A MULTI-OBJECTIVE GENETIC ALGORITHM FOR

CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY

Ramiro Varela, César Muñoz, María Sierra

University of Oviedo. Department of Computing. Artificial Intelligence Centre. Campus of Viesques, 33271 Gijón, Spain

Inés González-Rodríguez

University of Cantabria. Department of Mathematics, Statistics and Computing. Los Castros s/n,39005, Santander, Spain

Keywords: Multi-objective optimization, Genetic Algorithms, Cutting Stock, Meta-heuristics.

Abstract: In this paper, we confront a variant of the cutting-stock probl

em with multiple objectives. It is an actual

problem of an industry that manufactures plastic rolls under customers’ demands. The starting point is a

solution calculated by a heuristic algorithm, termed SHRP that aims mainly at optimizing the two main

objectives, i.e. the number of cuts and the number of different patterns; then the proposed multi-objective

genetic algorithm tries to optimize other secondary objectives such as changeovers, completion times of

orders weighted by priorities and open stacks. We report experimental results showing that the multi-

objective genetic algorithm is able to improve the solutions obtained by SHRP on the secondary objectives

and also that it offers a number of non dominated solutions, so that the expert can chose one of them

according to his preferences at the time of cutting the orders of a set of customers.

1 INTRODUCTION

This paper deals with a real Cutting-Stock Problem

(CSP) in manufacturing plastic rolls. The problem is

a variant of the classic CSP, as it is usually

considered in the literature, with additional

constraints and objective functions We have solved

this problem in (Puente et al. 2005, Varela et al.

2006 ) by means of a GRASP algorithm (Resende

and Ribeiro, 2002) termed Sequential Heuristic

Randomized Procedure (SHRP), which is similar to

other approaches such as the SVC algorithm

proposed in (Belov and Scheithauer, 2006). Even

though SHRP tries to optimize all objective

functions, in practice it is mainly effective in

optimizing the main two ones: the number of cuts

and the number of patterns. It is due to SHRP

considering all objective functions in a hierarchical

way that it pays much more attention to the first two

ones than to the remaining. In this work we propose

a Multi-Objective Genetic Algorithm (MOGA) that

starts from a solution computed by SHRP algorithm

and tries to improve it regarding three secondary

objectives: the cost due to changeovers or setups, the

orders’ completion time weighted by priorities and

the maximum number of open stacks.

Generated

rolls

Cutting

knives

Maximum width

Trim loss

Film

movement

Bi

g

roll

Pressure rollers

Trim loss

Generated

rolls

Minimum width

Figure 1: Working schema of the cutting-machine.

The paper is organized as follows. Next section

is devoted to briefly describe the production process

of plastic rolls. In section 3, the problem formulation

is given. As this formulation is rather complex, in

186

Varela R., Mu

˜

noz C., Sierra M. and Gonz

´

alez-Rodr

´

ıguez I. (2007).

A MULTI-OBJECTIVE GENETIC ALGORITHM FOR CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY.

In Proceedings of the Second International Conference on Software and Data Technologies - PL/DPS/KE/WsMUSE, pages 186-193

Copyright

c

SciTePress

section 4 we have introduced an example to clarify

both the formulation and the whole process of

obtaining a solution. In section 3, the main

characteristics of the proposed MOGA are

described. In section 4, we report results from a

experimental study. Finally, in section 5, we

summarize the main conclusions and some ideas for

future work.

2 PRODUCTION PROCESS

Figure 1 shows the schema of the cutting machine.

A number of rolls are cut at the same time from a

big roll according to a cutting pattern. Each roll is

supported by a set of cutting knives and a pressure

roller of the appropriate size. At each of the borders,

a small amount of product should be discarded,

therefore there is a maximum width that can be used

from the big roll. There is also a minimum width,

due to the capability of the machine to manage trim

loss. Moreover, a maximum number of rolls can be

cut at the same time. When the next cut requires a

different cutting pattern, the process incurs in a setup

cost due to changing cutting knives and pressure

rollers.

The problem has also a number of constraints

and optimization objectives that make it different

from conventional formulations. For example

underproduction is not allowed and the only

possibility for overproduction is a stock declared by

the expert. Once a cut is completed, the rolls are

packed into stacks. The stack size is fixed for each

roll width, so a given order is composed by a

number of stacks, maybe the last one being

uncompleted. Naturally, only when a stack is

completed it is taken away from the proximity of the

cutting machine. So, minimizing the number of open

stacks is also convenient in order to facilitate the

production process. Moreover, some orders have

more priority than others. Consequently the delivery

time of orders pondered by the client priority is an

important criterion as well.

