TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH

FORCE FEEDBACK OVER INTERNET

Ivan Petrovi

´

c

Faculty of Electrical Engineering and Computing, University of Zagreb, Unska 3, Zagreb, Croatia

Josip Babi

´

c

Kon

ˇ

car - Institute of Electrical Engineering, Ba

ˇ

stijanova bb, Zagreb, Croatia

Marko Budi

ˇ

si

´

c

Department of Mechanical Engineering, University of California, Santa Barbara, USA

Keywords:

Teleoperation, mobile robots, force feedback.

Abstract:

A teleoperation system has been developed that enables two human operators to safely control two collabo-

rative mobile robots in unknown and dynamic environments from any two PCs connected to the Internet by

installing developed client program on them and by using simple force feedback joysticks. On the graphical

user interfaces, the operators receive images forwarded by the cameras mounted on the robots, and on the

the joysticks they feel forces forwarded by developed obstacle prevention algorithm based on the dynamic

window approach. The amount and direction of the forces they feel on their hands depend on the distance

and direction to the robot’s closest obstacle, which can also be the collaborating robot. To overcome the in-

stability caused by the unknown and varying time delay an event-based teleoperation method is employed to

synchronize actions of each robot with commands from its operator. Through experimental investigation it is

confirmed that developed teleoperation system enables the operators to successfully accomplish collaborative

tasks in complex environments.

1 INTRODUCTION

Teleoperation is often employed in controlling mo-

bile robots navigating in unknown and unstructured

environments. This is largely because teleoperation

makes use of the sophisticated cognitive capabilities

of the human operator (Sheridan, 1992), (Murphy

and Rogers, 1996). Conventional teleoperated mo-

bile robots rely on visual contact with the operator,

either directly or through video transmissions. Guid-

ing such a robot is a formidable task, often compli-

cated by the limited view from the camera. Under

such conditions, a human teleoperator must exercise

extreme care, especially in obstacle-cluttered environ-

ments. In order to increase the system performance

and to reduce the operator stress and the task errors,

force feedback from the robot to the human operator

is usually employed, see e.g. (Sheridan, 1992), (Lee

et al., 2002).

With the rapid development of information tech-

nology, the Internet has evolved from a simple data-

sharing media to an amazing information world where

people can enjoy various services, teleoperation bee-

ing one of them. The use of Internet for teleoper-

ation tasks has become one of the hottest topics in

robotics and automation, see e.g. (Munir, 2001)–

(Lo et al., 2004). On the other hand, the Internet

also entails a number of limitations and difficulties,

such as restricted bandwidth, arbitrarily large trans-

mission delays, delay jitter, and packet lost or error,

all of which influence the performance of Internet-

based telerobotics systems. A number of approaches

have been proposed to ensure stability of the force

feedback loop closed over Internet, were the majority

of them are based on passivity theory (Munir, 2001),

(Niemeyer, 1996), (Niemeyer and Slotine, 2004) or

on the event based action synchronization using a

non-time refernce (Wang and Liu, 2005), (K. Brady,

2002), (Luo and Su, 2003). The later approach is used

in this paper because of its simplicity and effective-

ness.

There are many complicated and sophisticated

430

Petrovi

´

c I., Babi

´

c J. and BudisÇ

ˇ

R

´

c M. (2007).

TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH FORCE FEEDBACK OVER INTERNET.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 430-437

DOI: 10.5220/0001628104300437

Copyright

c

SciTePress

tasks that cannot be performed efficiently by a sin-

gle robot or operator, but require the cooperation of

number of them. The cooperation of multiple robots

and/or operators is particularly beneficial in cases

when robots must operate in unknown and dynamic

environments. Teleoperation of multiple robots by

multiple operators over Internet has been extensively

studied for couple of years. A good survey can be

found in (Lo et al., 2004).

In this paper we present a teleoperation system

that consists of two mobile robots, where one of them

serves as Scout and the other one as Manipulator.

Scout explores the remote site and with its sensory

information assists the operator controlling the Ma-

nipulator, which executes tasks of direct interaction

with working environment by using the robot arm

mounted on it. In order to guarantee safe robots

navigation in dynamic environments and/or at high-

speeds, it is desirable to provide a sensor-based col-

lision avoidance scheme on-board the robots. By

having this competence, the robots can react with-

out delay on changes in its surrounding. Usually used

methods for obstacle prevention are based on virtual

forces creation between the robot and the closest ob-

stacle, see e.g. (Borenstein and Koren, 1990) and

(Lee et al., 2006), where the force is inversely pro-

portional to the distance between them. In this pa-

per, we propose a new obstacle avoidance algorithm

based on the dynamic window (DW) approach pre-

sented in (Fox et al., 1997). Main advantage of our

algorithm is that it takes robot dynamic constraints

directly into account, which is particularly beneficial

for safe navigation at high-speeds as the safety mar-

gin depends not only on distances between the robot

and the nearby obstacles, but also on the velocity of

robot motion. The algorithm is implemented on both

robots and each robot considers the other one as the

moving obstacle.

