices designated for training of the students.

The B-DCS model allows to familiarize with the

processes taking place in the boiler and drying units

in the absence of processing system. It allows to

solve problems of mathematical modelling adequacy

of the basic processes in a boiler or a dryer. The

capacity of the B-DCS processing unit permits to

realize complicated optimization algorithms and to

analyze their efficiency.

207

Antropov D., Ivanova R., Sadykov R., Yeryomin S. and Kafiatullin R. (2006).

HEAT-AND-POWER PROCESSES OPTIMIZATION BY MEANS OF MODEL-BASED SIMULATION.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 207-212

DOI: 10.5220/0001210602070212

Copyright

c

SciTePress

2 FUNCTIONS OF THE B-DCS

The intelligent laboratory-scale plant implements the

following functions of the automatic control and

supervision:

Boiler automated control:

− Boiler control in an automatic mode using the set

algorithm (check readiness for start-up,

ventilation, kindling, initial heating, output of

operating conditions, shut down;

− Boiler regulation using basic process parameters

(load, fuel - air ratio, chamber pressure, etc.);

− Implementation of the process protection and

interlocking;

− Diagnosis of the boiler process equipment

condition;

Automated control of the boiler-house auxiliaries

consists of:

− Control of the deaeration unit, network, and

intake pumps;

− Water level control in the additional feed tank;

− Regulation of the temperature schedule and

heating system hydraulic mode;

− Energy transmitter logs (gas, steam, heat) and

automatic regulation of thermal energy output for

customers.

Dryer automated control and remote supervision:

Includes the following process control objects:

dryer; charging device; unloading mechanism;

receiver; condenser; hotwell.

Controlled parameters:

− dryer top pressure; pressures upstream of a

receiver.

− dryer lower part temperature; inlet and outlet air

temperatures;

− inlet and outlet product temperatures ;

− air consumption in a dryer;

3 STRUCTURE OF THE B-DCS

The B-DCS model includes the following basic

levels (fig. 1):

− emulation of sensing transducers and actuators

level

− processing unit level

− human interface (HI) level.

Field level - the level of the sensing transducers

and actuators. In the laboratory-scale plant the role

of sensing transducers is played by PC with program

emulation of a real object. Input-output (I/O)

modules are set on PC. The program simulates

functioning of field sensing transducers, emulating

their current output signals. Emulation programs

software can be based on the SCADA-system with

the proper scripts which are carrying out process

imitation or on special software based on the virtual

devices technology. Current signals are transferred

to the next level - on an input of the control unit.

4 MATHEMATICAL

MODELLING AND

OPTIMIZATION OF THE

BIOPRODUCTS DRYING

PROCESS

Let’s consider one of the variants of implementation

Figure 1: Structure of the B-DCS.

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

208

of the above mentioned B-DCS on the example of

the model of the dryer unit for drying bioactive

products. The creation and application of

computerized generalizing MMs and the

development of intensive drying process for

bioactive products exemplified by highly purified α

- amino acids.

The desiccation of highly purified α- forms of

irreplaceable amino acids as follows: Thr

(threonin), Trp (tryptophan), Leu (.Leucin), Ile (iso-

leucin) involves removal of the mixture of ethanol

(in which they are practically insoluble) and water

with solubility of 0.02-0.09 kg/kg at 20

0

C. The

residence time in vacuum dryer is up to 72 hours.

In view of the pressing requirement for the

development of commercial technology for intensive

desiccation of pure amino acids 25 types of dryers

were analyzed on the computer in an effort to find

the method of adequate intensive drying technology:

vacuum application, active hydrodynamic regimes.

A complex pilot plant was fabricated [1,2] for the

selection of appropriate drying process and the

following processes were tested : desiccation in

pseudo-liquified and densely purged beds ,

desiccation by pressure reduction (DPR), vacuum

oscillating desiccation - repeated alternation of

heating by hot gas and vacuum cooling, impulse

desiccation by depressurization of drying chamber

(DDC)- a new method proposed.

It was experimentally established that free moisture

is basically removed from the bioproducts being

investigated and they tend to agglomerate. The

agglomeration mechanism is related to the change in

the liquid phase composition upon desiccation: the

crystals partially dissolve in the mixture upon rapid

increase of water proportion (more volatile spirit is

removed faster) and subsequently start to stick to

each other. So as to loosen and break the

agglomerates the impulse depressurization was

effectively employed causing breaking normal

stresses depend-

ent on the duration and depth of terminal pressure

drop, size, inner structure and temperature of

agglomerates.

The proposed method alowed to meet the

requirements for the dispersive structure of amino

acids and to reduce

с

τ

to 0.5 hour or less. The

unit incorporates the dryer, heating agent feeding

line, depressurization system and receiver.

