ULTRA VIOLET IMAGING TRANSDUCER

CONTROL OF A THERMAL SPRAYING ROBOT

D. Breen, E. Coyle and D. M. Kennedy

Faculty of Engineering, Dublin Institute of Technology, Dublin, Ireland

Keywords: Thermal spraying, robot control, ultraviolet lighting, image processing.

Abstract: The thermal spraying industry has a global market of $1.3 billion. This industry relies heavily on manual

operation of the thermal spraying equipment or in some cases, robotic systems that require costly set up of

material for surface coating and time consuming trajectory planning. The main objective of this research

was to investigate novel ideas for automating the thermal spraying process. This requires transducers that

can provide information about arbitrarily shaped and orientated material for spraying and generating the

trajectory plan for the robot manipulator during the thermal spraying process in real time. The most

significant difficulty for any transducer, particularly low cost vision systems is the thermal spraying process

which in our research is molten material such as aluminium in an Oxy-Acetylene flame with temperatures

exceeding 3100

0

C. This paper outlines the concept and based on the experimental results presented

demonstrates combined optical and image processing techniques for obtaining information about objects

behind a butane flame.

1 THERMAL SPRAYING ROBOT

1.1 Introduction

Thermal spraying robotic research is concerned with

investigating a number of novel ideas, which will

contribute to the autonomous control of an

articulated thermal spraying robot manipulator. This

control of the thermal spraying process, which is

used in the application of wear, corrosion and

thermal barrier surface coatings will improve safety,

efficiency and costs in the surface coating industry.

Thermal spraying has an estimated global

mark

et of $1.3 billion dollars (AZoM). The

operation of thermal spraying equipment requires

the consideration of health and safety issues.

1.2 Health and Safety

In industrial applications, thermal-spraying

equipment is normally enclosed in specialist

enclosures designed to reduce noise, fumes and

observation via safety equipment by operators from

a safe location. R&D may not have these specialist

enclosures. Therefore health and safety risks must be

managed via appropriate health and safety

equipment and procedures. Powder Flame spraying

with an Oxy-Acetylene torch which is the system

used in this research produces intense bright flames

with a peak temperature in excess of 3,100

0

C.

Two-wire electric arc and plasma spraying

syste

ms produce UV-B and UV-C with their

associated health and safety risks to the operator.

Figure 1 shows a typical flame from the thermal

spraying process.

Figure 1: Thermal Spraying Process Flame.

The research presented in this paper uses UV-A

lighting which is also present in the thermal spraying

process.

1.3 Robot Control

The control of a robot manipulator requires

information about the kinematics and dynamics of

the robotic system being used for the thermal

412

Breen D., Coyle E. and M. Kennedy D. (2007).

ULTRA VIOLET IMAGING TRANSDUCER CONTROL OF A THERMAL SPRAYING ROBOT.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 412-417

DOI: 10.5220/0001622104120417

Copyright

c

SciTePress

spraying system. Information about the position and

orientation of the thermal spraying torch tip at

different locations along the object to be sprayed and

at different times which is known as trajectory

planning is produced. This information is supplied

into the robotic control system, which is used by the

inverse kinematic equations and dynamic equations

of motion to move the robot actuators to the desired

locations. Thermal spraying automation provides

this trajectory planning information via pre-

programming for specific objects, which is time-

consuming and costly.

The autonomous analysis of the position and

orientation of the thermal-spraying torch, which

would allow the spraying of unspecified objects at

unspecified orientations, would significantly reduce

set-up times and costs. However this level of

automation is significantly hampered by the thermal

spraying process. It is quite clear that the intense

flame would hamper many object-measuring

systems which could be used to obtain in real time,

the position and orientation of the thermal spraying

torch information. If however the flame could be

removed from the scene and a low cost camera used

to view the object with associated distance

measuring techniques, this would accommodate the

autonomous control of the thermal spraying process.

This research attempts to provide a possible

solution to this difficult requirement.