The paper is structured as follows. In Section 2,

we present overview of developed mobile robot tele-

operation system. Force feedback loops implementa-

tions are described in section 3. Section 4 describes

experimental results. We conclude with a summary

and a discussion of future work.

2 OVERVIEW OF THE SYSTEM

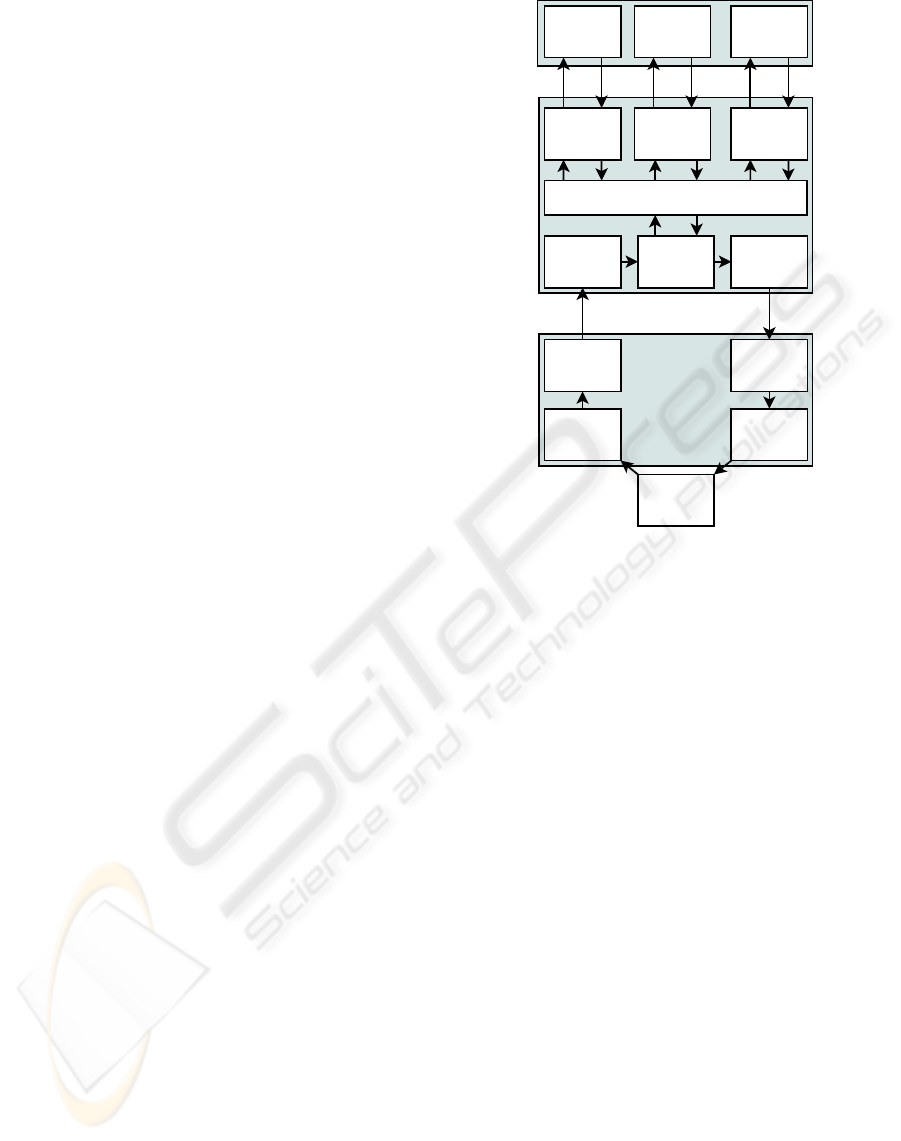

The teleoperation system considered in this paper is

schematically illustrated in Fig. 1. It consists of two

mobile robots (Scout and Manipulator) operating in

a remote environment and two operator stations with

PCs and force feedback joysticks. While the opera-

tors’ PCs (clients) are directly connected to the Inter-

net, robots’ on-board PCs (servers) are connected to

Internet via wireless LAN. Each operator controls a

single robot and receives visual and other data from

both robots.

Mobile robots that we use are PIONEER 2DX

(Scout) and PIONEER 3DX (Manipulator) manufac-

tured by ActivMedia Robotics. Scout is equipped with

an on-board PC, a ring with sixteen sonar sensors,

laser distance sensor and a Sony EVI-D30 PTZ cam-

era. Manipulator carries an external laptop computer,

a ring with sixteen sonars and a Cannon VC-C50i PTZ

camera. Additionally, a Pioneer arm with five degrees

of freedom and a gripper is mounted on the Manipu-

lator. Sonars on each robot are used for obstacle de-

tection.

Any personal computer with an adequate Inter-

net connection, a force feedback joystick and devel-

oped client application can serve as an operator sta-

tion. The client application has graphical user inter-

face (GUI) that enables the operator to preset the oper-

ation mode (driving, manipulation, observation) and

to supervise both mobile robot actions.

