USING 3D FEATURES TO EVALUATE CORK QUALITY

Beatriz Paniagua-Paniagua

1

, Miguel A. Vega-Rodríguez

1

, Hiroshi Nagahashi

2

Juan A. Gómez-Pulido

1

and Juan M. Sánchez-Pérez

1

1- Dept. Technologies of Computers and Communications. Extremadura University

Escuela Politécnica. Campus Universitario, s/n. 10071. Cáceres. Spain

2- Imaging Science and Engineering Laboratory. Tokyo Institute of Technology

R2-51, 4259 Nagatsuta-cho, Midori-ku, Yokohama 226-8503, Japan

Keywords: Image processing, cork quality classification, 3D feature extraction.

Abstract: In this paper we study different 3D features in cork material. We do this in order to solve a classification

problem existing in the cork industry: the cork stopper/disk quality classification. Cork Quality Standard

sets seven different cork quality classes for cork stopper classification. These classes are based on a

complex combination of cork stopper defects. In previous studies we only analysed those features that could

be detected/acquired with a 2D camera. In this study we work in a 3D environment, in order to extract those

features that we could not be extracted in a 2D approach. As a conclusion we can say that the most

important 3D cork quality detection feature takes into account dark and deep cork areas (usually, these areas

indicate deep and important defects). Furthermore, the 3D features have widely improved the results

obtained by similar features with a 2D approach, due to the 3D approach includes more information. This

fact allows us to extract more complex features, as well as improve the classification results.

1 INTRODUCTION

Oak is a tree that mostly grows in the western shores

of the Mediterranean Sea. Because of this fact, the

cork industry has a big economic importance and

great research interest in the native zones of this

material.

The most important industrial application of cork

is the production of disks and stoppers for sealing

wines, ciders, and champagnes. In the cork industry,

stoppers and disks are classified in different quality

classes based on a complex combination of its

defects. Due to this high heterogeneity degree,

traditionally, the classification process has been

carried out by human experts manually.

At the moment, there are several models of

electronic machines for the cork stoppers

classification in the market. The performance of

these machines is acceptable for high quality

stoppers/disks, but for medium or low quality, the

number of samples classified erroneously is large. In

conclusion, the stoppers/disks should be re-

evaluated by human experts later. This increases the

process price and the production time because a

human expert needs a minimum training period of 6

months to attain minimum classification accuracy,

although the learning process can last years.

Furthermore, a human classifier can introduce some

mistakes on the classification due to his/her

subjectivity degree. In conclusion, more research

efforts are necessary in the automatic cork

classification field.

We have to add to these reasons the fact that

Spain produces 31% (ASECOR, 2006) of the

worldwide cork. All these motivations have lead us

to the development of this research, whose final

main objective is the construction of a computer

vision system for cork classification based on

advanced methods of image processing and feature

extraction in order to avoid the human evaluation in

the quality discrimination process.

In this work we try to prove the accuracy of new

3D features in cork quality classification. In

previous works (Paniagua-Paniagua et al, 2006a;

Paniagua-Paniagua et al, 2006b), a wide study about

feature extraction was made. Now, we try to analyse

the automatic feature extraction of cork quality,

within a 3D approach. We have focused this study

on feature extraction, and several new cork quality

3D features have been obtained. We will test the

79

Paniagua-Paniagua B., A. Vega-Rodríguez M., Nagahashi H., A. Gómez-Pulido J. and M. Sánchez-Pérez J. (2007).

USING 3D FEATURES TO EVALUATE CORK QUALITY.

In Proceedings of the Second International Conference on Signal Processing and Multimedia Applications, pages 79-84

DOI: 10.5220/0002136700790084

Copyright

c

SciTePress

performance for each 3D feature, to see the

individual reliability of each quality discriminator.

However, the main final objective is the

development of a system that uses a complex

combination of features to make the automatic cork

quality classification.

The rest of the paper is organized as follows:

section 2 describes briefly the acquisition system

and data we have used. In section 3 we present the

theoretical bases of this work. Section 4 shows the

results and statistical evaluation for the new 3D

features studied, while section 5 exposes the final

conclusions.