3 PROBLEM FORMULATION

The problem is a variant of the One Dimensional

Cutting-Stock Problem, also denoted 1D-CSP. In

(Gilmore and Gomory, 1961) the first model is

proposed for this problem. It is defined by the

following data: (m, L, l=(l

1

,...,l

m

), b = (b

1

,...,b

m

)),

where L denotes the length of each stock piece (here

the width of the big roll), m denotes the number of

piece types (orders) and for each type i=1,…,m, l

i

is

the piece length (roll width), and b

i

is the order

demand. A cutting pattern describes how many

items of each type are cut from a stock length. Let

column vectors A

j

=(a

1j

,…,a

mj

) ∈ Ζ

+

m

, j=1,…,n,

represent all possible valid cutting patterns, i.e. those

satisfying

∑

=

≤

mi

iij

Lla

,...,1

where a

ij

is the number of pieces of order i that are

generated by one application of the cutting pattern

A

j

. Let x

j

, j=1,…,n, be the frequencies, i.e. the

number of times each pattern is applied in the

solution. The model of Gilmore and Gomory aims at

minimizing the number of stock pieces, or

equivalently minimizing the trim-loss, and is stated

as following

∑

=

−

=

nj

j

CSPD

xz

,...,1

1

min

mibxats

i

nj

jij

,...,1,..

,...,1

=≥

∑

=

njx

j

,...,1,Ζ =

∈

+

From this formulation, the problem is usually

solved by Linear Programming based methods

(Umentani et al. 2003). However, this model is not

directly applicable to our case mainly due to the

non-overproduction constraint, but it can be easily

adapted as we will see in the sequel. We start by

giving a detailed formulation of the main problem;

that considering all characteristics and optimization

criteria relevant from the point of view of the

experts. As the number of optimization criteria is too

large to deal with all of them at the same time and

the search space could be very large, we have opted

by introducing a simplified problem; i.e. a problem

with a lower number of objective functions and also

with a smaller search space in general. Once the

simplified problem is solved, the solution will be

adapted to the original problem; in this process all

the objectives will be considered.

3.1 The Main Problem

In order to clarify the problem definition, we present

the data of the machine environment and the clients’

orders, the form and semantics of a problem

solution, the problem constraints and the

optimization criteria in the hierarchical order in

which they are usually considered by the expert.

Given

• The set of parameters of the cutting machine:

the maximum width of a cut L

max

, the minimum

A MULTI-OBJECTIVE GENETIC ALGORITHM FOR CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY

187

width of a cut L

min

, the maximum number of

rolls that can be generated in a cut C

max

, the

minimum and the maximum width of a single

roll, W

min

and W

max

respectively, and the

increment of width

Δ

W between two

consecutive permitted roll widths.

• The setup costs. There is an elementary setup

cost SC and some rules given by the expert that

allows calculating the total setup cost from a

configuration of the cutting machine to the next

one. The setup cost is due to roller and cutter

changes as follows. The cost of putting in or

taking off a pressure-roller is SC; the cost of

putting in an additional knife is 3SC, and the

cost of dismounting a knife is 2SC.

• The types of pressure-rollers PR =

{PR

1

,…,PR

p

} and the mapping F

PR

from roll

widths to pressure-rollers.

• The mapping F

ST

from roll widths to stack sizes

or number of rolls in each stack unit.

• The orders description given by (M={1,...,m},

b = (b

1

,...,b

m

) , l=(l

1

,...,l

m

), p=(p

1

,...,p

m

)) where

for each order i = 1,…,m, b

i

denotes the

number of rolls, l

i

denotes the width of the rolls

and p

i

the order priority.

• The stock allowed for overproduction (S

={m+1,...,m+s}, bs = (b

m+1

,...,b

m+s

), ls =

(l

m+1

,...,l

m+s

)) where for each i=1,…,s, b

m+i

denotes the number of rolls of type m+i allowed

for overproduction and l

m+i

denotes the width of

these rolls.

• The set of feasible cutting patterns, for the

orders and stock given, A where each A

j

∈A is,

A

j

=(a

1j

,…,a

mj

,a

(m+1)j

,…,a

(m+s)j

) ∈ Ζ

+

m+s

and

denotes that, for each i=1,…,m+s, a

ij

rolls of

order i are cut each time the cutting pattern A

j

is

applied. A cutting pattern A

j

is feasible if and

only if both of the following conditions hold

∑

∪∈

≤=≤

SMi

iijj

LlaLL

maxmin

,

∑

∪∈

≤=

SMi

ijj

CaC

max

being L

j

and C

j

the total width and the number

of rolls of pattern A

j

respectively. D

j

= L

max

– L

j

denotes the trim-loss of the cutting pattern.

