ON THE USE OF OPTIMIZATION METHODS FOR THE

MINIMIZATION OF FERTILIZER APPLICATION ERROR WITH

CENTRIFUGAL SPREADERS

Teddy Virin

§

, Jonas Koko

§§

, Emmanuel Piron

§

and Philippe Martinet

§§§

§

Cemagref

03150 Montoldre, France

§§

LIMOS, Universit

´

e de Blaise Pascal

63177 Aubi

`

ere cedex, France

§§§

LASMEA, Universit

´

e de Blaise Pascal

63177 Aubi

`

ere cedex, France

Keywords:

Optimization, Augmented lagrangian, Centrifugal spreading, Fertilizer application error.

Abstract:

Fertilizer application is one of the most important operations in agricultural production. Thanks to their low

cost and robustness, centrifugal spreaders are widely used to carry out this task. However, when distances be-

tween successive paths followed by the tractor in the field are not constant, application errors occur. These ones

generally cause waters pollution and economic issues. In this paper, to limit harmful environmental effects

and disastrous drop in production due to centrifugal spreading, we propose an approach based on optimiza-

tion techniques to improve the fertilization quality. An optimization criterion relying on a spatial distribution

model, obtained in previous works, is considered. To compute optimal parameters which should be used as

reference variables for the control of the spreader in the future, mechanical constraints are introduced. Faced

with a large scale problem, we use an augmented lagrangian algorithm combined with a l-bfgs technique.

Simulations results show low application error values comparing to fertilization inaccuracies found without

optimization.

1 INTRODUCTION

Fertilization operation is commonly achieved to apply

nutrients to make up the soil deficiencies and there-

fore enable a correct growth of plants in farmlands.

Centrifugal spreading is the main technique used to

distribute mineral fertilizers with respect to desired

doses calculated from agronomical and pedological

reasonings. This method permits to have uniform dis-

tributions as long as the trajectories followed by the

tractor equipped with spreader are parallel and regu-

larly spaced. Unfortunately, the use of this kind of

applicator is quickly limited when geometrical sin-

gularities, such as irregularly spaced tramlines, non

parallel paths or start and end of spreading, occur. In-

deed, at these spots, local application errors can be

observed. In some cases, over-application can lead

to an eutrophication phenomenon causing the disap-

pearance of aquatic species (Isherwood, 1998). More-

over, when the distributed amounts are below the pre-

scribed dose, the final production is often very low.

Thus, these statements lead the different governments

in Northern Europe to impose some strict rules as

specified in (Bruxelles, 2005). Confronted with these

requirements, many researches are carried out in or-

der to not only reduce dramatic environmental effects

but also increase margins in agricultural crop produc-

tion. In this study, we focus on a new approach based

on optimization techniques. We consider a cost func-

tion formalized from the actual spatial distribution

model instead of using the traditional method relying

on the best arrangement of transverse distribution. To

take into account the mechanical limits of applicator,

constraints are also considered. Thus, the computed

optimal parameters should be used as reference values

for future works dealing with the control of spreader.

This paper is organized as follows. The next section

exposes the centrifugal spreading principles and the

related drawbacks. In section 3, the cost function

modeling is dealt with. To solve the problem in an

efficient way, the problem decomposition and the op-

timization techniques are detailed in section 4. In the

124

Virin T., Koko J., Piron E. and Martinet P. (2006).

ON THE USE OF OPTIMIZATION METHODS FOR THE MINIMIZATION OF FERTILIZER APPLICATION ERROR WITH CENTRIFUGAL SPREADERS.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 124-129

DOI: 10.5220/0001212501240129

Copyright

c

SciTePress

last section, because of more complicated phenomena

occurring in boundary zones, we apply this method

along parallel and non parallel trajectories only in the

main field body and expose simulation results.

