MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD

GANTRY MACHINE

Timo Knuutila, Sami Py

¨

otti

¨

al

¨

a and Olli S. Nevalainen

Department of Information Technology, University of Turku, FI-20014 Turku, Finland

Keywords:

Printed circuit board, electronics assembly, multi-head placement machine, optimization, production control.

Abstract:

In printed circuit board (PCB) manufacturing multi-head gantry machines are becoming increasingly more

popular in surface mount technology (SMT), because they combine high speed with moderate price.

This kind of machine picks up several components from the feeder and places them on the PCB. The process

is repeated until all component placements are done. In this article, a subproblem of the machine control is

studied. Here, the placement order of the components, the nozzles in the placement arm and the component

locations in the feeder are fixed. The goal is to find an optimal pick-up sequence when minimizing the total

length of the arm movements.

An algorithm that searches the optimal pick-up sequence is proposed and tested widely. Tests show that the

method can be applied to problems of practical size.

1 INTRODUCTION

The electronics industry has been one of the fastest

growing fields of industry in the last 20 years. Here,

one of the central fields is the manufacturing of

printed circuit boards (PCBs) which are needed ev-

erywhere in present days. Electronic components are

installed to PCBs with specialized, automated com-

ponent placement machines. Production batches of

similar PCBs can be very large especially in the mass

production of consumer electronics. PCBs can be

manufactured with a single machine or more com-

monly with an assembly line of several consecutive

machines of different types. An assembly line con-

sists of a solder paste printer, a few placement ma-

chines and an oven in which the components are fixed

onto the board. Usually, each placement machine is

specialized to place a certain set of component types.

In the past, components were attached to PCBs

mainly using through-hole technology (THT) but

nowadays, when minituarizing the products, the in-

dustry has changed over to surface mount technol-

ogy (SMT). In order to be successful, the component

placement operations require great accuracy from the

placement machine, because components and PCBs

have become smaller and smaller. While technology

has developed, different types of placement machines

have been invented, including dual-delivery, multi-

station, turret-type, and multi-head gantry machines.

Each machine type has its own special features and is

suitable for different types of assembly tasks, see e.g.

(Ayob et al., 2002) and (Ayob and Kendall, 2005) for

discussion.

The operation of a placement machine is con-

trolled with a control program which states the de-

tails of individual component placement steps. This

program should force the machine perform its task as

fast as possible while still satisfying high quality stan-

dards. A single PCB can include dozens of different

kinds of components and the total number of compo-

nents on one PCB can amount to several hundreds.

The actual placement of a component requires the use

of a suitable nozzle. One or more nozzles are at-

tached to the placement head of a machine. Normally,

nozzles can be changed when necessary. In some

machines the nozzle changes have to be done man-

ually while some others can change them automat-

ically. The placement machine fetches components

from a feeder unit capable of holding a large number

of copies of components of each type and then places

326

Knuutila T., Pyöttiälä S. and S. Nevalainen O. (2007).

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 326-335

DOI: 10.5220/0001638903260335

Copyright

c

SciTePress

feeders

placementhead

andnozzles

PCB

Figure 1: There are many multi-head gantry machines

in Siplace-series of Siemens. (The image is taken from

Siemens www-page.).

them onto the PCB being manufactured. The determi-

nation of the route the placement head travels during

a placement job can be considered a special asymmet-

ric travelling salesman problem (ATSP) . Solving the

problem requires efficient heuristics that have been

studied in (Ball and Magazine, 1988) (Leip

¨

al

¨

a and

Nevalainen, 1989) for example.

In this article the optimal control of a multi-head

gantry placement machine (Sun et al., 2004) is dis-

cussed. For example Siemens has this type of ma-

chines, see Figure 1 for details. Multi-head gantry

machines have increased their popularity in recent

times due to their flexibility and relatively low acqui-

sition price. In this machine the PCB is positioned

firmly on the stationary table. The machine has a

placement arm with a placement head at one end. The

placement head moves above the PCB and the com-

ponent feeders in (x, y)-plane parallel to the PCB. The

feeders are stationary and arranged as a linear array

along the x-coordinate-side of the PCB fixation table.

There are several (1-30 pieces) spindles (nozzle hold-

ers) in a placement head and each spindle can hold

any type of nozzle. A nozzle can grab a single compo-

nent at a time and different components may require

certain nozzle. Every nozzle of the placement head

can hold a component simultaneously. The placement

head can place one component at a time onto a PCB

and it must then move to the position required by the

next component. While performing a placement job

the machine will retrieve multiple components at a

time from the feeders into the nozzles of the place-

ment head and place them to predetermined positions

on the PCB. This process will be repeated as many

times as necessary. See (Py

¨

otti

¨

al

¨

a et al., 2005) for

more details on the design of the multi-head gantry

machine.

The controlling of a multi-head gantry machine

can be seen as a sequence of multiple decisions.

These include among others the selection of nozzles,

the feeder arrangement, the component pick-up and

placement sequencing. When the decisions are done

consecutively, each of them depends on the previous

ones. For instance the optimal component pick-up se-

quence depends on the beforehand selected nozzles

and the order in which the components are in feeder.

In this hierarchical way it is possible to find a suffi-

ciently efficient solution for manufacturing a certain

PCB but it will not guarantee a globally optimal solu-

tion in a sence of assembly time of a single job. Even

though the hierarchical method is complicated it has

led to some good results (Kumar and Li, 1995; Crama

et al., 1990; Lee et al., 1999) whereas the joint mod-

elling of this machine type leads to a mathematical

model of impractically high complexity.

