A HYBRID INTELLIGENT MULTI-AGENT METHOD FOR

MONITORING AND FAULTS DIAGNOSIS

Gang Yao and Tianhao Tang

Department of Electrical & Control Engineering, Shanghai Maritime University

1550 Pudong Road, Shanghai, 200135, P. R. China

Keywords: Multi-agent system, Monitoring and diagnosis system, Data mining, Fuzzy neural networks.

Abstract: This paper presents a hybrid intelligent multi-agent method for monitoring and faults diagnosis. A new

diagnosis process, combined with data mining and neural networks, are discussed as well as the functions

and structure of agent which implements these algorithms. At last, some simulation results are shown to

demonstrate the efficiency of the proposed system.

1 INTRODUCTION

The rapid development of modern industry calls for

safer and more efficient control processes.

Monitoring and faults diagnosis systems,

specifically combined with artificial intelligent

technologies, are implemented for state monitoring,

trend predicting and fault diagnosis. Thereby, it is

possible to improve the system efficiency and to

guarantee the operation safety in the control process

(Edgar 2000).

A general overview about distributed artificial

intelligence in industry was given in (Parunak 1994).

This paper reviewed the industrial needs for

distributed artificial intelligence, and gave special

attention to the needs arising from systems for

manufacturing, scheduling and control. Since then

more and more researches and contributions have

been done in this field.

However, the complexity of the monitoring and

diagnosis system is growing with the increasing

complexity of industrial plants. To keep the

monitoring and diagnosis system effective, it is

essential to encapsulate different tasks and to define

strict interfaces between plant components and

between components of the monitoring and

diagnosis system, although it is quite difficult. To

guarantee flexibility -- changing needs in case of an

industrial application, the monitoring and diagnosis

system has to be configurable and expandable

without the need of modifying any line of code

(Luder 2001). The diagnostic knowledge about an

industrial process is available on different parties

(process specialists, component manufacturers, etc.).

A modern monitoring and diagnostic system should

be able to integrate the diagnostic knowledge from

all available sources, even if different diagnostic

mechanisms are applied. To achieve an overall

diagnosis of a control process, several diagnostic

tasks have to be performed in parallel. This requires

new strategies to handle diagnostic conflicts that

might occur between different diagnostic results.

Multi-agent system (MAS), about which rapid

progress has been made, is an important research

branch in distributed artificial intelligence (DAI)

parallelized with distributed problem solving (DPS).

Possessing modularity, adaptability and other

attractive characteristics, MAS drew much attention

in recent years and is adopted by many researches in

monitoring and diagnosis system.

This paper presents a hybrid intelligent mutli-

agent method for monitoring and faults diagnosis,

which separates fault diagnosis process into several

steps excuted by different types of agents. The

macroscopical architecture of the MAS system and

microcosmic structure of an agent are designed in

section 2. Then, the intelligent monitoring and fault

diagnosis process is presented in section 3. At last,

the simulation experiment, applying the proposed

method in marine engine room, is carried out in

section 4.

155

Yao G. and Tang T. (2007).

A HYBRID INTELLIGENT MULTI-AGENT METHOD FOR MONITORING AND FAULTS DIAGNOSIS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 155-160