2 CENTRIFUGAL SPREADING

DRAWBACKS

According to the soil and crops characteristics, agri-

cultural engineers state the amounts to be applied

within the farmland. These desired doses often takes

the form of prescribed dose map. This map depicts the

field which is virtually gridded and where each mesh

corresponds to the previously specified doses. Fertil-

ization aims to distribute nutrients so that the actual

spread doses get close to the prescribed ones. This

spreading regularity is above all performed by cen-

trifugal spreaders with double spinning discs which

eject fertilizers along each tramline in the field. The

functioning principles of these applicators are very

simple. Indeed, while the tractor progresses, fertiliz-

ers granulars contained in the hopper pour onto each

disc and are ejected by centrifugal effect.

Nowadays, with precision farming technologies, in

order to apply inputs according to the machine lo-

cation and a prescribed dose map, tractor-implement

combination is equipped with a GPS antenna, a radar

speed sensor and an actuator. The two first tools en-

able to know the tractor position and speed. Con-

cerning the actuator, it permits to control the fertilizer

mass flow rate. The actual amount of applied fertiliz-

ers currently called spread pattern has an irregular dis-

tribution which is often underlined by the transverse

distribution curve obtained by summing the amounts

along each travel direction. An example of spread pat-

tern and its related transverse distribution for only one

disc are depicted in Figure 1. Thus, this spatial het-

eregeousness lead the tractor driver to follow outward

and return paths in order to have an uniform deposit

from transverse distribution summation for each suc-

cessive tramlines within the arable land. This strategy

is detailed in Figure 2. As we can notice, fertiliza-

tion strategy is essentially based on the best overlap-

pings of transverse distribution according to the dif-

ferent tractor trajectories. This method is applied for

experiments undertaken to evaluate fertilizer applica-

tion accuracy or to investigate device settings accord-

ing to tests procedures such as (ISO, 1985). So, these

procedures enable to select optimal machine settings

in order to obtain a regular deposit. Some studies re-

lying on these tests are also led to assess performance

of applicators like in (Yule et al., 2005). Deposits are

