HOLONIC PRODUCTION PROCESS: A MODEL OF COMPLEX,

PRECISE, AND GLOBAL SYSTEMS

Edgar Chacon, Isabel Besembel, Dulce Rivero

Universidad de Los Andes, Facultad de Ingeniería, Escuela de Sistemas, Departamento de Computación, Mérida, 5101

Juan Cardillo

Universidad de Los Andes, Facultad de Ingeniería, Escuela de Sistemas, Departamento de Sistemas de Control, Mérida,

Keywords: Holon, Holonic Production Units, Complex Systems Modelling, Discrete Event Dynamic Systems,

Continuous Production Process, Value Chain.

Abstract: Nowadays, it is necessary to have a complete description of the production process in order to plan,

program, control, and supervise the production process. It is hard to obtain this description due to the

existence of two contradictory points of views. First, the precision implicated in the construction of total and

complete models, and on the other hand, the need of having a global vision associated with the different

views of the process. These views normally show three important aspects: the structural organization of the

model, the dynamism between the main components, and the distinct temporal scales and levels, where are

taken the main decisions. The holonic approach (Erikson,2004) has been used to manage this complexity, in

order to have an abstraction that permit the integration of the mentioned points of views. In this paper we

propose, a structure for continuous production process based on holonic approach in order to obtain a global

vision and global model less complex of the production process.

1 INTRODUCTION

Nowadays, enterprises can be established in a virtual

manner building a dynamic network of enterprises in

order to obtain a determined product, in a moment

due. The high enterprises’ performance is due to the

establishment of precise objectives for a determined

configuration of the network.

The virtual enterprise, composed in this way

follows a set of production agreements, in order to

fulfil objectives by trying to diminish the production

cost of the product, in a production offer. This

virtual enterprise may be composed by a set of

enterprises or a set of unit of the enterprise itself.

The production agreements implicate the

establishment of a logistic, quantities, and qualities

of products and sub-products, and synchronization

points (E. Chacon,1998), (E. Chacon, 2004), (Juan

Cardillo, 2005).

The negotiation is obtained following the

existing common knowledge, for which it is

necessary to have the following:

• A description language of the production

methods

• Protocols for the acceptation of missions

among the enterprise participants,

following each one of production

capacities under a production method of

high level.

The enterprises participating in a negotiation

know the information services that offer each

enterprise by means of a yellow pages service. The

global model of a virtual enterprise focused in its

mission, can be viewed as an Holon. The knowledge

model of the holon follows a Discrete Event

Dynamic Systems Model (DEDS), where each one

of the steps that conforms the mission is described

by means of an operation region. Thus, a conformed

enterprise (virtual or not) is considered as an

enterprise holon which is composed by a set of

Production Units (inside production units or

enterprises) conforming the Production Units

Holonic System. The coordinator of the conformed

enterprise is charged to manage, control, and re-plan

each one of the steps of the mission in order to

402

Chacon E., Besembel I., Rivero D. and Cardillo J. (2007).

HOLONIC PRODUCTION PROCESS: A MODEL OF COMPLEX, PRECISE, AND GLOBAL SYSTEMS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 402-408

DOI: 10.5220/0001632704020408

Copyright

c

SciTePress

complete it. The established chronogram of the

conformed enterprise generates a particular mission

for each one of the Production Unit Holon (PUH).

Each step of the selected production method by the

PUH is associated to an operation region. The

coordinator of each PUH is charged to manage,

control, and re-plan each one of the steps of the

selected production method. In holonic architecture,

the groups are managed by itself following its

internal resources state knowledge, the production

order advance, and the knowing of its production

method that permits to obtain the product. Thus, a

holon is composed by one or more holons. The

advantage of use a holonic approach is due to have a

reference model that describes the composition of

the conformed enterprise (virtual or not) structure.

Here, a conformed enterprise and a holon are

modeled by following a business model where the

value chain and the product flow both establish the

base of the global modelling of a conformed

enterprise. In this work, we present a reference

model under the holonic approach that permits to

have a description of the production process

(conformed enterprise) as an embedded system

based on its business model, value chain, and

product flow. This presents one enterprise

(conformed enterprise) as a network of enterprises

(production units) composed to follow a production

mission. Section 2 is devoted to show the conformed

enterprise modelling method. Section 3 describes the

holonic approach of the production system, and

section 4 presents the conclusions and future works.