2 TOOLS AND DATA

As a first step, we need to acquire again all the

images in our Cork Image Database (CID), but in

this case with a 3D approach. For this purpose, we

have used a total of 350 cork disks (there are seven

different quality classes, 50 disks per class).

Furthermore, a laser camera system of the

ShapeGrabber Company was used (ShapeGrabber,

2005a; ShapeGrabber, 2005b). The storage is made

with “3pi” files, created by the ShapeGrabber

Software to represent scanned data in ASCII.

When scanning with the ShapeGrabber system,

the data are acquired following the rule: one profile

at a time. A profile is the data collected from the

processing of one full laser line. The points are

ordered in a profile in ascending order along the X-

axis. For each of these points, the coordinates of the

point (x, y, and z), the intensity value and the order

of the point in the profile are given. We will use this

information to extract the 3D cork quality features in

which this paper is focused on.

3 METHODS

This is the methodology we have followed in this

research.

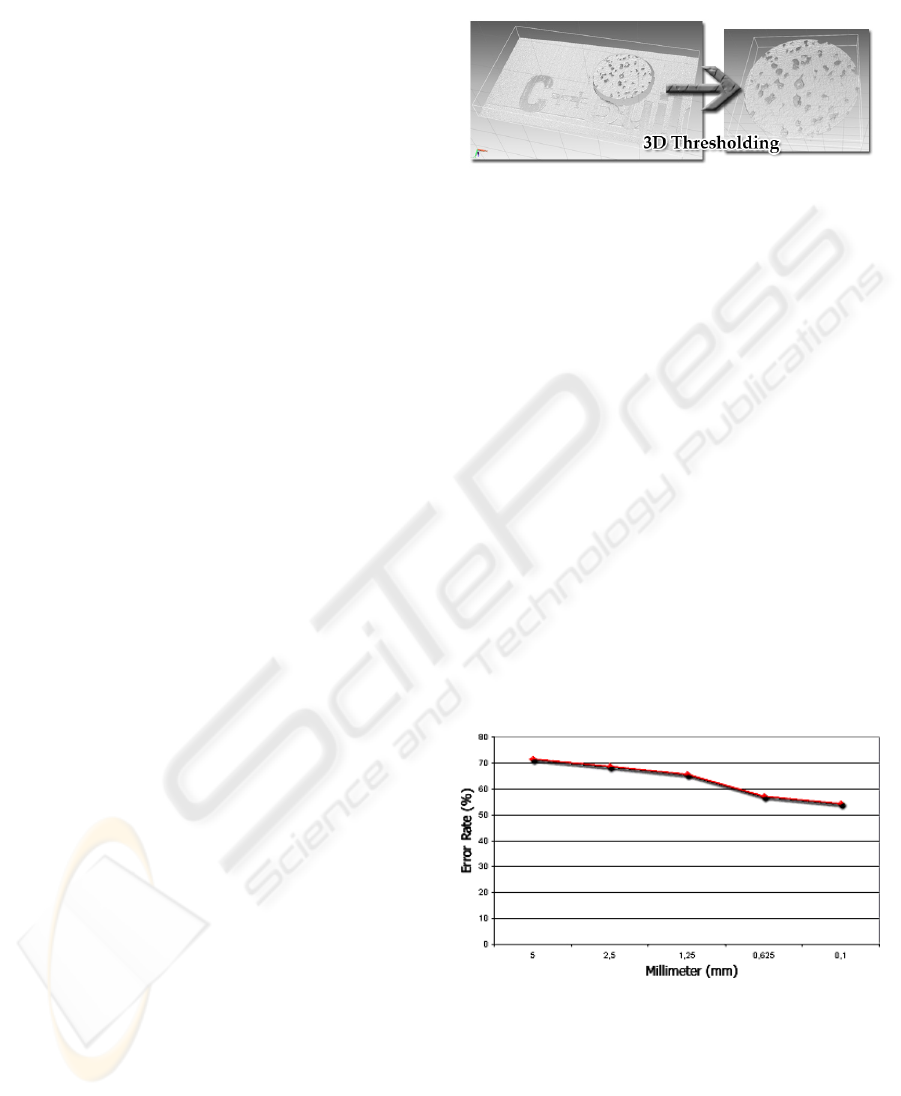

3.1 Background Thresholding

After the data acquisition and before going further in

our research, an automatic thresholding algorithm

was developed. This was made because the acquired

images had some superfluous areas (acquisition

surface that does not correspond to cork, see figure

1) that we needed to remove from each of the 3D

images in our CID. That is, we needed to delete the

background from the 3D cork images, in order to

perform the 3D feature extraction research.

