SCHEDULING OF MULTI-PRODUCT BATCH PLANTS USING

REACHABILITY ANALYSIS OF TIMED AUTOMATA MODELS

Subanatarajan Subbiah, Sebastian Panek, Sebastian Engell

Process Control Laboratory (BCI-AST), University of Dortmund, 44221 Dortmund, Germany

Olaf Stursberg

Industrial Automation Systems (EI-LSR), Technical University of Muenchen, Muenchen, Germany

Keywords:

Scheduling, timed automata, reachability analysis, multi-product batch plant.

Abstract:

Standard scheduling approaches in process industries are often based on algebraic problem formulations

solved as MI(N)LP optimization problems to derive production schedules. To handle such problems tech-

niques based on timed automata have emerged recently. This contribution reports on a successful application

of a new modeling scheme to formulate scheduling problems in process industries as timed automata (TA)

models and describes the solution technique to obtain schedules using symbolic reachability analysis. First,

the jobs, resources and additional constraints are modeled as sets of synchronized timed automata. Then, the

individual automata are composed by parallel composition to form a global automaton which has an initial

location where no jobs have been started and at least one target location where all jobs have been finished. A

cost optimal symbolic reachability analysis is performed on the composed automaton to derive schedules. The

main advantage of this approach over other MILP techniques is the intuitive graphical and modular modeling

and the ability to compute better solutions within reasonable computation time. This is illustrated by a case

study.

1 INTRODUCTION

Scheduling has applications in many fields and one

among them are the chemical industries employed

with multi-product batch plants. Multi-product batch

plants in contrast to continuous plants offer the ad-

vantage of an increased flexibility with respect to the

variation of the products, the volume of production,

and the range of recipes that can be processed by

the equipment. This flexibility makes the scheduling

task challenging. The scheduler has to take a large

number of decisions to answer questions of what,

when, where and how to produce the products in or-

der to satisfy the market demand. The scheduling

task is particularly challenging due to numerous con-

straints arising from process topology, the interlinks

between pieces of equipment, inventory policies, ma-

terial transfers, batch sizes, batch processing times,

demand patterns, changeover procedures, resource

and time constraints, cost functions and degrees of

uncertainty. Many scientists in the process logistics

community have contributed approaches to model and

solve such problems (Kallrath, 2002). In most promi-

nent approaches the problem is specified using the

frameworks of State Task Networks (STN) or Re-

source Task Networks (RTN) (Pantelides, 1994), fur-

ther transformed to an optimization problem modeled

as a mixed integer program (MILP or MINLP) and

solved using state-of-the art solvers such as CPLEX,

XPRESS-MP, etc. The modeling of mathematical

optimization problems is generally cumbersome, te-

dious and requires not only experience in algebraic

modeling but also a deep knowledge of the solver and

its internal algorithms.

Recently, techniques based on reachability analy-

sis for timed automata to solve scheduling problems

have gained attention. The framework of TA has been

originally proposed by (Alur and Dill, 1994) to model

timed systems with discrete dynamics. Many power-

ful tools for the modeling and analysis of real-time

systems such as UPPAAL, IF, KRONOS and TAOPT

have emerged. The authors of (Abdeddaim and Maler,

2001) have proposed to use TA to solve job-shop

scheduling problems based on the symbolic reacha-

141

Subbiah S., Panek S., Engell S. and Stursberg O. (2007).

SCHEDULING OF MULTI-PRODUCT BATCH PLANTS USING REACHABILITY ANALYSIS OF TIMED AUTOMATA MODELS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 141-148

DOI: 10.5220/0001627501410148

Copyright

c

SciTePress

bility analysis of TA. Promising results on challeng-

ing benchmark instances in job-shops were reported

in (Panek et al., 2006). The particular appeal of this

approach comes from the modular and partly graph-

ical modeling which enables inexperienced users to

build models. Another advantage is the availability

of powerful search algorithms that can easily be mod-

ified and extended for special purposes. Similar to

other approaches the reachability analysis of TA also

suffers from the drastic increase in the computational

cost with an increase in the problem size. The prob-

lem of state-space explosion in TA models can be re-

duced to some extent by state-space reduction tech-

niques (Panek et al., 2007), but arises again when the

problem instance is scaled. An advantage of the TA-

based approach is that good, though not provable op-

timal solutions are often found relatively quickly.

The structure of the rest of this paper is as fol-

lows: In Section 2, Resource Task Networks (RTN)

are introduced as the basic model for specifying batch

scheduling problems. Section 3 explains how the

RTN model can be translated into TA, and how the

corresponding scheduling problem can be solved by

symbolic reachability analysis. In section 4, differ-

ent greedy strategies to reduce the solution space are

explained. The description of the case study and the

results of the experiments for the example considered

are provided in section 5. The paper closes with con-

clusions and an outlook.