The approach used in this article is slightly differ-

ent from previous studies. Our aim is not to solve the

whole control problem but instead to consider a par-

ticular subproblem in greater detail. The subproblem

can be chosen because it is a part of the overall manu-

facturing problem. All subproblems have to be solved

in order to solve the entire problem. In this work, it

is especially asked in which order the multi-head arm

should pick up the components to be placed so that

the movements of the arm are minimized for a certain

printed circuit board (PCB). Two cases are discussed

here. In the first case the sequence for performing the

placements, the nozzles in the placement arm and the

order of component reels in the feeder are predeter-

mined and a pick-up sequence of the components and

its cost shall be computed. This is called the single

pick-up event problem (SPE). In the second case the

assumptions are as above, but the computed pick-up

sequence should be the one with a minimal cost (i.e.

time). This is called the minimal pick-up sequence

problem, MPS. Here again, the optimal machine con-

trol depends on both the placement sequence and the

feeder assignment at the same time, see (Leip

¨

al

¨

a and

Nevalainen, 1989) for discussion of the special case

with a single nozzle in the pick-up-placement head.

In this paper, there are multiple nozzles in the place-

ment head and the arm may contain multiple copies of

the same nozzle type as it is presently common due to

the very skewed distribution of different component

types on PCBs.

The rest of the work is organized as follows. The

notation and terminology are presented in section 2,

as well as the actual research problems. Then in sec-

tion 3 the problems are solved and possible algorithms

are proposed. The best proposed algorithm is tested

and the results introduced in section 4. The final sec-

tion consists of the concluding remarks.

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE

327

2 MINIMAL PICK-UP SEQUENCE

(MPS) PROBLEM

2.1 Notation and Terminology

The sets of component types and nozzle types are

denoted with C = {c

1

, . . . , c

n

} and T = {τ

1

, . . . , τ

m

},

respectively. A job w is a sequence consisting of

triplets (c, x, y), where c ∈ C and the pair x, y ∈ R

give the location of the component on the PCB. Let

τ(c) be a function defining the nozzle type that has

to be used to pick up a certain component of type c.

Note that different component types (say c

i

and c

j

)

may well require the use of a nozzle of the same type

(τ(c

i

) = τ(c

j

)). The multisets of component types

and nozzle types of job w are denoted with C(w) and

T(w), respectively. They are defined as

C(w) = {chii | (c, x, y) ∈ w}

T(w) = {τ(c)h ji | c ∈ C(w)},

where i and j give the number of copies of the par-

ticular c and τ(c), respectively. An arm a of capac-

ity a

max

is a sequence of nozzle types of length a

max

.

Similarly to jobs, let us denote with T(a) the multiset

of nozzle types in a. Given a job w and an arm a, we

say that a can pick up w if and only if T(w) ⊆ T(a),

that is, there is a nozzle of a correct type in a for each

component type of w. The ⊆-operator is here defined

between multisets (i.e. for each τ(c)h ji ∈ T(w) there

is τ(c)h j

′

i ∈ T(a) such that j ≤ j

′

). Note that the or-

der in which the component types appear in w and a

may be different. Consequently, this means that the

placement order may differ from the pick-up order.

Example. Suppose we have a job

w = (c

1

, x

1

, y

1

)(c

2

, x

2

, y

2

)(c

3

, x

3

, y

3

)(c

4

, x

4

, y

4

),

τ(c

1

) = τ(c

2

) = τ

1

, τ(c

3

) = τ(c

4

) = τ

2

, an arm of

capacity 5, 3 nozzles of type τ

1

and 4 of type τ

2

.

Clearly T(w) = {τ

1

h2i, τ

2

h2i}. Arm a

1

= τ

1

τ

1

τ

1

τ

2

τ

2

can pick up w, since T(w) ⊆ T(a

1

) = {τ

1

h3i, τ

2

h2i}.

On the other hand, arm a

2

= τ

1

τ

2

τ

2

τ

2

τ

2

can not pick

up w, since T(w) 6⊆ T(a

2

) = {τ

1

h1i, τ

2

h4i}.

2.2 Cost of a Pick-up Event

Suppose that we can pick up w using a. We next for-

malize a model for the actual execution of this pro-

cess. We assume for the sake of simplicity that there

is only one source for each component type in the

feeder unit. Then each component type c has a unique

location, say s(c), ranging over the different locations

in the feeder unit. Hence, s is an injective function

s: C → {1, . . . , f

max

}, where f

max

is the total number

of slots in the feeder unit.

The pick-up arm moves first to the location s(c)

of some component type c of the current job w. It

then selects the next of the remaining components and

moves to the corresponding location until all compo-

nents have been picked up. The distance between two

locations, say s(c

1

) and s(c

2

), is |s(c

1

) − s(c

2

)|. If

we assume that the movement time between the pick-

ups is linearly dependent on the distance between

the pick-up locations, then it suffices to consider just

these distances when defining the pick-up cost.

Let w

o

be a pick-up order of a sequence of place-

ment instructions w. Supposing that w can be picked

up with a, we define cost(w

o

, a, s), the cost of picking

w up in order w

o

with a given s, as

cost(w

o

, a, s) = MOV +

|w|−1

∑

i=1

|s(w

o

i+1

) − s(w

o

i

)|,

where MOV represents the cost of the movement be-

tween the feeder and the board.