Figure 1: 3D images before and after the 3D thresholding.

To do that, we only consider those 3D points that

have a lower depth of Z-axis value than those points

that belong to the background.

3.2 Initial Feature Extraction

The following step was the extraction of a 3D

feature suitable for doing some preliminary tests

with our 3D laser camera. Concretely, the feature

extracted is conformed by the percentage in the cork

area occupied by 3D points that are not only dark

(intensity) but also deep (coordinate Z). A cork

stopper with a high value in this feature will glimpse

having a low quality, because the higher this value

is, more deep defects will exist within the cork.

3.3 Resolution Study

Then, we decided to develop an initial study to

discover the optimal resolution value for using the

3D laser-camera in the acquisition of cork images.

Figure 2: Decreasing error rate tendency when the

resolution increases.

Figure 2 shows the error rate obtained in the cork

quality classification, using the previous 3D feature

and a minimum Euclidean Distance classifier. We

can see that when the resolution increases, the error

rate decreases.

SIGMAP 2007 - International Conference on Signal Processing and Multimedia Applications

80

3.4 Classification Criterion Selection

Our classification system acquires images from both

heads of the stopper/disk (see figure 3). Because of

that fact, we have carried out studies in which, using

our initial 3D feature (see section 3.2), we have

selected the optimal stopper-head criterion. The

three studied criteria are:

- The feature is computed by choosing the best

result obtained between both heads in the acquisition

process. The final error rate for this criterion was

59.42%.

- The feature is computed by choosing the worst

result obtained between both heads in the acquisition

process. The final error rate in this case was 70.28%.

- The feature is computed by choosing an

average value from the two obtained in both heads.

That is, we have to obtain the feature for each head

and make an average between them. In this situation

we obtained the best classification, being the error

rate 52.57%.

Figure 3: The two heads of a cork stopper/disk.

In conclusion, the best classification criterion is

the one that contemplates an average value between

both stopper heads. We have used it in all our

experiments.

3.5 3D Features Extraction

After making the acquisition of our whole CID with

the optimal resolution (in this case, the highest for

our 3D camera, 0.1 mm), we perform the last and

most important stage: extraction and

experimentation of new 3D cork quality features.

The studied features have been designed in a

heuristic way, by analizing the human experts

classifications and considering the visual features

they choose in their classifications. The conclusions

of this analysis make us chose the following 3D

features for our research:

Maximum depth of the defects within the cork

surface (and some variants).

Weighted sum of the defects according to their

relative depth.

Amount of defect pixels in a concrete depth

level.

4 RESULTS

All the results in this section have been obtained by

using a classifier of minimum Euclidean distance

(Shapiro and Stockman, 2001). We will use

confusion matrix in order to show the results.

As for the maximum depth of the defects, it seems

logical to think that the depth of the defects (cracks

and holes) will make a differentiation between the

different cork quality classes, because usually the

deeper a defect is, the more important this defect is.

However, the obtained results are not as good as we

expected (table 1). There is not tendency towards the

main diagonal in the confusion matrix, and all the

classifications are around classes 0 and 5. The error

rate is high (table2), being 80.28%.

Table 1: Confusion matrix for the Maximum Depth.

C0 C1 C2 C3 C4 C5 C6

C0

21 4 4 2 3 15 1

C1

15 2 6 2 1 24 0

C2

20 3 4 1 1 21 0

C3

14 5 3 2 3 23 0

C4

9 2 2 4 4 29 0

C5

9 2 2 1 0 36 0

C6

3 2 2 2 0 41 0

Table 2: Final results for the Maximum Depth.