The objective is to obtain a cutting plan (Π, x),

where Π=(A

1

,…,A

|Π|

)∈A

|Π|

and x = (x

1

,...,x

|Π|

) ∈Ζ

+

|Π|

denotes the pattern frequencies. The cutting patterns

of Π are applied sequentially, each one the number

of times indicated by its frequency. A

j

l

, 0≤j≤|Π|,

0≤l≤x

j

, denotes the lth cut corresponding to pattern

A

j

and CI(A

j

l

) is the cut index defined as

(

)

∑

−=

+=

1,...,1 jk

k

l

j

lxACI

Given an order i∈M its first roll is generated in cut

A

j

1

such that A

j

is the first pattern of Π with a

ij

≠ 0,

this cut is denoted CU

start

(i). Analogously, the last

roll of order i is generated in cut A

k

xk

so that A

k

is the

last pattern of Π with a

ik

≠ 0, this cut is denoted

CU

end

(i).

As we have considered feasible cutting patterns,

the only constraint that should be required to a

solution is the following

• The set of rolls generated by the application of

the cutting plan (Π, x) should be composed by

all rolls from the orders and, eventually, by a

number of rolls from the stock. That is, let s

i

is

the number of rolls of stock i

∈

S in the solution

∑

=∈∀

∈

jiji

xasSi ,

ΠA

j

Then, the constraint can be expressed as

follows:

∑

∈

=∈∀

ΠA

ijij

j

bxaMi

,

ii

bsSi ≤≤∈∀ 0,

Regarding objective functions, as we have remarked,

we consider two main functions

1. Minimize the number of cuts, given by

∑

j=1,…,|Π|

x

j

. The optimum value is denoted

z

1D-CSP

.

2. Minimize the setup cost, given by ∑

j=1,…,|Π|

SU(A

j-1

, A

j

), where SU(A

j-1

, A

j

) denotes the

setup cost from pattern A

j-1

to pattern A

j

calculated as it is indicated above.

Configuration A

0

refers to the situation of the

cutting machine previous to the first cut.

And two secondary functions

3. Minimize the completion times of orders

weighted by their priorities given by

()()

∑

∈Mi

endi

iCUCIp

4. Minimize the maximum number of open stacks

along the cut sequence. Let R(i,A

j

l

) denote the

number of rolls of order i generated from the

beginning up to completion of cut A

j

l

(

)

laxaAiR

ij

jk

kik

l

j

+=

∑

−= 1,..,1

,

and let OS(i,A

j

l

) be 1 if after cut A

j

l

there is an

open stack of order i and 0 otherwise. Then, the

ICSOFT 2007 - International Conference on Software and Data Technologies

188

maximum number of open stacks along the cut

sequence is given by

(

)

∑

∈

=Π=

Mi

l

j

xlj

AiOS

j

,max

,...,0|,|,...,1

3.2 The Simplified Problem

In the main problem, as formulated in the previous

section, it is often the case that two or more orders

have the same width or a stock has the same width

as one of the orders. So, from the point of view of

the cutting process, two cutting patterns A

i

and A

j

are

equivalent if both patterns define the cutting of the

same number of rolls of the same sizes, i.e. given the

set of widths L = {l

e

, e∈M∪S}, with cardinal |L|=

ms, ms≤m+s we have

LlaaAA

llsmk

kj

llsmk

ki

ji

kk

∈∀=⇔≡

∑∑

=+==+=

,

,...,0,,...,0

Now the simplified problem can be stated as

follows. Given

• The set of parameters of the cutting machine,

the setup costs, the types of pressure-rollers and

mapping F

PR

: as they are in the main problem

and the mapping function F

ST

as they are in the

main problem.