Logitech WingMan Force 3D Joystick used in our

experiments has two axes on which it can read inputs

and generate force: x (stick up-down) and y (stick left-

right) and two additional axes that can only read in-

puts: z (stick twist) and throttle. GUI provides ad-

ditional operator input, e.g. when switching between

operating modes. Both joystick references and GUI

input are collectively referred to as commands. When

client application is actively connected with the mo-

bile robot and driving operating mode is chosen on

the GUI, joystick x and y axes are used to input de-

sired translational and rotational velocities, respec-

tively. Force feedback is applied on the same two

axis, defying commands that would lead robot toward

detected obstacles. If manipulation operating mode is

chosen two joystick buttons are used to chose one of

arm’s 6 joints, third button sends the arm in its home

position and y axis is used to input chosen joint veloc-

ity and to display reflected force. In observation oper-

ating mode joystick x axis is used to tilt the camera, y

axis to pan it, throttle is used for adjusting zoom, and

one joystick button sends camera to its home position.

Communication between server applications run-

ning on the mobile robots’ on-board PCs and client

applications running on the operators’ PCs is initial-

ized and terminated by client applications. In spe-

cial cases, e.g. when robot is turned off or malfunc-

tioning or in case of communication failure, a server

application can refuse or terminate the connection.

Communication is implemented using three indepen-

dent communication modules: control module, im-

age transfer module and info module. Modules are

TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH FORCE FEEDBACK OVER INTERNET

431

Internet

n observer

stations

Dynamic

Window

Sonars

Environment

Commands

Force Feedback

operator

station 2

Image

Transfer

Module

Info

Module

Control

Module

Image

Transfer

Module

Info

Module

Control

Module

Image

Transfer

Module

Info

Module

ACTS

Framegrabber

WLAN

Dynamic

Window

Sonars

operator

station 1

Image

Transfer

Module

Info

Module

Image

Transfer

Module

Info

Module

ACTS

WLAN

Manipulator

Scout

Control

Module

Control

Module

Commands

Force Feedback

Framegrabber

Figure 1: Schematic overview of the teleoperation system.

executed within separate threads of applications and

communicate using separate communication sockets.

Modular structure decreases individual socket load

and enables each module to transfer specific type of

data without employing complicated packet schedul-

ing schemes.

Control module is used to transmit commands

from the joystick to the robot and force feedback sig-

nal from the robot to the joystick. Depending on the

operation mode, chosen on the client application GUI,

these command can be robot’s translational and angu-

lar velocities (driving mode), angular velocity of in-

dividual joints of the robot arm (manipulation mode)

or they could be commands sent to the camera: pan

and tilt angular velocity and zoom value (observation

mode). If the operator controlls mobile robot’s move-

ment or one of robot’s arm joints, control module de-

livers reflected force from the robot to the joystick. In

case the operator controlls the camera reflected force

is zero and it is only used for action synchronization.

Image transfer module transmits the frames of vi-

sual feedback signal from robots’ cameras to opera-

tors via GUI of the client application. It delivers video

signal image at a time. Cameras are connected to the

PCs via frame grabber cards and images are fetched

using ActivMedia Color Tracking System (ACTS) ap-

plication. ACTS is an application which, in combina-

tion with a color camera and frame grabber hardware

in a PC, enables custom applications to actively track

up to 320 colored objects at a full 30[fps] image ac-

quisition rate (ActivMedia, 2003). ACTS serves im-

ages to applications connected to it through TCP/IP.

This functionality was not used and communication

module was developed so that frequency and order

in which clients receive images can be directly con-

trolled. Server side communication module periodi-

cally requests an image form the ACTS and sends it

to the connected clients.

Info module transmits time noncritical informa-

tion, and is primarily used to synchronize local clocks

and transmit information about robot velocities and

arm positions to the clients.

3 FORCE FEEDBACK LOOPS

Force feedback from the remote environment gives

important information to the human operator. Two

force feedback loops have been implemented. One,

which is implemented on both mobile robots, for-

wards the force to the corresponding operator in case

of possible collision with the nearby obstacles or with

the collaborating robot. Anther one, which is imple-

mented only on Manipulator, forwards the force to its

operator’s hand when he controls the robot arm.

3.1 Event Based Action

Synchronization

Main drawback of closing a control loop over the In-

ternet is the existence of stochastic and unbounded

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

432

communication delay that can affect system perfor-

mance and even make it unstable. These problems

are usually addressed by ensuring passiveness of the

control loop, see e.g. (Munir, 2001), (Niemeyer,

1996) and (Niemeyer and Slotine, 2004) or by using a

non-time reference for action synchronization, as pre-

sented in (Wang and Liu, 2005), (K. Brady, 2002) and

(Luo and Su, 2003). The later approach is used here,

because there is no need for additional signal process-

ing and consequently the control system is compu-

tationally much simpler. The stability of the control

system with event-based action synchronization is en-

sured if a nondecreasing function of time is used as

the action reference (Xi and Tarn, 2000). The num-

ber of completed control cycles, which is obviously

a monotone increasing function of time, was chosen

for this reference. Each control cycle (Fig. 2) is a

sequence of the following actions:

1. Server application fetches the most recent force

feedback from the buffer and sends it to the client

application.

