SOME ASSEMBLY REQUIRED

Effectiveness Of Interactive 3D Graphics on Mobile Devices for Object Assembly

Guy W. Zimmerman

Department of Computer Science, Bowling Green State University, Bowling Green, Ohio, USA

Keywords: Mobile device, 3D graphics, assembly task, object complexity.

Abstract: A study was conducted to explore the effectiveness of interactive 3D graphics on a mobile device to present

instructions for an assembly task: building four Lego models of varying complexity. Our results show

significant improvement in assembly correctness and time to complete the assembly when subjects used an

interactive presentation compared to a non-interactive one. The study also explored the intuitive notion of

3D object complexity and compared perceived object complexity with experimentally measured values.

1 INTRODUCTION

Assembly tasks are commonplace. They present

themselves in a diverse set of contexts; from

building a child's bike to putting together a

computer. They can range in complexity from just a

few, to thousands of individual steps, sometimes

requiring multiple sub-assemblies along the way.

The procedures for carrying out assembly tasks are

commonly presented as combinations of written text

and diagrams.

The recent explosion in availability of 3D

graphics capable mobile devices, coupled with their

ability to access the world wide web, holds out the

potential for a rich source of applications, including

the delivery of instructions for assembly tasks.

In this paper, we consider the utility of

interactive 3D graphics as a component of a system

to deliver instructions for an assembly task –

assembling Lego models. We present the results of a

study which examined two related issues within this

domain: 1) the effectiveness of interactive 3D

graphics presented on a mobile device in

contributing to a subject's ability to correctly

complete an assembly task and 2) what are the

characteristics which define complexity of

assembled objects?

The rest of the paper is organized as follows: in

section 2 we give some background information and

relevant results from the research literature for each

of the above issues. In section 3 we describe the

details of the study. Section 4 contains the results of

the study along with our analysis. The final section

summarizes and concludes the paper.

2 BACKGROUND

The use of diagrams to assist people in the execution

of assembly tasks is ubiquitous. Examples include:

assembling prefabricated furniture, children's toys,

and origami figures to name just a few. Despite the

pervasive use of diagrams in the presentation of such

instructions for assembly tasks, only recently has

any research been done on the role such diagrams

play in supporting the assembly task (Novick, 2000).

Since most such presentations are provided in

printed form, much of the existing work has focused

on two-dimensional diagrams. These are typically

perspective drawings of the object to be assembled

using a predetermined viewpoint – presumably

selected by the instruction designer as being optimal

for the step of the assembly being illustrated. Novick

(2000) examined diagrams that accompany

instructions for folding origami figures. Argawala

(2003) presented a suite of design principles to

create two-dimensional diagrams as well as system

for the automated production of those diagrams.

Two classes of diagrams are distinguished –

structural and action. Structural diagrams (termed

Final by Novick) show all the parts of interest in

their final position and leave it to the user to

determine how to accomplish the assembly. In

action diagrams, the parts to be attached are spatially

191

W. Zimmerman G. (2007).

SOME ASSEMBLY REQUIRED - Effectiveness Of Interactive 3D Graphics on Mobile Devices for Object Assembly.

In Proceedings of the Second International Conference on Computer Graphics Theory and Applications - AS/IE, pages 191-196

DOI: 10.5220/0002084301910196

Copyright

c

SciTePress

separated from the (partially completed) object and

include arrows (or similar) to indicate how (the

action) the parts are to be attached. The authors note

that people generally prefer that instructions

partition the steps of an assembly over multiple

diagrams. However, it is most common for a single

diagram to illustrate some minimal number of steps,

partly to reduce the total number of diagrams –

reducing the production and printing cost.