DOI: 10.5220/0001647501550160

Copyright

c

SciTePress

2 SYSTEM ARCHITECTURE

2.1 Architecture of Proposed System

The framework of hybrid intelligent multi-agent

method, with hierarchical and federal organized

software agents that are responsible for different

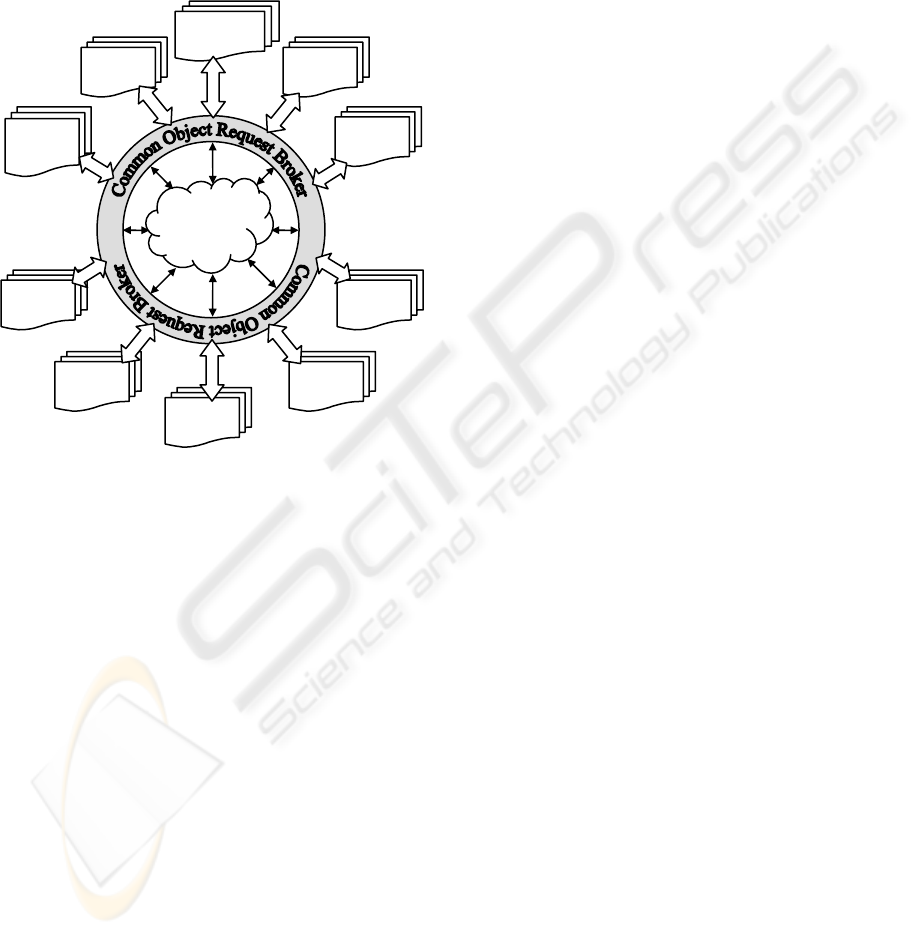

tasks, is presented in figure 1.

Figure 1: Architecture of MAS-based monitoring and

diagnosis system.

As shown in figure 1, many agents with different

capabilities are connected together by accessing

common object request broker (CORBA)

functionalities and through communication networks

to form a multi-agent society. In this society, each

individual has a special ‘survival skill’ that can work

autonomously and independently. For example,

when this MAS is connected to a control system, the

data access agent, who has the skill of accessing

database, it can get signals periodically and

automatically from given sensors and store them into

a record set with the intelligence of maintenance the

integrity of database.

On the other hand, like human beings, agents in

the figure trend to seek cooperation to fulfil more

difficult task if they believe that better rewards will

gain by cooperation or the job assigned to the

agents is impossible to achieve with their own

capability. A cooperation coalition will form

successfully if following precondition is met

v(A

1

)+ v(A

2

) ≤ v(A

1

+A

2

), (A

1

∩A

2

=φ)

(1)

Where v(A

1

) is the benefit gained by coalition A

1

after A

1

accomplished a job.

Management agent is the one who take charge of

negotiation within the formation of a cooperation

coalition. When a task is received, management

agent decomposes the task into sub-jobs or steps if

necessary, and then adopts contract net protocol to

distribute them to appropriate agents to form a

cooperation coalition. Other agents decide whether

to respond to the bidding or not according to the job

been doing, priority and rewards. After the mission

is accomplished, the cooperation coalition will

dismiss automatically.

This MAS approach will bring us following

advantages: Modularity and scalability, instead of

adding new capabilities to a system, agents can be

added and deleted without breaking or interrupting

the process; Adaptability, agents have the ability to

reconfigure themselves to accommodate new

changes and faults; Concurrency, agents are capable

of reasoning and performing tasks in parallel, which

in turn provides more flexibility and speeds up

computation; Dynamics, agents can dynamically

collaborate to share their resources and solve

problems and finally, Reliability, MAS are more

fault-tolerant and robust than traditional AI systems.