2 FLAME REMOVAL

2.1 Ultra Violet Lighting

During the research on measuring the distance to

objects with a low cost infra red laser and

monochrome camera the problem of the thermal

flame became a key issue. It was decided to

investigate the use of a monochromatic light source

and band pass filter to remove the thermal spraying

flame. It was decided to use the UV-A spectrum

(350 nm - 400 nm) as an initial area for research

because it is reasonable to assume there is the full

visible normal lighting (400 nm – 750 nm) and infra

red ( 750 nm – 1 mm) in the thermal spraying scene

and environment.

The light source used was a black light

fluorescent lamp used in dance halls which has an

amount of 387 nm wavelength light which matches

our band pass filter.

2.2 Camera and Filter Spectral

Response to Ultra Violet

A key aspect of the research was to use standard low

cost equipment. The first objective was to ensure

that the low cost monochrome camera has a

response under ultra violet lighting, as the data sheet

did not even provide data below 400 nm (Samsung).

A 387 nm narrow band pass filter was used. Figure 2

shows the camera and filters relative spectral

responses.

Figure 2: Camera and filter spectral response.

2.3 Ultra Violet Camera and Filter

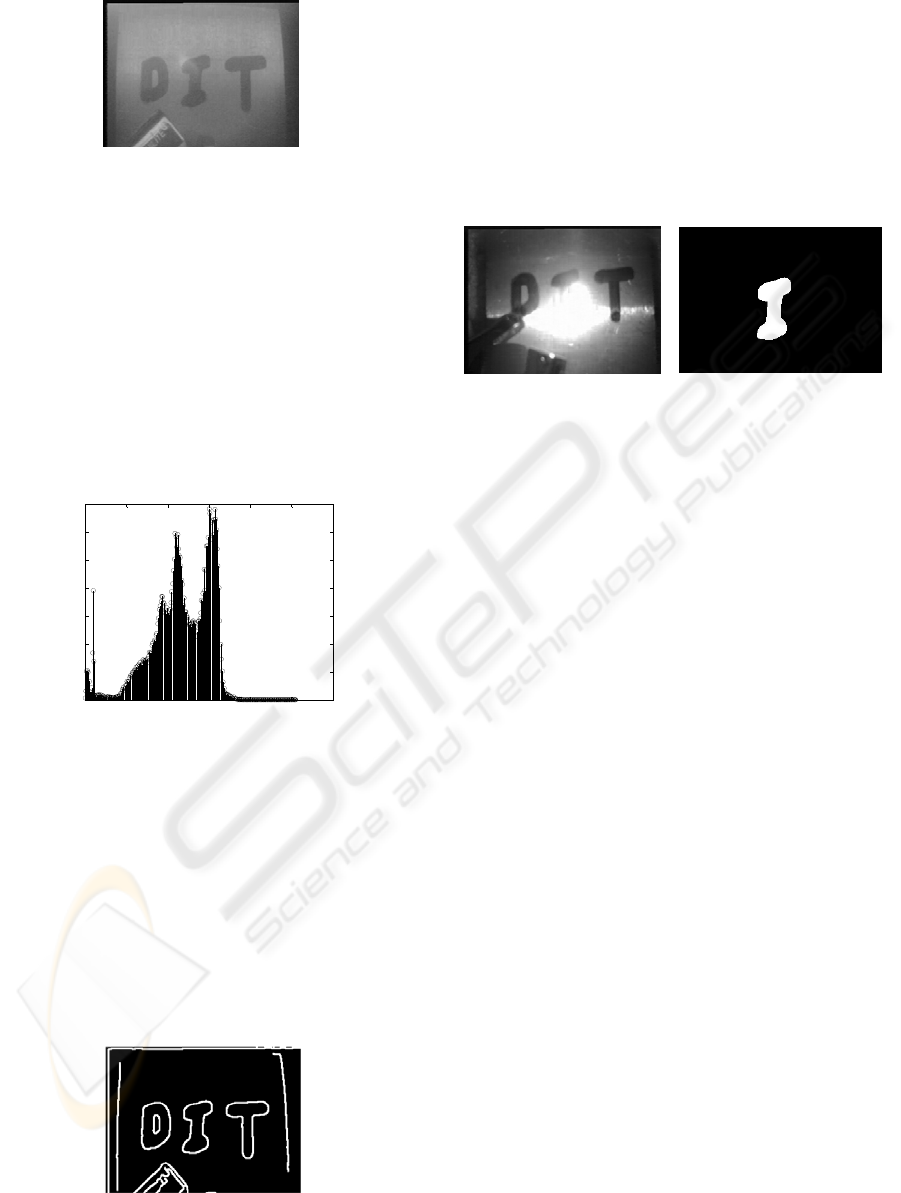

A small piece of aluminium metal 50 mm x 60 mm

with the letters D I T of height 15 mm written on it

was used as a test piece. The test piece under

internal daylight is shown in Figure 3. The test piece

of aluminium with DIT and the background are clear

and distinct.

Figure 3: Test piece of Aluminium.

A 387 nm filter was placed in front of the

camera under internal daylight and the result is

shown in Figure 4. The result shows a complete lack

of response from the camera.

400

700

Wavelength nm

1

0.5

Camera response

387 nm Filter

Spectral

response

ULTRA VIOLET IMAGING TRANSDUCER CONTROL OF A THERMAL SPRAYING ROBOT

413

Figure 4: Camera response internal daylight and 387 nm

filter.

A black light fluorescent lamp, which has a

certain amount of 387 nm wavelength light, was

then switched on and the cameras response is shown

in Figure 5.

Figure 5: Camera response to filtered 387 nm lighting.

0 50 100 150 200 250 300

0

500

1000

1500

2000

2500

Flame on indoor daylight histogram

Intensity value 0 - 255

Nu

m

be

r

of

pix

Due to the low intensity of 387 nm lighting, the

camera was moved closer to the test piece. The

background to the test piece is shown as dark stripes

to the left and right of the image. The response of

