TAKAGI-SUGENO MULTIPLE-MODEL CONTROLLER FOR A

CONTINUOUS BAKING YEAST FERMENTATION PROCESS

Enrique Herrera

1

, Bernardino Castillo

Centro de investigación y de Estudios Avanzados del I.P.N., Unidad Guadalajara, Av. Científica 1145, Colonia el bajío

C.P. 45010, Zapopan, México

Jesús Ramírez

Centro de Investigación y Asistencia en Tecnología y Diseño del Estado de Jalisco A.C., Av. Normalistas 800

C.P. 44270, Guadalajara, México

Eugénio C. Ferreira

IBB-Institute for Biotechnology and Bioengineering, Centre of Biological Engineering, Universidade do Minho

4710-057, Braga, Portugal

Keywords: Nonlinear system, Fuzzy model, Fuzzy controller, Fermentation process.

Abstract: The purpose of this work is to design a fuzzy integral controller to force the switching of a bioprocess

between two different metabolic states. A continuous baking yeast culture is divided in two sub-models: a

respiro-fermentative with ethanol production and a respirative with ethanol consumption. The switching

between both different metabolic states is achieved by means of tracking a reference substrate signal. A

substrate fuzzy integral controller model using sector nonlinearity was built for both nonlinear models.

1 INTRODUCTION

Control applications in bioprocesses have increased

in the last decades due to the fast advances on

computer and electronic technology. An adequate

control of fermentation processes allows reducing

production costs and increases the yield, while at the

same time achieving the quality of the desired

product (Yamuna and Ramachandra 1990).

In the case where the nonlinear model of the

process is known, a fuzzy system may be used. A

first approach can be done using the Takagi-Sugeno

(TS) fuzzy model, (Takagi and Sugeno, 1985),

where the consequent part of the fuzzy rules are

replaced by linear systems. This can be attained, for

example, using the method of sector nonlinearities

_________________________

1

On Ph. D. studies leave from the Centro de Investigación

y Asistencia en Tecnología y Diseño del Estado de Jalisco.

which allows constructing an exact fuzzy model

from the original nonlinear system by means of

linear subsystems (Tanaka and Wang, 2001). From

this exact model a controller may be designed based

on the linear subsystems.

Along this line of reasoning, in this work a fuzzy

integral controller based on sector nonlinearities is

proposed and applied to a continuous baker’s yeast

process. An interesting feature of this model is the

splitting in two different partial models: a respiro-

fermentative (RF) model with ethanol production

and the respirative (R) model with ethanol

consumption. The fuzzy integral controller is used to

force the switching of a bioprocess between both

different metabolic states by means of tracking a

reference substrate signal.

436

Herrera E., Castillo B., Ramírez J. and C. Ferreira E. (2007).

TAKAGI-SUGENO MULTIPLE-MODEL CONTROLLER FOR A CONTINUOUS BAKING YEAST FERMENTATION PROCESS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 436-439

DOI: 10.5220/0001622704360439

Copyright

c

SciTePress

2 FUZZY MODELS BASICS

2.1 Takagi-Sugeno Fuzzy Model

The Takagi-Sugeno fuzzy models are used to

represent nonlinear dynamics by means of a set of

IF-THEN rules. The consequent parts of the rules

are local linear systems. The ith rule of a continuous

fuzzy model has the following form:

11

() () ()

( ) ( ) 1 ,

ii

pp

ii

i

IF z (t) is M and...and z (t) is M

xt Axt But

THEN

y t C x t i ,...,r

=+

⎧

⎨

==

⎩

(1)

where

i

j

M

is a fuzzy set and r is the number of rules

in the fuzzy model; x(t)

∈

R

n

is the state vector, u(t)

∈

R

m

is the input vector, y(t)

∈

R

q

is the output

vector, A

i

∈

R

nxn

, B

i

∈

R

nxm

, y C

i

∈

R

qxn

are suitable

matrices and z(t)=[z

1

(t),…,z

p

(t)] is a known vector of

premise variables which may depend partially on the

state x(t). Given a pair of (x(t), u(t)) and a product

inference engine the aggregate TS fuzzy model can

be inferred as:

{}

1

1

() ( ()) () (),

() ( ()) (),

r

iii

i

r

ii

i

x

thztAxtBut

yt h zt Cxt

=

=

=+

=

∑

∑

(2)

where

1

11

( ( )) ( ( )) ( ( )) ,

pp

r

ii

ijj jj

i

jj

hzt M z t M z t

=

==

⎛⎞

=

⎜⎟

⎝⎠

∑

∏∏

for all t. The term

))(( tzM

j

i

j

is the membership

value of z

j

(t) in

i

j

M

. We have that

(()) 0

i

hzt ≥

and

1

(()) 1

r

i

i

hzt

=

=

∑

for all t and i=1,…,r.