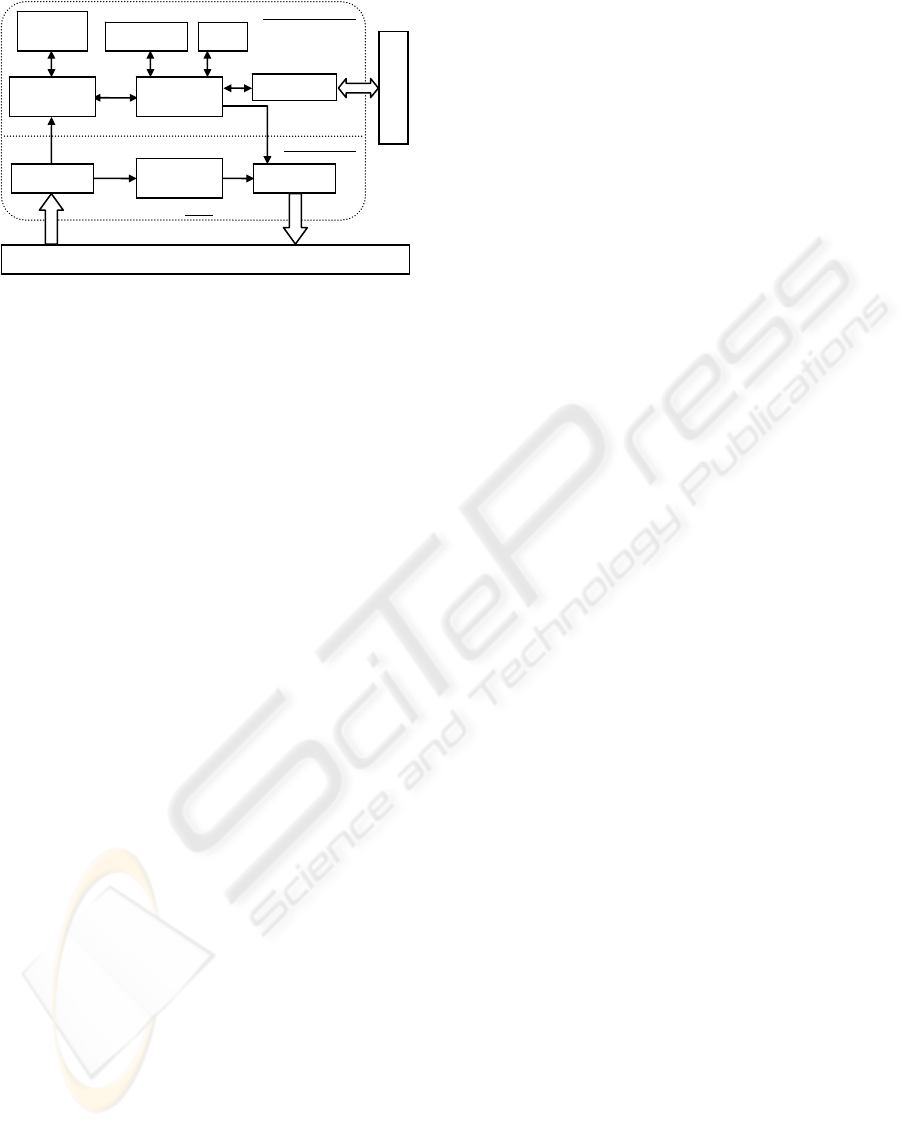

2.2 Architecture of an Intelligent Agent

At agent level, all the agents in proposed method

have the same hybrid behaviour architecture, where

the agents are capable of reactive and deliberative

behaviours. In general, the agents should be neither

totally deliberative nor totally reactive. If they are

only reactive, they cannot reason about their actions

and will not be able to achieve any sophisticated

behaviour; if they are just deliberative they may

never be able to act in time. The proposed

architecture is based on horizontal layering where all

layers are connected to the perception and actuation

of the agents with the environment. Figure 2 shows

the proposed agent architecture in monitoring and

diagnosis system.

In figure 2, an agent can collect information from

two channels: the perception module, which

apperceives from the ambient and to check the

influence of last action, and the communication

module, which receives message from other agents.

All the perception information is distinguished as

‘urgent’ or ‘not urgent’ based on the signal type,

priority, security policy and experience in order to

trigger corresponding response mechanism.

Clustering

Agent

FNN

Agent

RPCA

Agent

PDRNN

Agent

Local GUI

Agent

Remote GUI

Agent

Conflict

Resolution

A

g

ent

Managemen

t

Agent

DF

Agent

Data access

Agent

Communication

Networks

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

156

Figure 2: Architecture of an agent.

If an urgent message is received, the reactive

layer will be triggered, and the agent will execute

according to the most similar rule in rules library

without thinking. The reactive rules library could be

modified in accordance with the experience

automatically.

If the message is not urgent, the agent will

‘think’ for a while about how to respond. In this

period, agent uses its special ability to process this

information and then make decision with the

consideration of mental state, knowledge and its

goal. After the agent’s action is executed, if the

action really works, the agent will record this action

as a paradigm into reactive rules library and update

the mental state, knowledge base if necessary.

When the agent finds the job got from the

message is too difficult to accomplish, three options

are available: (1) if the agent know who can help it,

it will ask for help directly to that agent; (2) if the

agent has no idea who is the right agent, it will

contact the management agent to try to organize a

cooperation coalition; (3) if no one responds its

request, abandoning the goal is its last choice.

The special capability mentioned above is the

agent’s ‘survival skill’ encapsulated in information

processing module (IPM). Different method in IPM

determines different type of agent. As shown in

figure 1, ten kinds of agent are designed in this

system:

(1) Local and remote GUI agent: local and

remote graphical user interfaces (GUI) are used by

the operator users to display monitoring and

diagnosis results, initiate diagnostic processes, give

a phonic or flaring alarm, and receive user’s

instructions locally and extendedly.