2 MODELING WITH RTN

In the context of mathematical programming, STN

and RTN serve as starting points for formulating in-

tegrated mathematical models that can be solved to

obtain production schedules. A short description of

the RTN representation is given in this section based

upon a small example: a two stage process with 3

tasks and 3 resources. The resources R

1

, R

2

and R

3

handle batch sizes of b

1

, b

2

and b

3

units. In the first

stage, the single raw material S

1

is processed by task

T

1

in resource R

1

to produce the intermediate mate-

rial S

2

. In the second stage, the intermediate mate-

rial S

2

is processed by tasks T

2

in R

2

and T

3

in R

3

to

produce the end products S

3

and S

4

. The tasks T

1

,T

2

and T

3

requires d

1

,d

2

and d

3

time units, respectively.

There exists a timing constraint between tasks T

1

and

T

3

such that T

3

must be started within Y time units af-

ter T

1

has finished, as the intermediate product S

2

is

unstable and becomes unusable after Y time units. We

assume in the example that dedicated storage tanks

are available for each of the products that have the

same names as the products. The RTN model con-

T

1

T

2

T

3

S

1

P

1

S

2

S

3

S

4

[0,Y]

R

1

R

2

R

3

b

1

, d

1

b

2

, d

2

b

3

, d

3

Figure 1: RTN description of the example process.

sists of four basic elements; (i) state nodes, to rep-

resent the feeds, intermediate materials and the final

products, (ii) task nodes to represent the process op-

erations that transforms one or more input states to

one or more output states, (iii) resource nodes to rep-

resent the production units/equipments, and (iv) arcs

with fractional values to indicate the flow and the per-

centage of material transported to the successor state.

The default values for the flow are 1. The RTN de-

scription of the example process is shown in Figure 1.

The feed, intermediate materials and products (S

1

,···

S

4

) are represented as circles with diagonal lines. The

tasks T

1

, T

2

and T

3

are represented as rectangles and

connected to the corresponding resources R

1

, R

2

and

R

3

, respectively by dashed lines.

The standard RTN framework offers only limited

possibilities to describe timing constraints between

tasks. The timing constraint between task T

1

and T

3

is modeled by a new type of node called place de-

noted by P

1

. The notion of places is motivated by

Timed and Hybrid Petri Nets (Barthomieu and Diaz,

1991). Places can be connected to tasks in the same

fashion as states, however unlike states they repre-

sent no physical products. They contain either one

or no token. When one of the predecessor operations

is finished, a token is assigned in the place and it is

consumed when one of the successor operation starts.

The place in the RTN is marked by the time interval

[0, Y], signifying that a token can stay in the place for

at least 0, and for at most Y time units.

2.1 Timed Automata

Timed automata (TA) are extensions of finite-state au-

tomata with clocks and are used to model and analyze

systems with discrete dynamics and timed behaviour.

Time in TA is modeled using a set of clocks. A short

and informal definition of TA is given below, for a de-

tailed definition for TA please refer to (Alur and Dill,

1994).

2.1.1 Syntax

A timed automata is defined by a tuple, TA = ( L, l

o

,

F, C, E, inv), in which L represents the finite set of

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

142

locations, l

0

represents the initial location and F rep-

resents the set of final locations. C represents the set

of clocks assigned to the TA. The set E ⊂ L × Φ(C) ×

Act ×

P (C) × L represents the transitions. Φ(C) are

guards specified as conjunctions of constraints of the

form c

i

⊗ n or c

i

- c

j

⊗ n, where c

i

, c

j

∈ C, ⊗ ∈ { <,

≤, ==, 6=, >, ≥ } and n ∈ N. Act denotes a set of ac-

tions (e.g. invoking a new event or changing the value

of a variable).

P (C) represent the power set over el-

ements of C. inv represents a set of invariants which

assign conditions for staying in locations. An invari-

ant must evaluate to true when the corresponding lo-

cation is active. The automaton is forced to leave the

location when the invariant evaluates to false.

(l, g, a, r, l

′

) denotes a transition between a source

location l and target location l

′

with a guard g ∈ Φ(C),

performing an action a ∈ Act and resetting the clocks

r ∈

P (C). Such a transition can occur only when the

transition guard g ∈ Φ(C) is satisfied.

Figure 2 shows a simple TA with three locations

l

1

, l

2

and l

3

connected by transitions. The clock c

is reset in the first transition. The invariant c ≤ 3 in

location l

2

refers to the clock c and enforces the fol-

lowing transition which is enabled by the guard c ≥

2. The transitions are labeled with actions α and φ,

respectively. In the context of scheduling we use the

transitions α for allocating a resource to a task and φ

for releasing a resource of the task after completion.

TA models are created in a modular fashion as

sets of interacting automata. The interaction between

TA is established by synchronized transitions. Two

transitions are synchronized when they have the same

synchronization labels from Act. The corresponding

automata change their locations simultaneously. The

parallel composition of a pair of TA is performed by

combining a set of TA into one composed global TA

using the synchronization labels.