There are several ways to define the cost of the

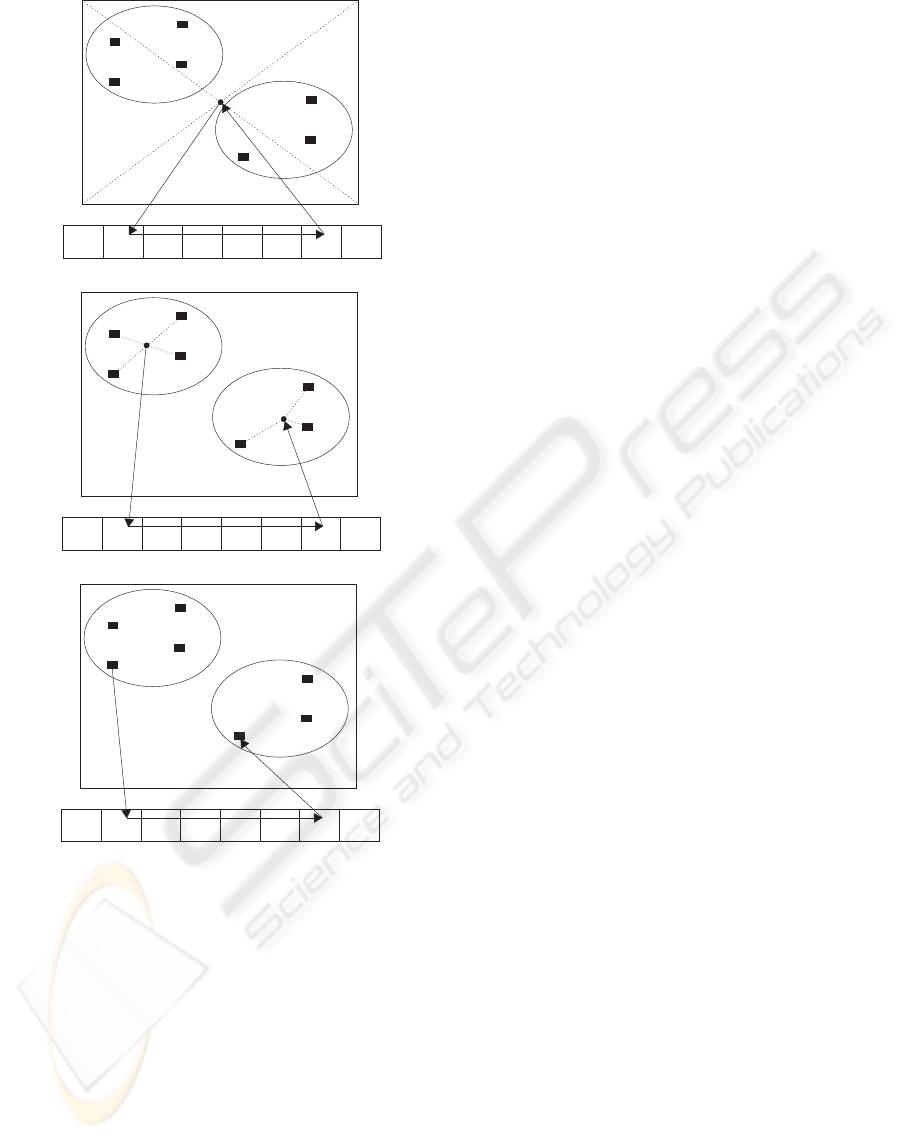

movement between the feeder and a PCB, see Fig. 2.

At the end of every placement the arm has to return to

the feeder to pick up the next set of components. Af-

ter the arm has picked up these components it travels

back on the PCB. We can approximate the locations of

the arm on the PCB roughly using the centre of PCB

only (see Fig. 2 a). The second and more gentle way

to approximate the start and end positions of the pick-

up phase is to use the centre point of the locations

which belong to the same load of the arm (i.e. the set

of components simultaneously in the placement arm)

(Fig. 2 b). The third and the most accurate way is to

use the exact location of the last component of pre-

vious and the first component of the next placement

phase (Fig. 2 c). Note that the third method can only

be used if the actual order of the component place-

ments is known.

It is obvious that different pick-up orders w

o

for

the same w have in general different costs. Our aim is

to select, for a given w, a and s, the ordering (permu-

tation) w

o

of w with the minimal cost. Let us denote

this cost, which we call the cost of a pick-up event for

w (given a and s), with ecost(w, a, s).

Problem 1. (Single pick-up event problem, SPE)

Given w, a and s, compute ecost(w, a, s) and the as-

sociated pick-up sequence w

o

for w (supposing one

exists).

2.3 Cost of a Pick-up Sequence

The number of component placements per PCB is

normally very large in comparison to the total num-

ber of nozzles in arm. Therefore the placements

must be divided into several subjobs. Given a job

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

328

PCB

feeder

c

i-1

c

i-2

c

i-3

c

i-4

s(c)

i

c

i

c

i+2

c

i+1

PCB

feeder

c

i-1

c

i-2

c

i-3

c

i-4

s(c)

i

c

i

c

i+2

c

i+1

PCB

feeder

c

i-1

c

i-2

c

i-3

c

i-4

s(c)

i

c

i

c

i+2

c

i+1

s(c)

i+1

s(c)

i+2

s(c)

i+1

s(c)

i+2

s(c)

i+1

s(c)

i+2

(a)

(b)

(c)

Figure 2: Three different ways to define the cost of the arm

movement between the feeder and PCB.

w and an arm a, the pick-up sequence of w using a

is any partition of w into subjobs w

1

, w

2

, . . . , w

p

(i.e.

w = w

1

· w

2

···w

p

) such that a can pick up each w

i

(i = 1.. p). The length of such a pick-up sequence is p.

