OOPUS

A Production Planning Information System to Assure High Delivery Reliability

Under Short-term Demand Changes and Production Disturbances

Wilhelm Dangelmaier, Tobias Rust, Thomas Hermanowski

Heinz Nixdorf Institut, Universität Paderborn, 33102 Fürstenallee 11, Paderborn, Germany

Daniel Brüggemann, Daniel Kaschula, Andre Döring, Thorsten Timm

Fraunhofer-ALB, Fürstenallee 11, 33102 Paderborn, Germany

Keywords: Production planning, production control, ERP, GUI, MLCLSP, Gantt chart, cumulative quantity table,

usability.

Abstract: Batch-sizing and scheduling is the central decision problem in the area of production planning. A special

challenge in this context is to handle the big amount of data in an adequate time interval. To aggregate and

to illustrate this data clearly, appropriate techniques are required. This paper presents a new approach to

integrate a Production Planning Table visualized by a Gantt chart and a cumulative quantity table for

maximum information transparency in production planning. The discussed solution is realized in OOPUS,

an object-oriented tool for planning and control, which became the leading production planning system in

two motor assembly plants of an international automobile manufacturer.

1 INTRODUCTION

The last years in the automotive industry were

affected by a strong trend towards decreasing life

cycles of products and at the same time increasing

time of innovation ongoing with a continuous

diversification of the product range. Furthermore the

pressure of competition increased dramatically due

to weakened purchasing power of customers, a

decreasing customer-specific brand affinity and

permanent changes of the market and customer

requirements (Harjes et al., 2004). In order to stay

competitive, automobile manufacturers have to

produce their products in high quality and at low

costs in even shorter time. A crucial meaning to

withstand these challenges belongs to ERP systems,

which control, standardize and optimize the business

processes along the whole value chain (Holland and

Light, 1999). An essential factor to achieve this goal

is the batch-sizing and scheduling. To satisfy the

changing demands the existing schedule has to be

adapted regularly. Under the objective of

minimizing the production costs and stocks, batch-

sizing and scheduling is a complex problem.

Depending on the type of production there are

many factors to be considered. These could be time-

dependent demands, capacities of production lines,

stocks, buffers, qualifications of workers, set-up-

and lead-times, stockouts, backlocks, alternative or

parallel identical machines, batch size and transport

restrictions as well as different shift calendars

(Tempelmeier, 2006; Stammen-Hegener, 2002).

Based on the resulting production plan, demands of

secondary and tertiary parts can be derived and the

capacity utilization analysed. If necessary, it should

be possible to adjust capacities within a short time.

In order to cope with this challenge, data from

several sources has to be related to each other and to

be presented to the user of an ERP system.

In the following a holistic solution for this

problem, called OOPUS (germ. Objektorientierte

Planung und Steuerung - object-oriented planning

and control), will be described in detail. This

information system was developed to meet the

specific requirements of an international automobile

manufacturer. Nowadays OOPUS is the leading

production system within two plants.

423

Dangelmaier W., Rust T., Hermanowski T., Brüggemann D., Kaschula D., Döring A. and Timm T. (2007).

OOPUS - A Production Planning Information System to Assure High Delivery Reliability Under Short-term Demand Changes and Production

Disturbances.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - DISI, pages 423-430