2 MODELING OF A

CONFORMED ENTERPRISE

A conformed enterprise describes both enterprises

composed by several semi-independent units or

virtual enterprises. This is due to the utilization of a

production model in conjunction with a value chain

and a production flow. Both enterprises are

modelled in the same manner. Thus, the value chain

expresses the sequence of the aggregate value of a

product (transformation, storage or transport) by

following of the production process itself. The use of

the value chains is the base to develop models of the

different business process that are specific of an

enterprise. A graphics representation of the value

chains is shown in figure 1. The product flow can be

defined as the different transformation stages, which

follows a resource (or a set of them) until the final

product achieving. The conjunction of the value

chain plus the product flow results the production

flow, which is the aggregate of functionalities and

transformations of the resources to generate the final

product.

...

...

...

...

Process 1 Process i

Process 2

Process N

Process i.1 Process i.j Proceso

i.m

...

...

...

...

Process 1 Process i

Process 2

Process N

Process i.1 Process i.j Proceso

i.m

Figure 1: Value chains.

Each stage of the value chain (Input resources,

processing or transformation and storage) of the

production flow is also viewed as a Production Unit

(PU), where the characterization of each PU depends

on how the resource (or a set of them) evolves, such

as: continuous, batch, manufacture, or hybrid.

Additionally, each PU does a specific transformation

depending on the properties of the resource (or

resources). However, it is possible to found common

or generic elements that characterize a PU in a

production flow. Each element is viewed as a

process inside of the PU. These processes are as

follows:

• A process to take hold of resources

• A process of transformation/transport

• A process of storage between each PU

process

Initially, resources are located and obtained for

the PU. The process to take hold of PU resources

warrants resources for a determined production

recipe. After, the PU selects a production method

required to transform the raw material. The selection

of the production method depends on the resources

properties, and then it is carrying out the

transformation process. When the transformation

process is finished, the transformed resource is

storing and waiting for the need of another PU.