2. Client application receives force feedback.

3. Received force is applied to the joystick.

4. New commands are read from the joystick.

5. The commands are sent to the server application.

6. Server application receives new commands and

refreshes the buffer. Depending on the operation

mode, DW algorithm or arm controller periodi-

cally fetches the command from the buffer and re-

freshes the force feedback on the buffer after its

execution. Commands are refreshed once for ev-

ery force feedback signal sent to the client appli-

cation.

Proper order of arrival of information packets is

crucial to stability of control system, even more than

their timely delivery. For this reason, UDP protocol is

used for sending operator commands and force feed-

back. UDP, unlike TCP, does not resend lost packets

and is therefore more suitable for real time applica-

tions. Additionally, UDP packets tend to be smaller

in size than corresponding TCP packets which yields

a smaller load on the communication channel. How-

ever, unreliable delivery of control packages could

break the control cycle and longer communication de-

lays may destabilize the system. To avoid this, server

application monitors control cycle duration and if it

exceeds a prescribed maximal value (e.g. 1 second),

server application initiates a new control cycle by

sending a fresh force feedback packet. All packets

that arrive outside their control cycles are simply ig-

nored.

receive

command

read

command

send

command

Client

Server

buffer

dynamic

window

send

force

receive

force

apply

force

joystick

operating mode

motion armcamera

Robot

arm

controller

camera

controller

Figure 2: Event-Based Action Synchronization between

client and server control modules.

Described event-triggered control ensures that the

force applied to the joystick corresponds to the com-

mand sent in the previous control cycle and that the

buffer state is refreshed with the command that cor-

responds to the force feedback sent in the current

control cycle. Therefore, action synchronization is

achieved using the control cycle number as a time in-

dependent reference and the system is stable.

Action synchronization between Manipulator and

its operator station is executed independently from ac-

tion synchronization between Scout and its operator

station. This arrangement is referred to as decentral-

ized event-based control (Lo et al., 2004) and it as-

sures that control cycle duration of one robot-operator

station pair is not affected by communication delays

of the other pair.

3.2 Collision Prevention

For safe robots navigation and cooperation in dy-

namic environments it is necessary to provide a

sensor-based collision prevention scheme on-board

each mobile robot. Here, we applied the DW algo-

rithm, which is a velocity space based local reactive

avoidance technique (Fox et al., 1997). Unlike di-

rectional reactive collision avoidance approaches (e.g.

potential filed, vector field histograms), the DW algo-

TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH FORCE FEEDBACK OVER INTERNET

433

rithm takes robot’s kinematic and dynamic constrains

directly into account by performing a search in space

of translational and rotational velocities. DW pro-

duces trajectories that consist of circular and straight

line arcs.

The DW algorithm can be integrated with a global

path planing algorithm, e.g. FD* algorithm as in

(Seder et al., 2005), for executing autonomous tasks

in partially unknown environments. While global

path planing algorithm calculates optimal path to a

specific goal, the DW algorithm takes into account

unknown and changing characteristics of the environ-

ment based on the local sensory information. We

used DW algorithm in a teleoperation system, with-

out global path planing algorithm, just to ensure safe

motion of the mobile robot and to help the operator to

better perceive obstacles. Therefore some modifica-

tions to the original algorithm had to be made.

Operator issues translational and rotational veloc-

ities’ references. DW algorithm evaluates the given

command while taking into account local sonar read-

ings and kinematic and dynamic robot constrains.

Commands that are not safe are not executed and

force feedback is generated in order to warn the oper-

ator.

Proposed DW-based collision prevention algo-

rithm consists of the following steps:

1. Desired velocities (v

d

, ω

d

) are fetched from the

buffer.

2. They are constrained by maximal and minimal

achievable velocities:

v

d

∈ [v

min

, v

max

],

ω

d

∈ [ω

min

, ω

max

]. (1)

3. Resulting velocities are additionally constrained

to values from the set of velocities V

nc

=

{v

nc

, ω

nc

} achievable in one robot control cycle.

v

d

∈ v

nc

= [v

c

− T ˙v

m

, v

c

+ T ˙v

m

],

ω

d

∈ ω

nc

= [ω

c

− T ˙ω

m

, ω

c

+ T ˙ω

m

], (2)

where v

c

and ω

c

are current velocities, ˙v

m

and ˙ω

m

are maximal accelerations/decelerations and T is

robot control cycle duration.

4. Minimal stopping path is calculated. Stopping

time and applied translational deceleration must

be established first. If condition

|

v

d

˙v

m

| > |

ω

d

˙ω

m

| (3)

is satisfied, maximal translational deceleration a

s

is applied during stopping time t

s

:

t

s

= |

v

d

˙v

m

|,

a

s

= ˙v

m

. (4)

Figure 3: Trajectory of a robot is described as a circular

arc.

If (3) is not satisfied it takes more time to stop

the rotation of the robot than its translation. Then

translational deceleration smaller than maximal is

applied:

t

s

= |

ω

d

˙ω

m

|,

a

s

= |

v

d

t

s

|. (5)

Minimal stopping path s

s

is then:

s

s

= v

d

(t

s

+ t

stm

) −

a

s

t

2

s

2

, (6)

where t

stm

is additional safety time margin.