2.2 Parallel Distributed Compensator

The parallel distributed compensator (PDC) is used

to design a fuzzy controller from a TS fuzzy model.

Each control rule is designed from the corresponding

rule of a TS model.

11

ii

p

p

I

F z (t) is M and...and z (t) is M

1

( ) ( ( )) ( ) 1 ,

r

ii

i

THEN u t h z t F x t i ,...,r

=

=− =

∑

(3)

where F

i

is the controller gain for the ith subsystem,

which makes Hurwitz the matrices A

i

-B

i

F

i

.

2.3 Integral Control

Consider the linear system

() () () ()

R

tAtButyt

ξξξ

ξξ

=+ +

,

(4)

where

,

ξ

ξ, A

ξ

, B

ξ

, u

ξ

(t) and

y

R

are given by

()

x

t

ξ

σ

⎡

⎤

=

⎢

⎥

⎣

⎦

,

()

x

t

ξ

σ

⎡

⎤

=

⎢

⎥

⎣

⎦

,

0

0

A

A

C

ξ

⎡⎤

=

⎢⎥

−

⎣⎦

,

0

B

B

ξ

⎡

⎤

=

⎢

⎥

⎣

⎦

,

0

()

R

R

yt

y

⎡

⎤

=

⎢

⎥

⎣

⎦

, u

ξ

(t)= -Fx + kσ

where

R

ey y

σ

=

=−

is a tracking error and y

R

(t) is

a reference signal. It is desired to design a state

feedback control such that y(t)→y

R

(t) as t→∞

(Khalil, 1996). If the pair (A,B) is controllable and

the following condition is achieved

0

AB

rank n p

C

⎡⎤

=

+

⎢⎥

−

⎣⎦

,

(5)

then it is possible to find a matrix K such that A

ξ

-B

ξ

K

is Hurwitz, assuring that y(t) - y

R

(t)→0 as t→∞;

where K=[-F, k] and k must be nonsingular.

3 THE EXACT FUZZY

CONTROLLER

A continuous baking yeast culture may be

represented by the following nonlinear system

))(()())(()( txdtButxftx

i

+

+

=

where

))(( txf

i

describes a respiro-fermentative baking yeast partial

model (RF) with ethanol production and a

respirative baking yeast partial model (R) with

ethanol consumption (Pormeleau, 1990). The RF

partial model is described by

RF model

1

1

1

max max

241

2

42

1

max max

2

41

12 2 2

2

42

3

max max

2

41

33

4

42

max

4

52

4

00

00

00

000

O

oOr rs

O

O

oOr rs

O

RF

O

ro rs

O

Oo

Y

xx

qYY Yq

Ko x Y Ks x

x

Y

xx

qkYkY kYq

x

Ko x Y Ks x

f

x

Y

xx

kYq kYq

x

YKox Ksx

x

kY q

Ko x

⎡⎤

⎛⎞

−

⎢⎥

⎜⎟

++

⎝⎠

⎢⎥

⎢⎥

⎛⎞

⎢⎥

−+ −

⎜⎟

⎢⎥

++

⎝⎠

=

⎢⎥

⎢⎥

−

⎢⎥

++

⎢⎥

⎢⎥

−

⎢⎥

+

⎣⎦

⎡⎤

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

(6)

TAKAGI-SUGENO MULTIPLE-MODEL CONTROLLER FOR A CONTINUOUS BAKING YEAST FERMENTATION

PROCESS

437

The R model can be divided in two sub models

(Ferreira, 1995):

Rqe1 model

max max

3

1

32 2

max 1

1

1

2

2

1

max

3

3

4

32

4

max max

1

65

32 2

00

()()

000

000

()()