considered to be uniform when the distance between

two overlapping lines are equal to the distance sep-

arating two successive tramlines. Moreover, if this

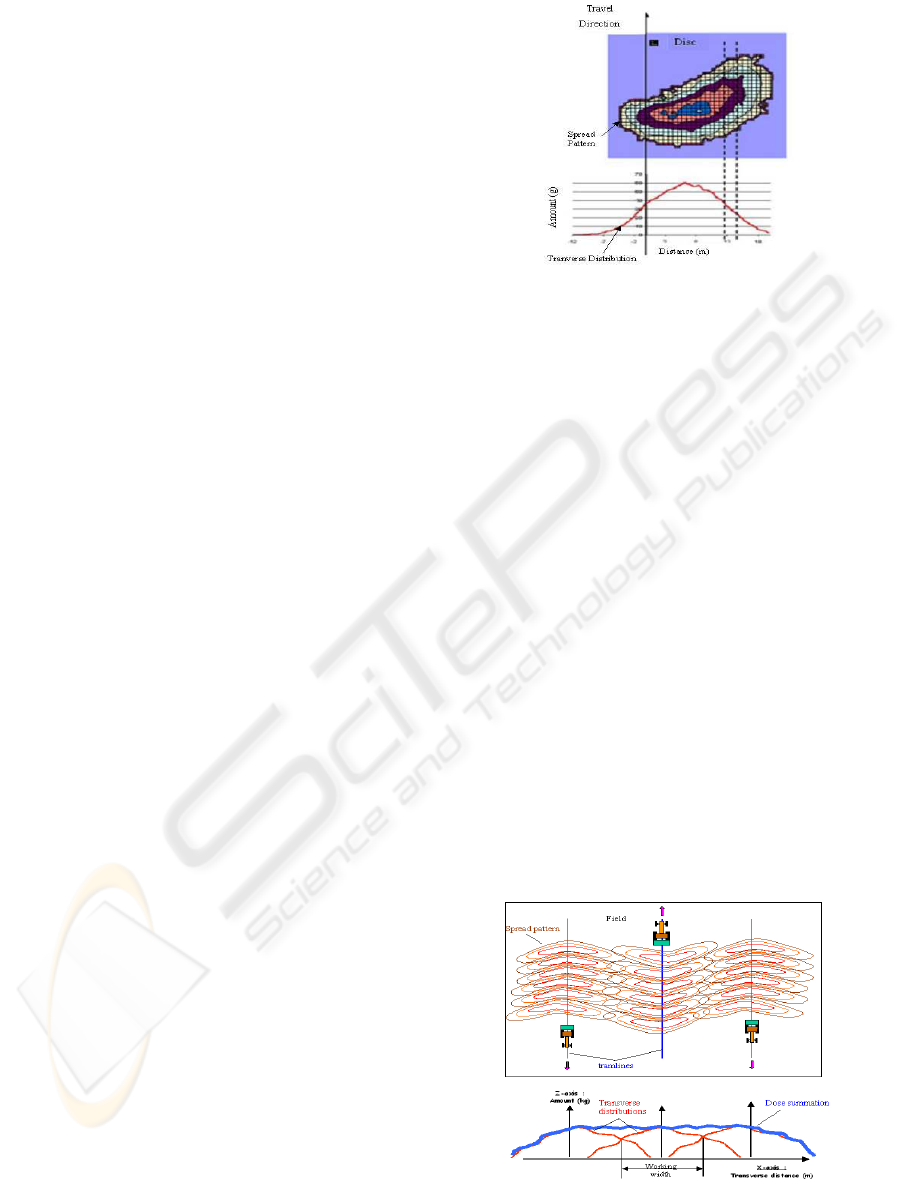

Figure 1: Spread pattern (spatial distribution) and trans-

verse distribution (red curve).

condition is checked, overlapping lines are symmetry

axes which make two consecutive paths coincide. In

this case, the distance between two successive trajec-

tories, called working width, is said optimal. Unfortu-

nately, when applying this strategy in the field, the ac-

tual phenomenon occurring during spreading process

is ignored. Indeed, the deposit on the ground results

in fact from the accumulation of several amounts dis-

tributed for different spreader GPS positions. There-

fore, when geometrical singularities occur, like non

parallel paths or start and end of spreading, fertiliza-

tion application errors appear as illustrated in Figure

3(c) where results are obtained by simulating spread

patterns overlappings with settings imposed by manu-

facturers rules. To limit these issues, a solution could

be to look for optimal paths for the machine as in (Dil-

lon et al., 2003).

However, this kind of solution cannot be applied

when tramlines are already fixed by other agricultural

operations like sowing. So, it is clear that some ef-

forts must be done to achieve better spread patterns

arrangement according to geometrical constraints met

Figure 2: Fertilization strategy based upon transverse dis-

tribution summation.

ON THE USE OF OPTIMIZATION METHODS FOR THE MINIMIZATION OF FERTILIZER APPLICATION ERROR

WITH CENTRIFUGAL SPREADERS

125

(a) Prescribed

dose map ob-

tained from

agronomical

considerations.

(b) Actual dose

map obtained by

applying the fer-

tilization method

based on adjust-

ment of transverse

distribution.

(c) Application errors

map calculated from the

difference between the

prescribed dose map and

actual dose map.

Figure 3: Application errors resulting from the reasoning based on the best transverse distribution investigation and not on

spread patterns overlappings.

in farmland during fertilization practice. The com-

puted adjustments should be continuously achieved

for each position of applicator by modifying its set-

tings. In this work, we study then a method which

permits to calculate optimal parameters to have the

best spread patterns arrangement within the field in

the presence of imposed tramlines.