The parallel composition of two individual au-

tomata A

1

= (L

1

,l

1,0

,F

1

,C

1

,E

1

,inv

1

) and A

2

=

(L

2

,l

2,0

,F

2

,C

2

,E

2

,inv

2

) is given by A

comp

= A

1

||A

2

= (L

1

× L

2

,(l

1,0

,l

2,0

),F

1

× F

2

,C

1

∪ C

2

,E,inv), with l

= (l

1

,l

2

) and E = E

1

(l

1

) ∧ E

2

(l

2

). A transition in

the composed automaton A

comp

(l,g,a, r,l

′

) ∈ E ex-

ist iff there exist transitions (l

1

,g

1

,a

1

,r

1

,l

′

1

) ∈ E

1

in

A

1

and (l

2

,g

2

,a

2

,r

2

,l

′

2

) ∈ E

2

in A

2

, with guard g =

g

1

∧ g

2

satisfied, r = r

1

∪ r

2

and a ∈ ((Act

1

∪ {0})

×(Act

2

∪ {0})). The symbol 0 here denotes an empty

action in which no state transition occurs. Similarly n

individual TA can be composed step by step to obtain

the composed automaton A

comp

:= A

1

||A

2

||···||A

n

.

An extension of TA with the notion of costs are

priced TA (PTA) (Behrmann et al., 2001). A priced

TA is equipped with an additional function P: L ∪ E

→ R

≥0

which assigns a cost to transitions and cost

l

1

l

2

l

3

C

:= 0

C

3

C

2

α

ϕ

Figure 2: A simple timed automata.

rates to locations. The cost of staying in a location for

d time units is given by d·P(L).

2.1.2 Semantics

The semantics of a composed PTA A is defined in

terms of a labeled transition system (Q,(l

0

,u

0

,0),∆),

with a state space Q ⊆L×R

|C|

× R

≥0

, the initial state

given by (l

0

,u

0

,0) ∈ Q with cost 0 and ∆ representing

the infinite transition relation. The state is a tuple (l,

u, p), where l denotes the location, u denotes a vec-

tor of clock valuations and p represents the cost. ∆

contains the following transitions:

1. Time transitions: (l,u, p)

τ

→ (l,u + 1τ, p +

P(L)·τ) iff for every θ ∈ [0,τ] the invariant inv(l) eval-

uates to true. The vector 1 is composed of ones and

has the dimension equal to the number of clocks in

the set C.

2. Discrete transitions: (l, u, p)

a

→ (l

′

,u

′

, p+P(e))

where there exists a transition e = (l,g,a,r, l

′

) in E

and θ ≥ 0 such that g(u+ 1θ) is satisfied and u

′

=

(u

′

1

,u

′

2

,··· ,u

′

|C|

)

T

with u

′

i

= 0 for every c

i

∈ r and u

′

i

=

u

i

+ θ otherwise.

A sequence of states and state transitions from ∆

constitutes a trace ρ of the composed priced automa-

ton A given by ρ = (l

0

,u

0

,0)

δ

1

→ (l

1

,u

1

, p

1

)

δ

2

→ ··· with

δ

i

∈ ∆. The state transitions in the trace are alter-

nating time transitions and discrete transitions. Each

trace corresponds to runs of the individual automata

thereby characterizing a possible evolution of the sys-

tem. An optimal trace ρ∗ is a path from the initial

state (l

0

, u

0

, 0) to a target state (l

n

, u

n

, p

n

) with mini-

mal p

n

. The set of traces is infinite due to the fact that

time delays τ are elements of time intervals defined

by invariant and guard constraints. This then makes

computing the optimal run from all possible runs a

challenging task.

A solution to this problem is provided by the zone

abstraction technique. A zone Z is an infinite set of

possible clock valuations in a location l, which is ex-

pressed as a conjunction of finitely many inequalities

such as c

i

- c

j

≤ n or c

i

≤ n with c

i

, c

j

∈ C and n

∈ R

≥0

. A symbolic state is formed by the combina-

tion of a location and the zone for the corresponding

location (l, z). All symbolic states q

s

constitute the

symbolic state space Q

s

. The symbolic semantics is

defined in terms of a symbolic transition system in

SCHEDULING OF MULTI-PRODUCT BATCH PLANTS USING REACHABILITY ANALYSIS OF TIMED

AUTOMATA MODELS

143

which zones Z replace single clock valuations u. A

symbolic trace ρ

s

is a sequence of symbolic states in

which the zones are computed by applying intersec-

tions, delay and reset operations defined for zones.