• The simplified orders description given by

(M’={1,...,m’}, b’ = (b’

1

,...,b’

m’

) ,

l’=(l’

1

,...,l’

m’

)), where for each order i = 1,…,m’,

b’

i

denotes the number of rolls and l’

i

∈L

denotes the width of the rolls. The simplified

orders list b’ are obtained from the original

order list b so as

∑

==

=

ik

llmk

ki

bb

',...,1

'

• The stock allowed for overproduction (S’

={m’+1,...,m’+s}, bs’ = (b’

m’+1

,...,b’

m’+s

), ls’ =

(l’

m’+1

,...,l’

m’+s

)) where for each i=1,…,s, b’

m’+i

=

b

m+i

denotes the number of rolls of type m’+i

allowed for overproduction and l’

m’+i

= l

m+i

∈L

denotes the width of these rolls (notice that two

different stock orders cannot have the same

width). Here both l’ and ls’ are lists with no

repeated elements, so they can be seen as sets

such that l’∪ls’=L, although, it is possible that

l’∩ls’≠∅. In what follows, we assume L to be

ordered, beginning with l’

1

,...,l’

m’

followed by

the elements from ls’ that do not belong to l’.

L=(l’

1

,….., l’

ms

), ms≤m’+s.

• The set of simplified feasible cutting patterns

for the simplified orders and stock given, E,

obtained from the set of feasible cutting patterns

for the original problem A, |E|≤|A|, where

every E

j

∈ E is E

j

=(e

1j

,…,e

msj

) ∈ Ζ

+

ms

meaning

that, for each i=1,…,ms, e

ij

rolls of width l’

i

are

cut each time the cutting pattern E

j

is applied. In

other words, each element of E is an

equivalence class of the quotient set of A with

the above relation, so it is a simplified

representation of a number of cutting patterns of

A.

The objective is to obtain a simplified cutting plan

(Π’,x’), where Π’=(E

1

,…,E

|Π’|

)∈ E

|Π’|

and

x’=(x’

1

,...,x’

|Π’|

)∈Ζ

+

|Π’|

denotes the pattern

frequencies.

As all the simplified cutting patterns are feasible,

the only constraint that should be requited to a

solution is the following

• The set of rolls generated by the application of

the simplified cutting plan (Π’, x’) should be

composed by all rolls from the orders and,

eventually, by a number of rolls from the stock.

That is, let s’

i

the number of rolls of stock of

width l’

i

in the solution, being 0 if there is no

m’+k ∈S’ such that l’

i

=l’

m’+k

,

∑

∈

=+∈∀

'

''},,..,1'{

ΠE

jiji

j

xesmsmi

Then, the constraint can be expressed as

follows:

∑

∈

+=∈∀

'

''','

ΠE

iijij

j

sbxeMi

,

0≤ s’

i

≤b’

m’+k

The objective functions are

1. Minimize the number of cuts calculated by

∑

j=1,…,|Π’|

x’

j

.

2. Minimize the number of simplified cutting

patterns |Π’|.

3. Maximize the amount of stock generated, that is

∑

i=1,..,ms

l’

i

s’

i

, so the trim-loss is minimized for a

given number of cuts.

Now let us to clarify how a solution of the simplified

problem can be transformed in a solution to the main

problem. To do so, we have to map each simple cut

from a simplified pattern E

j

to any of the cuts of

pattern A

k

of the equivalence class defined by E

j

. In

doing so, we can consider different orderings in the

simplified cutting plan, and also different orderings

between the single cuts derived from a simplified

cutting pattern, in order to satisfy all the

optimization criteria of the main problem. As we can

A MULTI-OBJECTIVE GENETIC ALGORITHM FOR CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY

189

observe, objectives 1 and 3 are the same in both

problems, but objective 2 is different. The reason to

consider objective 2 in the simplified problem is that

minimizing the number of patterns |Π’| it is expected

that the setup cost of the main problem is to be

minimized as well. This is because the setup cost

between two consecutive cuts A

k

and A

l

of the main

problem is null if both A

k

and A

l

belongs to the same

equivalence class E

j

.

To solve this simplified problem, in (Puente et al.

2005 and Varela et al. 2007) we have proposed a

GRASP algorithm. Then, the solution given by this

algorithm is transformed into a solution to the main

problem by a greedy algorithm that assigns items to

actual orders so as to optimize objectives 2, 3, and 4

in hierarchical order, while keeping the values of the

first two objectives. To be more precise, we clarify,

in the next section, how a simplified solution is

transformed into an actual solution by means of an

example.