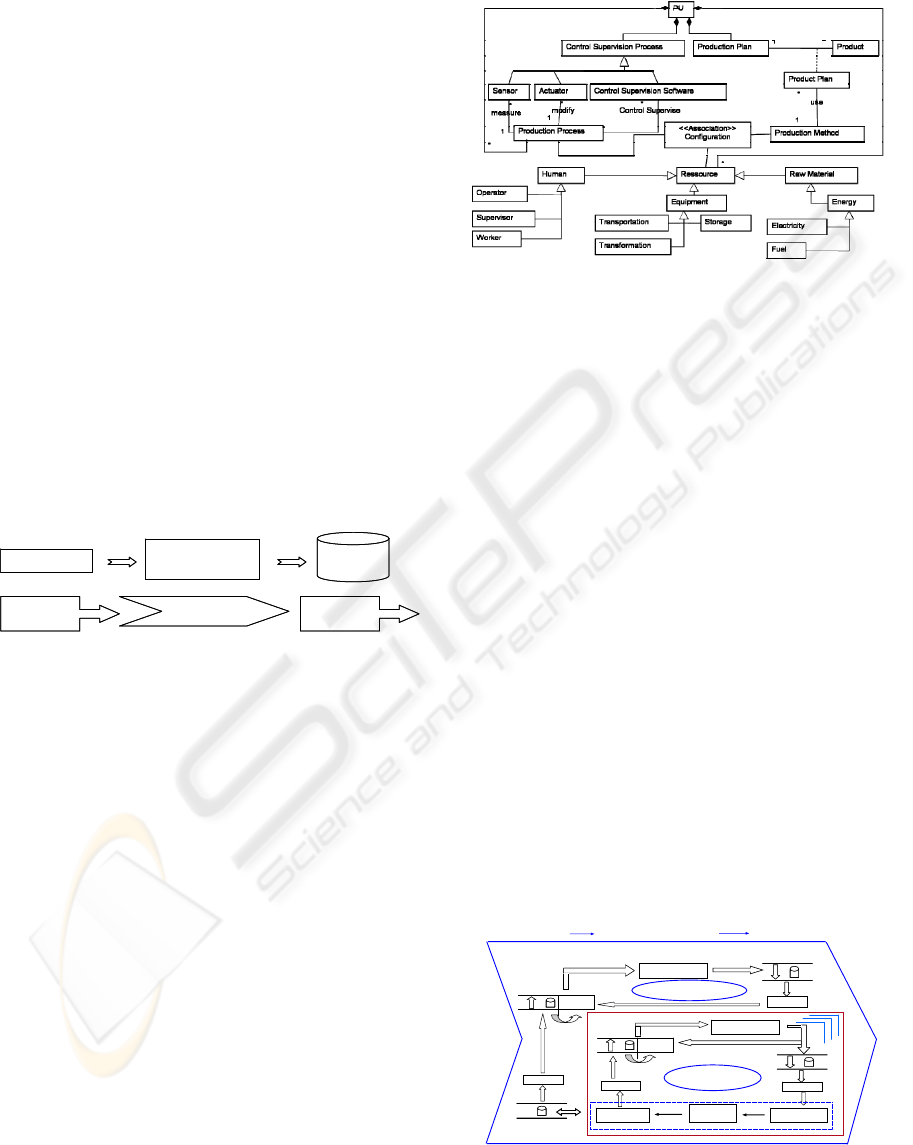

Figure 2 shows a structural model of a PU. This

model not only presents the controlled and

supervised system (control and supervision process

plus the production process) that makes the

transformation, also beholds the product plan,

production methods, configuration, and management

of the resources that are needed in the production

process. This structural description is the base to

extract the main information to do a planning of the

PU by considering which values or variables permit

the description of the PU state, such as: performance

indicators, reliability, and so on. Other variables that

may be taken into account are: quality of the

product, expected quantity of product, production

capacity, storage capacity (minimal and maximal),

etc. For example, PU production capacity is related

to the transformation process capacity, and also to

HOLONIC PRODUCTION PROCESS: A MODEL OF COMPLEX, PRECISE, AND GLOBAL SYSTEMS

403

the storage capacity, if and only if raw material and

the rest of the resources are guaranteed.

An object-oriented structural model of the PU

drawing by means of the Unified modeling

Language (UML) (JçI. Jacobson,

www.rational.com/uml), (A. Muller, 1997) is

presented in figure 3. The class diagram uses

rectangles to represent classes and lines to represent

relationships among classes. This diagram includes

three kinds of relationships, such as:

generalizations/specializations (arrows not fulfilled),

associations (lines), and compositions (line finished

in a filled diamond).

Figure 3 shows different entities or classes in the

PUH and how they are related. In particular, it is

highlighted a special class which is related to an

association between the classes ProductionPlan and

Product, named ProductPlan. Also, the class

Configuration which is charged to register all of the

different configurations of resources, production

process, control and supervision software, and

production method, as an association class between

the four aforementioned entities. It is viewed the

classification of the resources managed by the PU in

order to accomplish its production plan that support

the enterprise plan.

Resources

Tranformation

Transport

Storage

Raw

material

PUH

Finished

product

Resources

Tranformation

Transport

Storage

Raw

material

PUH

Finished

product

Figure 2: Model of a Production Unit.

For lack of space, this class diagram is showed

in a concise form; each class has a set of properties

(attributes and relationships) and operations, which

support the behavioural model of the PU.

The embedded model of figure 4 shows the

decisions scheme needed for each path of the value

chain of a PU. Our proposition uses an embedded

model that is based on the description of a Holon.

This model presents level works composed by

the production process and each one of the

established control loop. The designed controllers

(that takes decisions) are inside the communications

and information architecture, which needs

applications and industrial networks in order to

capture actual variable values, by means of sensors,

and to indicate controller actions, by means of

actuators. Thus, the controlled productive process is

viewed as a system that need to be controlled

(supervise, monitor, manage) by a supervisor. This

permits to view the whole productive system as an

embedded system conformed by a path of the value

chain that takes products, transform-them to

generate another derived product.

Figure 3: UML Class Diagram of a Production Unit.