The main advantage of the zone abstraction is that

the symbolic state space Q

s

is enumerable and forms

a directed symbolic reachability graph with nodes

from Q

s

and arcs from ∆

s

. The aim of the cost op-

timal reachability analysis is to find the cheapest path

from the initial state to a target symbolic state us-

ing weighted shortest path algorithms. The result-

ing shortest path obtained corresponds to the optimal

symbolic trace ρ

s∗

. The shortest trace ρ

∗

can then be

derived by picking the minimal clock valuations u

∗

i

from the zones Z

∗

i

of the symbolic states along the

path.

3 SCHEDULING BASED ON TA

After the global composed timed automaton is

constructed through parallel composition, a (cost-

optimal) reachability analysis is performed to derive

the schedules. This enumerative technique explores

the symbolic state space step-by-step by evaluating

the symbolic successor relation on-the-fly. The ba-

sic reachability algorithm from (Panek et al., 2007) is

given below:

Algorithm 1 A cost-optimal reachability algorithm

1 cost

∗

= ∞

2

W := {q

0

}; P := ∅

3 While

W 6= ∅

4 q = selectRemove(

W )

5 If q /∈

P

6 P := P ∪ {q}

7 If cost(q) < cost

∗

8 If final(q)

9 cost

∗

:= cost(q)

10 Else

11

S := succ(q)

12

S

′

:= reduce(

S )

13

W := W ∪ S

′

14 End

15 End

16 End

17 End

The algorithm operates on the nodes of the graph

which contains the information on the location, clock

valuations, accumulated cost and some additional

data. The list of nodes that are to be explored is rep-

resented by the set

W called the waiting list. The

waiting list

W initially contains only the initial node

q

0

which in our case corresponds to the state where

no jobs have been started. The set

P represents the

passed list, a list of already explored nodes, which is

normally empty at the start of the search algorithm.

cost

∗

holds the cost of the best path found so far

and q corresponds to the node that is currently ex-

plored.

S is the set of immediate successors that can

be reached by a single transition from q. The function

selectRemove(W ) selects and removes a node from

W which is minimal according to the ordering ≤

sel

defined by the tree search strategy. In order to avoid

visiting and exploring the same node repeatedly, the

test q /∈

P is performed. final(q) checks whether q

is a target node. The function succ(q) computes the

immediate successor nodes of q and stores them tem-

porarily in

S . The function reduce (S ) is used to re-

move those nodes that cannot contribute to a better

path or to the optimal run. The test cost(q) < cost

∗

compares the cost value of the current node with the

best cost value found, thereby avoiding exploration

of non-optimal runs if the comparison fails. The de-

cision criteria for the function reduce are based on

timed transitions to successor nodes and will be dis-

cussed in detail in the following sections.

4 REDUCTION TECHNIQUES

This section discusses three methods to make the

search for the optimal schedule more efficient.

4.1 Immediate Schedules

In (Abdeddaim and Maler, 2001), it has been shown

that for job-shop problems with the makespan min-

imization as objective, the trace corresponding to

an optimal schedule is always immediate. A non-

immediate trace contains a transition sequence ··· →

(l,u)

τ

→ (l, u+ τ)

α

→ (l

′

,u

′

) → · · · where the α transi-

tion taken at (u+τ) is already enabled at (u+ τ

′

) with

τ

′

< τ. Such traces exhibit periods of useless waiting

in the schedule. Waiting is useless if, e.g., no tasks

are started while the required resource is available

(see Figure 3). Non-immediate traces can be trans-

formed to immediate traces by reducing such waiting

periods to zero. A reduction by τ − τ

′

leads to the

partial trace (l,u)

τ

′

→ (l,u + τ

′

)

α

→ (l

′

,u

′

) and can re-

duce the overall length of the corresponding schedule.

This infers that it is sufficient to search for immedi-

ate traces in the symbolic state space. The effect of

the reductions of the waiting times is that the zones

in the symbolic states collapse to single clock valua-

tions and the symbolic reachability graph is reduced

to nodes representing symbolic states (l,u). The arcs

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

144

(l ,u) (l’’ ,u’’)

(l’ ,u’)(l’’’ ,u’’’)

d < t

Laziness = t

i

k

R

1

R

2

(l ,u)

(l’’ ,u’’)

(l’ ,u’)

(l’’’ ,u’’’)

Non-immediate

i

R

1

R

2

k

time time

k

k

t

Figure 3: Non-immediate and Lazy schedule.

of the symbolic reachability graph become timed tran-

sitions: pairs of discrete and time transitions τa in

which τ is the smallest possible delay needed to sat-

isfy the guard of the discrete transition with the action

a. Zones Z in the symbolic states can be replaced by

vectors of clock valuations u such that (l,u) is a state

of an immediate trace.