The cost of a pick-up sequence is simply the sum of

the costs ecost(w

i

, a, s) of individual pick-up events.

One can partition w into subjobs in many different

ways and the total picking cost depends on the par-

ticular partition. The minimum cost pick-up sequence

for given w, a and s is a pick-up sequence with a min-

imal cost denoted by mcost(w, a, s).

Problem 2. (Minimal pick-up sequence prob-

lem, MPS) Given w, a and s, find a pick-up sequence

w

1

, w

2

, . . . , w

p

for w such that

p

∑

i=1

ecost(w

i

, a, s)

is minimal and compute the associated mcost(w, a, s).

3 SOLVING THE SPE AND MPS

3.1 Pick-up Events

Let us first consider the SPE (problem 1) which deter-

mines for given w, a and s the minimal pick-up order-

ing w

o

. This problem can be solved for small a even

by a brute force -method which checks all the possi-

ble ways of feeder-to-nozzle-combinations. However,

for greater arm sizes the algorithm becomes soon un-

practical in special when the SPE-problem should be

solved repeatedly a great number of times.

We first consider only the movements above the

feeder unit and thus ignore the cost of moving to the

PCB and back. It is obvious that if w contains several

occurrences of the same component type, all of these

should be picked up once the arm is in the appropri-

ate location. (The is true, because the machine model

does not allow so called gang pick-ups) Hence, the

problem reduces into finding the shortest path con-

necting all the feeder locations

S(w) = {s(c) | c ∈ C(w)}.

Now let s

min

and s

max

be the minimal and maximal

elements of S(w). It is clear that the length of any

path connecting all the members of S(w) (points on

a line segment), is at least s

max

− s

min

. Therefore,

we have two obviously minimal connecting paths: the

ones connecting the points of S(w) in their increasing

or decreasing order.

In practise, the length of the initial movement de-

pends also on the location s(w

o

1

) and the initial lo-

cation of the arm (the location where it was left af-

ter placing the last component of the previous place-

ment). Similarly, the last pick-up is followed by the

movement to the first placement location on the PCB.

The placement order of w defines what these loca-

tions exactly are. If the placement orders of all pick-

up events w

1

, w

2

, . . . , w

p

are known beforehand, the

initial location of the arm, when event w

i

is started, is

the last placement of the previous event w

i−1

, and the

location we move after the pick-up of w

i

can be found

from the first placement of w

i

.

However, the placement order is not necessarily

known to us. Formerly the reason for this was that

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE

329

PCB

feeder

s

min

s

start

s

max

(x

c

,y)

c

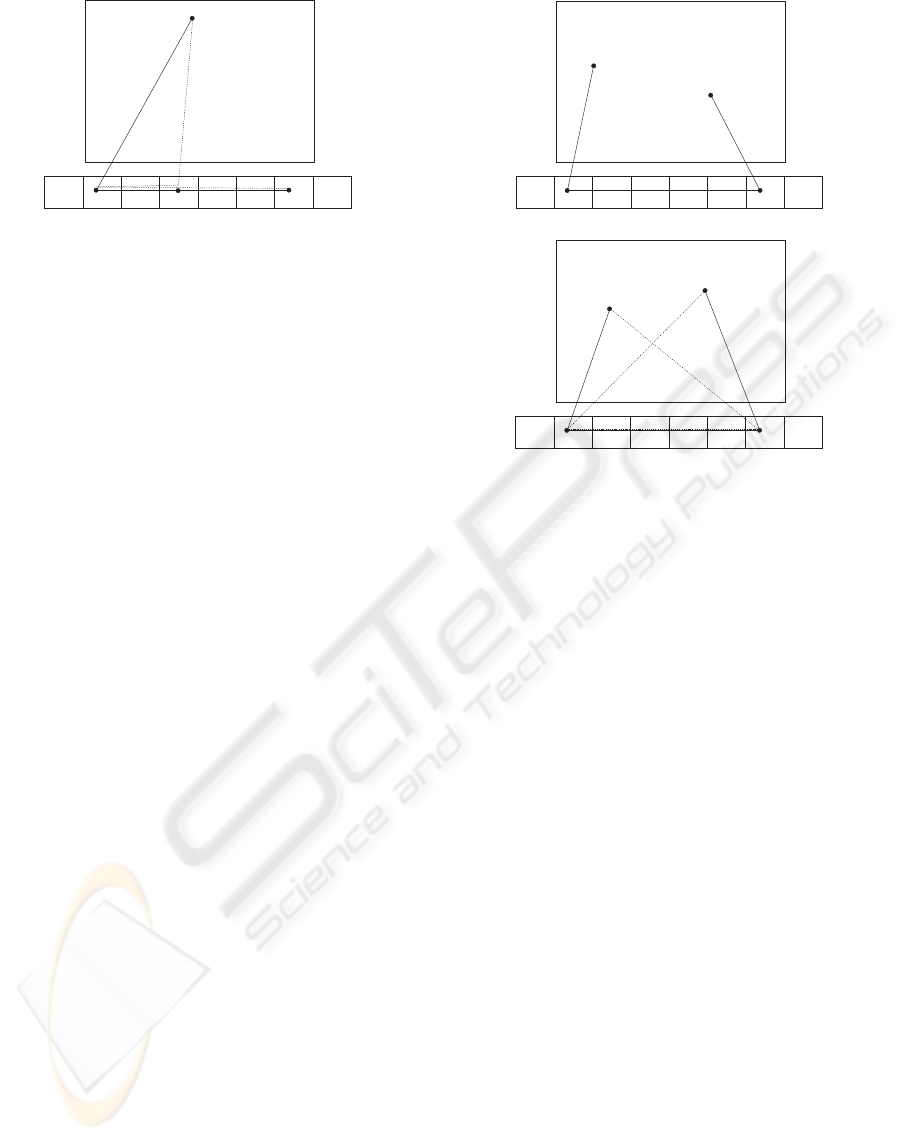

Figure 3: The linear ordering of the pick-up points gives us

the minimal path.