5. For the given velocities (v

d

, ω

d

) coordinates of

N

p

points on circular or straight line arc (Fig. 3)

are calculated using following equations:

γ

i

= 2α

i

= 2T N

c

i

N

p

,

x

i

= x

c

+ sgn(v

d

)rsin(γ

i

),

y

i

= y

c

+ sgn(v

d

)sgn(ω

d

)rcos(γ

i

), (7)

where (x

c

, y

c

) is the center of the arc, r =

v

d

ω

d

its radius, i = 1, . . . , N

p

is the index specifying

the point on the trajectory, from 1 to N

p

and N

c

is the number of cycles for which the algorithm is

executed.

6. Minimal allowed distance to obstacle ρ

min

is:

ρ

min

= r

r

+ s

c1

+

+(s

c2

− s

c1

)

v

d

v

max

+ s

cω

ω

ω

max

, (8)

where r

r

is robot radius, s

c1

safety clearance at

low translational velocities, s

c2

safety clearance

at high translational velocities and s

cω

rotational

safety clearance. Rotational safety clearance is set

to s

cω

= 0 because it is considered safe to rotate

the robot in place. This clearance can be set to a

higher value if rotation in place is not considered

safe, e.g. when rotating the robot with extended

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

434

robot arm. At low translational velocities (i.e. ve-

locities close to zero) s

c2

contributes little or not

at all to ρ

min

(ρ

min

= r

r

+s

c1

, v

d

= 0, s

cω

= 0).

At high translational velocities (i.e. velocities

close to maximum value) s

c1

has little or no in-

fluence on ρ

min

value (ρ

min

= r

r

+ s

c2

, v

d

=

v

max

, s

cω

= 0).

7. For every point on the trajectory (v

d

, ω

d

), starting

with the one closest to the robot, distance to the

closest obstacle ρ

i

(v

d

, ω

d

) is calculated and if the

condition:

ρ

i

(v

d

, ω

d

) ≥ ρ

min

(v

d

, ω

d

) (9)

is true the calculation is executed for the next

point on the trajectory. If (9) is satisfied for all

N

p

points on the trajectory then it is considered

clear, force feedback is zero and the algorithm is

finished.

8. If the condition (9) is not satisfied, path to the i-th

point on the trajectory is calculated:

s

p

= v

d

i

N

p

T N

c

(10)

9. If the path to the i-th point s

p

is smaller than stop-

ping path s

s

s

p

< s

s

, (11)

i.e. it is possible to stop the robot before it comes

closer than ρ

min

to the obstacle, trajectory is con-

sidered safe, force feedback is calculated and the

algorithm is finished. Force feedback is calculated

as follows:

F

amp

= β

p

x

2

o

+ y

2

o

,

F

ang

= atan2(y

o

, x

o

), (12)

where F

amp

and F

ang

is force feedback amplitude

(scaled to [0, 1] with scaling factor β) and direc-

tion, respectively, (x

o

, y

o

) is the closest obstacle

position in mobile robots coordinates and atan2 is

arctangent function.

10. If the condition (11) is not met, the investigated

trajectory leads to collision, i.e. leads robot closer

than ρ

min

to the obstacle. To prevent collision,

desired velocities magnitudes are decreased:

v

d(i+1)

= v

di

− v

d1

/N

s

,

ω

d(i+1)

= ω

di

− ω

d1

/N

s

, (13)

where v

d(i+1)

and ω

d(i+1)

are velocities for the

next iteration of the algorithm, v

di

and ω

di

are ve-

locities of the current iteration, v

d1

and ω

d1

are

original commanded velocities that entered the

first iteration of the algorithm and N

s

is the num-

ber of steps in which velocities are decremented.

If the new values are different than zero, algo-

rithm is repeated from step 4) until safe trajectory

is found.

3.3 Force Feedback from the

Manipulator’s Arm

During robot arm movement force is reflected when

the joint being controlled rotates to an angle that is

less than 10

◦

away from its maximum value:

F

arm

= F

max

(1 −

ξ

max

− ξ

i

10

),

|ξ

max

− ξ

i

| < 10

◦

, (14)

where F

arm

is the reflected force amplitude corre-

sponding to the current joint angle ξ

i

, F

max

maximal

reflected force amplitude, and ξ

max

maximal joint an-

gle. Feedback force informs the Manipulator’s oper-

ator that the controlled joint approaches its maximal

angle.

4 EXPERIMENTS

In order to validate the developed system a number

of experiments have been carried out during which

different signals have been recorded. Results of four

illustrative experiments are given here.