the camera clearly shows the letters D I T.

els

The monochrome image pixels have dynamic

range values between 0 and 255. The response of the

camera in this experiment provides a low dynamic

range image. Using Matlab

TM

this low dynamic

range is shown quantitatively by its histogram in

Figure 6. There are no intensity values between 185

and 255, however there is good separation between

the letters DIT and the background shown by the dip

in the histogram at an intensity value of 133.

Figure 6: 387 nm image histogram.

The low dynamic range response is due not

only to the response of the camera but from the lack

of 387 nm intensity in the black light and the 387 nm

filters attenuation effect.

2.4 Flame Removal from Image

Using a small butane lighter flame in front of the test

piece under daylight lighting produces the image

shown in Figure 7.

Figure 7: Daylight with flame.

Clearly image information behind the flame is

completely obliterated because of the saturation

effects of the flame on the cameras photo sensors,

which is shown quantitatively in the images

histogram in Figure 8.

Figure 8: Flame on daylight histogram.

The histogram shows 8.2% of the pixels in the

image have what we would consider saturated values

between 250 and 255, which are caused by the

butane flame. It would be extremely difficult to

obtain information from behind the flame such as

the area or centroid in pixels of the letter I in this

image.

0 50 100 150 200 250 300

0

500

1000

1500

387 nm image histogram

Intensity value 0 - 255

Number of pixels

The main developments reported in this paper

will detail a process for obtaining this and other

information about the letter I, a process which could

be developed and applied to the thermal spraying

control process.

Placing the 387 nm filter in front of the camera

and turning on the black light with the butane flame

on produces the image shown in Figure 9.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

414

Figure 9: 387 nm lighting flame on.

This technique was extremely encouraging, as

the letters D I T are clearly visible. There is a slight

transmission of flame intensity just above the letter

I. Letters on the butane torch are also visible. Figure

10. is a histogram of the flame on in the 387nm

image.

The histogram for the image shown in Figure

10 suggests this is a low contract image and there is

considerable room for improving image information

(contrast) above pixel value 185. This could be

achieved by increasing the intensity of the 387 nm

lighting source.

Figure 10: Flame on 387 nm image histogram.

