HEURISTIC ALGORITHMS FOR SCHEDULING IN A

MULTIPROCESSOR TWO-STAGE FLOWSHOP

WITH 0-1 RESOURCE REQUIREMENTS

Ewa Figielska

Warsaw School of Computer Science, Lewartowskiego 17, 00-169 Warsaw, Poland

Keywords: Heuristics, Linear Programming, Flowshop scheduling, Parallel unrelated machines, Resource constraints.

Abstract: This paper deals with the problem of preemptive scheduling in a two-stage flowshop with parallel unrelated

machines at the first stage and a single machine at the second stage. At the first stage, jobs use some

additional resources which are available in limited quantities at any time. The resource requirements are of

0-1 type. The objective is the minimization of makespan. The problem is NP-hard. Heuristic algorithms are

proposed which, while solving to optimality the resource constrained scheduling problem at the first stage

of the flowshop, select for simultaneous processing jobs according to rules promising a good (short)

schedule in the flowshop. Several rules of job selection are considered. The performance of the proposed

heuristic algorithms is analyzed by comparing their solutions with the lower bound on the optimal

makespan. The results of computational experiments show that these heuristics are able to produce near-

optimal solutions in short computation time.

1 INTRODUCTION

During the last years, the flowshops with multiple

processors (FSMP) also called hybrid flowshops,

have received considerable attention from

researchers (e.g. Gupta 1988; Chen 1995; Haouari

and M’Hallah, 1997; Brah and Loo (1999), Linn and

Zhang, 1999; Ruiz and Maroto, 2006).

In this paper, we extend multiprocessor flowshop

scheduling research by including resource

constraints. We consider the problem of scheduling

in a two-stage flowshop where jobs use additional

renewable resources, which are available in limited

quantities at any time. This problem can be

described as follows. There are

n preemptive jobs

to be processed at two stages in the same

technological order, first at stage 1 then at stage 2.

At stage 1 there are

m

parallel unrelated machines,

stage 2 has one machine. A job upon finishing its

processing at stage 1 is ready to be processed at

stage 2; it may be processed at stage 2 when the

machine is available there, or it may reside in a

buffer space of unlimited capacity following stage 1

until the machine at stage 2 becomes available. At

stage 1, a job can be processed on any of the parallel

machines, and its processing times may be different

on different machines. The processing times of job

j ( nj ,,1 …

=

) are equal to

ij

p (if it is executed on

machine

i

( mi ,,1 …

=

)) and

j

s

time units,

respectively, at stage 1 and at stage 2. The

processing of a job on a machine of stage 1 may be

interrupted at any moment and resumed later on the

same or another machine. A job during its

processing at stage 1 does not need a resource or

uses one unit of this resource (0-1 resource

requirements). There are

l types of resources. A

resource of type

r

( lr ,,1 …

=

) is available in an

amount limited to

r

W units at a time. The total usage

of resource

r

at any moment by jobs simultaneously

executed on parallel machines cannot exceed the

availability of this resource. The objective is to find

a feasible schedule which minimizes makespan,

max

C , which is equal to the maximum job

completion time at stage 2.

The considered problem is NP-hard in the strong

sense since the problem of preemptive scheduling in

the two-stage flowshop with two identical parallel

machines at one stage and one machine at another is

NP-hard in the strong sense (Hoogeveen et al.,

1996).

452

Figielska E. (2007).

HEURISTIC ALGORITHMS FOR SCHEDULING IN A MULTIPROCESSOR TWO-STAGE FLOWSHOP WITH 0-1 RESOURCE REQUIREMENTS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 452-455

DOI: 10.5220/0001643404520455

Copyright

c

SciTePress

The heuristic algorithms proposed for the

considered problem, while solving to optimality the

resource constrained scheduling problem at the first

stage of the flowshop, select for simultaneous

processing jobs according to rules promising a good

(short) schedule in the flowshop. Several rules of job

selection are considered.

The problem under consideration arises in real-

life systems that are encountered in a variety of

industries, e.g. in chemical, food, cosmetics and

textile industries. These systems are often subjected

to some additional resource constraints for example

on the availability of the additional resources such as

skilled labour and tools. Preemption of jobs usually

results in shortening the schedule. The problem with

parallel unrelated machines at the first stage and a

single machine at the second stage may arise in a

manufacturing environment in which products are

initially processed on any of parallel machines and

then each product must go through a final testing

operation, which is to be carried out on a common

testing machine.