DOI: 10.5220/0002384504230430

Copyright

c

SciTePress

2 PROBLEM DEFINITION

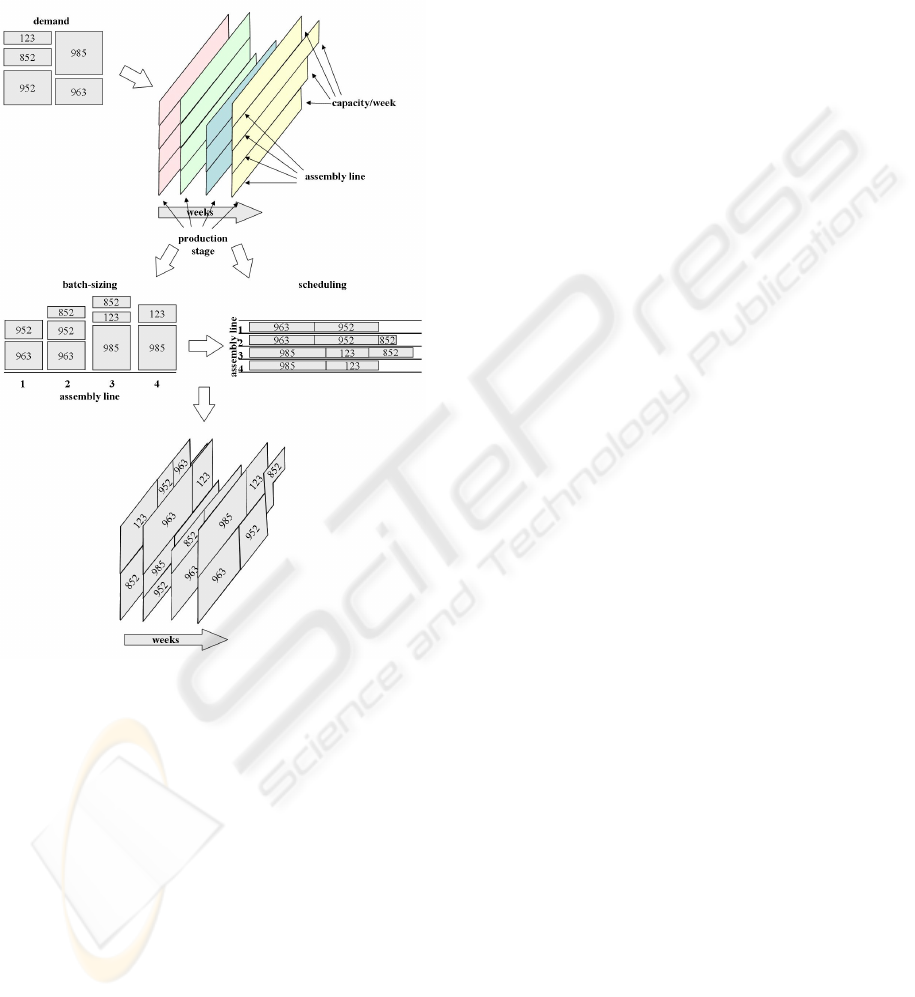

Production planning is a two-step process (see

Figure 1). First, suitable batch-sizes have to be

determined based on time-dependent demands. Then

an optimal schedule has to be generated.

To determine appropriate batch-sizes in OOPUS,

the Multi-Level-Capacitated Lot-Sizing Problem

(MLCLSP) (Katok et al., 1998; Tempelmeier, 2003)

has to be modified. On the basis of a standard-

MLCLSP, extensions like parallel identical

machines and the initial and final inventory are

required.

The MLCLSP is an np-complete problem and

can therefore not be solved with an optimizer in

appropriate time (Maes et al., 1991). Hence, a

suitable heuristic has to be designed.

Due to the changing capacities of machines

scheduling is also a very complex problem. Each

shift of a batch requires a recalculation of the batch

length and the completion date. Under the

requirement of optimal scheduling subject to set-up

times and stocks, this problem can not be solved

with an optimizing algorithm. For this reason, an

appropriate heuristic (like a priority rule procedure)

is required.

Due to these heuristics and the multiplicity of

not forecasted influences (e.g. urgent orders or

changes of demand quantities) this information has

to be represented transparently. This enables the

responsible planner to reconstruct and manually

reschedule the production plan in an adequate way.

Production planning systems are characterized

by an enormous complexity of information which is

often distributed in different isolated software

solutions. But this complexity not only arises

because of the quantity of all relevant elements, but

in particular also from their mutual cross-linking.