2.1 3D Graphics

As noted, instructions are most commonly produced

for print distribution and as such the accompanying

diagrams are 2-dimensional. Given the widespread

availability of computers with significant 3D

graphics capabilities, it is natural to consider the

replacement of static 2-dimensional diagrams with

animated and/or interactive 3-dimensional models as

the visual component in the presentation of

instructions for assembly tasks. Kashiwazaki (2005)

discusses potential advantages of 3D 'contents' as

compared to 2D 'contents' in the teaching of

assembly/disassembly procedures. Likewise the

Virtual Manuals™ application produced by

ParallelGraphics (Virtual Manuals). However, in

both cases only anecdotal evidence is provided as to

their effectiveness.

We note that as soon as we change to this latter

paradigm, many of the issues and restrictions

imposed by 2D representations vanish. For example,

it is no longer necessary to consider an optimal

viewpoint. Further, there is no longer a good reason

to illustrate multiple assembly steps simultaneously

(i.e. within a single diagram). It seems intuitively

obvious that illustrating one step at a time would

present the smallest cognitive load on the user,

enabling them to focus on the specific task,

increasing their ability to correctly complete the

assembly as rapidly as possible. A few papers have

appeared addressing some of these issues. Nousch

(1999) describes a software package named

BEAVER which allows users to design furniture and

automatically create instructions for its assembly,

however no data is provided as to the effectiveness

of the generated assembly instructions. A study

comparing the relative effectiveness of augmented

virtual-reality technology (AR), traditional CAI and

printed assembly instructions in the assembly of a

Duplo block model found an 82% reduction in errors

(Tang 2003).

A significant advantage of printed instructions is

in their mobility. A user can take the instructions to

the task, something not generally possible with AR

or desktop systems. However, presenting

instructions using 3D graphics on mobile devices

would seem combine the best of both worlds. While

the constant changes in technology make the

definition of ‘mobile device’ a moving target, for the

purposes of this paper the term mobile device will

imply a handheld computing device possessing a

display screen and input mechanism. This includes

cell phones and PDAs and in particular excludes

traditional desktop computers. In a study by

Zimmerman (2003) a virtual-reality presentation

using VRML was developed to illustrate the

construction of an origami figure. The study

compared the effectiveness of the presentation on a

traditional desktop computer to that on a PDA and

found little difference between the two platforms in

terms of errors in construction.

2.2 Object Complexity

We suggest that once we restrict the visual

representation to the depiction of a single step of the

assembly, the complexity of the task is largely

determined by the inherent complexity of the object

being assembled. Qualitative data from a prior study

(Zimmerman 2003) suggested 3D interactive

graphics were only differentially useful in situations

where the object was sufficiently complex. This

leads us to consider the question: what are the

characteristics that define complexity? For this

context specifically: what types of objects are

complex enough so that the use of interactive 3D

graphics enhances a user's ability to complete the

assembly with fewer errors and more rapidly as

compared to other traditional representations? We

posit the following list of potential characteristics:

• Number of parts

• Amount of symmetry

• Number of distinct part types

• Relative orientation (in 3D space) of parts

• Proximity of parts relative to one another.

• Volume of space which parts occupy

The issues discussed above have led us to

investigate the use of interactive 3D graphics on

mobile devices in the presentation of instructions for

an assembly task. This study is discussed in the next

section.

3 RESEARCH STUDY

Our study was motivated by the following two

questions

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

192

A B C

D

Figure 1: The 4 Lego Models.

1. How effective is the use of 3D graphics on a

mobile device in the presentation of instructions

for a construction task?

2. Can we identify object characteristics that

contribute to the difficulty of their assembly?

3.1 Materials and Task

To address the above two questions we selected for

our task the assembly of 4 separate Lego models. In

terms of complexity, we elected to focus on two

factors: symmetry and relative proximity of parts.