2 FRAMEWORK OF THE

HEURISTIC ALGORITHMS

The proposed heuristic algorithms proceed in the

following steps:

1. A linear programming (LP) problem is solved to

minimize time

T needed for finishing all jobs

at stage 1 of the flowshop under relaxed

resource constraints over time

T

. As a result,

the minimal value of

T and the values of the

time

ij

t (

njmi ,,1,,,1 …… ==

) during which

job

j

is processed on machine i are obtained.

2. Using the values of

ij

t obtained in Step 1 as

well as the values of

j

s (

j

s is the processing

time of job

j

at stage 2), weights,

j

w

, for all

jobs are determined on the basis of 6 different

expressions presented in Table 1.

3. The schedule at stage 1 of the flowshop is

constructed in the form of a sequence of partial

schedules using the values of

T

,

ij

t , and

j

w .

In a partial schedule at most m (m is the

number of machines) jobs are assigned to

machines for simultaneous processing during

some period of time so that resource constraints

are satisfied at every moment. The consecutive

partial schedules are created in subsequent

iterations of an iterative procedure. Assignment

of jobs to machines in a partial schedule is

found maximizing the weighted assignment

ij

m

i

n

j

j

vw

∑∑

==11

(

ij

v = 1 if job

j

is processed

on machine

i in a current partial schedule, and

0 otherwise) under resource constraints. In each

created partial schedule, conditions on

optimality formulated in (Slowinski, 1980,

1981) are satisfied.

4. Completion times of jobs at stage 1 are

calculated.

5. A schedule on the machine of stage 2 is

constructed using the values of

j

s , and ready

times of jobs at stage 2, which are equal to

corresponding completion times at stage 1.

Table 1: Weights used in the heuristic algorithms.

Algorithm

Weight

j

w of job

j

A1 1

A2

random number from

)1,0[U

A3

{

}

j

knk

Z

Z

,,1

min

…=

A4

{}

knk

j

s

s

,,1

max

…=

A5

{

}

{}

knk

knk

j

j

s

Z

Z

s

,,1

,,1

max

min

…

…

=

=

A6

{

}

j

knk

Z

Z

,,1

min

…=

+1 if

jj

sZ ≤ ,and

{}

knk

j

s

s

,,1

max

…=

if

jj

sZ >

j

Z is the processing time of job

j

at stage 1,

j

Z =

∑

=

m

i

ij

t

1

. In A3, A4 and A5 the maximal value of

j

w is equal to 1, in A6 the maximal

j

w is equal to 2 if

jj

sZ

≤

, and 1 if

jj

sZ > .