Without an adequate information system, this

complexity implicates high requirements of the users

ability to collect and integrate information and to

evaluate and plan actions. Hence it is decisive for an

easy handling of this complex data that it is

presented in an aggregated and clearly arranged (i.e.

user-friendly) form. Beside the aggregation and

visualization of this data, the timeliness of the data is

also critical. For this reason the data have to be

synchronized in real time with the different sources.

This ensures a reliable planning and an adequate

change management.

3 STATE OF THE ART

3.1 Getting an adequate ERP System

The market consists of a multiplicity of standardized

ERP systems, which offer solutions for a large part

of production planning and control tasks, such as

requirement planning, batch-sizing and scheduling

and stock-keeping. However, analyses of these ERP

systems in detail shows some disadvantages. The

standardization of the planning procedures of a

production system often does not correspond exactly

with the functionality required by the customer.

Adjustments of these procedures are often not

possible or very expensive and time-consuming.

Apart from costs based on consulting and

implementation activities, further costs of worker

qualifying measures evolves. Additionally, the

standardization of software often implicates a bad

usability concerning special requirements, which can

affect the acceptance of the system and increases the

qualification time, especially of inexperienced users.

Another problem is the integration of a

standardized system into an existing IT-landscape.

Especially in big enterprises the IT-landscape often

Figure 1: Process of

b

atch-sizing and scheduling.

ICEIS 2007 - International Conference on Enterprise Information Systems

424

consists of a large number of different isolated

software solutions, which mostly cannot be changed

completely due to the current economic situation.

3.2 Representation of Planning Data

There exist different concepts for appropriate

representation of planning data in ERP systems.

Most providers of ERP systems use Gantt charts

for displaying a schedule graphically (Wilson,

2003). A Gantt chart consists of a horizontal bar

chart with time intervals and either resources,

operations or orders as the vertical axis. Individual

operations (e.g. batches) are displayed as horizontal

bars in the chart, indicating the time at which the

operation begins and ends. The disadvantage of a

Gantt chart is that at a large number of batches the

representation is not clear and it is very difficult to

get information about the entire processing status.

The cumulative quantity concept (Schönsleben,

2004) is a representation used in serial production to

show changes of dates and quantities clearly. The

concept is based on cumulated parts, related to a

certain time (e.g. an inventory deadline). By these

cumulative quantities, planned and actually realized

quantities of parts can be compared. The difference

of the target cumulative quantity (TCQ) and the

actual cumulative quantity (ACQ) points a

quantitative advance (TCQ < ACQ) or a quantitative

deficit (TCQ > ACQ) in relation to the given

demands. Particularly in the case of planning and

controlling large quantities of parts, the use of

cumulative quantities is a suitable concept (Kurbel,

2005).

4 OOPUS

Based on the requirements defined in chapter 2 the

software OOPUS has been developed. Thereby

experiences from an earlier project called OOPUS-

DPS (Dangelmaier et al., 1997/99), which operates

successfully at a big automotive supplier since a few

years, were used. A detailed description of the

underlying model that fits all specific requirements

would exceed the scope of this paper, but can be

found in (Dangelmaier et al, 2007). As a main focus,

a user friendly graphical user interface consisting of

a planning table and a cumulative quantity table was

designed to support the planer in all areas of his

work.

OOPUS is realised as a holistic concept. First,

data (e.g. customer orders, capacities of machines,

etc.) from different systems have to be imported. On

basis of these data the automatic production

mechanism generates a valid and loading optimal

production plan, which regards every organisational

frame condition like different planning areas or

linked assembly lines (AL). In order to consider

short term changes or special experiences of the

planner, the responsible planner can adapt the

automatically generated plan. This holistic concept

is illustrated in Figure 2.

Figure 2: Holistic concept of OOPUS.

5 GUARANTY OPTIMAL

INFORMATION

TRANSPARANCY

One main issue of the software OOPUS was to

present the large number of relevant data in a highly

ergonomic way. The main approach to realize this

was the idea of two functional split but data coupled

graphical user interfaces.

The planning table displays the batches on their

assembly lines over time in form of a Gantt chart in

a concise way. The planner can directly change the

plan by different batch actions like moving or

changing the batch size.