(2) Management agent: management agent is

used to decompose task and start organizing

cooperation as mentioned in section 2.1.

(3) Conflict resolution agent: a conflict

resolution mechanism is required to investigate

whether the diagnostic results, as reported by

different diagnostic agents, are contradicting or

completing each other. The diagnostic agents do not

communicate with each other to merge their

knowledge, but do report their diagnosis to a conflict

resolution agent. For this purpose, the history credit

evaluation of a diagnosis agent is important. Beyond

this, knowledge of relations among the components

and among the possible failures which may be

related within the components, need to be well

known (H.Worn 2002).

(4) Directory facilitator agent: the directory

facilitator (DF) agent is responsible for

communication and agent management. It can

provide the naming service, represent the authority

in the platform and also provide Yellow Pages

service by means of which an agent can find other

agents providing the services he requires in order to

achieve his goals. All the capabilities of the

registered monitoring and diagnostic agents and the

available CORBA functionalities are managed by

the facilitator agents.

(5) Data access agent: what data access agent can

do has discussed as an example in section 1.

(6) Clustering agent, Relative Principal Com-

ponent Analysis (RPCA) agent, Parallel Diagonal

Recurrent Neuron Network (PDRNN) agent and

Fuzzy Neural Network (FNN) agent: these agents

are dealing with monitoring and diagnosis process

which will be discussed in next section.