3 COST FUNCTION

In order to develop a suitable optimization criterion,

we must consider the spread pattern model. This

model needs then the definition of some parameters

such as the time (t ∈ R), the spatial domain, in other

words the field, (Ω ∈ R

2

), the path (s(t) ∈ Ω), the

coordinates of points (x ∈ Ω), the distance between

s(t) and x (r(x, t) ∈ R) and the angle between

−−−→

s(t)x

and s(t) (θ(x, t) ∈ R). The spread pattern shown in

Figure 1, is currently defined by its medium radius

and medium angle. The first parameter, varying with

the speed of disc, corresponds to the distance between

the disc centre and the spread pattern one while the

second, modifiable with the fertilizers dropping

point on the disc, states the angle between the travel

direction and the straight line passing through the

disc centre and the spatial distribution one. Here, the

respective mass flow rates for the right and left discs

are defined by m(t) and d(t). ρ(t) and ξ(t) stand

for the medium radius related to the right and left

discs respectively. At last, ξ(t) and ψ(t) correspond

to the right and left discs medium angles. All these

parameters are defined in R. By assuming σ

r

and σ

θ

to be the respective constant standard deviations for

the medium radius and the medium angle, we can

calculate the right and left spatial distributions q

r

and

q

l

, according to (Olieslagers, 1997), as:

q

r

(x, m(t), ρ(t), ϕ(t)) = τ · exp(−A(x, t)

2

/a)

· exp(−B(x, t)

2

/b) (1)

q

l

(x, d(t), ξ(t), ψ(t)) = κ · exp(−C(x, t)

2

/a)

· exp(−D(x, t)

2

/b) (2)

with A(x, t) = r(x, t) − ρ(t) (3)

B(x, t) = θ(x, t) − ϕ(t) (4)

C(x, t) = r(x, t) − ξ(t) (5)

D(x, t) = θ(x, t) − ψ(t) (6)

and where a = 2σ

2

r

, b = 2σ

2

θ

, τ = m(t)/(2πσ

r

σ

θ

)

and κ=d(t)/(2πσ

r

σ

θ

). To simplify notations,

we define M (t) = (m(t), d(t)) ∈R

2

, R(t) =

(ρ(t), ξ(t)) ∈R

2

and Φ(t) = (ϕ(t), ψ(t)) ∈ R

2

. The

global distribution is then obtained as the summation

of right and left contributions:

q

tot

(x, M (t), R(t), Φ(t)) = q

r

(x, m(t), ρ(t), ϕ(t))

+q

l

(x, d(t), ξ(t), ψ(t)) (7)

Thus, the actual distributed dose Q ∈ R

2

during the

interval of time (0, T ) for single tramline can be cal-

culated as:

Q(x, M, R, Φ)=

Z

T

0

q

tot

(x, M (t), R(t), Φ(t)) dt (8)

If Q

∗

stands for the prescribed dose, the cost function

to be minimized is given by:

F (M, R, Φ) =

Z

Ω

[Q(x, M, R, Φ) − Q

∗

]

2

dx (9)

Given that (9) cannot be calculated in an analytical

way, discretization is necessary. So, Ω is gridded

so that Q and Q

∗

can be computed with bilinear ap-

proximations. A temporal discretization is also car-

ried out. This is done by dividing the interval (0, T )

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

126

into n elements with equal length δ = T/n. We

can then define t

j

= jδ with j = 0, 1, ..., n. Con-

sequently, we can assume M

j

= M(t

j

), R

j

= R(t

j

)

and Φ

j

= Φ(t

j

). The corresponding vectors are de-

fined as M = [M

0

· · · M

n

]

T

, R = [R

0

· · · R

n

]

T

and

Φ = [Φ

0

· · · Φ

n

]

T

. In order not to untimely solicit ac-

tuators, constraints are introduced. So, the functions

M, R and Φ and their time derivative are subject to

bound constraints. The set of solutions is then defined

by S =

(M , R, Φ) ∈ R

6(n+1)

so that:

M

min

≤ M ≤ M

max

R

min

≤ R ≤ R

max

Φ

min

≤ Φ ≤ Φ

max

|M

i+1

− M

i

| ≤ αδ

|R

i+1

− R

i

| ≤ βδ

|Φ

i+1

− Φ

i

| ≤ γδ,

(10)

where α, β and γ are known parameters fixed with

respect to the machine mechanical characteristics. We

obtain then a nonlinear programming problem given

by:

(P) min

(M ,R,Φ)∈S

F (M , R, Φ) (11)

The set S is in our case bounded closed. Thus, ac-

cording to the Weierstrass theorem, the problem (P)

has at least one solution. In most cases, there exist

several tramlines and the actual distributed dose for

all trajectories is then obtained by the summation of

the applied dose for each indexed k path:

Q(x, U )=

w

X

k=1

Q

k

(x, U ) (12)

withQ

k

(x, U )=

Z

t

k

f

t

k

i

q

tot

(x, M (t), R(t), Φ(t))dt(13)

and where U = (M, R, Φ). Here, w is the number

of paths and the trajectories s

k

(t) are assumed to be

defined in the interval (t

k

i

, t

k

f

). If we consider also

the definitions of M

k

j

= M(t

k

j

), R

k

j

= R(t

k

j

), and

Φ

k

j

= Φ(t

k

j

) we can then use the discretization tech-

niques as before. Consequently, from these defini-

tions, optimization in the whole field considering all

paths can be carried out by solving the problem (P).

4 METHODOLOGY OF

OPTIMIZATION

Fields mostly include many tramlines several hundred

metres long. If we apply the discretization scheme

previously detailed, we are confronted with a large

scale problem. Indeed, in our case, like most pre-

scribed dose map, the field is 1 m gridded. To lose

informations as little as possible, 2 samples of pa-

rameters per elementary mesh are computed. So if

we consider for example only 4 tramlines 100 m long

within the farmland, after discretization, the number

variables raises to 4800. From this statement, it is

clear that solving the optimization problem without

decomposition is prohibitive. Let us precise some no-

tations before the decomposition explanations:

K

1

= {k ∈ N| 1 ≤ k ≤ w} ,

K

2

= {k ∈ N| 1 ≤ k ≤ w − 1} ,

K

3

= {k ∈ N| 2 ≤ k ≤ w} ,

L

1

= {l ∈ N| ∀z ≥ 2 ∈ N, 1 ≤ l ≤ z} ,

L

2

= {l ∈ N| ∀z ≥ 2 ∈ N, 2 ≤ l ≤ z} ,

Ω =

S

k∈K

1

Ω

k

, Ω

k

=

S

l∈L

1

Ω

k

l

,

with Ω

k

∈R

2

the k

th

subdomain of Ω, and Ω

k

l

∈R

2

the

l

th

subdomain of Ω

k

. Here, we decompose the prob-

lem so that each path s

k

(t) is individually dealt with.

So, the subdomains Ω

k

are defined so that:

∂Ω

k

∩ Ω

k+1

= s

k+1

(t), ∀(k, t) ∈ K

2

× (t

k+1

i

, t

k+1

f

)

∂Ω

k

∩ Ω

k−1

= s

k−1

(t), ∀(k, t) ∈ K

3

× (t

k−1

i

, t

k−1

f

)

In order to make easier to understand the spatial de-

composition, Figure 4 illustrates the example of three

parallel tramlines in a domain Ω with a rectangular

geometry.

Figure 4: Rectangular domain Ω divided into 9 subdomains

Ω

k

l

, 1 ≤ l ≤ 3, 1 ≤ k ≤ 3.