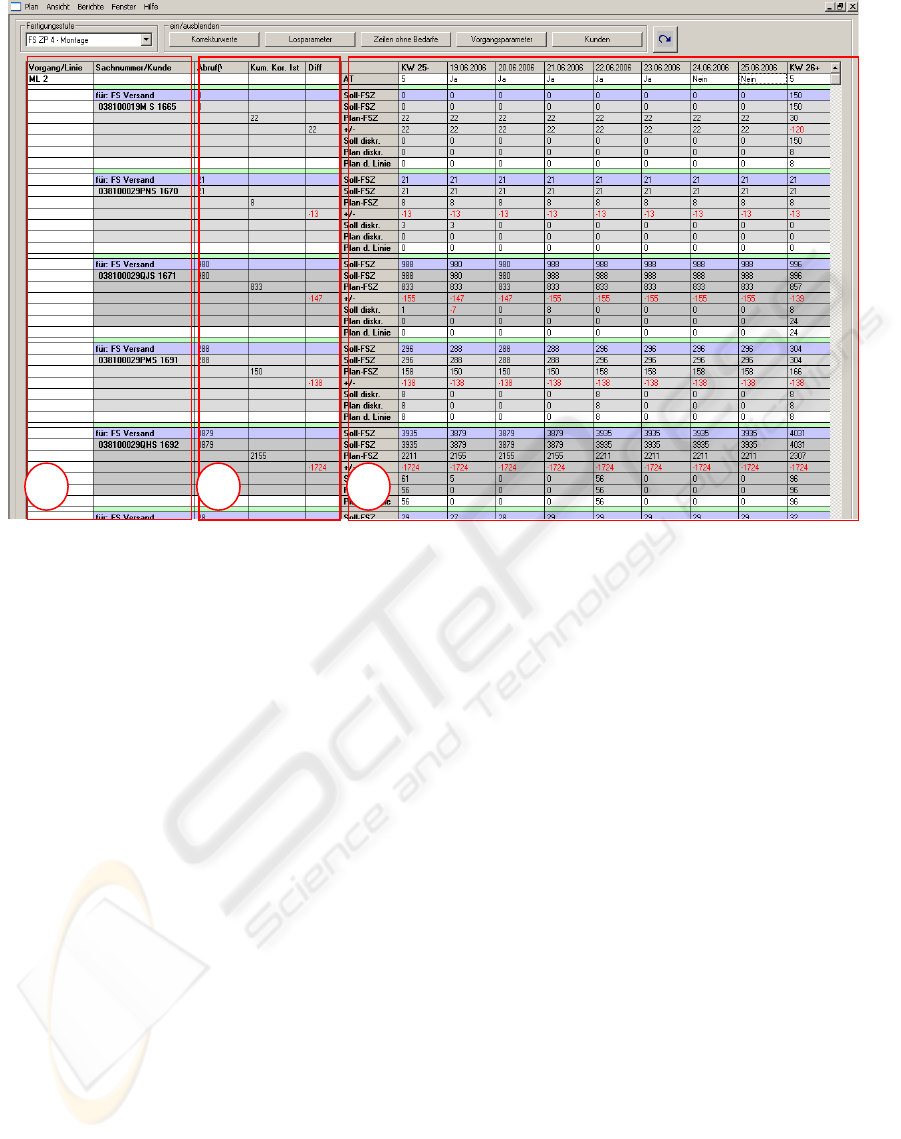

The plan visualized in the planning table is

shown in the cumulative quantity table (Figure 3) by

its forecasted cumulative quantities where it can be

compared with the demands.

5.1 Cumulative Quantity Table

The cumulative quantity table (CQT) gives an

overview of the manufacturing program which has

to be realized and of the manufacturing program

which would be realized by exact adherence of the

actual viewed plan. Thereby the planner is able to

detect mismatches of planned and required product

quantities easily. Exactly these mismatches have to

OOPUS

Plannin

g

OOPUS

ERP-Systems

OOPUS - A Production Planning Information System to Assure High Delivery Reliability under Short-term Demand

Changes and Production Disturbances

425

be avoided, because they can lead to high costs. In

addition to this information, several other parameters

like free capacities of assembly lines or batch

parameters are shown to support the planner in

creating a plan which can hold the fixed dates for all

orders.