4.2 Ordinary and Strict Non-Laziness

In (Abdeddaim and Maler, 2001) also a concept to

avoid unnecessary waiting known as non-laziness

was introduced. Consider a case in which a current

node (l,u) with two discrete transitions as succes-

sors namely α

R

1

i

and α

R

2

k

that allocate resources R

1

and R

2

to jobs i and k, exists. The releasing tran-

sitions are represented as φ

R

1

i

and φ

R

2

k

. The transi-

tion α

R

2

k

was already enabled at the same time when

the transition α

R

1

i

was enabled. In the partial trace

(l,u)

0α

R

1

i

→ (l

′

,u

′

)

tφ

R

1

i

→ (l

′′

,u

′′

)

0α

R

2

k

→ (l

′′′

,u

′′′

) the enabled

transition α

R

2

k

is taken at a later stage by waiting to

finish job i thereby introducing laziness. In order to

remove laziness in a trace, waiting in a node for t or

more than t units is forbidden when all the following

conditions are satisfied:

(a) there exists a successor of (l,u) in which an

operation of duration d can be started by an enabled

discrete transition that allocates a resource to a job.

(b) The duration d of this operation satisfies d ≤ t

(c) if the allocating transition is permanently en-

abled and the resource allocated by that transition is

available for more than d −t units (provided d > t).

The term ordinary laziness is used since a short wait-

ing time according to conditions (b) and (c) is per-

mitted. A stricter condition with respect to waiting is

the strict non-laziness, which is obtained by removing

conditions (b) and (c). Thus, whenever there exists

at least one timed transition to start a new task wait-

ing is forbidden in a state. In comparison to ordinary

non-laziness this scheme prunes more time succes-

sors. However the strict condition might also prune

i

k

time

(l,u)

(l’,u’) (l’’,u’’)

i

k

time

(l,u)

(l’,u’)

(l’’,u’’)

k

time

(l,u)

(l’,u’)

(l’’,u’’)

i

τ

0α (

k)

0α (

i)

τα (

k)

τϕ (

i)

τϕ (

k)

τϕ (

i)

Allocate - Allocate

Finish - Allocate

Finish- Finish

τ

0α(

i)

0α (

k)

0α (

k)

0α (

k)

τϕ (

i)

0ϕ (

i)

0α (

k)

τα (

k)

τϕ (

k)

τϕ (

i)

0ϕ (

i)

0ϕ (

k)

Figure 4: Sleep set configurations.

the optimal trace as in some problems the optimal

schedules may have a short waiting period.

4.3 Sleep-Set Method

The sleep-set method was originally introduced in

(Godefroid, 1991) to reduce possible partial orders

and to avoid exploring obsolete runs in the reacha-

bility graph. The application of the method to job-

shop problems was first implemented in (Panek et al.,

2006). In the symbolic reachability graph different

symbolic traces which correspond to the same sched-

ule may exist. This is due to the interleaving seman-

tics of the TA model. Such traces includes transitions

that are taken at the same absolute time but can be

traversed in different logical orders. In general, such

transitions share a common symbolic state at the start

and at the end of the transition with the same cost.

Three common and possible configurations that can

be identified in the reachability graph are shown in

Figure 4. The left part of the figure shows a pair

of α transitions that can be traversed in two differ-

ent ways from a common start node (l,u). The possi-

ble logical order of the transition pair are {α(i), α(k)}

and {α(k),α(i)}. Both allocating transitions share

the same end state, cost and corresponds to the same

schedule shown. Such traces form so called diamond

structures in the reachability graph. Similar kind of

structures arising due to pairs of α and φ transitions

and the corresponding schedule are shown in the same

figure. Thus, it is evident that only one of the traces in

the diamond structure has to be explored and the rest

can be pruned.

The idea of the sleep-set method to remove obso-

lete traces is to compare pairs of immediate successor

transitions from a node and mark some of them as

candidates to be pruned. However pruning of marked

candidates can only take place when both transitions

are independent. Pairs of timed transitions are said

to be independent if the corresponding operations do

not require the same resource and taking one transi-

tion does not block the other. It should be noted that

SCHEDULING OF MULTI-PRODUCT BATCH PLANTS USING REACHABILITY ANALYSIS OF TIMED

AUTOMATA MODELS

145

pairs of φ and mixed pairs of α and φ transitions are

independent as a single resource cannot finish two op-

erations at the same time. Not all pairs of α transi-

tions are always independent as they might compete

for the same resource. An outgoing transition τδ is

said to be time persistent in a given symbolic state

(l,u, p) at time t, if the discrete transition δ is taken at

t + τ for every partial run starting from (l,u, p) with

τ ≥ 0. Given a symbolic state with outgoing transi-

tions τδ

i

and τδ

j

, τδ

j

is marked as a candidate for re-

duction if τδ

i

is time persistent and vice versa. If both

are time persistent, then the transition with a higher

resource index is removed. This reduction however

does not work when comparing two α transitions as

they are not time persistent. An allocated task must

always be finished. This shows that all outgoing tran-

sitions that release a resource are time-persistent and

appear in future parts of the trace. Since α transitions

are not time persistent, in general they cannot be re-

moved. However it is possible to identify eager α

transitions which become implicitly time persistent in

a non-lazy run. A transition τα

i

which is an imme-

diate successor

S of a state is called eager if for all

τ

j

φ

j

∈

S either (a) τ + dur(α

i

) ≤ min

j

{τ

j

|τ

j

φ

j

∈ S }

or (b) τ ≥ max

j

{τ

j

|τ

j

φ

j

} or (c) τ ≥ 0 if no φ transi-

tions exist in S . A strict approach is to use the same

strategy to remove transitions if they are independent

and not to check whether the transition is time persis-

tent. This strict pruning strategy causes a considerable

reduction of the reachability graph to a considerable

amount. However, it may remove the optimal trace as

a pruned transition can be part of the optimal trace.