3 HOLONIC APPROACH IN

PRODUCTION SYSTEMS

A holon for a manufacturing enterprise is defined as

a constructor block; cooperative and autonomous for

transforming, transporting, storing and/or validating

physical objects and information (H. Brusel, 1998).

A holon has the autonomy to create and control the

execution of its owns plans, it may cooperate with

other holons to jointly develop an acceptable plan to

reach the system mission. The cooperation among

holons is accomplished by one evolution of the

holarchy in the organization (a holon system).

In a Holonic system production, the objective is

to achieve a complete spectrum of the range of the

control function that goes from the production plans,

that controller at the highest level, until the

process/machine that control the lowest level.

A Holon possesses two constituent elements: a

connected transformation system and a system of

taking of decisions. The decisions system monitors

the resources and the evolution of the order that are

being controlled in the plant floor, by associate

elements for such an end.

Transducer

Supervisor

u(k)=g(Cond,x(k))

ObserverObserverObserver

TransductorTransductor

Physical

Process

Sensor

Instrumentation

Actuator

Instrumentation

Transducer

Controller

u(t)=g(Xop,x(t))

Obser vadorObs ervadorObser vador

TransducerTransducer

x’(k+1)=f(x(k),u(k))

y(k)=h( x(k))

x’(t)=f(x(t),u (t))

y(t)=h(x(t))

Physical

Image

Products Transformation

Products

Figure 4: Production process embedding model.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