C0 C1 C2 C3 C4 C5 C6 TOT.

Right 21 2 4 2 4 36 0

69

Wrong 29 48 46 48 46 14 50

281

Because of the bad results obtained, we decided

to make an observation of the 3D data in our

database. Doing this we realized that it could be

possible that the bad results were produced by a side

deviation in some cork stoppers. This fact makes the

cork stopper sides irregular for the research, as we

show in figures 4 and 5.

USING 3D FEATURES TO EVALUATE CORK QUALITY

81

Figure 4: Deviations in the head surface of the cork disk.

Figure 5: Deviations in the lateral side surface of the cork

disk.

But this fact is not strange in industrial

environments, due to the cork stoppers production

machines can introduce some mistakes in some

stoppers, and because cork is a porous material to

which the environmental temperature can affect.

Due to these deformations in the data, it was decided

to make some additional experimentation with this

3D feature. In this new set of experiments we added

two important details to the 3D max depth feature:

(a) We only considered the very dark pixels (these

are clearly defects, and there is not confusion with

the deviated sides); (b) Searching for a depth level

that was representative, we considered as maximum

depth level the maximum depth with at least X dark

pixels. That is, we were looking for big deep areas.

We tested in our research several different values for

X: 10, 25, 50, 100, 150, 175, 200,… Figure 6 shows

the results obtained.

As we can see, for the experiment detailed, the

best results were obtained in case of X = 200, that is,

the maximum depth must have at least 200 dark

pixels (error rate = 78%). This value is clearly an

inflection point in the graph.

An error rate of 78% improved our previous result

(80.28%) but it was still a bad result. For this reason,

a second set of experiments was made (figure 7). In

this case, we apply the inverse reasoning: we search

for a maximum depth with not a lot of pixels,

because it seems normal that there are not many very

deep defects in a cork stopper, and if many deep

defects exist maybe this can be a cluster of pixels

due to a cork side deviation and not due to defects.

Figure 7 presents the results obtained. Almost all the

experiments obtain the same result, an error rate of

66.28%.

Figure 6: First set of experiments with the maximum

depth.

This is the best result we have obtained with the

maximum depth feature. Observe that cork

classification is different from other classification

problems, such as character recognition: even a

human expert, sometimes, can not make a clear

decision about if a stopper/disk absolutely belongs to

a certain class or a contiguous one. Therefore, using

only one classification feature (the maximum depth)

and for this complex classification problem, an error

rate of 66.28% is an encouraging result.

Figure 7: Second set of experiments with the maximum

depth.

Regarding the weighted sum of the defects

according to their relative depth, we use equation 1.

For this 3D feature, we have divided the cork

stopper pixels in 7 different depth levels (from 0 to

6), being p

x

in the equation the amount of pixels in

the X depth level. Each level supposes a different

weight in the final sum (if the pixel is deeper, the

defect associated with this pixel will be more

serious). This feature was chosen in order to

consider the possible severity of cork defects. Thus,

the greater depth level is, the bigger the severity of

those defects is.

SIGMAP 2007 - International Conference on Signal Processing and Multimedia Applications

82

(1)

Table 3 shows the confusion matrix obtained by this

3D feature, while table 4 shows its final results. The

confusion matrix offers very good results. The

tendency towards the main diagonal is very clear,

except for class 5 due to the influence of classes 4

and 6. The error rate obtained with this feature is

51.14%. This result improves the results we have

obtained in previous works (Paniagua-Paniagua et

al, 2006a; Paniagua-Paniagua et al, 2006b), showing

the importance of using 3D features, and not only

2D features in the cork classification.

Table 3: Confusion matrix for the Weighted Depth.

C0 C1 C2 C3 C4 C5 C6

C0

35 14 1 0 0 0 0

C1

20 22 7 1 0 0 0

C2

1 10 29 10 0 0 0

C3

0 1 14 33 1 1 0

C4

0 0 1 12 22 4 11

C5

0 0 0 4 20 6 20

C6

0 0 1 4 13 8 24

Table 4: Final results for the Weighted Depth.

C0 C1 C2 C3 C4 C5 C6 TOT.