We controlled for total number of parts and number

of distinct part types by using the same collection of

20 pieces in each of the 4 models; 12 4x2 bricks, 4

2x2 bricks and 4 6x2 bricks. All bricks were a

medium brown color. All models consisted of 4

levels with at least 3 bricks in each level. The 4

models, designated A-D, were intended to exhibit

higher levels of complexity. Model A was

symmetric in 2 dimensions. Model B was symmetric

in 1 dimension. Models C and D possessed no

symmetry at all. Further, in model C, there were no

gaps between pieces within each level, while model

D was designed to have a high number of such gaps.

The models were designed to allow them to be

assembled level by level; all pieces from level one

were added first, then level 2, etc. Figure 1 shows

the four models along with the three piece types

used in the construction.

3.2 Assembly Instruction Presentation

The assembly instruction presentation was

implemented using VRML 2.0 (Virtual Reality

Modeling Language). This was largely a choice of

convenience since we had previously created a tool

which automated the process of creating VRML

Lego presentations for use in another study. Also, a

VRML 'browser' was readily available for our target

mobile device. Technical implementation details of

the tool and the modelling can be found in

(Zimmerman, 2006); here we give an overview of

what the user saw and how they interacted with the

presentation.

There were three principal visual components on

the display: a virtual building board, the user

animation/step interface and the individual Lego

bricks that collectively made the model. A simulated

sky/horizon was also implemented to provide a

spatial frame of reference for the building board.The

user moved through the steps by clicking the

forward/backward buttons on the interface. At the

beginning of each step the current piece to be added

to the model was shown on the display directly

above its correct position on the model. During each

step the user could initiate an animation of the brick

being correctly lowered into position. Alternatively,

the user could simply click the 'next' button and the

current piece would simply be added without the

animation. For all 4 models, all pieces within one

level were added before any pieces from higher

levels and pieces within a level were added in order

furthest from the default viewpoint first.

The 3D presentation was delivered on a Compaq

h3850 running Microsoft Pocket PC version 3. This

model used the SA1110 ARM processor with 64

megabytes of RAM. The VRML model was

rendered within Pocket Internet Explorer 5.5 with

the Pocket PC Cortona VRML client plugin. The

display screen measured 3.8 in (diagonal) with

resolution 240x320 with 16 bit color. The PDA was

placed in a cradle on a desk. Additional desk space

was provided for the subject to carry out the model

assembly. Subjects were free to move any of the

resources as they saw fit. The subjects used a stylus

to click buttons on the interface and to rotate the

SOME ASSEMBLY REQUIRED - Effectiveness Of Interactive 3D Graphics on Mobile Devices for Object Assembly

193

model (FR condition). The 3D presentation interface

is shown in Figure 2.

Figure 2: The 3D Presentation Interface.

3.3 Interaction Style

To provide a control group to help address the first

research question, two variations of the presentation

were provided: SV (static viewpoint) and FR (full

rotation). In the SV condition, the viewpoint was

fixed. Thus each step of the presentation was

analagous to a single-step, perspective view, action-

style assembly diagram, with the animation of the

piece being the action. The FR condition added the

ability of the subject to rotate the model freely in 3D

space using the navigation capability of the VRML

browser. The subject was also allowed to reset the

model's orientation to the intial one using the 'reset

viewpoint' feature of the browser.

3.3 Subjects

Nine subjects completed the task in each of the SV

and FR conditions. All of the subjects were graduate

students in Computer Science classes. Subjects were

permitted to move forward and backward through

the presentation steps at their discretion and as many

times as they wanted. There was no time limit for

the task. Subjects were shown all the features of the

user interface but were not given any guidance as to

how they should proceed. In other words, subjects

were free to use the presentation as it best suited

them.

3.4 Procedure

All of the subjects performed the task in a laboratory

at our University. Each subject completed the task

by themselves. Each subject completed a standard

psychometric spatial ability test and a biographical

survey which included questions about their prior

experience with Legos and 3D graphics. They then

received training on the use of the PDA interface for

their presentation. The training phase of the

protocols took about 10 minutes for each subject.