5 EXAMPLE PROCESS

In order to depict the applicability and the effective-

ness of the approach discussed here, the case study

presented by (Bauer et al., 2000) is considered. The

case study is a multi-product chemical batch plant

with 3 stages in which two end-products, X and Y,

are produced from three raw materials, A, B and C.

The production process considered is: one batch of

material A and C each reacts to produce one batch of

product X; similarly one batch of B and C reacts to

produce one batch of product Y. The plant executing

the production process is shown in Figure 5.

The first stage consists of three buffer tanks B11,

B12 and B13 that store the raw materials A, C and

B. The second stage consists of three reactors R1, R2

and R3. Each reactor may be filled from each raw

material buffer tank in the first stage; implying that it

is possible to produce either product X or Y in each

reactor. After processing the materials a reactor may

B11

R1

R3

R2

M

M

M

B13

B31

B32

P1

P3

LIS

LIS

LIS

LIS

LIS

LIS

13

11

21

22

23

12

B12

P2

Level2

Reactants

Reaction(Reactors)

Level3

Products

Level1

Rawmaterial

(Buffertanks)

P5

P4

A

C

B

X

Y

Figure 5: The structure of the example process.

contain one batch of the product (resulting from two

batches of raw material). The third stage consists of

two buffer tanks B31 and B32 which are used to store

the end-products X and Y. Each of the tanks has a

maximum capacity to store three batches of the prod-

uct. The proposed scheduling problem is to derive

production schedules to produce 2 batches of the end-

products with a minimum makespan. After being pro-

cessed by the reactors the materials must be drained

into the buffer tanks in the third stage immediately.

RTN description of the problem considered is

shown in Figure 6. Materials A, C and B are rep-

resented as S

1

,S

2

and S

3

. The tasks T

1

,T

2

and T

3

represents the task of pumping materials A, C and B

into buffer tanks B11, B12 and B13, respectively. The

tasks T

4

,T

6

and T

8

represent the step of draining one

batch of A from B11 into the reactors R1, R2 and R3.

Similarly, tasks T

11

, T

13

and T

15

represent draining of

material B from B13 into the reactors. The tasks T

5

,

T

7

and T

9

represent mixing one batch of C from B12

with one batch of A, already present in R1, R2 and R3

in order to produce X. The tasks T

10

,T

12

and T

14

rep-

resent similar actions for producing one batch of Y.

The tasks T

16

,T

17

and T

18

represent the step of drain-

ing one batch of X from R1, R2 and R3, respectively,

into the buffer tank B31. Tasks T

19

,T

20

and T

21

rep-

resent draining one batch of Y from R1, R2 and R3

into tank B32. The tasks T

22

and T

23

represent drain-

ing of two batches of X from B31 and two batches

of Y from B32 to the product storage, respectively.

The constraint on the waiting time is expressed by the

places P

2

, P

4

, P

6

, P

8

, P

10

and P

12

. The places P

1

, P

3

,

P

5

, P

7

, P

9

and P

11

are established to ensure that mate-

rial C is drained into the reactors only after either A

or B has been drained.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

146

R

1

S

1

0.5

T

1

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

[0,0]

S

4

S

2

S

5

S

3

S

6

S

12

S

11

S

10

S

9

S

8

S

7

S

13

S

15

S

16

S

14

T

4

T

5

T

6

T

16

T

17

T

22

T

18

T

7

T

8

T

9

T

10

T

11

T

12

T

13

T

15

T

14

T

2

T

3

T

19

T

20

T

23

T

21

0.5

0.5 0.5

0.5 0.5

0.5 0.5 0.5 0.5 0.5

0.5

R

4

R

5

R

2

R

6

R

4

R

3

R

5

R

6

R

7

R

9

R

8

R

10

P

1

P

2

P

3

P

4

P

5

P

6

P

7

P

8

P

9

P

10

P

11

P

12

Figure 6: The RTN of the example process.

5.1 TA Model

The TA model consists of 10 resource automata to

model the individual resources. The places are mod-

eled as separate automata. The resource automata and

the place automata have one clock each to measure the

task durations and time interval for storage. An addi-

tional global clock which is never reset is included in

the model to measure the makespan. The resource au-

tomaton for resource R

4

and the place automaton P

2

are shown in Figure 7. The automaton R

4

has one idle

location and four busy locations indicating the exe-

cution of either of the tasks T

4

or T

5

or T

10

or T

11

.