3 IMAGE PROCESSING

3.1 Canny Edge Setection

Using the Matlab

TM

image processing toolbox the

image in Figure 9 was processed using the canny

edge detector with a Gaussian filter standard

deviation value of 1.5 and high-low threshold values

of 0.16 and 0.064 respectively which produced an

edges image shown in Figure 11.

Figure 11: Edges image.

The edges image in Figure 11 was image

processed further to remove the perimeter objects

using the Matlab function imclearborder

leaving only the letters D I T. Using the Matlab

TM

functions for labelling, selecting and infilling the

letter I, bwlabel, bwselect and imfill the

letter I was extracted as shown in Figure 12. For

contrast the flame image is shown beside the

extracted letter I

Figure 12: Flame on and extracted letter.

3.2 Feature Extraction

Using the Matlab

TM

image processing toolbox and

0 50 100 150 200 250 300

0

200

400

600

800

1000

1200

1400

Flame on 387 nm filter and blacklight histogram

Intensity value 0 - 255

Number of pixels

the Matlab

TM

function regionprops a number of

characteristics for the letter I were obtained. Some of

these features are:

Area 2561 pixels

Centroid 131, 112 measured

from top left corner

Eccentricity 0.9148

Orientation 83

0

Perimeter 264 pixels

From analysis of the above, it is a

straightforward process to obtain accurate real world

values from image pixel values for actuating a robot

manipulator using perspective transformations,

inverse kinematics and camera calibration

techniques.

4 THERMAL SPRAYING

SPECTRA

4.1 Thermal Spraying Process

To determine the band pass filter and lighting

wavelength for the removal of the thermal spraying

flame and combustion material spectrum in the

thermal spraying process would require extensive

testing and the purchase of a range of filters. The

reason for this is that there are a number of thermal

spraying processes such as powder, arc, plasma and

ULTRA VIOLET IMAGING TRANSDUCER CONTROL OF A THERMAL SPRAYING ROBOT

415

a vast range of surface coating materials all

producing their own combustion spectra

The following is a list of some of the more

common surface coating materials.

Tungsten carbide/cobalt

Chromium carbide/nickel chromium

Aluminium bronze

Copper nickel indium

Hard alloys of iron

To apply this technique of using

monochromatic ultra violet lighting and narrow band

pass filter to remove the combustion process,

theoretical research into the spectrum produced by

the specific process where autonomous control

would be beneficial is required. The reason for this

is that the emission spectra of flames is sensitive to

(Zirack):

temperature

gas/air or gas/oxygen mixture ratio

gas purity

burner type

gas flow (laminar or turbulent)

coating materials

height of observation in the flame

Research can however provide reasonable

indicators of a location for the band pass filter and

where spectral problems may arise. The thermal

spraying process used for this research was powder

thermal spraying using an Oxy-Acetylene torch.

4.2 Oxy-Acetylene Flame

The Oxy-Acetylene flame is a chemical reaction

resulting from the combination of acetylene C

2

H

2

with oxygen 0

2

. Figure 13 shows the two stages of

the chemical reactions (Materials Engineering

Group, MEG)

+

Figure 13: Oxy-Acetylene flame.

A neutral flame with products of combustion

CO

2

and H

2

O is produced with maximum heat

output when equal quantities of oxygen and

acetylene are used (MEG). Controlling this mixture

would form part of the overall thermal spraying

robot control system.

This is an idealised view and many other

ordinary molecules and unstable radicals are

produced in an Oxy-Acetylene flame in air.

4.3 Oxy-Acetylene Emission Spectra

The visible spectrum runs from 400 nm to 750 nm

and the infra red spectrum runs from 750 nm to 1

mm (HyperPhysics). This suggests a portion of the

ultra violet spectrum between 350 – 400 nm

commonly known as the UV-A spectrum for the

research as it excludes the visible and infra red

spectrum.

Research is now concentrated on identifying

weak spectra between 350 nm and 400 nm from the

powder flame spraying Oxy-Acetylene in air flame

with a range of molten surface coating materials,

which is widely used in the powder spraying

industry.