For each model to be constructed, each subject

received an empty 8x8 inch building board along

with a supply of Lego building bricks. A total of 6

brick types were provided; only 3 of which were

required to build the model. The other 3 were

'distractors' intended to demand increased attention

on the part of the subject in using the presentation.

The pieces were presorted into separate bins, with

more than enough pieces to complete each model.

Each subject is considered to have completed the

procedure and assembled a scoreable model if they

start the assembly procedure and declare themselves

to be finished.

Subject hands, the model and as much as

possible, the presentation on the screen were

videotaped. Subject assembly time was extracted

from the videotape and was defined as the time from

the moment that they started until they completed

the assembly task.

There were a total of 20 pieces in each model.

The first piece placed on the board was used a

reference point for all the remaining pieces. The

placement of a piece at a given step was scored as

one error if it was 1) an incorrect piece for that step

or 2) incorrectly positioned relative to the initial

reference piece.

4 RESULTS AND ANALYSIS

We considered the impact of the independent

variables: Model Complexity, Interaction Style and

Experience on two dependent variables: Number of

Errors and Assembly Time. The overall means and

standard deviations of these variables are shown in

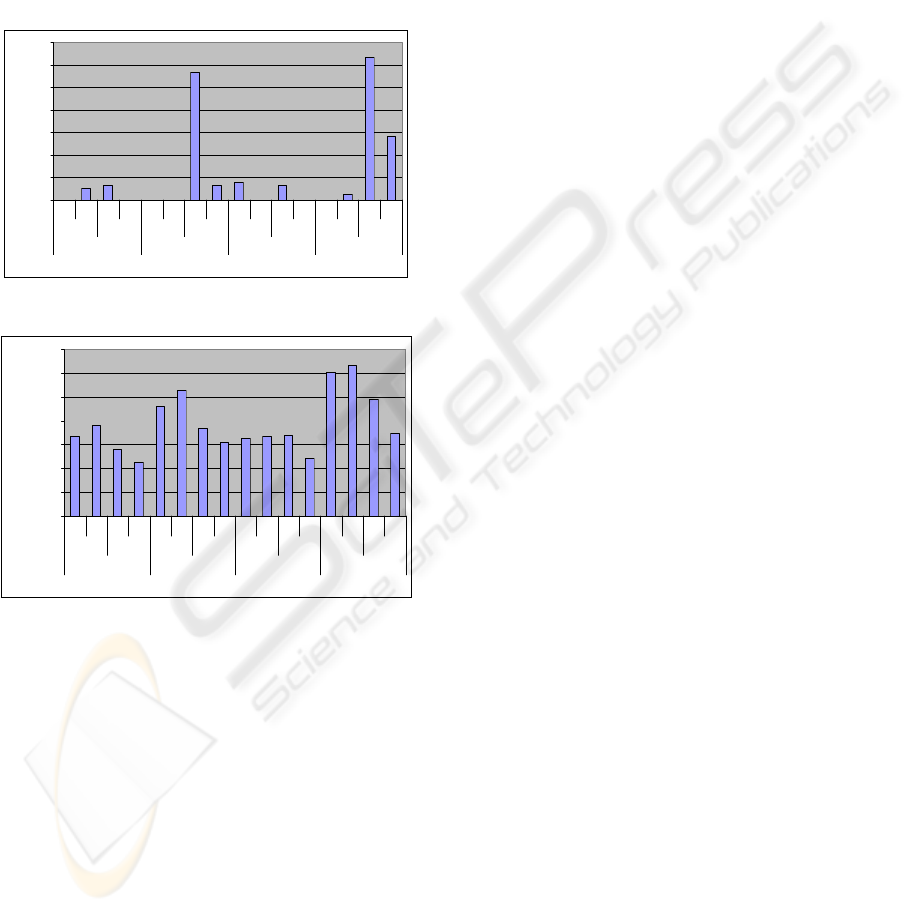

Tables 1 and 2. Figures 3 and 4 display the means

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

194

Table 1: Number of Errors.