3 ILLUSTRATIVE EXAMPLE

To illustrate the problem and the solution method we

present the following example. Consider the case of

the two-stage flowshop with 2 machines at stage 1

and a single machine at stage 2. The number of jobs

n =10, the resource availability at any moment,

1

W =1. Job processing times and resource

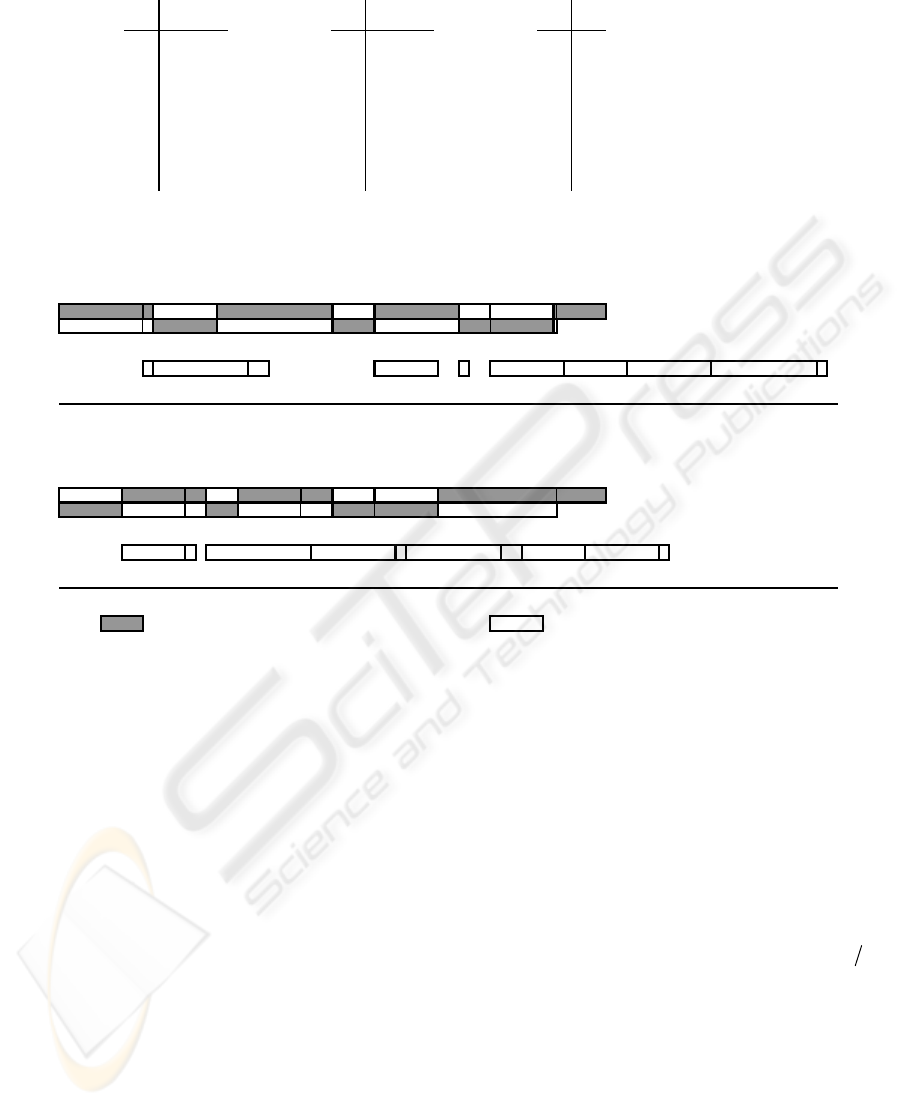

requirements are shown in Figure 1.

HEURISTIC ALGORITHMS FOR SCHEDULING IN A MULTIPROCESSOR TWO-STAGE FLOWSHOP WITH 0-1

RESOURCE REQUIREMENTS

453

j

ob processing times job processing times resource requirements

at stage 1: at stage 2: at stage 1:

machine machine

j

ob 1 2

j

ob 1

j

ob

1610 1 1 11

resource availability = 1

214 9 2 8 2 1

312 8 3 10 3 0

41310 4 6 4 1

5612 5 6 50

62316 6 7 6 0

768 7 2 70

813 9 8 9 8 0

91922 9 1 9 1

10 8 23 10 1 10 1

Figure 1: Data for an illustrative example.