Two different cumulative quantities are shown

for each part number the planner is responsible for.

On the one hand the target cumulative quantities and

on the other hand the actual cumulative quantities

(see Section 3).

The CQT is logically divided into three parts

from left to right:

1) The left part structures the CQT line-by-

line in assembly lines and part numbers

2) The middle part contains general and up to

date information of the part numbers

3) The right part shows the development of

the cumulative ACQ’s and TCQ’s weekly

and (additionally) daily

To create a high ease of use that supports the

planner in a maximum way, the following functions

were implemented:

o Coloured visualisation to highlight

significant data :

- Negative differences are red numbers to

signal demand deficit

- Editable fields are blue in the background

o Hiding of rows and blocks which are not

necessary for the planning task

o Weekly and daily quantities available

5.2 Planning Table

After a description of the planning table user

interface the process of plan adaptation will be

presented in detail.

5.2.1 Plan Visualization

The planning table visualizes the batches of the

users associated assembly lines (AL) in form of a

Gantt chart. Batches can be manipulated by different

actions to adapt the plan.

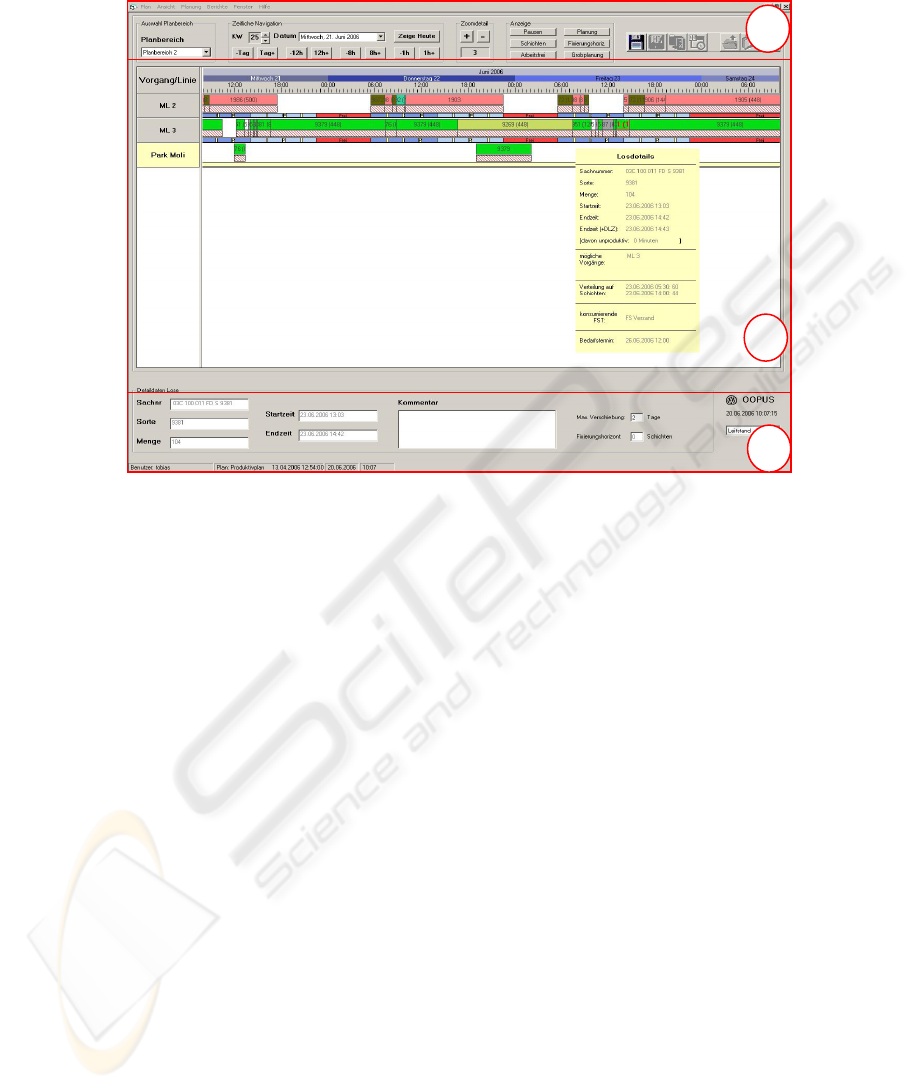

Figure 4 shows the planning table. The graphical

user interface can be divided into three parts top

down.

1) Navigation and action area

1 2 3

Figure 3: The cumulative quantity table.

ICEIS 2007 - International Conference on Enterprise Information Systems

426

Below the menu bar at the very top is the action and

navigation area where the user can navigate in time,

change the appearance of the planning table and

execute fundamental planning actions.

There are several possibilities to navigate in time

and to view the plan in different zoom levels, so the

user can adapt the view to his needs. The level of

detail can be changed in 10 different levels, from a

period of 20 minutes up to a period of 20 days. This

gives the user the possibility to look at the plan very

closely as well as to get a good overview of the

capacity utilization in a bigger time period. To

navigate in time the user can scroll the time line in

the Gantt chart by drag & drop or by pushing

buttons in the navigation and action area. It can

directly be moved to a week and a day in this week

and at the present point in time. To correspond to the

different zoom levels there are different steps to

move forwards or backwards in time.

On the right side of this area is a toolbar that

includes fundamental planning functions like

starting the planning algorithm or saving the current

plan.

2) Gantt chart

This is the main area of the planning table where all

batches are visualised on the assembly lines and