3

00

()()

ee Os

Os

Rqe

ee

ee Os

x

x

Yq Ki Y q

Ke x Ki x Ks x

x

x

kY q

Ks x

x

f

x

x

kYq Ki

Ke x Ki x

x

xx

kYq Ki kYq

Ke x Ki x Ks x

⎡⎤

⎢⎥

++ +

⎢⎥

⎢⎥

⎡

⎤

−

⎢⎥

⎢

⎥

+

⎢⎥

⎢

⎥

=

⎢⎥

⎢

⎥

−

⎢⎥

⎢

⎥

++

⎣

⎦

⎢⎥

⎢⎥

−−

⎢⎥

++ +

⎣⎦

(7)

Rqe2 model

max max

41

22

42 2

max

1

1

2

2

max max

41

42 42

422

max max

41

62 5 62

42 2

00

000

00

00

O

Oo s O O

O

Os

Rqe

O

Oo Os

O

O

Oo s O O

O

Y

xx

Yeq q Y Ye

Ko x Ks x Y

x

kY q

Ks x

f

Yxx

kY eq kY eq

Ko x Ks x Y

Yxx

kY eq q kY kY e

Ko x Ks x Y

⎡⎤

⎛⎞

−

⎢⎥

⎜⎟

++

⎝⎠

⎢⎥

⎢⎥

−

⎢⎥

+

⎢⎥

=

⎢⎥

⎢⎥

−

++

⎢⎥

⎢⎥

⎛⎞

⎢⎥

−−+

⎜⎟

⎢⎥

++

⎝⎠

⎣⎦

1

2

3

4

x

x

x

x

⎡

⎤

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎣

⎦

(8)

The input B matrix for all the models is given by

12 34

[, , , ]

T

in

B

xxS xx=− − + − −

(9)

where x

1

is the biomass, x

2

is the substrate, x

3

is the

ethanol, x

4

is the dissolved oxygen, S

in

is the inlet

substrate concentration, D is the dilution rate,

u(t)=D. The yield coefficients k

1

to k

6

and the

remaining parameters values are described in

Ferreira, (1995). The oxygen transfer rate (OTR) is

assumed to be a measurable and known perturbation,

and thus d=[0 0 0 OTR]

T

. Before designing a fuzzy

controller an exact fuzzy model must be first built.

When the nonlinear dynamic model for the

baking yeast is known, as well as all their

parameters, a fuzzy exact model can be derived from

the given nonlinear model. This requires a sector

nonlinearity approach (Tanaka and Wang, 2001).

From the models (6-9) the fuzzy exact model can be

constructed. The premise variables for the RF partial

model (6) and the input B matrix (9) are chosen as:

4

4

1

)(

xKo

x

tz

+

=

2

1

2

)(

xKs

x

tz

+

=

12 3 4

123 4

() , () , () , () .

xx x x

z

txztxztxztx=== =

The membership functions can be obtained from

2

1

() ( ())

ii

i

zt M zt a

=

=

∑

where the following property

12

(()) (()) 1Mzt Mzt+=

must be accomplished

(Tanaka and Wang , 2001). The linear subsystems

,

R

FRF

ijklmn ijklmn

AB

are derived from

max max

2

2

1

max max

2

12 2 2

2

3

max max

2

4

33

max

52

00

00

00

000

O

oOr rs

O

O

oOr rs

RF

ijklmn

O

O

ro rs

O

Oo

Y

qYY Yq

Y

x

Y

qkYkY kYq

x

A

Y

x

Y

x

kYq kYq

Y

kYq

ab

ij

ab

ij

ab

ij

a

i

⎡⎤

⎛⎞

−

⎢⎥

⎜⎟

⎝⎠

⎢⎥

⎡⎤

⎢⎥

⎛⎞

⎢⎥

⎢⎥

−+ −

⎜⎟

⎢⎥

⎢⎥

=

⎝⎠

⎢⎥

⎢⎥

⎢⎥

⎢⎥

−

⎣⎦

⎢⎥

⎢⎥

−

⎢⎥

⎣⎦

[

]

, , ,

T

RF

ijklmn k l in m n

BcdSef=− − + − −

(10)

i,j,k,l,m,n = 1,2.

where a

i

, b

j

, c

k

, d

l

, e

m

, f

n

are the maximum and

minimum values of z

1

(t), z

2

(t), z

x1

(t), z

x2

(t), z

x3

(t) and

z

x4

(t) respectively. The following ranges for x

1

(t)

∈

[0,

10], x

2

(t)

∈

[0, 1], x

3

(t)

∈

[0, 5] and x

4

(t)

∈

[0, 0.007]

were assumed.