3 INTELLIGENT MONITORING

AND DIAGNOSIS PROCESS

Faults diagnosis for complex control system is the

process of mining valuable omen variables from

mass data collected by sensors and mapping omen

variables to faults modes. Thereby data mining plays

an important role in diagnosis. In this paper, a new

hybrid intelligent monitoring and diagnosis method

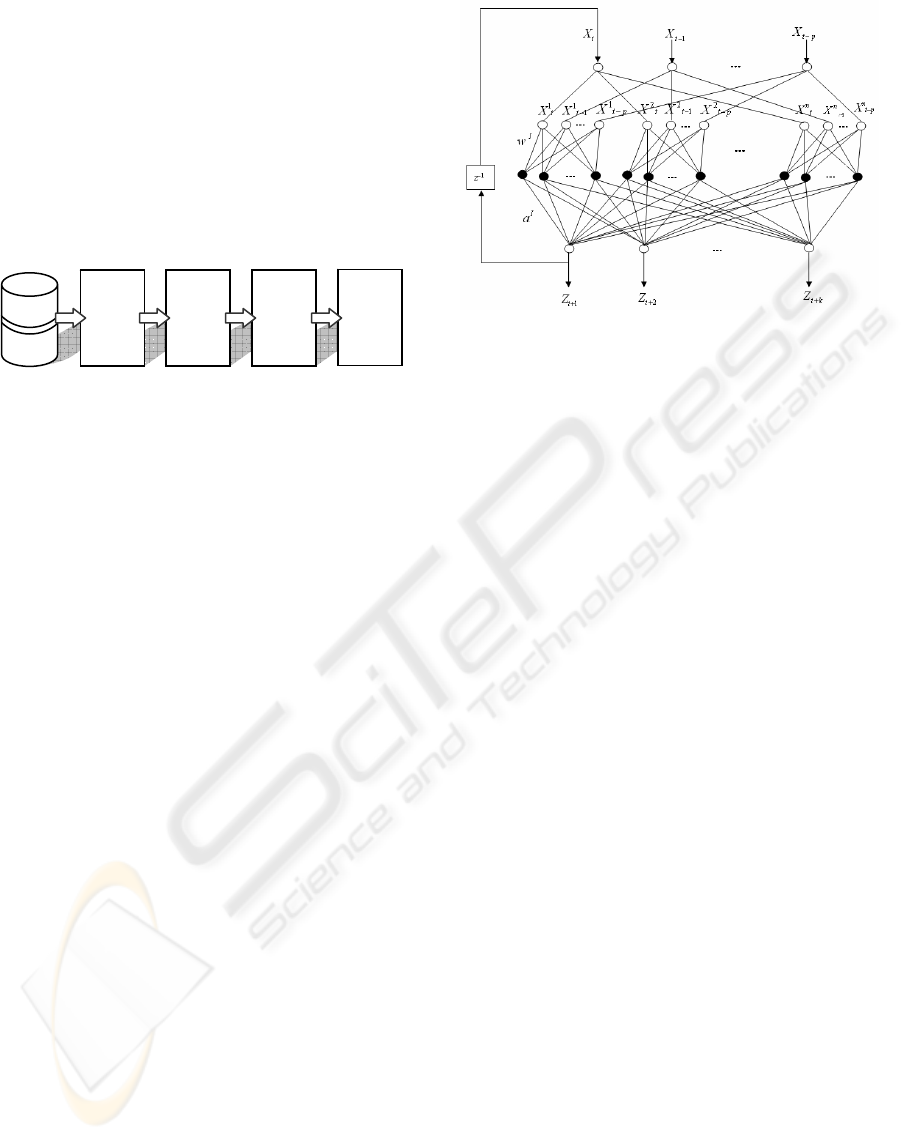

is proposed in figure 3. This method divided the

process of data mining and fault mode mapping into

several independently data fusion modules, which

are implemented by agents:

(1) Database: database is made up with two main

storage areas, which correspond to history and

online data access respectively. History data are

used for intelligent data mining, executed by

collaborated agents, and real time data are collected

by the data access agent from sensors.

Other Agent

Reactive

Rules

Information

Processing

Mental

State

Knowledge Goal

Urgent

Ambient

Not urgent

Decision

Making

Perception

Agent

Deliberation Layer

Reactive Layer

Communication

Action

A HYBRID INTELLIGENT MULTI-AGENT METHOD FOR MONITORING AND FAULTS DIAGNOSIS

157

(2) Pre-processing module based on clustering

methods: This module is executed by clustering

agent. Data selection and data mining usually do not

need all the data, some data object and propriety has

no contribution to the modelling, on the contrast

they will greatly reduce the efficiency of data

mining, even will lead to the variation of data

mining result. In this case, it is very necessary to

select data effectively. Pre-processing module based

on clustering methods can select the preventative

points as feature data and filter some fake data.

Figure 3: Data mining based intelligent information fusion

method.

(3) Data reduction module based on RPCA:

Data reduction will figure out the essential data set

to shrink the scope, which is the further step of

reduction based on data selection. Data reduction

also is called as data enriching, the process of which

is transferring the original data set to the more

compact data set without losing any semantics.

Herein Relative Principal Component Analysis

Algorithm (RPCA) is adopted and encapsulated in

the IPM of RPCA agent, which can avoid the

parameters having bigger absolute values or

variation values to play the great role when getting

main element, which is the shortage of PCA method.

For RPCA, more representative main element can be

got from the data array made up with evenly

distributed system variables series. This module is

majorly used to reduce data dimension and extract

system feature (Tianhao Tang 2005).

(4) Trend prediction module based on neural

network: Prediction mode can predict some

phenomena or data value. Parallel Diagonal

Recurrent Neuron Network (PDRNN), which is

implemented in PDRNN agent, can realize multiple

dimension and parallel time frequency prediction,

and it has the high prediction precision to make its

result good for the fault trend analysis. The

architecture of this neural network is shown in figure

4. The transfer function of neuron adopts Sigmoid,

and training method is back propagation algorithm.

Details about this neural network refer to (Tianzhen

Wang 2004).

Figure 4: Architecture of PDRNN.

(5) The last step is to do system fault detection

based on omen variable and parameters prediction.

The core issue of fault diagnosis is to abstract signal

feature and to establish the relationship between the

features and different functional states. More

complex modern industry system has more complex

faults. One fault often demonstrates many omens,

while one omen maybe includes information about

many kinds of faults. The relationship between

omen and fault is hard to be expressed by precise

mathematic expression, so fuzzy logic diagnosis

method can be used. The basic principle of fuzzy

logic diagnosis is to establish the fuzzy relation

matrix

R

~

between fault mode (cause) and omen

variable according to the known information, then to

select omen membership vector X. The fault mode

membership matrix Y can be calculated from fuzzy

relation equation Y=X*

R

~

, thus fault causes can be

diagnosed.