4 AN EXAMPLE

In this section we show an example to clarify the

whole process of obtaining a cutting plan for the

main problem and, in particular, how a simplified

solution is transformed in a solution to the main

problem by MOGA. The problem data and final

results are displayed as they are by the application

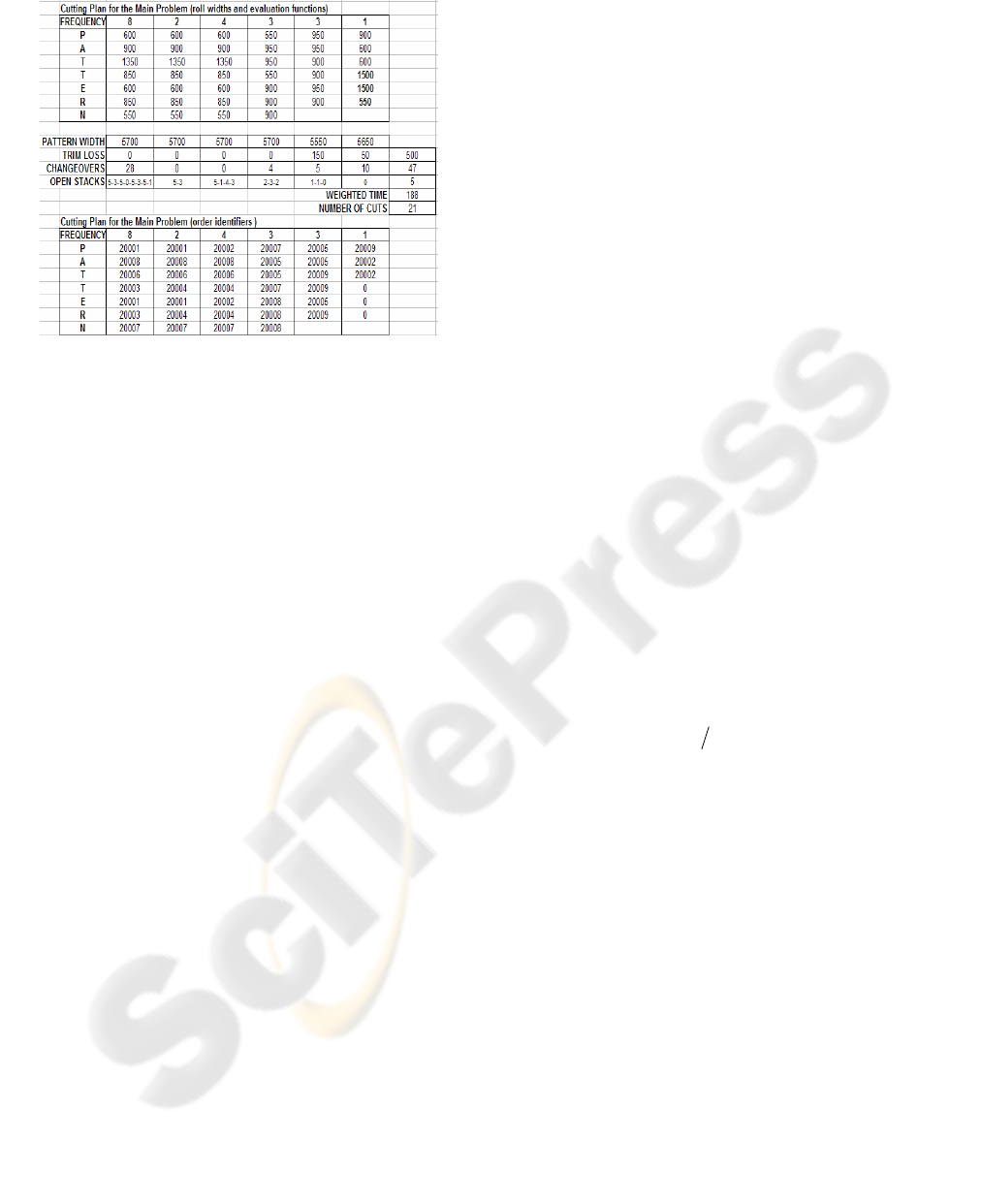

program. Figure 2 shows an instance and the

corresponding simplified problem. A real instance is

given by a set of orders, each one defined by a client

name, a client identification number, the number of

rolls, the width of the rolls and the order priorities.

Additionally, the maximum and minimum allowed

width of a cut should be given, in this case 5500 and

5700 respectively and also a stock description to

choose a number of rolls from if it is necessary to

obtain valid cutting patterns. In this example up to

10 rolls of each width 1100, 450 and 1150 could be

included in the cutting plan. Furthermore, some

other parameters (not shown in Figures) are

necessary, for instance, two additional data should

be given to evaluate the number of open stacks and

setup cost: the number of rolls that fit in a stack

(mapping F

ST

) and the correspondence between the

size of pressure rollers and the width of the

supported rolls (mapping F

PR

). Here we have

supposed that every stack contains 4 rolls and that

the correspondence between pressure roller types

and width rolls is the following: type 1 (0-645), type

2 (650-1045), type 3 (1050-1345), type 4 (1350-

1695). All the allowed widths are multiples of 5 and

the minimum width of a roll is 250 while the

maximum is 1500. Finally, the maximum number of

rolls in a pattern is 10.

a)

b)

Figure 2: An example of problem data (main and

simplified instance).