5 DRYING PROCESS

DESCRIPTION

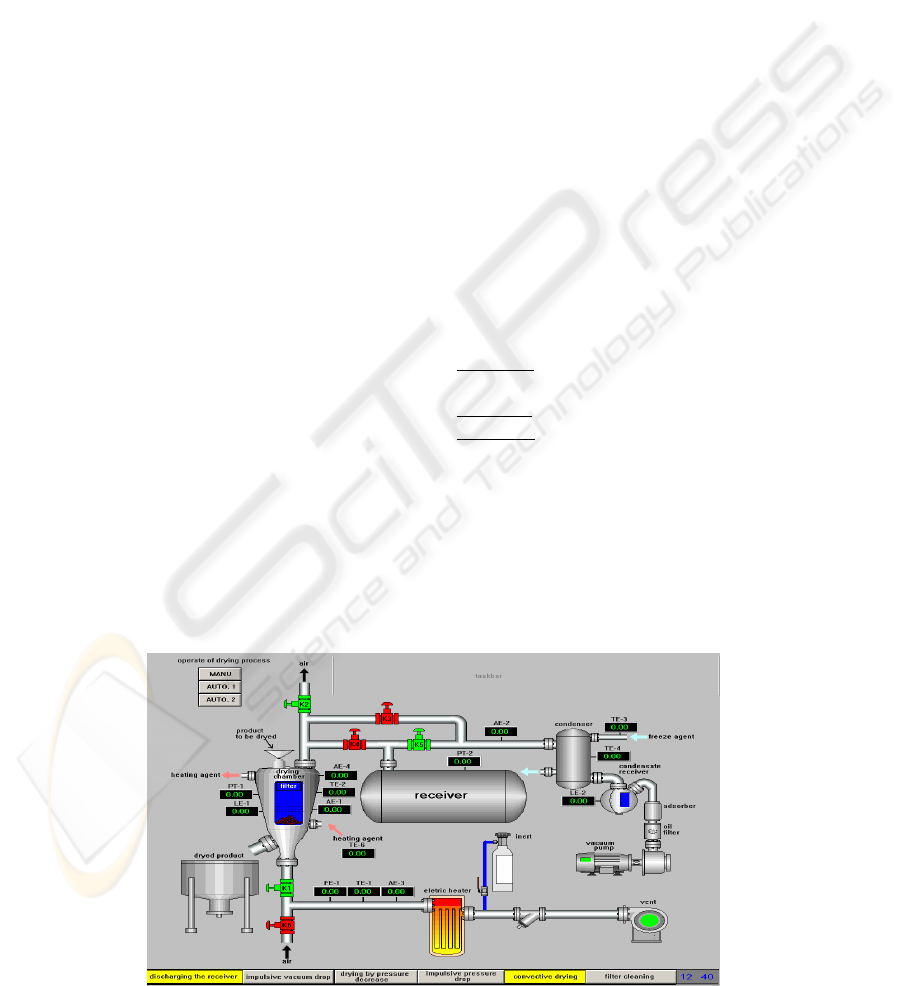

The installation scheme is represented in fig. 2

(screen shot of the engineer’s interface). The raw

material goes through the charging device of the

drying apparatus and then enters the drying

chamber. In the drying chamber the product is

exsiccated by hot air. The product is unloaded

pneumatically in the loading tank. In the drying

chamber vacuum creation is possible with the help

of pumping system consisting of the pump, the

condenser and the hotwell .The drying process can

be carried out in various ways. In emulation system

in the capacity of control and regulating blocks the

most widespread drying regimes are used.

Regime 1

– Drying in filtering and pseudo-liquefied

layers.

Regime 2

– Drying by pressure decline.

Regime 3

– Drying by the combined pressure drop

and vacuum.

This method integrates the following regimes of

drying:

− Preheating;

− Depressurization;

− Pumping out;

− Layer tossing up;

− Clearing the filter.

Figure 2: HI of the dryer unit.

HEAT-AND-POWER PROCESSES OPTIMIZATION BY MEANS OF MODEL-BASED SIMULATION

209

In the course of mathematical modelling the pressure

drop hydrodynamic calculations were made, based

on the model of stationary adiabatic flow from a

larger vessel via a confuser without friction. The

equation [2] in the explicit form was obtained for Pc.

The depressurization stage as vacuum dehydration

process was divided into two parts. The duration of

air evacuation

()

ов

τ

was calculated from the

formula [3]:

()

∫

=

κ

κ

τ

κ

τ

P

xP

ов

PPQ

dPV

00

,

)(

(1)

(1)

where V - free volume of drying chamber; k -

polytrope index; Р, Р

н

– pressures: current and

vapour saturation of multi component liquid phase;

Q (P) efficient pumping speed of vapour/air mixture

calculated by constant volume method [7];

x

G

-

vector of liquid phase composition; T - material

temperature; index "0" - adopted for initial values.