The uncertain relationship between fault and

omen can be well expressed in fuzzy diagnosis, but

the relation matrix

R

~

is hard to be established. On

the other hand, fault diagnosis can be regarded as a

kind of pattern recognition which maps the fault

omen to fault causes. The relation matrix

R

~

reflects

the mapping. For the complex system, the mapping

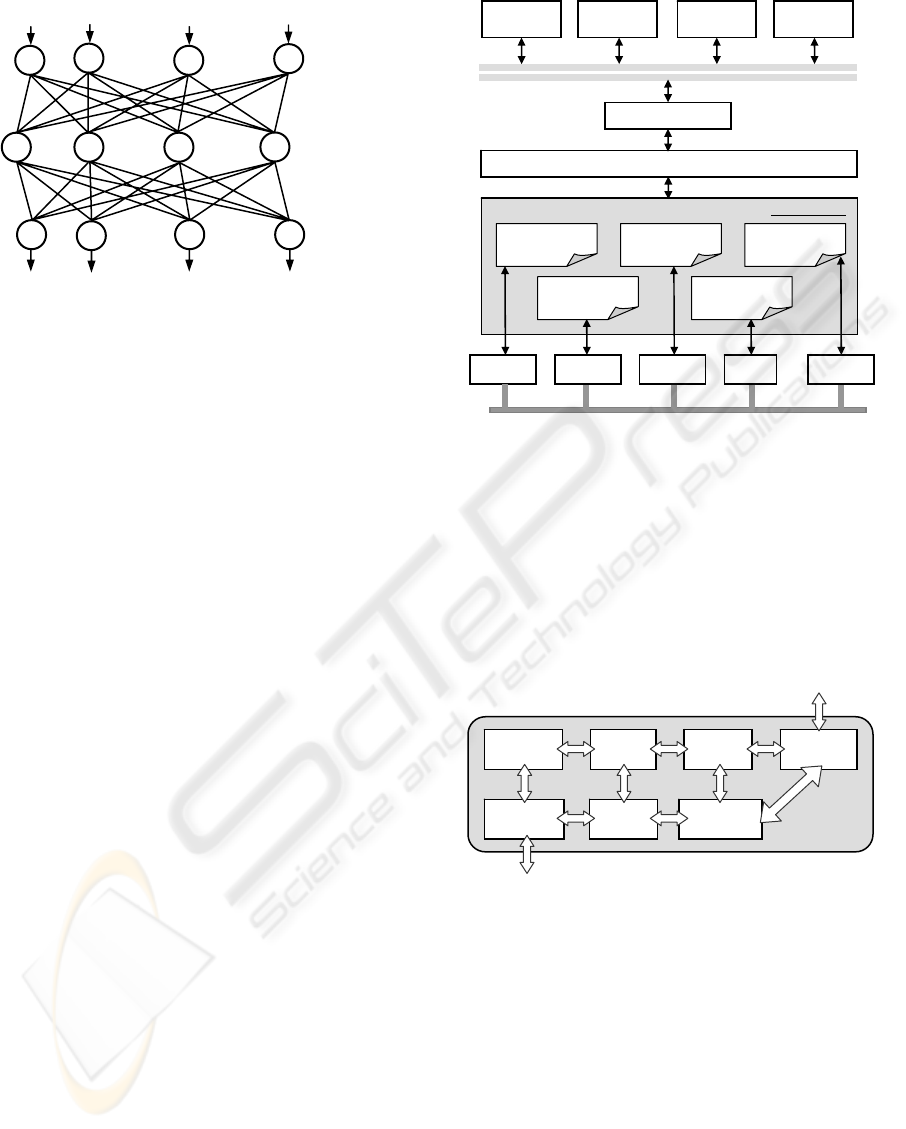

is non-linear. A fuzzy neural network (FNN) is used

to establish the matrix

R

~

, as shown in figure 5

This FNN is realized in FNN agent, and two new

fuzzy operators, the generalized probability sum

operator and the generalized probability product

operator, are used as transfer function to express the

concepts of the generalized union and the

generalized intersection calculating. Details about

the FNN refer to (Tang, etc., 1998).

History

Online

Database

Pre-treat

module

based on

clustering

methods

Data

reduction

module

based on

RPCA

Trend

prediction

module

based on

PDRNN

Faults

diagnosis

module

based on

FNN

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

158

Figure 5: Architecture of fault diagnosis neural network.

4 SIMULATION EXPERIMENT

The hybrid intelligent multi-agent monitoring and

diagnosis system mentioned above has been used in

marine engine room, which is a typical complex and

distributed system.

Marine engine room is made up principally with

main engine remote control & protection system

(MECS), auxiliary engine control system (AECS),

ship power station automatic control system (PSCS),

boiler automatic control system (BCS), cabin

monitoring and alarm system (CMAS), and pump

control system (PCS), etc. For every sub systems, a

cooperative coalition is formed to implement

monitor and diagnosis.

The overall

state monitoring and fault diagnosis

system for marine engine room is shown in figure 6. The

architecture of a

cooperative coalition is shown in

figure 7.

As mentioned before, there are several different

types of agents sharing the same architecture but

having different capability in the proposed system,

which means that the connotation of IPM is different

according to the functionality of the agent. Thereby,

in figure 6, the architecture of all kinds of agents is

implemented in Jade, but the inner methods of IFM

are coded in different programming language with

consideration of coding convenience.