Tasks T

4

and T

11

process one batch of material S

4

and

S

6

with task duration of 15 and 11 units. The tim-

ing constraint between task T

5

and task T

16

is mod-

eled by the place automaton P

2

on the right side. Task

T

5

after finishing its process in R

4

produces a token

in the place P

1

by taking the synchronized transitions

in R

5

and P

2

with the label φ

5

. The clock C

12

is re-

set and forces P

2

to leave the location filled without

waiting. This happens by starting task T

16

and by tak-

ing the synchronized transitions with label α

16

in R

7

and P

2

. An automatic translation from the RTN to the

TA model was performed by the tool TAOPT (Panek

et al., 2005).

5.2 Computational Experiments

The scheduling problem presented in the example

process was solved by a Xeon machine with a CPU

speed of 3.06 GHz, 2.0 GB of memory and a linux op-

erating system. For the cost optimal symbolic reacha-

bility analysis, the software tool TAOPT (Panek et al.,

2005) which supports different state space reduction

techniques as discussed above: immediate traces,

Figure 7: Structure of the resource and place automaton.

(strict) non-lazy runs and sleep-set method was used.

A combination of the depth-first and best-first strategy

was used for exploring the graph. Among the nodes

in the waiting list, the node with the maximum depth

is given a higher priority, among the nodes with the

same depth, priority is given to the node with a mini-

mum cost. If two or more nodes have the same depth

and cost, one of them is chosen randomly.

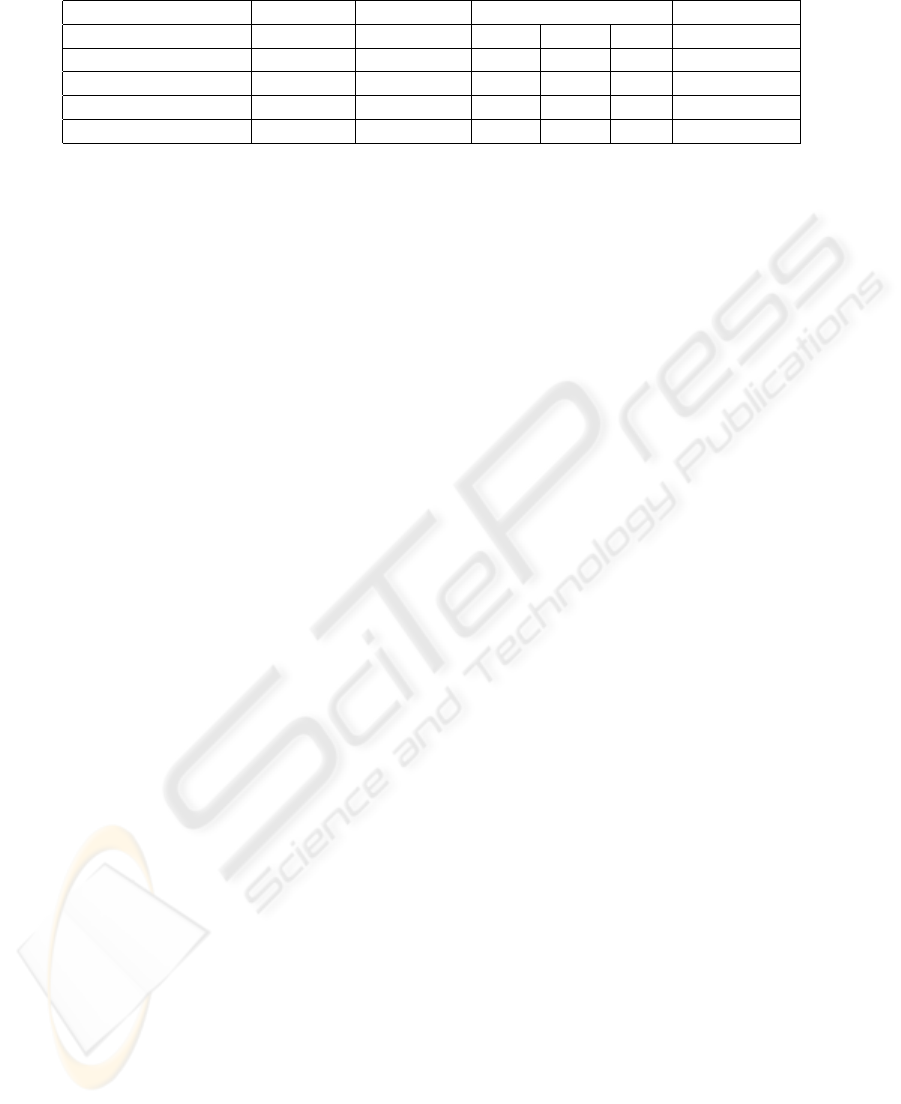

The Table 1 shows the results obtained by re-

stricting the search to only immediate traces repre-

sented as None and with other state space reduction

techniques: ordinary non-lazy runs (NL

ordinary

), strict

non-lazy runs and strict sleep-set method (SSM

strict

).