404

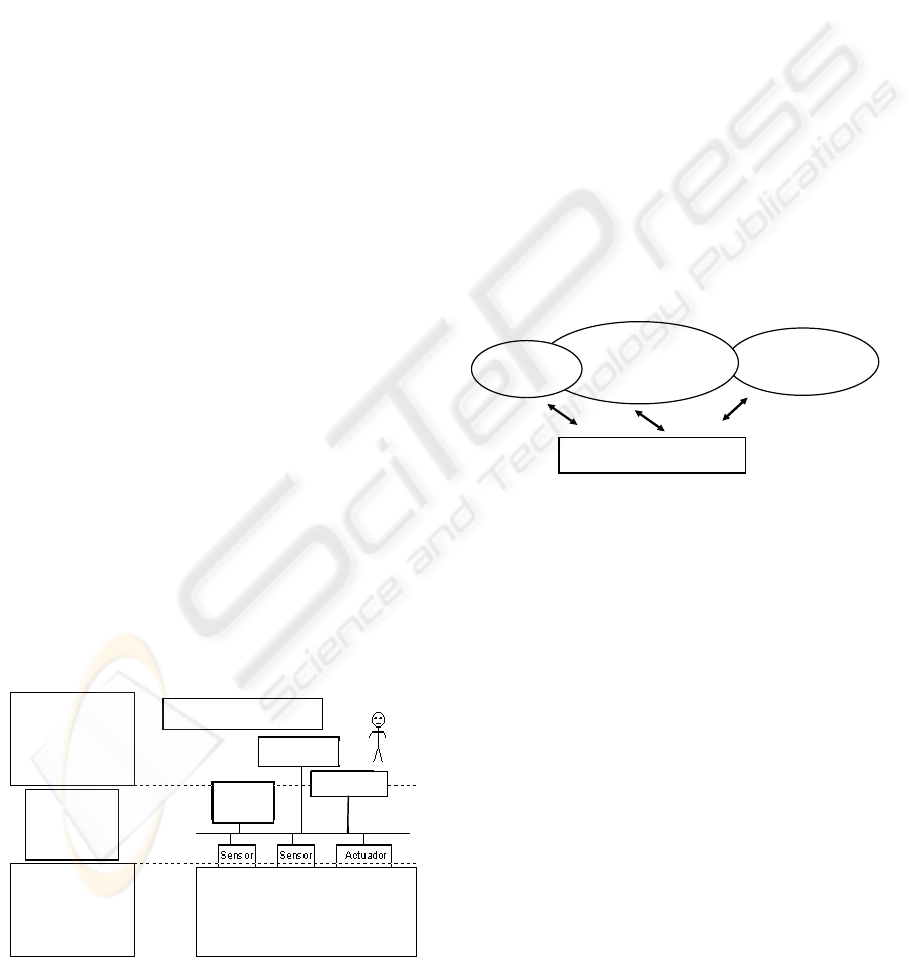

The integral automation of systems outlines a

global vision of the productive process, where each

element that intervenes in the production should be

taken into account to be able to control, to

supervise, and to management the production, to

see figure 5. The automation scheme is based on the

construction of models that represent the Unit of

Production so much in its structural aspect, like in

its dynamics. The control schemes assure that the

behavior of the system is inside that wanted, for that

which the knowledge that one has of the state of the

system allows to evaluate which should be the viable

control actions with the purpose of assuring that the

system reaches the wanted state.

In the productive system, the control is

subordinated to the objective fixed to the Unit of

Production, and the objectives are determined for

what the Unit of Production can make.

The process has a proper behaviour that depends

on the physical and chemical laws in particular in a

condition of given operation. This behaviour it can

describe formally as a Hybrid Dynamic System.

When having the description of the dynamics,

the behaviour can be controlled by a automatic

supervisory system or by means of the intervention

of a human being.

The product of the production process is

obtained by means of a group of resources that can

suffer changes in the time, thus the information of

the state of the process, and of the resources should

be continually monitoring with the purpose of

determine, if the system completed the production

objective, or on the contrary it could not complete

the production objective by failure in some of the

resources. This change should be management to

define a new production scheme in the Unit of

Production or to verify in another level if it is

possible to have a form of assuring the objective

fixed for the set of Units of Production.

Head

Neck

Body

Take of decision

Aplications

Process

Object

Server

Gui server

Net

Figure 5: Integral automation of systems.

Considering the Unit of Production with the

capacity to have autonomy (a Holon: Holon Unit of

Production, HUP). HUP is composing of a BODY,

NECK, and HEAD. In the body is where the

processes: of transformation of the matter, of storage

or transport are developed. This it is carried out by a

group of physical devices as reactors, compressors,

store, etc.. In the head are the mechanisms of taking

of decisions, based on the knowledge of the

production process and the necessary resources.

These mechanisms of taking of decisions are

developed by the classic techniques of supervisory

control or by approach of intelligent systems. The

neck is the interface between both, this is composed

by the whole infrastructure tele-informatics that

stores and transports the information. Thus, in the

head are the applications of taking of decisions that

determine the behaviour that should have the body.

In the neck is the communication mechanism

between the head and the body (process), their

implementation is all the mechanisms that allow to

capture information of the process and to send

commands to the process. See figure 6.

Process

Control

Management Maintenance

Figure 6: Relation ships between Holon and TIC

infrastructure.