Model Interaction Experience Mean Std dev N

A FR N 0.00 0.000 5

Y 0.50 1.000 4

Total 0.22 0.667 9

SV N 0.67 1.155 3

Y 0.00 0.000 6

Total 0.22 0.667 9

Total N 0.25 0.707 8

Y 0.20 0.632 10

Total 0.22 0.647 18

B FR N 0.00 0.000 5

Y 0.00 0.000 4

Total 0.00 0.000 9

SV N 5.67 6.028 3

Y 0.67 1.633 6

Total 2.33 4.123 9

Total N 2.13 4.357 8

Y 0.40 1.265 10

Total 1.17 3.073 18

C FR N 0.80 1.789 5

Y 0.00 0.000 4

Total 0.44 1.333 9

SV N 0.67 1.155 3

Y 0.00 0.000 6

Total 0.22 0.667 9

Total N 0.75 1.488 8

Y 0.00 0.000 10

Total 0.33 1.029 18

D FR N 0.00 0.000 5

Y 0.25 0.500 4

Total 0.11 0.333 9

SV N 6.33 0.577 3

Y 2.83 2.483 6

Total 4.00 2.646 9

Total N 2.38 3.292 8

Y 1.80 2.300 10

Total 2.06 2.711 18

of each condition in a bar chart. In both the tables

and figures, A-D refer to the models, FR/SV refer to

the interaction style, and Y/N refers to user's prior

experience with Legos.

For Errors we found three significant main

effects. 1) Model Complexity F(3,12) = 7.19 p < .01;

the means suggest that Model D was the most

difficult and from the test we know that complexity

(as measured by number of errors) is different

among the 4 models. 2) Interaction style F(1,16) =

20.77, p=0; the means suggest that subjects made

fewer errors with the FR interaction style. 3)

Experience F(1,16)=8.69, p<.01; the means indicate

the subjects with Lego experience made fewer

errors. We also found two significant interactions.

Table 2: Assembly Times.

Model Interaction Experience Mean Std dev N

A FR N 336.20 87.159 5

Y 380.25 84.673 4

Total 335.78 83.821 9

SV N 280.67 164.755 3

Y 224.17 64.750 6

Total 243.00 101.017 9

Total N 315.38 113.677 8

Y 286.60 105.904 10

Total 299.39 107.122 18

B FR N 461.00 135.757 5

Y 528.75 139.972 4

Total 491.11 133.556 9

SV N 368.33 50.560 3

Y 308.67 141.871 6

Total 328.56 118.780 9

Total N 426.25 116.456 8

Y 396.70 175.012 10

Total 409.83 148.418 18

C FR N 326.60 31.350 5

Y 336.50 60.523 4

Total 331.00 43.500 9

SV N 340.33 84.642 3

Y 240.83 80.041 6

Total 274.00 90.941 9

Total N 331.75 51.566 8

Y 279.10 84.975 10

Total 302.50 75.116 18

D FR N 605.00 200.400 5

Y 631.25 35.538 4

Total 616.67 144.031 9

SV N 488.67 67.530 3

Y 347.17 130.665 6

Total 394.33 129.678 9

Total N 561.38 166.963 8

Y 460.80 177.277 10

Total 505.50 175.388 18

The interaction between Model Complexity and

Interaction Style: F(3,12)=9.22, p<.01. For more

complex models, subjects with FR did better than

subjects with SV. Also, in terms of Errors, we found

a significant interaction between Interactivity and

Experience: F(1,16)=8.51, p<.01. That is, the FR

interaction was differentially more helpful to less

experienced subjects.

We also found two significant main effects for

Assembly Time. For Model Complexity

F(3,12)=18.3, p=0; the models had different

complexity as measured by completion time – more

difficult problems took longer. For Interaction Style

F(1,16)=12.7, p<.01, indicating the subjects were

able to complete the tasks in less time using the FR

interaction style. There were no significant

interactions.