the pick-up and the placement sequencing problems

were interconnected so that both of them should be

solved jointly. Currently, another reason for the lack

of this information has arisen: There are placement

machines which decide the printing order automati-

cally at the pick-up phase. The best we can then do is

to approximate the initial and final locations with the

center of the PCB or with the average of the place-

ment locations. In the former case, we use the same

constant location in all cost calculations, in the latter

case the center point is specific to each pick-up event.

Let us denote this center point with (x

c

, y

c

).

Consider the three pick-up points s

min

, s

max

and

s

start

, where s

start

is the first pick-up place. If

s

start

6∈ {s

min

, s

max

}, suppose (without loss of gen-

erality) that

s

start

− s

min

≤ s

max

− s

start

,

i.e. the start position is closer to the smallest posi-

tion than to the largest one. The minimal route on top

of the feeder goes now first from s

start

to s

min

(pick-

ing all the components on the way) and then all the

way to s

max

. The difference to the length of a route

starting directly at s

min

is hence s

start

− s

min

. Al-

though the distance from (x

c

, y

c

) to (s

start

, 0) might

be shorter than to (s

min

, 0), the difference is always

smaller than s

start

− s

min

due to the triangular in-

equality (consider the triangle with corners at (x

c

, y

c

),

(s

min

, 0), and (s

start

, 0)), see Fig. 3. Hence, the lin-

ear ordering of the points gives us the minimal path

even in this case. If the arm is moved by two motors,

one for the x-directional and one for the y-directional

movement and these operate at the same speeds, the

movement time is related to the maximum of the coor-

dinate distances (the Chebyshev distance). Naturally,

the triangular inequality holds here, too.

The SPE can now be solved trivially by

sorting the locations s(w

i

) into ascending or-

der. The smallest and largest positions are

then s(w

o

1

) and s(w

o

|w|

), respectively. The value

of ecost(w, a, s) is d((x

c

, y

c

), (s(w

o

1

), 0)) + s(w

o

|w|

) −

PCB

feeder

s

min

s

max

(x

i

,y)

i

(x

f

,y)

f

PCB

feeder

s

min

s

max

(x

i

,y)

i

(x

f

,y)

f

Figure 4: The arrangement of components depends on x

i

and x

f

.

s(w

o

1

) + d((s(w

o

|w|

), 0), (x

c

, y

c

)), where d is an appro-

priate metric. If the movements between the PCB and

the feeders are ignored (or the cost is constant) the

formula simplifies to s(w

o

|w|

) − s(w

o

1

).

Suppose now that the printing order is known, and

that (x

i

, y

i

) and (x

f

, y

f

) are the initial and final loca-

tion of the arm in some pick-up event. That is, (x

i

, y

i

)

is the location where the last component of the previ-

ous pick-up event was placed and (x

f

, y

f

) is the loca-

tion where the first component of this pick-up event

will be placed. A similar geometrical analysis gives

again (see Fig. 4), that

• if x

i

≤ x

f

, the component pick-ups should be ar-

ranged in an ascending order of s(c) and

• if x

i

> x

f

, the component pick-ups should be ar-

ranged in a descending order of s(c).

The corresponding value of ecost(w, a, s) is

then d((x

i

, y

i

), (s(w

o

1

)), 0)) + |s(w

o

|w|

) − s(w

o

1

))| +

d((s(w

o

|w|

), 0), (x

f

, y

f

)).

3.2 Pick-up Sequences

The task in the MPS is to partition a large w into sub-

jobs w

1

, w

2

, . . . , w

p

such that the accumulated pick-up

cost is minimal. Note first that the greedy partition-

ing that gives minimal number of pick-ups (Knuutila

et al., 2007) (pick up always as many components as

possible) does not always give an minimal solution

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

330

when the goal is to minimize the length of arm move-

ments. However, the greedy algorithm still minimizes

the number of pick-up rounds. Consider the following

example:

w = (c

1

, x

1

, y

1

), . . . , (c

5

, x

5

, y

5

),

s(c

1

) = 1, s(c

2

) = 2, s(c

3

) = 100,

s(c

4

) = 101, s(c

5

) = 102,

τ(c

i

) = τ for i = 1..5, and

a

max

= 3.

The greedy partitioning would first pick component

types c

1

, c

2

, c

3

and then c

4

, c

5

. The simplest defi-

nition of ecost(w, a, s) would give a cost of (100 −

1)+(102−101) = 100, whereas the cost for partition

c

1

, c

2

and c

3

, c

4

, c

5

would be (2− 1) + (102− 100) =

3.

The same counter example gives the following

costs for the second definition of ecost(w, a, s). In the

greedy case

d((x

c

, y

c

), (1, 0)) + (100− 1) +

d((x

c

, y

c

), (100, 0)) + d((x

c

, y

c

), (101, 0)) +

(102− 101) + d((x

c

, y

c

), (102, 0)),

and in the alternative case

d((x

c

, y

c

), (1, 0)) + (2− 1) +

d((x

c

, y

c

), (2, 0)) + d((x

c

, y

c

), (100, 0)) +

(102− 100) + d((x

c

, y

c

), (102, 0)).