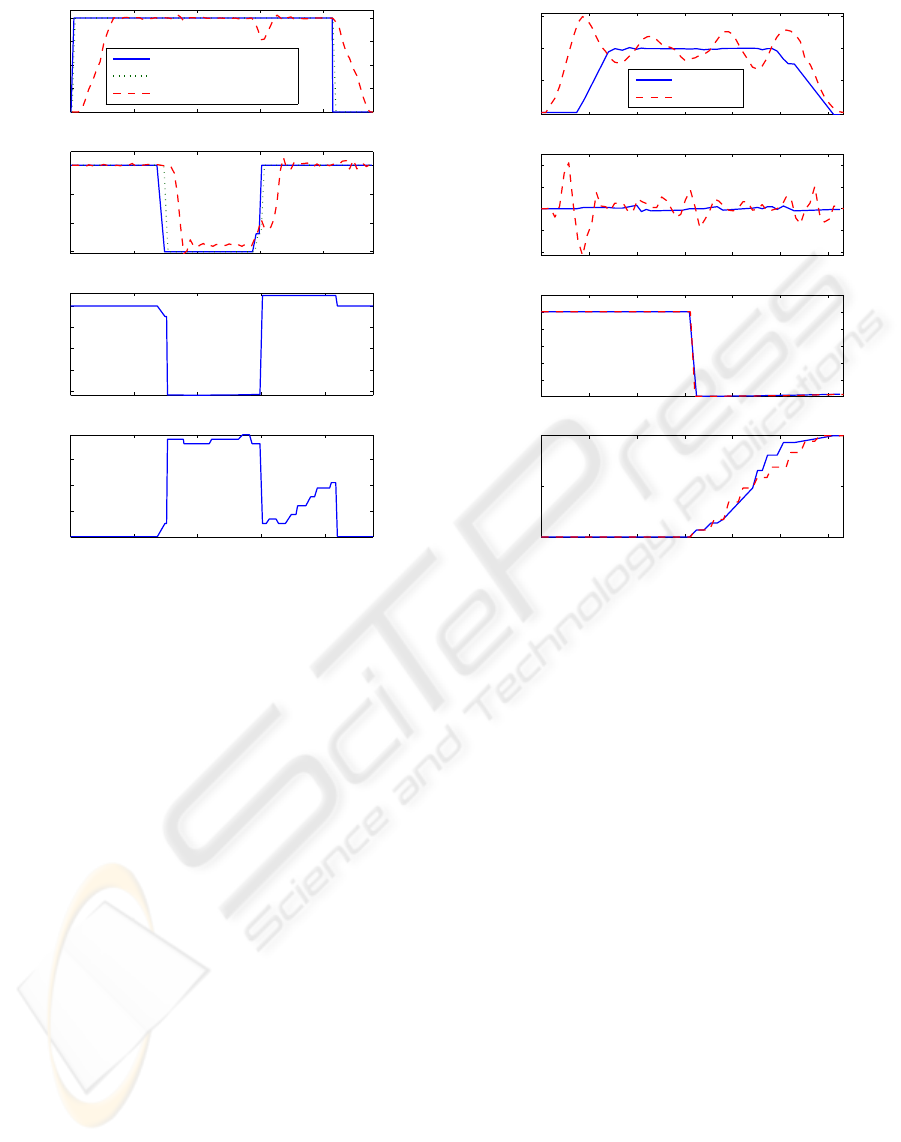

In the first experiment the operator drove the robot

around an obstacle. The commanded velocities on

client side (CS), commanded velocities on server side

(SS), measured velocities, applied force feedback di-

rection and amplitude were recorded. During the first

phase of the experiment (from 0 s to 3 s, Fig. 4)

robot moves forward and the obstacle is outside the

DW sensitivity region. Measured velocities match the

commanded ones and no force is reflected. When the

operator starts turning the robot, the obstacle enters

DW sensitivity region and force is reflected at −80

◦

informing the operator that the obstacle is on the right

from the robot (from 3 s to 6 s), and at the same time

DW limits the robot angular velocity, while transla-

tional velocity matches the commanded one. At ap-

proximately t = 6s, the operator stops turning the

robot, and the reflected force falls down, DW algo-

rithm limits for a short time first the robot transla-

tional velocity and then angular velocity. Then the

robot moves away from the obstacle and both veloc-

ities match the commanded ones, but the reflected

force again slowly increases, which is caused by the

next obstacle entering DW sensitivity region.

In the second experiment two operators, located at

different places, attempted to drive the Scout and Ma-

nipulator robots into a head-on collision. This is the

most difficult case for the modified DW algorithm to

handle as both robots see the other as a moving obsta-

cle. Velocities of both robots drop rapidly when the

TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH FORCE FEEDBACK OVER INTERNET

435

0 2 4 6 8

0

50

100

150

200

v [m/s]

0 2 4 6 8

−30

−20

−10

0

ω [deg/s]

Commanded velocity (CS)

Commanded velocity (SS)

Measured velocity

0 2 4 6 8

−80

−60

−40

−20

0

force direction [deg]

0 2 4 6 8

0

0.2

0.4

0.6

force amplitude

t [s]

Figure 4: One robot experiment: driving around a corner.

distance between them approaches the DW sensitiv-

ity range (at approximately t = 3s, Fig. 5). At the

same time reflected forces sent to both operators rise.