For all tests the complete reachability graph was ex-

plored. The second column that represents the total

time needed to compute the reachability graph and the

total number of nodes explored in the the third column

reveal that the strict sleep-set method reduces the state

space and computational effort considerably. On the

other hand it prunes the optimal solutions. The fourth

column represents the time taken in CPU seconds to

SCHEDULING OF MULTI-PRODUCT BATCH PLANTS USING REACHABILITY ANALYSIS OF TIMED

AUTOMATA MODELS

147

Table 1: Computational results.

First solution Best solution

Reduction technique Total time Total nodes time nodes C

max

C

max

None 58.832 493167 0.032 1875 100 98

NL

ordinary

2.104 37483 0.048 2157 98 98

SSM

strict

0.476 13374 0.120 6492 131 128

SSM + NL

ordinary

1.084 28583 0.040 681 102 98

compute the first feasible solution when different re-

duction techniques were used. The test with nor-

mal sleep set method which compares and removes

only time persistent pairs of transitions in combina-

tion with ordinary non-lazy runs was performed. This

is represented as SSM + NL

ordinary

in the table 1. The

combination of SSM + NL

ordinary

found the optimal

solution. This is due to the fact that only time per-

sistent transitions were pruned. No solutions could

be found for the strict non-laziness setting when ap-

plied alone or in combination with the strict sleep-set

method and the normal sleep-set method. It should

be noted that the reduction techniques ordinary non-

lazy runs and the normal sleep-set method are the

only combinations which theoretically guaranty that

the optimal solution is not pruned. The strict sleep set

method in general should only be used as a heuristic.

6 CONCLUSION

A new and a straightforward approach to model

scheduling problems in multi-product batch plants

and to derive production schedules based on symbolic

reachability analysis of TA has been introduced. The

experimental results show that the method can solve

scheduling problems in process industries efficiently

within a limited computation time. The main aspect

to be considered is the time required by the TA ap-

proach to specify and formulate the scheduling prob-

lem. It is relatively easy when compared to formulat-

ing it as MILP which are usually cumbersome. The

efficiency of the approach to derive solutions with re-

duced computational effort have been achieved with

different search space reduction techniques.

Future work on the TA based approach will focus

on online scheduling problems in which the arrival

time of jobs is not known in advance and subject to

random perturbations.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the financial sup-

port by the Graduate School of Production Engineer-

ing and Logistics at the University of Dortmund.

REFERENCES

Abdeddaim, Y. and Maler, O. (2001). Job-shop scheduling

using timed automata. Computer Aided Verification

(CAV), Springer, pages 478–492.

Alur, R. and Dill, D. (1994). A theory of timed automata.

Theor. Comp.Science, 126(2):183–235.

Barthomieu, B. and Diaz, M. (1991). Modeling and

verification of time dependent systems using timed

petri nets. IEEE Transactions Software Engineering,

126(2):259–273.

Bauer, N., Kowalewski, S., Sand, G., and Loehl, T. (2000).

A case study: Multi product batch plant for the

demonstration of scheduling and control problems.

In ADPM2000 Conference Proceedings-Hybrid Dy-

namic Systems, pages 383–388. Shaker.

Behrmann, G., Fehnker, A., Hune, T., Peterson, P., Larsen,

K., and Romjin, K. (2001). Efficient guiding to-

wards cost-optimality in UPPAAL. In Proceedings

TACAS’01, pages 174–188.

Godefroid, P. (1991). Using partial orders to improve auto-

matic verification methods. In Proc. 2nd Workshop on

Computer Aided Verification, 531 of LNCS:176–185.

Kallrath, J. (2002). Planning and scheduling in the process

industry. OR Spectrum, 24:219–250.

Panek, S., Engell, S., and Lessner, C. (2005). Scheduling

of a pipeless multi-product batch plant using mixed-

integer programming combined with heuristics. In Eu-

ropean Symposium on Computer Aided Process Engi-

neering, ESCAPE 15, pages 1033–1038.

Panek, S., Engell, S., and Stursberg, O. (2006). Efficient

synthesis of production schedules by optimization of

timed automata. Control Engineering Practice, pages

149–156.

Panek, S., Engell, S., Subbiah, S., and Stursberg, O. (2007).

Scheduling of multi-product batch plants based upon

timed automata models. Submitted to Comp. Chem.

Eng.

Pantelides, C. (1994). Unified frameworks for optimal pro-

cess planning and scheduling. In Proceedings 2nd

conference Foundations of Computer Aided Process

Operations, pages 253–274.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

148