Moreover, if we assume the vectors M

k

l

, R

k

l

, Φ

k

l

to be the respective restrictions of M , R and Φ in the

subdomain Ω

k

l

, we can also define also the set S

k

l

as

the restriction of S in the same subdomain. By tak-

ing into account the symmetries conditions exposed

in section 2, the natural decomposition of (P) is given

by:

(P

′

)

min

P

z

l=1

P

w

k=1

J

k

l

(x, M

k

l

, R

k

l

, Φ

k

l

)

(m

k

l

, R

k

l

, Φ

k

l

)∈S

k

l

, (l, k) ∈ L

1

×K

1

(14)

where

J

k

l

(x, M

k

l

, R

k

l

, Φ

k

l

) =

Z

Ω

k

l

[Q

k

l

(x) − Q

∗

]

2

dx (15)

ON THE USE OF OPTIMIZATION METHODS FOR THE MINIMIZATION OF FERTILIZER APPLICATION ERROR

WITH CENTRIFUGAL SPREADERS

127

with Q

k

l

(x) the actual distributed dose within Ω

k

l

tak-

ing into account not only the amounts already ap-

plied in Ω

k−1

l

and Ω

k

l−1

but also the future distributed

dose along the path s

k+1

(t) which is predicted so that

it respects the symmetries properties previously ex-

plained. The problem (P

′

) is an optimization prob-

lem subject to inequality constraints. For (l, k) ∈

L

1

× K

1

, to minimize the functional J

k

l

we consider

then the problem (P

ineq

) defined as:

(P

ineq

)

min J

k

l

(M

k

l

, R

k

l

, Φ

k

l

)

u

j

≤ h

j

(M

k

l

, R

k

l

, Φ

k

l

) ≤ v

j

,

j = 1, 2, ...dim(M

k

l

)

(16)

where h

j

denotes the j

th

double inequality, u

j

and

v

j

its lower and upper bound. In order to obtain

an acceptable solution after algorithm execution and

avoid solving the problem which consists in determin-

ing saturated constraints, we choose to apply an aug-

mented lagrangian algorithm (Bertsekas, 1982) asso-

ciated with a l-bfgs technique shown to be efficient

with large scale optimization problem (Byrd et al.,

1994). Moreover, desirous of obtaining the best fer-

tilizer application in the field, it is important to note

that the optimization algorithm is not time-bounded.

5 APPLICATION

Here, we focus essentially on main fiel body applica-

tion and not on boundaries area where more complex

phenomena occur. A constant prescribed dose fixed

at 100 Kg/Ha is considered because even in the case

of uniform desired rate, application errors appear. The

speed of tractor is also constant and equal to 10 Km/h.

The studied farmland is illustrated in Figure 5.

0 50 100 150 200

−100

−50

0

50

100

x−coordinate (m)

y−coordinate (m)

main field body trajectories

headlands

boundaries

N

1

2

3

4

5

6

P

Path number P

Figure 5: Field with parallel and non parallel tramlines.

The default working width is fixed at 24 m. A nar-

rowing occurs at the end of the first path. The distance

between the 4

th

and 5

th

tramlines is 23 m while it is

equal to 21 m between the 5

th

and 6

th

trajectories. In

practice, the manufacturers settings do not vary dur-

ing time and are determined to be optimal with 24 m

working width. With these settings, we obtain errors

shown in Figure 6. As we can notice, over-application

areas appear on the left and the right of the 4

th

tram-

Figure 6: Application errors obtained with the manufactur-

ers settings.

line. Over-dosage is very important at the end of the

first path and almost reaches 95%. Futhermore, we

can distinguish an under-application zone slightly be-

low the break-point which marks the travel direction

change for this same trajectory. Everywhere else, er-

ror is included between -6% and +7% and is then ac-

ceptable. To reduce these fertilization errors, we ap-

ply our optimization methodology as detailed in the

previous section making sure that the considered me-

chanical constraints gather the characteristics of the

most used spreader. As in practice, for consecutive

parallel tramlines, optimal parameters are computed

so that they are time independent. So, calculated vari-

ables for the paths 3 to 6 are constant during time and

are recapitulated in Table 1. These values are very

close to actual current values.