Considering the geometry of the feeder (a straight line

segment), distances to adjacent slots from the PCB

center are practically the same. Hence, the greedy

distance is approximately

d((x

c

, y

c

), (1, 0)) + 3∗ d((x

c

, y

c

), (100, 0)) + 100,

and the alternative is

2∗ d((x

c

, y

c

), (1, 0)) + 2∗ d((x

c

, y

c

), (100, 0)) + 3.

If the distances to feeder slot 1 and slot 100 are ap-

proximately the same from the PCB center (e.g. they

are at the left and right ends of the feeder), then the al-

ternative partitioning is clearly a winner here, too. A

similar inspection can be carried out also for the third

definition of ecost(w, a, s).

3.2.1 Brute Force Method

Solving the MPS seems to lead to an exhaustive

search over all possible ways of partitioning w into

subsequences. Procedure

sequence

implements a

brute-force algorithm for this problem. The global

variables

best

and

bestcycle

store the value and the

partition of the best solution found so far. The cur-

rent partition is given by the array

cycle

. Argument

p

gives the level of a current recursive call and

cost

expresses the ecost of the subjobs 1 to (p-1). Algo-

rithm

sequence

is initially called as

sequence(1,0)

with

cycle[0] = 1

since at the first pick-up cycle

at least one component has to be picked up and the

cost should be zero before any components has been

picked up. At the beginning,

best

is initialized to

some large value. After the execution, the result is in

array

bestcycle

.

// cycle = array of the start indexes of

// pick-up cycles

// p = current pick-up cycle

// N = length of the placement sequence w

sequence (int p, int cost)

int i, k, x;

k := cycle[p - 1]; // start of the

// previous cycle

// i = tentative start of the next cycle

FOR i = k+1 TO k + pick-up head size DO

IF the pick-up head can pick components

from k to i - 1 THEN

x := ecost(k, i - 1);

IF ((cost + x) < best) THEN

IF i = N+1 THEN // solution

best := cost + x;

bestcycle := cycle;

ELSEIF i <= N

cycle[p] = i;

sequence(p + 1, cost + x);

END END END END

END

The greedy method to form a pick-up sequence

(introduced in (Knuutila et al., 2007)) minimizes the

number of pick-up-cycles for given w and a. The min-

imal solution (in terms of total length of arm move-

ments) found by

sequence

seems always to be clearly

better than that generated by the greedy method when

measuring the performance using the length of tour

the placing arm has to travel to pick up all components

for a certain job. A problem here is that

sequence

is

capable of solving only small problems in which the

job size is few dozens of components; its running time

explodes for placement tasks of practical size.