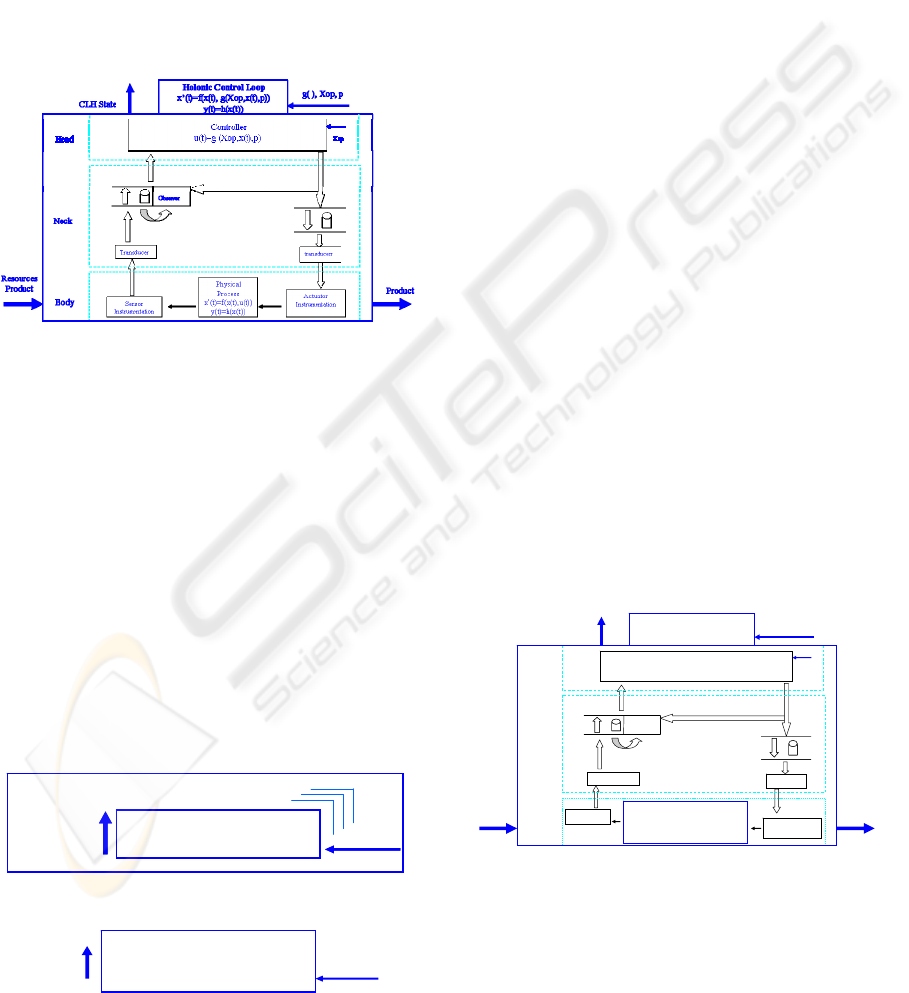

3.1 Holonic Control Loop

The basic functional unit for the automation of a

production system is the control loop. This control

loop is redefined how the Holonic Control Loop

(HCL), it possesses all the characteristics of a

Holon.

The HLC is conformed by a body that contains the

physical process that possesses implicit the actuator

and the set of sensors and whose model, without

losing generality, we can describe as a dynamic

system in state equations. The neck of the HCL this

conformed by the architecture tele-informatics and

proper applications that are able to capture, to try, to

store, to adapt, and to transfer so much information

of the sensor as toward the actuator. The head of the

HCL (controller) is conformed by the mechanism of

taking of decisions, this mechanism can have a rigid

form (PID, etc.) or not (neuronal net, etc.). This

controller, that is able to regulate to an operation

HOLONIC PRODUCTION PROCESS: A MODEL OF COMPLEX, PRECISE, AND GLOBAL SYSTEMS

405

point, is designed using the physical model of the

process (knowledge model), its can be described by

dynamic equations and /or algebraic that dependent

of the operation point, of the state or output and of

parameters that belong to an operation region. In

definitive the Holonic Control Loop is an

autonomous system that possesses two input and two

outputs characterized by products and information.

Input Product: products supplies and resource. Input

Information: Controller’s type, Operation Point,

Parameter of Controller. Output Product: sub-

product or finished product. Output Information:

State of the controller process. To see figure 7.

Figure 7: Holonic Control Loop.

3.2 Supervisor Holon

As we know, a process possesses more than a

control loop. To each control loop we have redefined

as the HCL. The management of all the loop control

relapses in a supervisor. The supervisor possesses all

the characteristics of a holon. Thus, when

composing all the loops control we obtain the

Controlled Holonic Systems. See figure 8.

The Controlled Holonic System is a system that

has i models (maybe one for each control loop), each

model has a set the m of nominal values of operation

that can be reached with a set the j types of

controllers which are adjusted under an approach

determined with n parameters. Just as it shows it the

figure 9

Control Loop Holon

x’(t)=f(x(t), g(Xop,x(t),p))

y(t)=h(x(t))

Controller Holonic System

g( ), Xop, p

CLH State

Control Loop Holon

x’(t)=f(x(t), g(Xop,x(t),p))

y(t)=h(x(t))

Controller Holonic System

g( ), Xop, p

CLH State

Figure 8: Controller Holonic System.

Controlled Holonic System

(

)

(

)

()

)t(xh)t(y

p),t(x,Xopg),t(xf)t(x

ii

nimjiii

=

=

nmj

p,Xop(),g

CLH State

Figure 9: Embedding Controlled Holonic System.