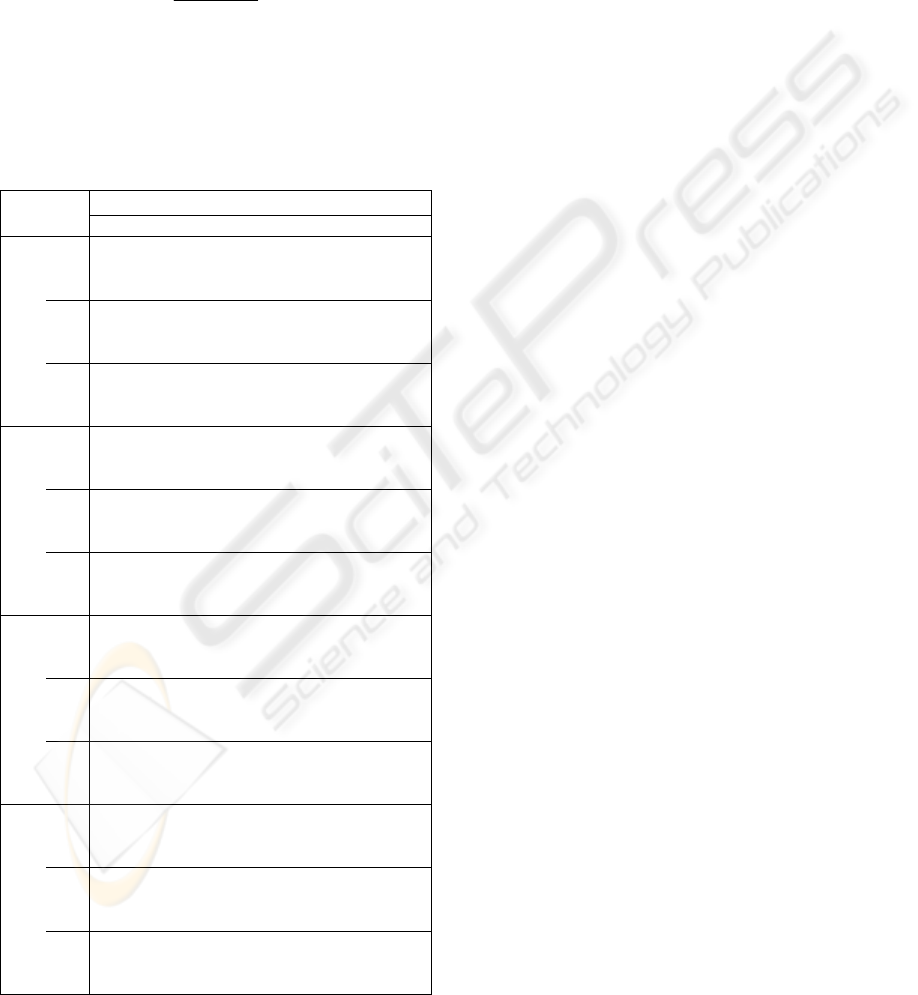

(a)

partial sch.

index: 1 2 3 4 5 6 7 8 9 10

stage: 1

1m11017 9 6 9651

m2884 64322

3

2m1 87 49652 31

10

time

010203040506070

(b)

partial sch.

index: 1 2 3 4 5 6 7 8 9 10

stage:

1m1 5 1 10 6 10 9 6 7 9 9

m2 2 332 8 84 4 6

2m1 5 1 3 2 8 7 4 6 9

10

time

010203040506070

processing time of a job using a resource at stage 1 processing time of a job which does not use a resourc

e

Figure 2: An illustrative example. The resulting schedules: (a) a schedule obtained by heuristic algorithm A1, (b) a schedule

obtained by heuristic algorithm A5.

Figure 2 presents two flowshop schedules for this

instance, one created by algorithm A1 (Figure 2a)

and another created by A5 (Figure 2b). The first

stage schedules in Figures 2a and 2b are composed

of 10 partial schedules. In each of these partial

schedules at most 2 jobs are processed

simultaneously and the total resource usage does not

exceed the resource availability,

1

1

=W , e.g. in the

partial schedule of index 1 in Figure 2a, jobs 10 and

8 are processed simultaneously and use at every

moment 1 and 0 units of the resource, respectively.

The first stage schedules in Figures 2a and 2b have

the same length, but completion times of jobs in

these schedules are different. For example, in the

first stage schedule in Figure 2a, job 10 finishes its

processing at stage 1 at 8 time units and in Figure 2b

- at 23 time units. This results in different lengths of

the flowshop schedules provided by A1 and A5.

4 COMPUTATIONAL STUDY

In this section, the results of a computational

experiment conducted to evaluate the performance

of the proposed heuristic algorithm are presented.

720 randomly generated instances were created and

examined. Instances were generated for =n 50, 100,

150, and 200,

=

m 2, 4, and 6, and for one resource

type. The resource availability

1

W was set at 2m ,

and for 55% of jobs resource requirements were set

at 1. Processing times at stage 2,

j

s , were generated

from

]100,1[U

(

],[ baU

denotes the discrete

uniform distribution in the range of

],[ ba ) for all

instances. Processing times at stage 1,

ij

p , were

generated from 9 ranges: U[30,120], U[45,180], and

U [60,240] for instances with m = 2, U [90,360], U

[120,480], and U [150,600] for m = 4, U[150,600],

U[200,800], and U [250,1000] for m = 6. The ranges

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

454

for processing times were selected so as to include

the cases when the length of the optimal schedule at

stage 1,

*

1

C , is close to the sum of job processing

times at stage 2,

∑

=

n

j

j

s

1

.

As an effectiveness measure we use the relative

percentage deviation of a heuristic solution from the

lower bound on the optimal makespan defined as

%100

max

×

−

=

LB

LBC

δ

where

},max{

21

LBLBLB = , where

1

LB =

*

1

C +

)(min

,,1 jnj

s

…=

and

2

LB = )(min

,,1,,,1 ijnjmi

p

…… ==

+

∑

=

n

j

j

s

1

,

*

1

C is the minimal makespan at stage 1.

Table 2: Computational results.