3.2.2 Dynamic Programming

We apply dynamic programming to search the mini-

mal solution in a fast way. Fast algorithm is required

also for this subproblem since searhing for a minimal

pick-up sequence will be an important part of higher

level optimization software. Consider job w of length

n. Dynamic programming can be applied since the

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE

331

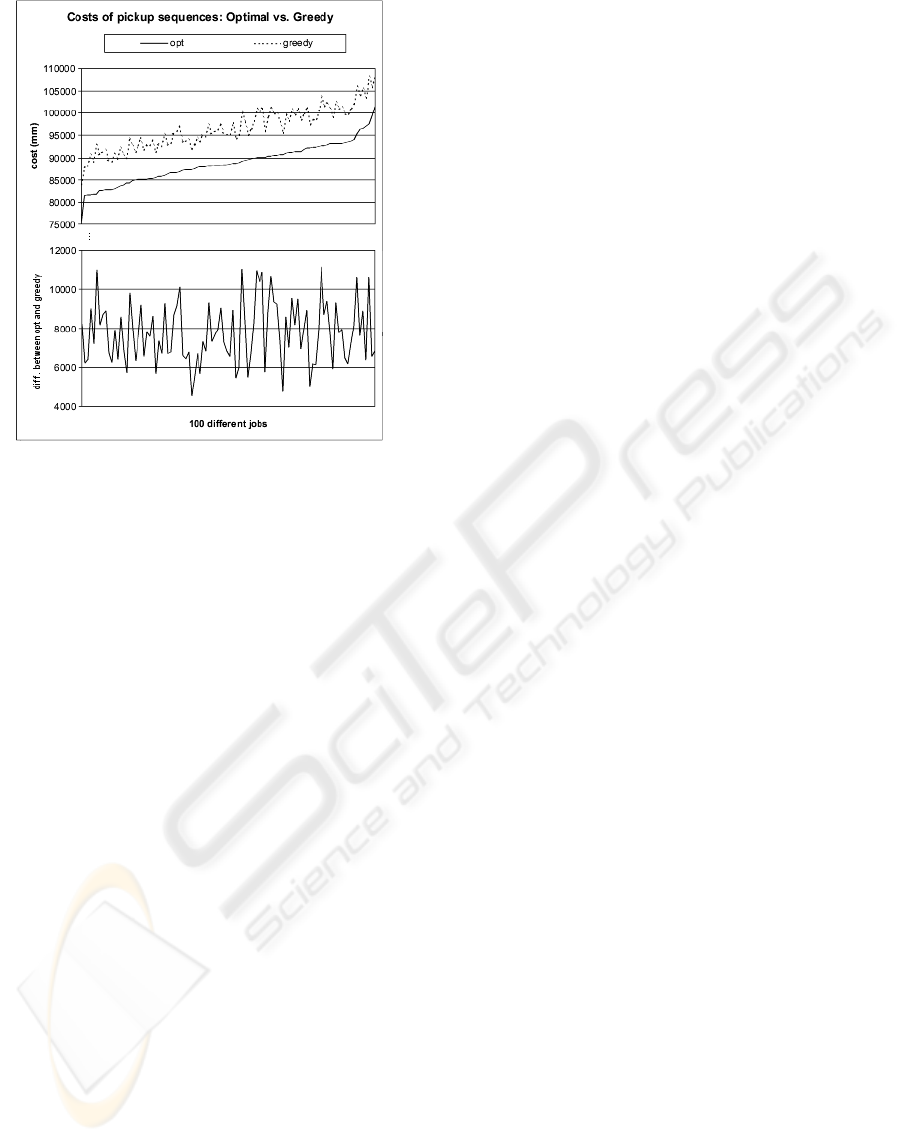

Figure 5: The pick-up sequence generated by the greedy

method is clearly worse than the minimal solution found by

exhaustive search when measuring the length of arm move-

ments in mm. We tested here 100 different jobs of length

600 with arm size of 20, 7 seven different nozzles, and 20

(also the number of feeders) different components per job.

solution for any suffix w

k

of job w must be mini-

mal regardless the solution of the earlier subjobs w

i

(i < k) which must be minimal, too. The minimal so-

lutions for all starting points of subjobs are searched

and memorized starting from the last one (the subjob

of length 1) and proceeding towards longer subjobs.

Finally, the minimal solution for the subjob of length

n (the actual job) is found. For this method the run-

ning time T(n, a

max

) is O(na

2

max

) in the worst case and

the memory usage M(n) = θ(n

2

).

Procedure

dynamic_sequence

uses global arrays

comp_costs

and

comp_parts

;

comp_parts

stores

the minimal cycle sequences for every suffix of a job

and

comp_costs

holds the costs of these sequences.

The procedure uses backward recursion by starting

from the end of the job and proceeding towards the

beginning. At each step

j

,

round_min

is set to some

big value and the maximum number of components

that the placing arm can hold simultaneously start-

ing from the

j

’th placement instruction is stored into

a_can

. Then, ecosts for all possible pick-ups of com-

ponents from

j

to (

j + a_can

) are calculated in turn

and summed with the costs of corresponding suffixes

stored in

comp_costs

. List

part_list

and variable

round_min

keep the information of the best cycle se-

quence of the current round.

Part_list

is formed

by linking the minimal cycle sequence list of a cor-

responding suffix on the right of the current one. Fi-

nally, the

bestcycle

(as in the previous algorithm) is

constructed on the basis of

comp_parts[1]

and the

minimal cost of the pick-up sequence for the job is

returned.

// bestcycle = array of the start indexes of

// the pick-up cycles for the

// minimal cycle sequence

// N = length of the placement sequence w

// part_list = linked list, integers as items

// comp_costs = array of minimum cost for all

// possible job suffixes

// starting positions

// between [1, N]

// comp_parts = array of length N of linked

// lists which items determine

// the minimums stored

// into comp_costs

dynamic_sequence : int

int i, j, x, round_min;

FOR j := N DOWNTO 1 DO

round_min := positive infinity;

a_can := max number of components

that arm can hold at once

starting from j’th placement

instruction;

FOR i := 1 TO a_can DO

x := ecost(j, j + i - 1);

IF j + i - 1 < N THEN

x := x + comp_costs[j + i];

END

IF x < round_min THEN

round_min := x;

create new part_list;

part_list.put_right(i);

IF j + i - 1 < N THEN

part_list.append(

comp_parts[j + i]);

END

END

END

comp_costs[j] := round_min;

comp_parts[j] := part_list;

END

construct bestcycle -table

by comp_parts[1] -list;

RETURN comp_costs[1];

END

The suffix of a job is independent of the prefix of the

job only in cases (a) and (c) of Fig. 2. Therefore, the

dynamic programming approach cannot be applied if

the placement locations are approximated as in case

(b). However, case (c) is sufficient; in practice the

component locations are usually known.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

332

350

Feeder bankof20feeders

PCB

300

200

350

....................

50

Figure 6: Some essential dimensions of a typical multi-head

gantry in mm. The distances are realistic and they represent

existing gantry-machines.

4 RESULTS OF EXPERIMENTAL

TESTS

In this section it is demonstrated that algorithm

dynamic_sequence

is fast enough to solve problems

appearing in practice. It is also experimented how the

cost of a pick-up sequence behaves when the arm size

varies. For evaluating procedure

dynamic_sequence

we use a Markov-model with 20 states to gen-

erate challenging component placement tasks, see

(Py

¨

otti

¨

al

¨

a et al., 2005) and (Py

¨

otti

¨

al

¨

a et al., 2006).

The model is fully connected and the transition prob-

abilities vary in wide range. As a result of this

data generation model, the component type of the ith

placement depends on the types of previous compo-

nents and the number of different component types

is non-uniform. However, the (x, y)-pairs (component

positions on a PCB) of placement instructions are still

uniformly distributed over the PCB in our test data

generator.

The dimensions of a the placement machine are

indicated in Fig. 6. Independent step motors move

the placement head in x- and y-directions with same

speed.

In all tests, the nozzles of a placing arm are se-

lected using the uniform distribution -based heuristic

introduced in (Py

¨

otti

¨

al

¨

a et al., 2006). In this heuristic,

different types of nozzles are chosen into the arm in

the same ratio as the nozzle type requirements occur

in the placement job. The running times are measured

in real-time seconds.