In the same manner that the previous sub-section

the Supervisor Holon (SH) is conformed by a body,

a neck and head. The Body of SH is conformed by

the Controlled Holonic System which generates state

values of the process (as sensors), and possesses

implicit actuator given by: g (), Xop, p. The neck of

SH is conformed by the tele-informatics architecture

and set of applications that allow to detect events

(they are able to capture, to try, to store, to adapt,

continuous information of the state variable in

events) as generating the set point (g (), Xop, p)

toward the loops control. The head of the SH this

conformed by the mechanism of taking of decisions,

that is design using approach of modelling of

Discrete Event Systems generated by the Controlled

Holonic System.

In definitive the Supervisor Holon is an

autonomous system that possesses two input and two

outputs characterized by products and information.

Input Product: products supplies and resource. Input

Information: recipe, scheduling of Operation. Output

Product: sub-product or finished product. Output

Information: State of the supervisor process. See

figure 10.

3.3 Holonic Production Unit

It is possible that a production process has more than

a supervisor. To each supervisor we have redefined

it as the Supervisor’s Holon. The management of all

the supervisors relapses in a coordinator; this

coordinator possesses all the characteristics of a

holon: Production Unit Holon. Thus, when we

compose all the supervisors, we obtain the

Supervised Holonic System. (See figure 11).

Supervisor

u(k)=g (Xop,x(k),p)

Detecting Event

ObserverObserver

Set point

Supervisor Holon

x’(k+1)=f(x(k), g(Xop,x(k),p))

y(k)=h(x(k))

Xop

Resouces

Product

Neck

Head

Product

SH State

Body

Controlled Holonic System

(

)

(

)

()

)t(xh)t(y

p),t(x,Xopg),t(xf)t(x

ii

nimjiii

=

=

nmj

p,Xop(),g

CHS State

g( ), Xop, p

Figure 10: Supervisor Holon.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

406

Supervisor Holon

x(k+1)=f(x(k), g(Xop,x(k),p))

y(k)=h(x(k))

Supervised Holonic System

g( ), Xop, p

SH State

Figure 11: Supervised Holonic System.

The Supervised Holonic System is a system that

has i models (maybe but of one for supervisor), each

model has a set m of nominal values of operation

that can be reached with a combined j of types of

recipes which are adjusted under an approach

determined by supervisor with n of parameters. Just

as is shown it the figure 12.

(

)

(

)

()

)k(xh)k(y

p),k(x,Xopg),k(xf)1k(x

ii

nimjiii

=

=+

nmj

p,Xop(),g

SHS State

Supervised Holonic System

Figure 12: Embedding Supervised Holonic System.

In the same manner that the previous sub-section

the Production Unit Holon (PUH) is conformed by a

body, a neck and head. The Body of PUH is

conformed by the Supervised Holonic System which

generates state values of the supervisor process (as

sensors), and possesses implicit actuator given by: g

(), Xop, p., i.e. recipes, scheduling, etc.. The neck of

PUH is conformed by the tele-informatics

architecture and set of applications that allow to

detect events (they are able to capture, to try, to

store, to adapt, information of the state variable of

the supervised process in events) as generating the

set point (g (), Xop, p) toward the supervisor. The

head of the PUH this conformed by the mechanism

of taking of decisions, that is design using approach

of modeling of Discrete Event Systems generated by

the Supervised Holonic System.

In definitive the Production Unit Holon is an

autonomous system that possesses two input and two

output characterized by products and information.

Input Product: products supplies and resource. Input

Information: negotiated production demand. Output

Product: finished product. Output Information: State

of the productive process. See figure 13.

Coordinator

u(k)=g (Xop,x(t),p)

Detecting Event

ObserverObserver

Recipes

Production Unit Holon

x(k+1)=f(x(k), g(Xop,x(k),p))

y(k)=h(x(k))

Xop

Resources

Product

Neck

Head

Product

PUH State

g( ), Xop, p

Body

Supervised Holonic System

(

)

(

)

()

)k(xh)k(y

p),k(x,Xopg),k(xf)1k(x

ii

nimjiii

=

=

+

nmj

p,Xop(),g

SHS State

Figure 13: Production Unit Holonic.