The monitor and alarm client interface, running

on local and extended GUI agent, and the fuzzy

neural network in FNN agent are coded in Visual

Basic 6.0 (VB6). Other algorithms involving in the

process of intelligent data mining are coded in

Matlab 6.5.

Figure 6: Architecture of marine engine room state

monitoring and fault diagnosis system.

JMatLink, a small toolkit to connect Java with

Matlab, is used to call for the data mining function

in an m-file for Java monitoring agent.

To implement calling VB methods and forms

from Java, Java Native Interface (JNI) mechanism is

utilized.

Figure 7: Architecture of a cooperative coalition.

In this experiment, several faults of main engine

were adopted to test the faults diagnosis system. Ten

parameters of main engine, such as engine cylinder

exhaust gas temperature, maximum cylinder

pressure, etc, are chosen as omen variables.

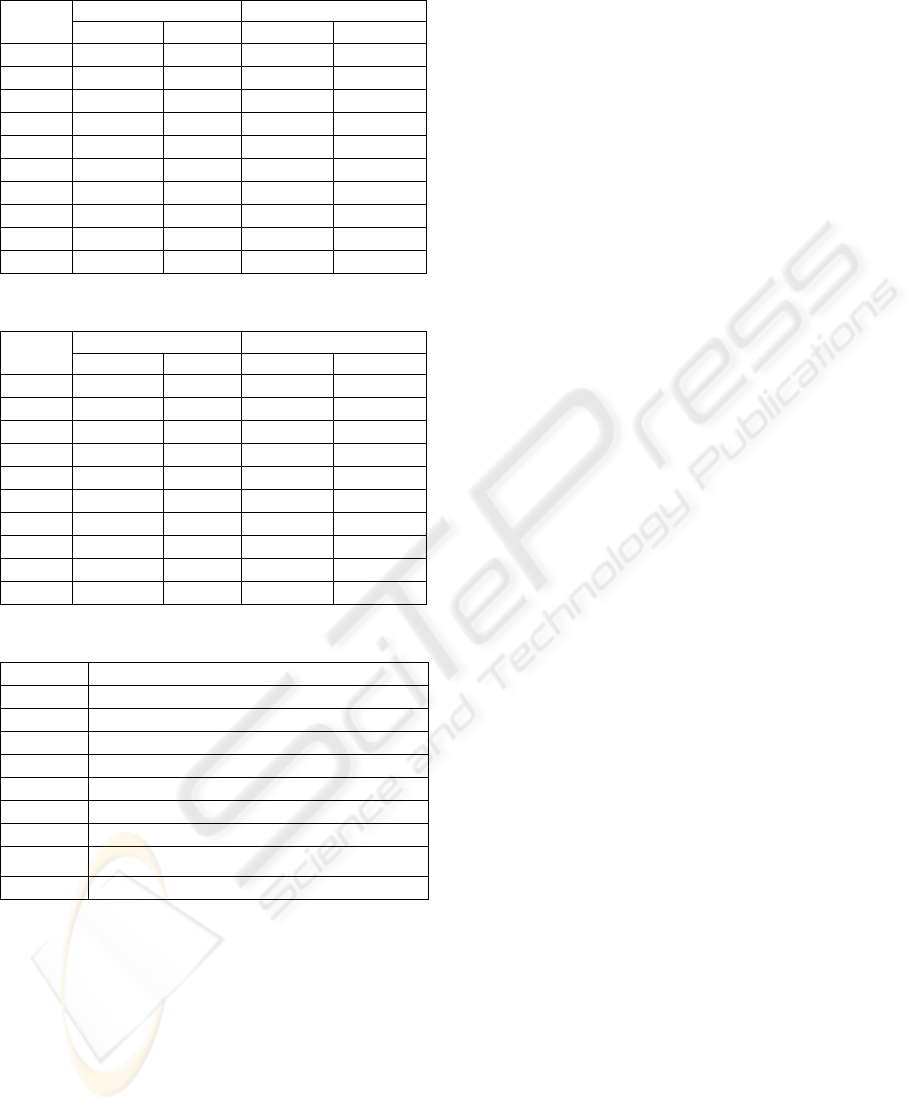

Table 1 shows the comparison between samples

of normal state and three faults state and diagnosis

results. The acronyms of omen variables are

interpreted in Table 2.