The ordinary molecules which are the stable

products of combustion, H

2

0

2

, C0

2

, C0, 0

2

or N

2

in

hydrogen flames do not provide spectra of any

appreciable strength in the visible or ultra violet

spectrum (Zirack).

The only product of combustion that may have

an appreciable spectrum in the UV band is the

hydroxyl radical OH which give band peaks at 281

nm 306 nm and 343 nm. Oxyacetylene flames not

only produce spectra of hydrogen flames but also

emit radiation of hydrocarbon radicals. Between the

350 nm and 400 nm wavelengths a weak CH band

occurs at 387/9 nm and a strong band at 432 nm are

found in air acetylene flames.

This suggests many wavelengths between 350

and 400 nm may be suitable for removing the Oxy-

Acetylene flame in air but we must add the spectrum

from the surface coating material to ensure there is

no appreciable interference from the molten material

in our chosen UV band. This is an area for continued

research. However a review of published work by

De Saro relating to emission spectra of molten

elements such as aluminium and copper provides

information on spectra of interest as follows:

Oxygen 0

2

Acetylene C

2

H

2

Stage 1

C

2

H

2

0

2

= 2C0 +H

2

Stage 2

C0 + H

2

+ 0

2

= C0

2

+ H

2

0

Aluminium 390 – 400 nm

Iron 260 – 262 nm

Magnesium 380 - 385 nm

Copper 320 – 330 nm

Results so far suggest using a narrow band pass

filter and lighting between 350 and 370 nm

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

416

In addition to the interference from the

emission spectra, an added complication is the

molten material itself. This will act as a dust cloud

and have the effect of reducing contrast in the

image.

The image processing techniques necessary for

this research are those associated with low contrast

images and reconstructing edges and shapes such as

those provided by techniques like the Hough

transform. (Young)

5 CONCLUSION

This paper has detailed a system of combining

optical filtering and image processing which can be

used to obtain information about low contrast

objects behind or within a test butane flame.

The paper also suggests a region within the

UV-A spectrum, which shows promise for

implementing ultra violet image control of a

thermal-spraying robot. Further work on identifying

the spectra of a greater range of surface coating

materials is required.

The ability to see through a flame could have

benefits in other industries such as the fire fighting

service and welding. The system detailed could be

fitted as a single eye head up display or fitted to a

small mobile robot where there are low smoke flame

environments.

REFERENCES

AZoM, Thermal Spraying – An Overview,

http://www.azom.com/detailes.asp?AtricleID=511

(last accessed January 2007).

DeSaro R, Weisberg A, Craparo J. 2005, In Situ, Real

Time Measurement of Melt Constituents in the

Aluminium, Glass and Steel Industries, Energy

Research Co., Staten Island New York.

England, G.,. “Wear Resistance”

http://www.gordonengland.co.uk/wear.htm (last

accessed January 2007)

HyperPhysics,

http://hyperphysics.phyastr.gsu.edu/hbse/ems3.html

(last accessed January 2007)

Materials Engineering Group, Oxy-Gas Welding,

http://www.meg.co.uk/meg/app04.htm (last accessed

January 2007)

Matlab

TM

. http://www.mathworks.com (last accessed

january 2007)

Samsung 1/3 CCD image sensor for CCIR cameras,

http://www.datasheetcatalog.com/datasheets_pdf/K/C/

7/3/KC73129MP.shtml

(last accessed January 2007).

thefabricator.com, Theraml spray safety and OSHA

compliance, (last accessed January 2007)

http://www.thefabricator.com/Safety/Safety_Article.cfm?I

D=45

Young, David, 1995, Hough transforms,University of

Sussex, Brighton, U.K.

http://homepages.inf.ed.ac.uk/rbf/CVonline/LOCAL_

COPIES/YOUNG/vision4.html

(last accessed January

2007)

Zirak Giorgio, 2000, Flame Emission Spectroscopy:

Fundamentals and Applications, NILES University of

Cairo,Egypt

ULTRA VIOLET IMAGING TRANSDUCER CONTROL OF A THERMAL SPRAYING ROBOT

417