As we can observe in Figure 1, the main instance

with 10 orders is reduced to a simplified instance

with only 6 orders. This is a conventional 1D-CSP

instance with two additional constraints: the

maximum number of rolls in a pattern and the

minimum width of a pattern. Figure 2 shows a

solution to the simplified problem with 21 cuts and 4

different patterns, where 3 stock rolls have been

included in order that the last pattern to be valid.

Figure 3 shows the final solution to the main

problem. The figure shows the order identifiers,

where 0 represents to the stock. A solution is a

sequence of cutting patterns, where each pattern

represents not only a set of roll widths, but also the

particular order the roll belongs to. The actual

solution is obtained from a simplified solution by

means of a greedy algorithm that firstly considers

the whole set of individual cuts as they are expressed

in the simplified solution. Then it assigns a customer

order to each one of the roll widths in the simplified

cuts, and finally considers all different actual

patterns maintaining the order derived from the

simplified solution. The MOGA proposed in this

paper starts from this solution and tries to improve it

by considering different ordering of the cutting

patterns.

ICSOFT 2007 - International Conference on Software and Data Technologies

190

Figure 3: A cutting plan for the problem of Figure 2.

The changeover of each pattern refers to the cost

of putting in and out cutting knives and pressure

rollers from the previous pattern to the current one.

As we can observe, the first pattern has a

changeover cost of 28 because it is assumed that it is

necessary to put in all the 7 cutting knives and 7

pressure rollers before this pattern. In practice, this

is not often the case as a number of cutting knives

and pressure rollers remain in the machine from

previous cuts. Regarding open stacks, each column

shows the number of them that remain incomplete in

the proximity of the machine from a cut to the next

one, i.e. when a stack gets full after a cut, or it is the

last stack of an order, it is not considered.

5 MULTIOBJECTIVE GENETIC

ALGORITHM

According to the previous section, the encoding

schema is a permutation of the set of patterns

comprising a solution. So, each chromosome is a

direct representation of a solution, which is an

alternative to the initial solution produced by the

greedy algorithm. The initial solution is the one of

Figure 3 which is codified by chromosome (1 2 3 4 5

6 7 8 . . . 21), i.e. each gene represents a single cut.

As objectives 2, 3 and 4 depend on the relative

ordering of patterns and also on their absolute

position in the chromosome sequence, we have used

simple genetic order based operators (Goldberg,

1989, chap. 5) that maintain these characteristics

from parents to offsprings.

The algorithm structure is quite similar to a

conventional single GA: it uses generational

replacement and roulette wheel selection. The main

differences are due to its multi-objective nature. The

MOGA maintains, apart from the current population,

a set of non dominated chromosomes. This set is

updated after each generation, so that it finally

contains an approximation of the pareto frontier for

the problem instance.

In order to assign a single fitness to each

chromosome, the whole population is organized into

dominant groups as it follows. The first group is

comprised by the non dominated chromosomes. The

second group is comprised by the non dominated

chromosomes from the remaining population and so

on. The individual fitness is assigned so that a

chromosome in a group has a larger value than any

chromosome in the subsequent groups. Moreover,

inside each group, the fitness of a chromosome is

adjusted by taking into account the number of

chromosomes in its neighbourhood in the space

defined by the three objective functions. The

chromosomes’ neighbors are those that are in the

chromosome’s niche count. The evaluation

algorithm is as it follows.

Step 0. Set F to a value sufficiently large

Step 1. Determine all non-dominated chromosomes

Pc from the current population and assign F to

their fitness.

Step 2. Calculate each individual’s niche count m

j

:

(

)

∑

∈

=

c

Pk

jkj

dshm

where

()

(

)

⎩

⎨

⎧

<−

=

otherwise0

if1

2

sharejksharejk

jk

dd

dsh

σσ

and d

jk

is the phenotypic distance between two

individuals j and k in Pc and

σ

share

is the

maximum phenotypic distance allowed between

any two chromosomes of Pc to become

members of a niche.

Step 3. Calculate the shared fitness value of each

chromosome by dividing it fitness value by its

niche count.