Data access

Agent

RPCA

Agent

Clustering

Agent

PDRNN

Agent

Conflic

t

Resolution

Facilitato

r

Agent

FNN

Agent

CORBA

Plant

Gateway

CORBA

Ethernet network

Extended

GUI Agent

C

ooperat

i

ve

alliance

C

ooperat

i

ve

alliance

C

ooperat

i

ve

alliance

C

ooperat

i

ve

alliance

C

ooperat

i

ve

alliance

Fieldbus

MECS AECS PSCS BCS CMAS

…

M

ulti-agen

t

Extended

GUI Agent

Local

GUI Agent

Local

GUI Agent

1

x

jk

w

ij

w

2

x

i

x

n

x

1

B

2

B

k

B

m

B

1

A

2

A

j

A

h

A

Omen Layer

Rule Layer

Fault Layer

A HYBRID INTELLIGENT MULTI-AGENT METHOD FOR MONITORING AND FAULTS DIAGNOSIS

159

Table 1: Fault diagnosis results.

Normal state Main oil pump abrasion

Sample Result Sample Result

Pmax 0.50 0.485 0.05 0.052

Pcs 0.50 0.488 0.35 0.405

Tcs 0.50 0.499 0.35 0.381

Tex 0.50 0.446 0.20 0.228

Ntk1 0.50 0.486 0.35 0.408

Ntk2 0.50 0.496 0.35 0.408

Pti 0.50 0.495 0.35 0.416

Tto 0.50 0.513 0.35 0.404

Tko1 0.50 0.497 0.35 0.386

Tko2 0.50 0.497 0.35 0.396

Table 1: Fault diagnosis results (Cont.).

Fuel injection late Fuel injection pipe leak

Sample Result Sample Result

Pmax 0.05 0.063 0.05 0.051

Pcs 0.80 0.715 0.20 0.232

Tcs 0.65 0.534 0.35 0.378

Tex 0.95 0.931 0.05 0.141

Ntk1 0.65 0.613 0.35 0.379

Ntk2 0.65 0.612 0.35 0.378

Pti 0.65 0.604 0.35 0.411

Tto 0.65 0.591 0.50 0.512

Tko1 0.65 0.596 0.35 0.407

Tko2 0.65 0.595 0.35 0.402

Table 2: Interpretation of omen variables.

Pmax

maximum cylinder pressure

Pcs

scavenging air pressure

Tcs

scavenging air temperature

Tex

cylinder exhaust temperature

Ntk1

rpm of No.1 turbocharger

Ntk2

rpm of No.2 turbocharger

Pti

inlet pressure of turbocharger

Tto

outlet temperature of turbocharger

Tko1

No.1 air cooler outlet temperature

Tko2

No.2 air cooler outlet temperature

From the table, we can see that diagnosis agent

can get close results compared with the samples, and

it means that fault could be detected exactly. Besides

these faults in Table 1, dealing with other faults,

diagnostic agent can get similar results.

5 CONCLUSIONS

This paper describes a concept of building a hybrid

intelligent monitoring and diagnosing system for

complex control process based on the application of

MAS, and also proposed a new fault diagnosis

process integrates several algorithms implemented

within the MAS method, which allows the flexibility,

the extendibility, and a cost-effective development

of the system. Details about the overall architecture,

algorithm encapsulated in IPM, and coding tools are

discussed. And at last, some simulation experiment

results are given to demonstrate the efficiency of the

presented system.

ACKNOWLEDGEMENTS

This work was supported by National Natural

Science Foundation of China (60572051) and the

project from Shanghai Education Foundation

(05FZ04).

REFERENCES

Edgar, T. F., Dixon, D. A., and REKLAITIS, G. V., 2000,

Vision 2020: Computational Needs of the Chemical

Industry, (University of Texas Press).

Parunak, V., 1994, Applications of distributed artificial

intelligence in industry. In O’Hare and Jennings, (eds)

Foundations of Distributed Artificial Intelligence

(Chichester: Wiley Inter-Science).

Luder, A., et al., 2001, Industrial requirement and overall

specification. Prepared within the PABADIS IST

research project no. IST-1999-60016. Available at

www.pabadis.org.

H.Worn,et al, 2002, A distributed multi-agent architecture

for monitoring and diagnosis

Tianhao Tang, Tianzhen Wang. 2005, ANN-based

multiple dimension predictor for ship route prediction.

Proceedings of ICINCO 2005, Barcelona, Spain

Tianzhen Wang, Tianhao Tang. 2004 A Mult-dimension

Predictor based on PDRNN.ICARCV, P1359-1364

Tang, T. et al 1998. A fuzzy and neural network integrated

intelligence approach for fault diagnosing and

monitoring. Proceedings of the 1998 UKACC

International Conference on Control, vol.2, pp.975-

980. Swansea, UK.

Tianhao Tang, Yao Gang. June 27-29, 2005, A Fault-

tolerant Control Method Based on Adaptive Fuzzy

Neural Networks for Ship Control System, 2005

International Conference on Control and Automation,

Budapest, Hungary

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

160