Right 35 22 29 33 22 6 24

171

Wrong 15 28 21 17 28 44 26

179

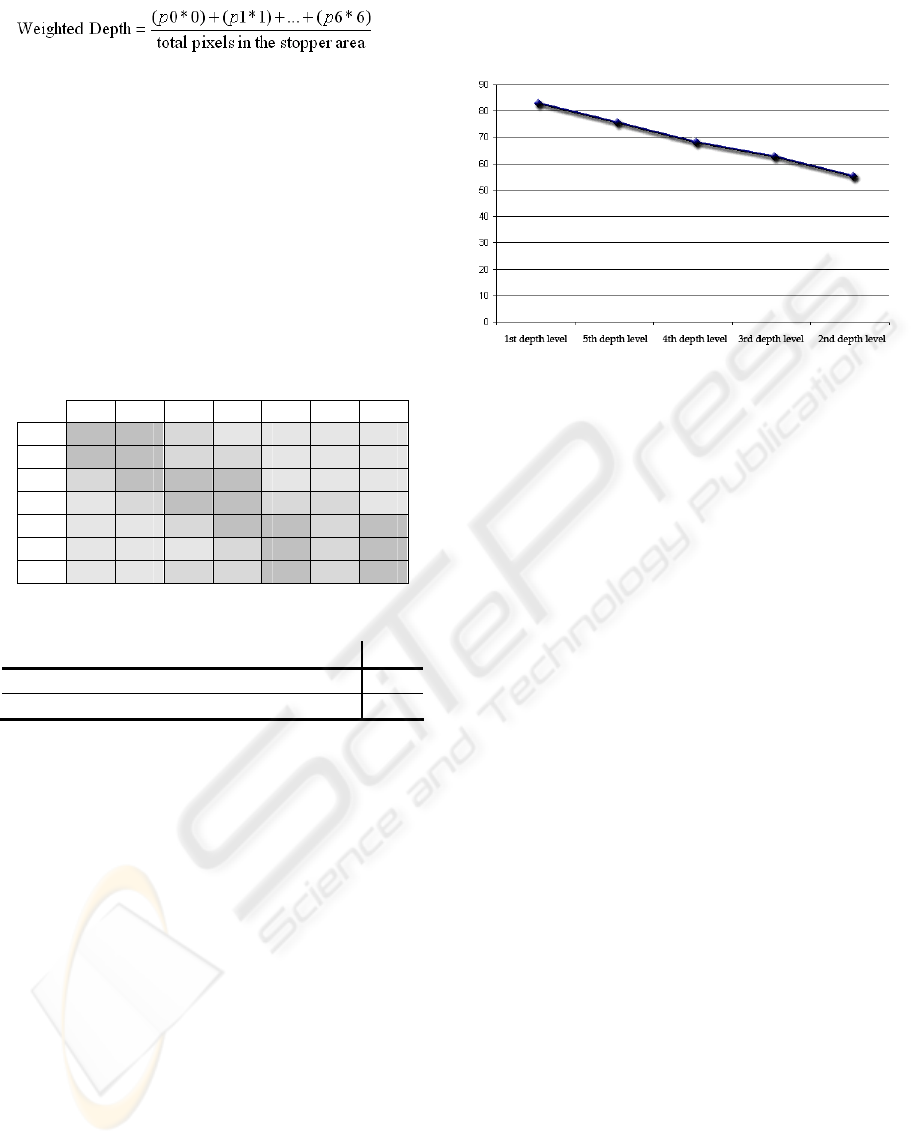

Finally, we evaluate the 3D feature that considers

the amount of defect pixels in a concrete depth level.

With this study we want to know if there is some

depth level among the defects that is more important

in order to obtain a good classification results. In

this case we study 5 different depth levels (from 1 to

5): level 0 is not studied because it has not a real

importance, being not a defect but the cork surface;

in the same way, depth level 6 is not considered

because there are not so much pixels for this level in

most 3D cork images. Figure 8 displays the final

results (error rates after doing a cork classification

only based on the defect pixels in a concrete depth

level).