where the plan can directly be changed by different

actions on the batches.

Below each assembly line (e.g. ML 2) there are

different visualization elements that provide the

planner with information about the shifts that are

planned at each time. Blue bars represent productive

time intervals, yellow bars break times and red bars

signalize that the shift is not productive. Grey bars

indicate areas that can not be manipulated by the

user (e.g. past the production horizon).

The big bars over the shifts represent batches

that are planned to be produced at this time on this

assembly line. The batches are divided into two

parts. The upper part visualizes the batch itself; the

lower part gives information about the batch status

and the production progress of this batch. The

numbers on the batches indicate their part number

and their planned quantities. The colour of the status

bar signalizes the status of the batch according to the

availability of needed materials. Like a traffic light

the colours change from red to yellow and then to

green the closer the batch gets to its production start.

If the first part of the batch is produced, the status

bar gets green and its length decreases to show its

progress.

Tooltips are accessible for every visualization

element (

Figure 4 shows a tooltip for a batch).

1

2

3

Figure 4: The planning table.

OOPUS - A Production Planning Information System to Assure High Delivery Reliability under Short-term Demand

Changes and Production Disturbances

427

3) Information area

At the bottom of the planning table is the

information area, where details of the selected batch

and the current plan are shown.

In this area important information (e.g. plan has

been saved) are shown and feedback to actions (e.g.

batch could not be moved to this assembly line) is

given.

5.2.2 Plan adaptation

The user can manipulate the plan in three different

ways:

1) automatic planning

2) semi-automatic planning

3) manual planning

1) Automatic planning

To create a completely new plan, based on the

customer requests and the planned capacities, the

user can start the automatic planning algorithm. The

result of the algorithm replaces the current

productive plan for the current planning area.

2) Semi-automatic planning

OOPUS offers semi-automatic functions to change

the current plan. Some of these are:

o Fix the batches that should persist and plan

the rest automatically

o Create a batch based on an open demand

o Move a batch to an open demand

o Change the batch size based on an open

demand

3) Manual planning

OOPUS offers a very easy and intuitive moving of

batches via drag & drop. After a move the batch size

is recalculated dynamically by taking both capacities

of shifts and included breaks into account. This may

lead to a resizing of the batch after a moving action.