δ

(%)

n m

A1 A2 A3 A4 A5 A6

50 2 1.38 1.40 0.06 0.75 0.06 0.04

2.78 3.35 1.30 0.54 0.12 0.06

4.15 4.43 2.74 0.27 0.20 0.14

4 3.26 1.94 0.31 0.46 0.15 0.40

7.21 4.60 3.77 0.60 0.52 0.60

7.68 6.25 5.81 0.82 0.89 0.74

6 2.65 1.39 0.25 0.52 0.16 0.52

8.24 5.16 4.64 0.87 0.77 0.84

8.90 7.80 6.87 1.55 1.68 1.51

100 2 0.74 0.51 0.03 0.39 0.02 0.01

1.80 2.49 0.60 0.21 0.04 0.02

1.52 1.33 1.00 0.03 0.05 0.02

4 1.26 1.08 0.08 0.26 0.08 0.25

5.06 3.18 1.87 0.18 0.22 0.18

3.45 2.70 2.50 0.17 0.21 0.16

6 2.03 1.01 0.06 0.23 0.07 0.25

5.64 4.03 2.46 0.40 0.31 0.42

4.02 4.03 3.76 0.47 0.47 0.43

150 2 0.21 0.42 0.02 0.19 0.02 0.00

1.62 1.16 0.28 0.19 0.02 0.01

0.95 0.90 0.91 0.02 0.02 0.02

4 0.71 0.61 0.00 0.22 0.01 0.16

4.24 2.05 1.44 0.15 0.10 0.19

1.94 1.60 1.37 0.06 0.07 0.06

6 0.76 0.49 0.04 0.20 0.01 0.20

4.14 2.36 1.86 0.24 0.17 0.24

2.66 2.46 2.17 0.18 0.20 0.19

200 2 0.46 0.42 0.01 0.21 0.02 0.00

1.10 0.99 0.17 0.30 0.01 0.01

0.69 0.48 0.38 0.01 0.01 0.01

4 0.60 0.44 0.04 0.19 0.03 0.10

2.15 1.70 0.86 0.12 0.05 0.12

1.47 1.22 1.16 0.05 0.05 0.05

6 0.83 0.25 0.02 0.10 0.03 0.10

2.46 1.57 0.90 0.12 0.07 0.12

1.75 1.67 1.64 0.10 0.10 0.10

The results of a computational experiment are

presented in Table 2 All entries in this table are

average values over 20 instances.

From Table 2, we can observe that deviations,

δ

, significantly decrease, as the number of jobs

grows, and they increase with the number of

machines. We can see that algorithms A3, A4, A5,

and A6 always outperform A1 and A2, and A4, A5,

and A6 produce near-optimal solutions. On the

average over the entire collection of instances,

relative deviations of the heuristic makespan from its

lower bound are equal to 2.79%, 2.15%, 1.43%,

0.32%, 0.19%, and 0.23% for A1, A2, A3, A4, A5,

and A6, respectively.

The CPU times are small for all the heuristic

algorithms and equal to about 0.3, 1.5, 3, 4.5, and

6.5 seconds for n =50, 100, 150, and 200,

respectively.

REFERENCES

Brah, S.A. and L.L. Loo (1999). Heuristics for scheduling

in a flow shop with multiple processors. Europ. J. of

Opernl Res.113,113-112

Chen, B. (1995). Analysis of classes of heuristics for

scheduling a two-stage flow shop with parallel

machines at one stage, J. of Opernl Res. Soc. 46, 234-

244.

Gupta J.N.D. (1988). Two stage hybrid flowshop

scheduling problem. J. of Opernl Res. Soc. 39, 359-

364.

Haouari, M. and R. M’Hallah (1997). Heuristic algorithms

for the two-stage hybrid flowshop problem, Oper. Res.

Let. 21, 43-53.

Hoogeveen J.A., J.K. Lenstra and B. Veltman (1996).

Preemptive scheduling in a two-stage multiprocessor

flow shop is NP-hard. Europ. J. of Opernl Res. 89,

172-175.

Linn, R, W. Zhang (1999). Hybrid flow shop scheduling: a

survey. Comp. and Ind. Engin. 37, 57-61.

Ruiz, R., C. Maroto (2006). A genetic algorithm for hybrid

flowshops with sequence dependent setup times and

machine eligibility. Europ. J. of Opernl Res. 169, 781-

800.

Slowinski, R. (1980), Two approaches to problems of

resource allocation among project acticities – A

comparative study. J. Opl Res. Soc. 31, 711-723.

Slowinski, R. (1981), L'ordonanacement des taches

preemptives sur les processeurs independants en

presence de ressources supplementaires. RAIRO

Inform./Comp. Science, vol.15, No.2, 155-166.

HEURISTIC ALGORITHMS FOR SCHEDULING IN A MULTIPROCESSOR TWO-STAGE FLOWSHOP WITH 0-1

RESOURCE REQUIREMENTS

455