When force feedback signals reach their maximal val-

ues velocities of both robots drop to zero. Robots

stop and the collision is avoided. Fluctuation of the

Scouts’s rotational and translational velocities is due

to difficulties that its low-level velocity control sys-

tem had while following reference values. In spite of

this modified DW algorithm successfully prevented

robots from colliding. Force feedback angle should

be 0

◦

during this experiment as the obstacle is di-

rectly in front of the robot. However, this angle varies

between 0

◦

and 10

◦

. No stochastic processing was

implemented and sonars were treated as rays whose

orientation depends on sonar’s position on the robot.

Such an error is tolerated due to the fact that the force

feedback is used only to provide the operator with a

general notion about the position and distance to the

closest obstacle.

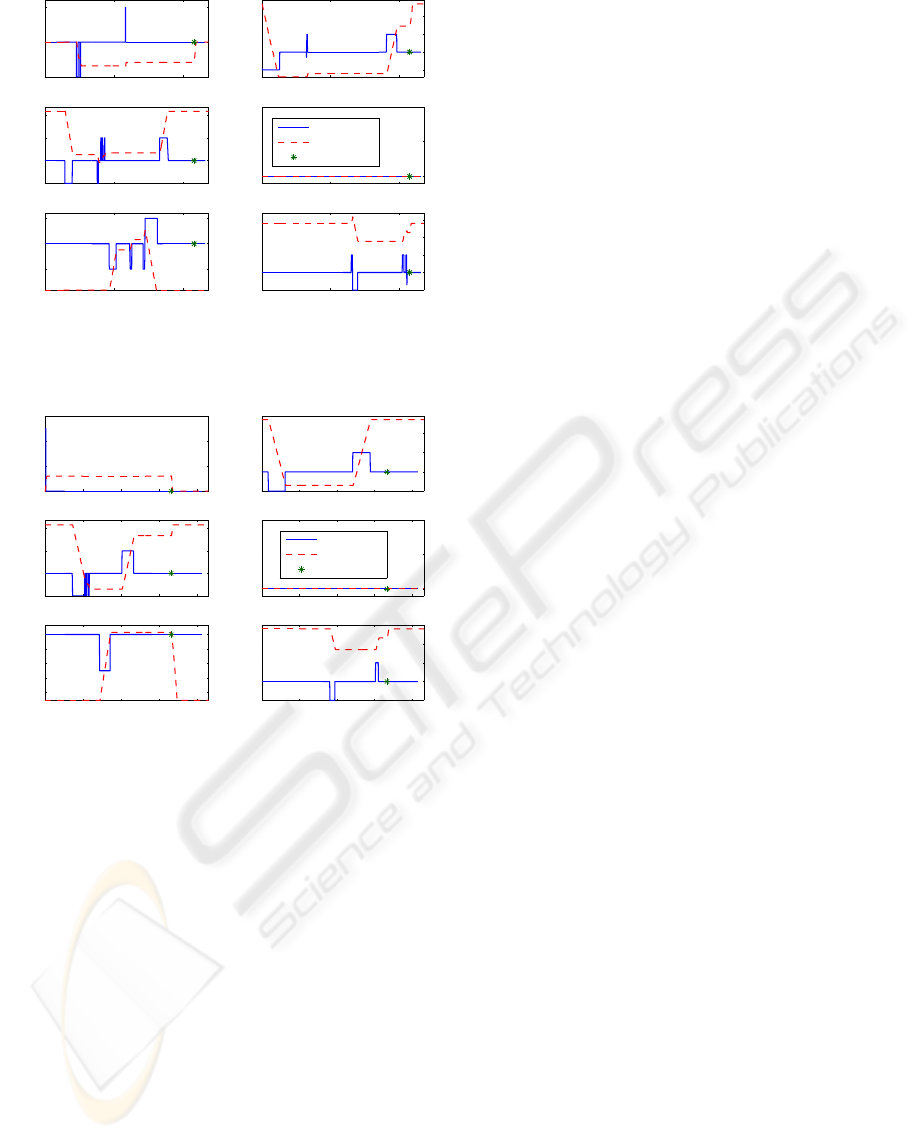

In the last two experiments the task was to pick up

a small cardboard box of the floor, place it on the Ma-

nipulator’s back and put the arm at the home position.

Only one operator controlling Manipulator accom-

plished it after few attempts and with some unneces-

0 1 2 3 4 5 6

0

100

200

300

v [m/s]

0 1 2 3 4 5 6

−10

−5

0

5

10

ω [deg/s]

0 1 2 3 4 5 6

−8

−6

−4

−2

0

2

force direction [deg]

0 1 2 3 4 5 6

0

0.5

1

force amplitude

t [s]

Manipulator

Scout

Figure 5: Velocities and force feedback recorded during two

robot collision experiment.

sary adjustments (Fig. 6). Adjustments were needed

as the camera is mounted close to the ground (for bet-

ter object grasping) not covering the entire workspace

of the arm. Another problem is the lack of infor-

mation about the third dimension which complicates

the adjustments of joint angles even when the arm

is visible to the operator. The same task can be ac-

complished much easier and faster (approximately 60

seconds in contrast to approximately 110 seconds) if

Scout and Manipulator cooperate (Fig. 7). Scout’s as-

sistance gives the Manipulator’s operator better view

of the distant site enabling him to see the arm during

the whole procedure and giving him a feel of the third

dimension.