Step 4. Create the next non dominated group with

the chromosomes of Pc, remove these

chromosomes from the current population, set F

to a value lower than the lowest fitness in Pc, go

to step 1 and continue the process until the

entire population is all sorted.

This evaluation algorithm is adapted from (Zhou and

Gen, 1999). In their paper, G. Zhou and M. Gen

A MULTI-OBJECTIVE GENETIC ALGORITHM FOR CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY

191

propose a MOGA for the Multi-Criteria Minimum

Spanning Tree (MCMSP). In the experimental study

they consider only two objective functions.

In order to compute d

jk

and

σ

share

values we

normalize distances in each one of the three

dimensions to take values in [0,1]; this requires

calculating lower and upper bounds for each

objective. The details of these calculations are given

in (Muñoz, 2006). Also, we have determined

empirically that

σ

share

= 0,5 is a reasonable choice.

6 EXPERIMENTAL STUDY

In this section we present results from some runs of

a prototype implemented in (Muñoz, 2006) for the

problem instance of Figure 2. The program is coded

in Builder C++ for Windows and the target machine

was Pentium 4 at 3,2 Ghz. with HT and 1Gb of

RAM.

Table 1: Summary of results from three runs of MOGA

starting from the solution of Figure 3 for the problem of

Figure 1. Parameters of MOGA refer to /Population

size/Number of generation/, the remaining Crossover

probability/Mutation probability/

σ

share

are 0,9/0,1/0,5.

Each cell shows the cost of /changeovers/weighed

times/maximum open stacks.

Run 1 2 3

Pars. /200/200/ /500/500/ /700/700/

Time(s.) 37 649 1930

49/188/6 47/176/6 39/172/6 (*)

49/186/7 47/184/5 (*) 47/184/5 (*)

44/196/5 (*) 39/179/7

Pareto

frontier

reached

45/184/6

(*) These values represent solutions non-dominated by

any other reached in all three runs

In the first set of experiments, the MOGA starts

from the solution of Figure 2. Table 1 summarizes

the values of the three objective functions

(changeovers, weighed time and maximum open

stacks) for each of the solutions in the approximate

pareto frontier obtained in three runs with different

parameters. As we can observe, the quality of the

solutions are in direct ratio with the processing time

given to the MOGA. The values of objective

functions for the initial solution of Figure 3 are

47/188/5, which is dominated by some of the

solutions of Table 1. So, it is clear that it is possible

to improve on secondary objectives in solutions

obtained by procedure SHRP.

Table 2: Summary of results of MOGA starting from 9

different simplified solutions to the instance of Figure 2a

with the same values of number of cuts (21) and patterns

(4), except solution 6 which has 3 patterns, with different

amount of stock generated. For each instance, two runs

have been done with parameters /500/500/0,9/0,1/0,5, the

first (Normal) in the same conditions as before; while in

the second, the niche count is not computed but it is taken

as 1 in all cases.

Inst. Initial Normal Niche c. = 1

1 39/184/5 38/174/5 (*) 55/188/6

38/197/4 (*) 42/212/8

48/199/6

50/197/5

49/190/6

52/190/5

48/201/5

2 39/187/5 38/174/5 (*) 38/174/5 (*)

38/197/4 (*)

3 43/187/5 42/174/5 (*) 42/174/5 (*)

42/197/4 (*)

4 46/185/5 43/185/5 (*) 55/177/5 (*)

5 56/185/5 55/177/5 (*) 54/194/7 (*)

63/182/6

6 36/186/5 38/177/5 (*) 38/177/5 (*)

7 56/192/5 50/188/5 (*) 50/203/5

50/197/6

50/195/7

8 55/213/5 61/193/5 56/181/5 (*)

63/179/6 (*) 52/182/5 (*)

70/188/5 67/173/5 (*)

71/179/5 63/179/6 (*)

60/180/6 (*) 62/180/6

71/178/6

61/193/5

9 42/201/6 (*) 54/180/6 51/177/7 (*)

46/181/5 (*) 52/176/7 (*)

55/180/5 44/181/6 (*)

44/182/5 (*) 53/172/7 (*)

60/179/6 54/169/7 (*)

59/183/4 (*) 54/173/5 (*)