The average running times of the method of sec-

tion 3.2.2 for 100 jobs of each different length (job

length classes were 200, 300, 400,...,3000) are shown

in Fig. 7. The tests were performed for 20 different

component types, 7 nozzle types and arm size of 14.

The average running times show a clear linear ten-

dency on the number of placements in the job. Figure

average running time

0

0,01

0,02

0,03

0,04

0,05

0,06

0,07

0,08

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

job length

time (seconds)

Figure 7: The average running times of procedure

dynamic sequence.

for jobs of different length. The re-

sults are for each job length averages of N = 100 test jobs

generated by the Markov-model described earlier.

average running time

0

200

400

600

800

1000

1200

1400

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

job length

time (seconds)

Figure 8: The running times of brute force. -method for

jobs of different length.

9 shows how the running time of the method based on

dynamic programing changes when the arm capacity

is increased from 7 to 30. Again the running times

are averages of 100 different jobs for each arm size.

Job length was 600, the number of different compo-

nents 20, and the number of different nozzle types 7.

Note, that in both figures (7 and 9) the shape of the

curve correlates well to the complexity class of dy-

namic program. However, figure 8 shows that brute

force-based method cannot be used in practice.

Figure 10 demonstrates the decrease of the num-

ber of pick-ups when the arm size increases. Here the

numbers of pick-ups are the ones of minimal pick-

up sequences. The minimal cost of pick-up sequence

decreases notably when the number of nozzles in a

placing arm increases. Figure 11 shows this effect for

job length 600, component types 20, different nozzles

7, and 100 different jobs for every arm size between

7-30).

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE

333

average running time

0

0,01

0,02

0,03

0,04

0,05

0,06

0,07

7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

arm size

time (seconds)

Figure 9: The average running times of varying arm sizes.

Averages are for N = 100 randomly generated jobs for each

arm sizes.

average number of pickups

0

50

100

150

200

250

300

350

400

450

500

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

arm size

number of pickups

Figure 10: The average number of pick-ups for varying arm

sizes.

5 CONCLUSION

In this research the subproblem relating to the control

of a multi-head gantry placing machine was consid-

ered. Unlike the usual approach to this topic, this arti-

cle focused on a situation where the placement order

of the components is fixed and the pick-up order of

the components was to be determined.

Multiple nozzles in the placement arm, the lin-

ear ordering of the different components in the feeder

unit, and the fact that different types of components

require different nozzles make this problem complex.

In this case, the greedy algorithm that minimizes the

number of component pick-ups does not, opposite

to expectations, yield the minimal length pick-up-

route of the placement arm. An efficient algorithm

that applies dynamic programming was developed for

searching the minimal pick-up sequence. The running

time of the algorithm is linear on the number of com-

ponents to be placed and quadratic on the arm size.

average cost of pickup sequence

0

50000

100000

150000

200000

250000

300000

350000

400000

450000

500000

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

arm size

cost (mm)

Figure 11: The average cost of pick-up sequences for vary-

ing arm sizes.

REFERENCES

Ayob, M., Cowling, P., and Kendall, G. (2002). Optimisa-

tion for surface mount placement machines. In Uni-

versity of Nottingham.

Ayob, M. and Kendall, G. (2005). A survey of surface

mount device placement machine optimisation: Ma-

chine classification. In Computer Science Technical

Report No. NOTTCS-TR-2005-8. University of Not-

tingham.

Ball, M. and Magazine, M. (1988). Sequencing of inser-

tions in printed circuit board assembly. In Operations

Research 36(2), pp. 192-201.

Crama, Y., Kolen, A., Oerlemans, A., and Spieksma, F.

(1990). Througput rate optimization in the automated

assembly of printed circuit boards. In Annals of OR,

Vol. 26, pp.455-480.

Knuutila, T., Py

¨

otti

¨

al

¨

a, S., and Nevalainen, O.S. (2007).

Minimizing the number of pickups on a multi-head

placement machine. In The Journal of the Operational

Research Society.

Kumar, R. and Li, H. (1995). Integer programming ap-

proach to printed circuit board assembly time opti-

mization. In IEEE Trans. Components, Packaging and

Manufacturing Technology, part B: Advanced Packag-

ing, Vol. 18 pp. 720-727.

Lee, S., Lee, H., and Park, T. (1999). A hierarchical method

to improve the productivity of a multi-head surface

mounting machine. In Proc. of the IEEE Interna-

tional conference on Robotics and Automation, De-

troit, Michigan.

Leip

¨

al

¨

a, T. and Nevalainen, O. (1989). Optimization of

the movements of a component placement machine.

In European Journal of Operational Research,38, pp.

167-177.

Py

¨

otti

¨

al

¨

a, S., Knuutila, T., Johnsson, M., and Nevalainen,

O.S. (2005). Improving the pickups of components on

a gantry-type placement machine. In TUCS Technical

Report 692. Turku Centre for Computer Science.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

334

Py

¨

otti

¨

al

¨

a, S., Knuutila, T., and Nevalainen, O.S. (2006).

The selection of nozzles for minimizing the num-

ber of pick-ups on a multi-head placement machine.

In GTCM2006 Conference, Groningen, The Nether-

lands.

Sun, D., Lee, T., and Kim, K. (2004). Component allocation

and feeder arrangement for a dual-gantry multi-head

surface mounting placement tool. In International

Journal of Production Economics 95 (2005) 245-264.

MINIMIZING THE ARM MOVEMENTS OF A MULTI-HEAD GANTRY MACHINE

335