5 CONCLUSION

A teleoperation system has been developed that en-

ables two human operators to safely control two mo-

bile robots in unknown and dynamic environments

over the Internet. Each operator receives images dis-

played on the graphical user interface, which are for-

warded by the cameras mounted on the robots, and

force feedback on the joystick, which is reflected from

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

436

0 50 100

−50

0

50

join 1

0 50 100

−50

0

50

100

joint 3

0 50 100

−50

0

50

joint 5

t [s]

0 50 100

−50

0

50

100

joint 2

0 50 100

0

5

10

joint 4

0 50 100

−50

0

50

100

150

gripper

t [s]

ξ [deg]

home position

˙

ξ[deg/s]

Figure 6: Motion of the robot arm joint angles during the

one experiment.

0 20 40 60 80

0

20

40

60

join 1

0 20 40 60 80

−50

0

50

100

joint 3

0 20 40 60 80

−80

−60

−40

−20

0

joint 5

t [s]

0 20 40 60 80

−50

0

50

100

joint 2

0 20 40 60 80

0

5

10

joint 4

0 20 40 60 80

−50

0

50

100

150

gripper

t [s]

ξ [deg]

home position

˙

ξ[deg/s]

Figure 7: Motion of the robot arm joint angles during the

two robots experiment.

the robot controlled by him. To overcome the in-

stability caused by the unknown and varying time

delay, event-based teleoperation system is employed

to synchronize actions of each robot with command

from its operator. Through experimental investigation

it is confirmed that developed teleoperation enables

the operator to successfully accomplish teleoperation

tasks in complex environments.

Developed teleoperation system could be easily

adjusted to different robot and sensor types to allow

application to different tasks. A possible application

could be in missions of finding and rescuing victims

from collapsed buildings in cases of natural disas-

ters, fires or terrorist attacks. For example, Scout

could be a small flying robot with various sensors that

could easily maneuver the site searching for the vic-

tims while Manipulator could be stronger robot able

to clear its way into the wreckage and carry them out

of danger zone.

REFERENCES

ActivMedia (2003). ACTS ActivMedia Robotics Color

Tracking System — User Manual. ActivMedia

Robotics LLC, Amherst.

Borenstein, J. and Koren, Y. (1990). Teleautonomous guid-

ance for mobile robots. In IEEE Transactions on Sys-

tems, Man and Cybernetics.

Fox, D., Burgard, W., and Thurm, S. (1997). The dynamic

window approach to collision avoidance. In IEEE

Robotics & Automation Magazine.

K. Brady, T. J. T. (2002). An Introduction to Online Robots.

The MIT Press, London.

Lee, D., Martinez-Palafox, O., and Spong, M. W. (2006).

Bilateral teleoperation of a wheeled mobile robot over

delayed communication network. In Proceedings of

the 2006 IEEE International Conference on Robotics

and Automation.

Lee, S., Sukhatme, G., Kim, G., and Park, C. (2002). Haptic

control of a mobile robot: A user study. In IEEE/RSJ

International Conference on Intelligent Robots and

Systems EPFL.

Lo, W., Liu, Y., Elhajj, I. H., Xi, N., Wang, Y., and

Fukada, T. (2004). Cooperative teleoperation of a

multirobot system with force reflection via internet.

In TIEEE/ASME Transactions on Mechatronics.

Luo, R. C. and Su, K. L. (2003). Networked intelligent

robots through the internet: issues and opportunities.

In IEEE Proc.

Munir, S. (2001). Internet-Based Teleoperation. PhD thesis,

Georgia Instituteof Technology, Atlanta.

Murphy, R. and Rogers, E. (1996). Cooperative assistance

for remote robot supervision. In Presence: Teleoper-

ators and Virtual Environments.

Niemeyer, G. (1996). Using Wave Variables in Time De-

layed Force Reflecting Teleoperation. PhD thesis,

MIT, Cambridge, MA.

Niemeyer, G. and Slotine, J.-J. E. (2004). Telemanipula-

tion with time delays. In The International Journal of

Robotics Research.

Seder, M., Ma

ˇ

cek, K., and Petrovi

´

c, I. (2005). An integrated

approach to real-time mobile robot control in partially

known indoor environments. In IECON.

Sheridan, T. (1992). TTelerobotics, Automation, and Hu-

man Supervisory Control. MIT Press, Cambridge,

MA.

Wang, M. and Liu, J. N. K. (2005). Interactive control for

internet-based mobile robot teleoperation. In Robotics

and Autonomous Systems.

Xi, N. and Tarn, T. J. (2000). Stability analysis of non-

time referenced internet-based telerobotic systems. In

Robotics and Autonomous Systems.

TELEOPERATION OF COLLABORATIVE MOBILE ROBOTS WITH FORCE FEEDBACK OVER INTERNET

437