Table 1: Optimal values for successive parallel tramlines

(M

f

: Mass Flow Rate (Kg/min); R

m

: Medium Radius; θ

m

:

Medium Angle (

◦

)).

Left Disc

Path 3 Path 4 Path 5 Path 6

M

f

19.32 17.92 19.41 20.6

R

m

15.13 14.61 14.7 15.17

θ

m

-20.78 -20.96 -19.66 -19.79

Right Disc

Path 3 Path 4 Path 5 Path 6

M

f

20.7 21.24 17.26 16.95

R

m

15.49 15.55 14 14

θ

m

18.93 18.37 18.61 18.79

Unlike the previous paths, optimal variables for the

two first trajectories are dependent time. The opti-

mized parameters for the first path are shown in Fig-

ure 7. The parameters for the left and right discs

appear respectively on the left and the right. As ex-

pected, after the travel direction change, the medium

radius drops. For the left disc, the mass flow rate

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

128

Figure 7: Optimal parameters for the first path.

Figure 8: Optimal parameters for the second path.

slightly varies around break-point and seems not to

be affected by the occurring narrowing. However,

for the right disc, it increases before the break-point

and drops after this one. Concerning the medium an-

gle, a similar evolution is observed around this point.

Figure 8 shows an increasing of all parameters for

each disc. This phenomenon can be explained by the

narrow pass occurring when the tractor comes in the

main field body. The values reached after stabilization

are close to the ones set by manufacturers with 24 m

spaced parallel trajectories.Figure 9 exposes a simu-

lation result in the main field body with the optimized

parameters. As we can notice, application errors are

reduced comparing to the ones exposed in Figure 6.

Optimization leads to errors included between -10%

and +6.3%, which is very satisfying with regard to

environmental and economic requirements.

6 CONCLUSION

A new method for optimization of fertilizer applica-

tion by centrifugal spreaders has been presented. To

Figure 9: Application errors obtained after optimization.

make sure that optimized parameters respect the ac-

tual process and can be used as reference variable for

the future control of the machine, bounds constraints

have been considered. Given the large scale prob-

lem resulting from the discretization, we have decom-

posed it and applied an augmented lagrangian algo-

rithm with a l-bfgs technique. Optimal parameters en-

able to really limit application errors. Future studies

are needed to optimize spreading process in bound-

aries zones. The computed variables for the whole

field should then significantly enhance spreading ac-

curacy.

REFERENCES

Bertsekas, D. P. (1982). Constrained Optimization and La-

grange Multipliers Methods. Academic Press, New

York.

Bruxelles (2005). Mise en oeuvre de la directive 91/676/cee

- pollution par les nitrates a partir de sources agricoles.

Byrd, R. H., Nocedal, J., and Schnabel, R. B. (1994). Rep-

resentations of quasi-newton matrices and their use

in limited memory methods. Mathematical Program-

ming, 63:129–156.

Dillon, C. R., Shearer, S., Fulton, J., and Kanakasabai, M.

(2003). Optimal path nutrient application using vari-

able rate technology. In Proc. of the Four th European

Conference on Precision Agriculture, pages 171–176.

Isherwood, K. F. (1998). Mineral Fertilizer Use and the

Environment. IFA.

ISO (1985). ISO 5690/1 Equipment for distributing fertil-

izers - Test methods - Part 1: Full width fertilizer dis-

tributors. International Organization for Standardiza-

tion, Geneve.

Olieslagers, R. (1997). Fertilizer distribution modelling for

centrifugal spreader design. PhD thesis, K.U. Leuven.

Yule, I., Lawrence, H., and Murray, R. (2005). Performance

of fertiliser spreading equipment for precision agricul-

ture applications. In 1st International Symposium on

Centrifugal Fertiliser Spreading, pages 10–18.

ON THE USE OF OPTIMIZATION METHODS FOR THE MINIMIZATION OF FERTILIZER APPLICATION ERROR

WITH CENTRIFUGAL SPREADERS

129