SOME ASSEMBLY REQUIRED - Effectiveness Of Interactive 3D Graphics on Mobile Devices for Object Assembly

195

Finally, for the FR interaction we examined the

correlation between spatial ability (as measured by a

standard psychometric test) and the use of 1) the

rotation feature and 2) the animation feature. There

was a positive significant correlation (r=.810)

between spatial ability and subject's use of the

animation feature. High spatial ability subjects used

the feature significantly more. There was a negative

correlation (r=-.748) between spatial ability and the

use of the rotation feature. Low spatial ability

subjects relied on the feature significantly more.

0,00

1,00

2,00

3,00

4,00

5,00

6,00

7,00

NYNYNYNYNYNYNYNY

FR SV FR SV FR SV FR SV

ABCD

Model, Interaction, Experience

Errors

Figure 3: Mean Error Counts.

0.00

100.00

200.00

300.00

400.00

500.00

600.00

700.00

NYNYNYNYNYNYNYNY

FR SV FR SV FR SV FR SV

ABCD

Model, Interaction, Experience

Figure 4: Mean Assembly Times.

In terms of the research questions, we see that

users with the FR condition made fewer errors and

completed the task in less time. This suggests that

using 3D interactive representations as a component

of assembly instructions on a mobile device was

effective. Also, we can see from figures 3 and 4 that

the 4 models do exhibit varying degrees of

complexity as measured by Number of Errors and

Assembly Times and that these two measures 'agree'

on the ordering: A and C near equal in complexity,

followed by B, then D. In terms of visual

characteristics, it seems that the number of 'gaps'

between the pieces is the best predictor of

complexity and symmetry mattered less so.

5 SUMMARY

We examined the utility of interactive 3D graphics

as a component of a system to deliver instructions

for an assembly task – assembling Lego models. The

study results indicate that the presentation of models

with many gaps between the pieces were more

difficult to follow than was the case for models with

fewer gaps. However, being able to interact with the

model mitigated the complexity: even for small

examples such as these, the use of interactive 3D

graphics seems to be worth it.

ACKNOWLEDGEMENTS

This work was supported in part by the New Media

and Emerging Technologies initiative at Bowling

Green State University.

REFERENCES

Agrawala, M., et al., 2003. Designing effective Step-By-

Step Assembly Instructions. ACM Transactions on

Graphics, 22(3). 828-837.

Kashiwazaki, K., Kikuta, Y., Ohigashi, M., and Tanaka,

Y. 2005. Interactive 3D learning contents based on 3D

meme media architecture. In Proceedings of the 4th

international Symposium on information and

Communication Technologies, 92, 14-19.

Nousch, M., Jung, B., (1999). CAD on the World Wide

Web: Virtual Assembly of Furniture with BEAVER.

Proceedings of the Fourth Symposium on Virtual

Reality Modeling Language, 113-119.

Novick, L and Morse, D, Folding (2000). Folding a fish,

making a mushroom: The role of diagrams in

executing assembly procedures. Memory & Cognition

28, 1242-1256.

Tang, A., Owen, C., Biccca, F. and Mou, W.,

2003.Comparative Effectiveness of Augmented

Reality in Object Assembly. Proceedings of CHI 2003,

5(1), 73–80.

Virtual Manuals, http://www.parallelgraphics.com/virtual-

manuals/

Zimmerman, G., Barnes, J., Leventhal, L. , 2003. A

Comparison of the Usability and Effectiveness of

Web-Based Delivery of Instructions for Inherently-3D

Construction Tasks on Handheld and Desktop

Computers. Proceeding of the Eighth International

Conference on 3D Web Technology, 49-54.

Zimmerman, G. 2006 A Tool for the Automatic Creation

of Animated VRML Lego Model Assembly Task

Presentations. BGSU Department of Computer

Science Technical Report May-01-06.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

196