The analysis of internal heat mass transfer at the

stage of vapour pumping showed that it is described

by non linear differential equations of filtration and

heat transfer [1, 2]:

,

,

τ

ρλ

τ

ρ

τ

ρ

∂

∂

+

⎟

⎠

⎞

⎜

⎝

⎛

∂

∂

∂

∂

=

∂

∂

⎟

⎠

⎞

⎜

⎝

⎛

∂

∂

∂

∂

=

∂

∂

U

r

z

T

z

T

c

z

P

K

z

U

сс

pс

(2)

(2)

where

ημ

/КК

р

= - molar filtration

coefficient; К – permeability of capillar porous

solid ;

η

- kinematic viscosity coefficient of

vapour/air mixture being removed;

μ

- apparent

molecular mass of vapour/air mixture being

removed ;

с

ρ

- dry material density;

r

- heat of

vapour formation; с – specific heat;

λ

- heat

transfer coefficient; U – humidity of material;

τ

-

time; z – spatial coordinate (or material layer plane

orthogonal towards axis z ).

It was determined that heat transfer had no

influence on the process and, thus, vacuum

desiccation process has local invariants - functions

() ()

TxTU

G

,

and

()

TP which do not depend

on

τ

. The availability of invariants radically

reduces the required scope of experimental research

relating to combined heat and dehydrating influence

of desiccation process on the preparations and

facilitates kinematic calculations of desiccation

process. The measurements showed that at the layer

height H = 0.03 - 0.02 m the temperature of pressure

reduction desiccation was the same throughout the

whole product. In view of this the local invariants

play a balancing role and are calculated via

integration of the following system of ordinary

differential equations (SODE) [3]:

()

,

,

Ixy

dT

xd

UI

dT

dU

GG

G

−=

=

rUcI /

=

, (3)

whilst dehydration kinetics - by integration of

equation as follows:

[

]

()

()

[]

RTU

V

RT

R

c

r

VM

PQ

RT

q

R

cM

V

dT

dU

αμ

ρβμ

μ

ρ

τ

ρβμ

GG

G

G

G

G

G

,

,

,

⋅+

−

⋅+

+⋅−

⎟

⎠

⎞

⎜

⎝

⎛

=

, (4)

where

⋅

⋅

, - scalar product of vectors; М – mass

of dry material; R – universal gas constant; vectors

α

G

и

β

G

are determined only by the conditions of

vapour/liquid equilibrium [3],

х

G

, y

G

- vectors of

composition of liquid phase and removed vapours,

to be determined from the equation of vapour/liquid

equilibrium. The equation (4) is solved together with

the equations of material and power balance of

vapour pumping stage (DPR):

(

)

()

,

,0)(M

U,

τ

ττ

τ

ρ

ρ

τ

μ

q

d

dU

rM

d

dT

cM

d

d

VPQ

d

dU

dxyxdU

=−

=++

−

=

G

G

G

(а - liquid phase material balance) (в - vapour

material balance) (с - damp product power balance)

as ordinary differential equations system of

summarizing order n + 2.

Thus, a non trivial property of distillation material

balance was revealed (first equation of the system

(5)) to accumulate the error upon numerical

integration [3]. In system (5)

(a)

(в) (5)

(с)

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

210

ρ

- vapour density, М – dry product mass in the

dryer,

()

τ

q - heat supply rate. The system

thermodynamic parameters are determined by the

additivity rule:

хсUсс

с

GG

,+=

, (6)

yrr

GG

,=

,

where

с

с – specific heat of the dry product, c

G

and

r

G

- molar specific heat evaporation heat of the

components.

The analysis of heat mass transfer in the pseudo

liquified bed was performed within the external task

of mass exchange particle - heating agent for the

binary liquid mixture ethanol-water on the basis of

equations set (ES) of Stephan - Maxwell multi

component diffusion. The total mass exchange

intensity was set empirically by function

()

TU

в

,

ϕ

- relative air humidity at the outlet

from the layer, determined by methods of structural

risk minimization [5]. For heating stage kinetics ES

was derived:

() ()

()

()

()

,

,

,

,

,

т.н.

2

22

ττ

ττ

ϕ

ϕ

μϕμϕ

μτ

d

dU

U

xy

d

xd

TTcG

d

dU

c

r

d

dT

TxPP

TPP

TxPTP

MRT

G

d

dU

y

p

Hba

aaa

Hbaa

ya

⋅

−

=

−+⋅=

⎥

⎦

⎤

⎢

⎣

⎡

−

−

⋅−=

GG

G

(7)

where the composition of the vapours removed

(index y) from the amino acids

у

y

G

is calculated

with consideration of water vapours heating by gas,

index 2 refers to water,

g

ρ

– gas density at normal

volume flow rate G, с

p

– gas specific heat at

constant pressure.