(*) These values represent solutions non-dominated by

any other reached from the same simplified solution

In the second set of experiments, we have taken

9 more simplified solutions, different from that of

Figure 2b, and have applied MOGA to each of them

with the same parameters as in the second run of

Table 1. In these experiments, we have considered

also the MOGA without fitness adjustment, i.e. by

considering a niche count equal to 1 in all cases. The

results are summarized in Table 2. As we can

observe, in general, MOGA reaches better solutions

with fitness adjustment, even though it takes a larger

time (about 640 s. versus 600 s.). Only for instances

ICSOFT 2007 - International Conference on Software and Data Technologies

192

8 and 9 is the version without fitness adjustment

equal or better. On the contrary, for instance 1 the

results without fitness adjustment are clearly much

worse. These results show that MOGA is able to

reach solutions better than the initial one. Here it is

important to remark that the initial solution is not

included into the initial population of MOGA and

that this population is completely random; i.e. all

cuts are randomly distributed, what usually

translates into a very high changeover cost. In

practice, good solutions tend to aggregate equal cuts

consecutively in order to minimize changeovers.

This fact could be exploited when generating the

initial population in order to reduce the computation

time required by MOGA.

Also, these results suggest that the neighborhood

strategy should be reconsidered, in particular that a

static value for parameter

σ

share

is not probably the

best choice.

7 CONCLUSIONS

In this paper we have proposed a multi-objective

genetic algorithm (MOGA) which aims to improve

solutions to a real cutting stock problem obtained

previously by another heuristic algorithm. This

heuristic algorithm, termed SHRP, focuses mainly

on the two main objectives and considers them

hierarchically. Then, the MOGA tries to improve

other three secondary objectives at the same time,

while keeping the values of the main objectives. We

have presented some results over a real problem

instance showing that the proposed MOGA is able to

improve the secondary objective functions with

respect to the initial solution, and that it offers the

expert a variety of non-dominated solutions.

As future work, we plan reconsidering the

MOGA strategy in order to make it more efficient

and more flexible so that it can take into account the

preferences of the experts with respect to each one

of the objectives. In order to improve efficiency we

will try to devise local search techniques and

initialization strategies based on heuristic

dispatching rules. Also, we will consider alterative

evolution strategies for multi-objective optimization

(Goldberg, 1985, Chapter 5) and other multi-

objective search paradigms such as exact methods

based on best first search (Mandow and Pérez-de-la-

Cruz, 2005). In this way we could compare different

strategies for this particular problem.

ACKNOWLEDGEMENTS

This research has been partially supported by

contract CN-05-127 of the University of Oviedo and

the company ERVISA, and by FICYT under

research contract FC-06-BP04-021.

REFERENCES

Belov, G., Scheithauer, G. 2006b. Setup and Open Stacks

Minimization in One-Dimensional Stock Cutting.

(submited to INFORMS Journal of Computing).

Gilmore, P. C., Gomory, R. E., 1961. A linear

programming approach to the cutting stock problem.

Operations Research 9, 849-859.

Goldberg, D. E. 1989. Genetic Algorithms in Search,

Optimization and Machine Learning. Addison-Wesley.

Mandow, L., Pérez-de-la-Cruz, J.L. 2005. A new approach

to multiobjective A* search. IJCAI-05 19th Int. Joint

Conf. on Artificial Intelligence, 218-223.

Muñoz, C., 2006. A Multiobjective Evolutionary

Algorithm to Compute Cutting Plans for Plastic Rolls.

Degree project, University of Oviedo, School of

Computing, Gijón (In Spanish).

Puente, J., Sierra, M., González-Rodríguez, I., Vela, C. R.,

Alonso, C., Varela, R., 2005.

An actual problem in

optimizing plastic rolls cutting.

Workshop on

Planning, Scheuling and Temporal Reasoning, in

CAEPIA 2005. Santiago de Compostela.

Resende, M. G. C., Ribeiro, G. C., 2002. Greedy

randomized adaptive search procedures. In F. Glover

and G. Kochenberg eds. Handbook of Metaheuristics,

p. 219-249. Kluwer Academic Publishers.

Varela, R. Vela, C. R., Puente, J. Sierra, M. R. González-

Rodríguez, I., 2007.

An effective solution for an actual

cutting stock problem in manufacturing plastic rolls.

(submitted to Annals of Operations Research).

Umetani, S. Yagiura, M., Ibaraki, T., 2003. One-

dimensional cutting stock problem to minimize the

number of different patterns. European Journal of

Operational Research 146, 388-402.

Zhou, G., Gen, M., 1999. Genetic algorithm approach on

multi-criteria minimum spanning tree problem.

European Journal of Operational Research 114, 141-

152.

A MULTI-OBJECTIVE GENETIC ALGORITHM FOR CUTTING-STOCK IN PLASTIC ROLLS INDUSTRY

193