4 CONCLUSION AND FUTURE

WORK

In the work, we show an implemented architecture

that allows to have a recursive (embedded) structure,

represented by each Holon. The information stays

up-to-date by means of mechanisms topologically

equal. The coordination is carried out by means of

supervisors generated for each built configuration

based on a production mission. The stages for the

supervisor's construction are defined like one of

negotiation. This negotiation to define the objective

and the generation of synchronization points based

on the defined configuration. Once finished the

stages of selection of the configuration and

establishment of the synchronization points the

supervisor you instance for the duration of the

mission.

It is necessary to establish negotiation

mechanisms for the establishment of the mission,

since the global knowledge of the production

capacities is known internally, and the configuration

is obtained after the evaluation of the different arisen

alternatives of each participant's internal capacities.

The protocol Contract Net of the FIPA appears as

the most suitable mechanism for the establishment

of a common mission.

ACKNOWLEDGEMENTS

This work is partially supported by the ECOS-

NORD Program France-Venezuela on virtual net of

production

HOLONIC PRODUCTION PROCESS: A MODEL OF COMPLEX, PRECISE, AND GLOBAL SYSTEMS

407

REFERENCES

H. Brusel, J. Wyns, P. Valckenaers, L. Bongaerts y P.

Peeters. Reference architecture for holonic

manufacturing systems: PROSA. Computer in

Industry. Vol. 37. 1998. pp. 255-274.

E. Chacón. Automatización Integral de Sistemas de

Producción Continuos: Tecnologías de Integración y

Automatización. Reporte técnico de la Universidad de

Los Andes. Mérida. Venezuela. Diciembre, 1998.

E. Chacón, I. Besembel, F. Narciso, J. Montilva y E.

Colina. An Integration Architecture for the

Automation of Continuous Production Complexes.

ISA Transactions. Journal of the Americna Intitute of

Physics. Vol 41, Nº 1, pag. 95-113,2002.

E. Chacón, I. Besembel, J-C Hennet. Coordination and

Optimization in Oil and Gas Production complexes.

Computer in Industry. Elsevier Vol. 53, pag. 17-37,

2004.

G. Doumeingts, B. Vallespir, M. Zanettin y D. Chen. Cim

grai integrated methodology, a methodology for

designing cim systems. Reporte técnico de la

Universidad de Bordeaux, Francia. Mayo. 1992.

International Product Data Management Users Group.

Integrating/Interfacing PDM (Product Data

Management) with MRP II (Manufacturing Resource

Planning) http://www.pdmic.com/IPDMUG/

wpipdmug.html - model. 1996.

I. Jacobson, G. Booch y J. Rumbaugh. Specification of the

UML. Rational Software .

http://www.rational.com/uml/

K. Kosanke, F. Vernadat y M. Zelm. CIMOSA: Enterprise

engineering and integration. Computer in Industry.

Vol. 40. Elsevier Science. 1999. pp. 83-97.

J. Montilva, E. Chacón y E. Colina. METAS: Un método

para la automatización integrada en sistemas de

producción continua. Actas de las IV Jornadas

Panamericanas de Automatización. Caracas. Mayo

2000.

A. Muller. Modelado de Objetos con UML. Eyrolles y

Ediciones Gestión 2000, S. A., 1997.

PERA. Pera reference model for CIM. ISA publication.

http://www.pera.net

PRM. Production Resource Manager. IBM. Last Update

april 1996. http://www.research.ibm.com/

pdtr/prm.html

Ramadge, P .J. G. and Wonham, W. M. (1989) The

control of discrete event systems. Proceedings of the

IEEE, 77 (1): 81-87.

T. J. Williams. A Reference Model for Computer

Integrated Manufacturing (CIM). International Purdue

Works.

Juan Cardillo, Edgar Chacón, Isabel Besembel, Milagros

Rivero, Unidad de Producción como célula

fundamental de los procesos Holónicos de Producción,

V Congreso de Automatización y Control, CAC 2005,

Universidad Simón Bolívar, Caracas-Venezuela

Eriksson, Penker, Lyons, Fado. UML 2 Toolkit. Wiley,

2004.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

408