From the model (10) the substrate integral

controller for the RF partial model can be designed

using the following model:

[]

max

2

2

0

10

,

RF

sj

j

T

RF

llin

x

kYrq b

A

BdS

σ

⎡⎤

−

⎡⎤

=

⎢⎥

⎢⎥

−

⎣⎦

⎣⎦

=− +

(11)

From models (10) and (11) the

,

R

FRF

ijklmn ijklmn

AB

matrices for the RF partial integral PDC

can be written as

max max

2

2

1

max max

2

12 2 2

2

3

max max

2

33 4

max

52

000

000

000

0 000

0 1 000

O

oOr rs

O

O

oOr rs

O

RF

ijklmn

O

ro rs

O

Oo

Y

qYY Yq

Y

x

Y

qkYkY kYq

x

Y

A

x

Y

kYq kYq x

Y

kYq

ab

ij

ab

ij

ab

ij

a

i

σ

⎡⎤

⎛⎞

−

⎢⎥

⎜⎟

⎝⎠

⎢⎥

⎡⎤

⎢⎥

⎛⎞

⎢⎥

⎢⎥

−+ −

⎜⎟

⎢⎥

⎢⎥

⎝⎠

⎢⎥

=

⎢⎥

⎢⎥

⎢⎥

−

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

−

⎢⎥

⎢⎥

−

⎣⎦

[

]

, , , , 0

T

RF

ijklmn k l in m n

BcdSef=− − + − −

(12)

i,j,k,l,m,n = 1,2.

A general fuzzy rule to infer all the fuzzy rules

for the RF PDC can be stated as:

IF z

1

(t) is “M

1i

(z

1

(t))” and z

2

(t) is “M

2j

(z

2

(t))” and

zx1(t) is “M

3k

(z

x1

(t))” and z

x2

(t) is “M

4l

(z

x2

(t))” and

z

x3

(t) is “M

5m

(z

x3

(t))” and z

x4

(t) is “M

6n

(z

x4

(t))”

() ()

RF

ijklmn

THEN u t F x t=−

(13)

From (12) and using the notation given by (4)

the aggregated fuzzy controller for the RF partial

model turns to be

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

438

{}

64

1

() ( ()) () () ,

RF RF RF

ijklmn ijklmn ijklmn R

x

thztABF tytd

ψ

ξ

⎡⎤

=−++

⎣⎦

∑

(14)

where

2( 1) 4( 1) 8( 1)

16( 1) 32( 1),

nm l k

ji

ψ

=+ −+ −+ −

+−+−

1

234

11 2 2 3

45 6

( ( )) ( ( )) ( ( )) ( ( ))

( ( )) ( ( )) ( ( ))

ijkx

lx mx nx

hzt M ztM ztM zt

M

ztM ztM zt

ψ

=

×

(15)

It has to be noticed that x

1

, x

3

and x

4

are not

taken into account in the PDC design; this is because

these states are not intended to be stabilized but to

switch between the RF and R partial models. The

fuzzy controller for the models Rqe1 and Rqe2 were

constructed following the same procedure.