The stage models are included into the calculation

sequentially , are interrelated by marginal conditions

and , in the aggregate, form a common DDC

process model adequate to the experimental data

obtained [2].

The hardware and operating modes of the

bioproducts drying shop have been optimized to

reported expenses in accordance with the approaches

[6]. The task of the pressure drop system design is

delineated and solved by decomposition. The

optimum operating modes of the unit are defined by

formulation and solution of the task of optimum

control with criterion functional:

()

[]

{}

∫

−+++=

c

dETTEZGЕЕ

М

I

hiathaaipii

τ

τ

0

1

, (8)

where

i

E ($/s) – expenses irrespective of the

mode,

pi

E – cost of 1 second of vacuum pump

operation,

ai

E – cost of 1 m

3

of sterile air,

ha

E

-

cost of heating of 1 m

3

of air per 1 К, index i

designates i variant of hardware,

()

τ

Z – regime

function equal to 0 at depressurization stages and to

1 at heating stages. Allowable equations

(

)

(

)

(

)()

[

]

τ

τ

τ

τ

ψ

ZTGM

ha

,,,

=

(9)

are limited by certain conditions ensuring product

quality. The analysis of the task with the application

of maximum principle of Pontryagin revealed the

structure of optimum control:

(

)()

[

]

τ

τ

ψ

ортhaорт

ZTGM ,,,

max

maxmax

=

(10)

where

maxmax

, GM

and

max

ha

T

-

maximum allowable values of parameters. It was

revealed that the increased rate of depressurization

system results in reduction of reported expenses on

DDC bioproducts. Optimum

()

τ

орт

Z and

с

τ

highly depend on the composition of the removed

mixture (

с

τ

for spirit is 4.4 times lower than

с

τ

for water). The regime optimization reduced the

reported expenses and

с

τ

by 40 %. In comparison

with vacuum-desiccators

с

τ

is reduced by order of

1

÷

2.

6 SIMULATION RESULTS

Some tests were made with irreplaceble amino acid

– Leucin. Figure 3 shows the results of the design

data and simulation experiments for main

parameters U - liquid specific mole contention

x –

alcohol mole fraction , T – temperature of the

material.

HEAT-AND-POWER PROCESSES OPTIMIZATION BY MEANS OF MODEL-BASED SIMULATION

211

Figure 3: Design and experimental data comparison of

Leucin drying. G = 0,007 m

3

/s, T

гр

= 95 °C, Н = 0,005 m,

τ

v

= 5 min. Firm lines – design: 1 – U, 2 – x

v

, 3 – T; — —

— – T, experiment, о – U, experiment.

7 CONCLUSIONS

In this paper we have presented a task-level system

which can be used for the following purposes:

1. Students familiarization with heat-mass transfer

processes in power equipment.

2. Development and identification of new

mathematical models of above-mentioned processes.

3. Optimization of the real equipment selection and

its operation modes.

On the example of the model of the dryer unit

theoretical base for optimization of bioactive

products drying technology have been developed.

The analysis of the problem with the application of

the Pontryagin’s maximum principle has revealed

optimal control structure. At the expense of the

mode optimization the costs and time of a

α-amino

acids drying (

τ

d

) are reduced by more than 40 %. In

comparison with the vacuum-shelf dryers

τ

d

of the

bioactive products is reduced by 1 - 2 orders.

REFERENCES

Sadykov R.A., Antropov D.N. Optimum equation and

automation of desiccation technology for

bioproducts. Izvestiya RAN. Series energetics. ¹6,

2005, pp. 85-92.

Sadykov R.A., Antropov D.N. Power saving drying

technology for bioactive products. Kazan. Kazan State

Energy University, 2005, p.174.

Sadykov R.A. Transfer process at short term phase contact

(on the example of drying processes). . Kazan. Kazan

State Energy University , 2004, p.176.

Sadykov R.A., Antropov D.N., Kafiatullin R.A.

Bioproduсts drying optimal control in oscillating

regimes. ICINCO – 2005. Second international

conference on informatics in control, automation and

robotics. Barcelona, Spain, September, 14 – 17, 2005.

Vol. I. p.p. 176 – 181.

Kryanev A.V., Lukin G.V. Mathematical methods of

indefinite data processing.- M.: Phyzmatlit, 2003. 216

pp.

Baumstein I.P. Classification of the tasks of optimum

control of the drying processes.

Rozanov L.N. Vacuum technology. M.: Higher School,

1982.207 pp.

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

212