Thanks to this study we have empirically proved

that the different depth levels have different

importance in cork quality classification. We can see

that the extreme levels (1 and 5) are the levels with

less importance (the worst classification results), and

that the defects with a medium depth are the most

important in the classification process. In particular,

the defect pixels in the second depth level are those

that have more importance, obtaining this feature the

best result (error rate = 55.42%).

Figure 8: Final results (error rates) for the depth levels

study.

5 CONCLUSIONS

The study in the 3D field has improved our cork

quality classification. We think this is because in this

field the extracted features can be more complex and

give more information about the cork quality that

those obtained in a 2D environment. After making a

deep study about different 3D cork quality features,

the obtained results are those displayed in figure 9.

Observe that all the 3D features have obtained

certain discriminatory information that improves the

cork classification according to its quality (all the

features obtain better results than the random

classification), although the goodness of the

obtained results widely varies. The best result is

produced by using the 3D feature “Weighted Depth”

(error rate = 51.14%). This result improves our

previous works (Paniagua-Paniagua et al, 2006a;

Paniagua-Paniagua et al, 2006b), where the best

error rate obtained was 65.71%, because of the

complex conditions of heterogeneity and

overlapping in this classification problem.

Moreover, our result even improves other related

works, in which the best error rate was 57.5%

(Chang et al, 1997). For all these reasons, the result

obtained in this research is a very encouraging

result. On the other hand, the 3D features offer us

new classification details that could not be perceived

with our previous 2D works.

USING 3D FEATURES TO EVALUATE CORK QUALITY

83

Figure 9: Summary of all the results (error rates) obtained

with this study of 3D features.

As future work, we will improve the performance

of the system (processing time) by using FPGAs

(Vega-Rodríguez et al, 2004), and we will extend

our research to other classification factors, as Gabor

Wavelets (Tang et al, 2003).

ACKNOWLEDGEMENTS

This work has been developed in part thanks to the

OPLINK project (TIN2005-08818-C04-03).

REFERENCES

ASECOR (Agrupación Sanvicenteña de Empresarios del

CORcho), 2006. Production statistics in the term 2006,

http://www.asecor.com.

Chang J., Han G., Valverde J. M., Griswold N. C., Duque-

Carrillo J. F., Sánchez-Sinencio E., 1997. Cork

Quality Classification System using a Unified Image

Processing and Fuzzy-Neural Network Methodology.

In IEEE Trans. on Neural Networks, 8(4), pp. 964-

974.

Paniagua-Paniagua B., Vega-Rodríguez M.A., Gómez-

Pulido J.A., Sánchez-Pérez J.M., 2006a. Comparative

Study of Second-Order Gray Level Texture Statistics

to Evaluate Cork Quality. In The 6th IASTED

International Conference on Visualization, Imaging,

and Image Processing, Palma de Mallorca, Spain pp.

447-452.

Paniagua-Paniagua B., Vega-Rodríguez M.A., Gómez-

Pulido J.A., Sánchez-Pérez J.M., 2006b. Comparative

Study of Thresholding Techniques to Evaluate Cork

Quality. In The 6th IASTED International Conference

on Visualization, Imaging, and Image Processing,

Palma de Mallorca, Spain pp. 441-446.

ShapeGrabber Inc., 2005a. ShapeGrabber CentralTM

Manual.

ShapeGrabber Inc., 2005b. ShapeGrabber Laser System

SG Series Manual.

Shapiro L.G., Stockman G.C., 2001. Computer Vision, Ed.

Prentice Hall, New Jersey.

Tang L., Tian L., Steward B.L., 2003. Classification of

Broadleaf and Grass Weeds Using Gabor Wavelets

and an Artificial Neural Network. In Transactions of

the American Society of Agricultural Engineers, vol.

46, no. 4, pp. 1247-1254.

Vega-Rodríguez M.A., Sánchez-Pérez J.M., Gómez-

Pulido J.A., 2004. Using Computer Vision and FPGAs

in the Cork Industry. In IEEE Mechatronics and

Robotics 2004, MechRob'04, Aachen, Germany, pp.

265-270.

SIGMAP 2007 - International Conference on Signal Processing and Multimedia Applications

84