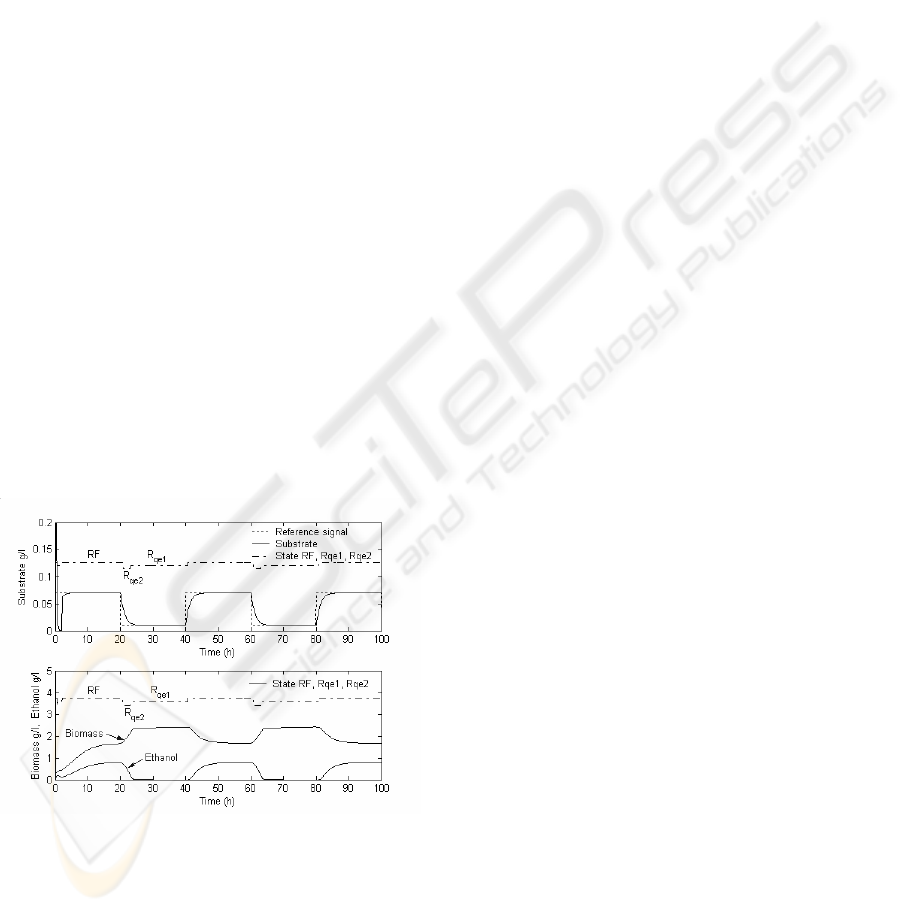

4 SIMULATION RESULTS

The application of the proposed controller scheme

was simulated using MATLAB™. In order to force

the switching between the RF and the R baking yeast

partial models, the substrate fuzzy controller was

forced to track a square reference signal, varied

between 0.01 g/l and 0.07 g/l. S

in

was set to 5 g/l.

The behavior of the substrate fuzzy tracking

controller as well as the biomass and ethanol

behavior are shown in figure 1.

Figure 1: Fuzzy controller performance and biomass and

ethanol behavior.

It can be notice that on the RF model, ethanol is

produced, limiting the biomass growth; when the

Rqe2 partial model is enable the ethanol is

consumed promoting biomass growth, and on the

Rqe1 state partial model the ethanol is consumed

and the biomass is growing just due to the substrate

uptake. To test the fuzzy integral controller

performance, it was enabled when 2 hours of

fermentation elapsed time was accomplished.

5 CONCLUSIONS

Based on the idea of splitting a continuous baking

yeast model, a TS fuzzy model was proposed using

the sector nonlinearities method, giving an exact

representation of the original nonlinear plant.

Moreover, a controller for each partial model was

constructed. It is worth noting that the controller was

capable to force the switching along the partial

models. Therefore, the approach presented here may

be considered a valid method to design a controller.

ACKNOWLEDGEMENTS

This paper has been supported by the Mexican

Consejo Nacional de Ciencia y Tecnología

(CONACyT), under grants 46538, 41148 and the

Ph.D. Schoolarship 70662.

REFERENCES

Ferreira, E., 1995. Identificação e controlo adaptivo de

processos biotecnológicos. Ph. D Thesis, Universidade

do Porto, Portugal.

Khalil, H. 1996. Nonlinear Systems, second edition.

Prentice Hall. United States of America.

Pormeleau, Y., 1990. Modelisation et controle d’un

procéde fed-batch de culture des levures á pain

(saccharomyces cerevisiae). Ph. D. Thesis. Ecole

Polytechnique de Montréal, Canada.

Takagi, T., Sugeno, M., 1985. Fuzzy identification of

systems and its applications to modelling and control.

IEEE Trans. Sys, Man Cyber, 15, 116-132.

Tanaka, K., Wang, H., 2001. Fuzzy control systems

design and analysis, a linear matrix inequality

approach. John Wiley & Sons, United States of

America.

Yamuna, R., Ramachandra, R., 1999. Control of

fermenters - a review. Bioprocess Engineering, 21, 77-

88.

TAKAGI-SUGENO MULTIPLE-MODEL CONTROLLER FOR A CONTINUOUS BAKING YEAST FERMENTATION

PROCESS

439