OOPUS ensures that batches can only be moved to

assembly lines where they are allowed to produce

and that they do not start or end in areas which are

not productive like breaks or weekends.

OOPUS guarantees that there is no overlaying of

two batches. If a user moves a batch over an existing

batch the two batches are planned in a row without a

gap between them. Depending on where the batch

was released the batch is planned before or after the

one it was released over.

If conflicts occur, for example because the gap is

too small or the capacity of the new shift is lower

then the one the batch was planned before, gaps with

sufficient capacities are automatically searched and

a dialog appears which offers the user to move the

batch to the next adequate gap.

The different actions the user can perform to

change the plan are:

o Move a batch manually

o Create a new batch

- based on a chosen start time

- based on a chosen end time

o Delete one ore more batches

o Fix one or more batches

o Move a batch based on open demands

o Change batch size

o Set one or more batches to the status “free

for production”

o Set one or more batches to the status

“produced”

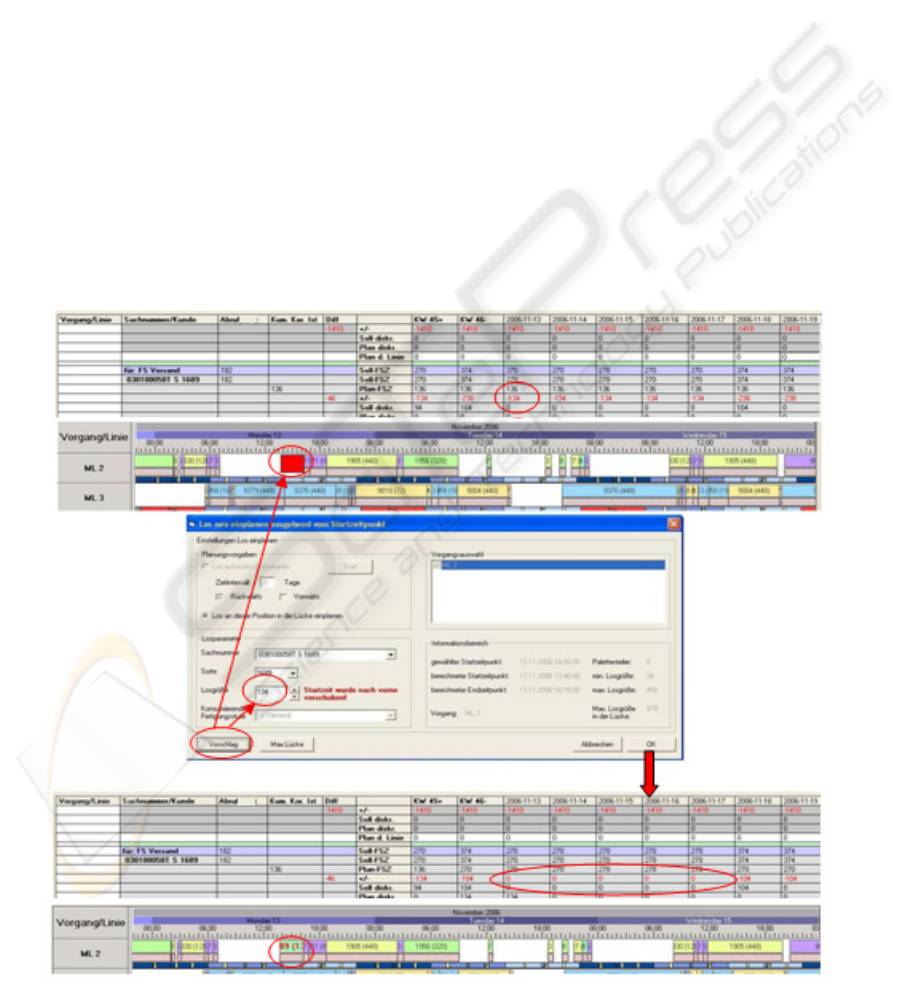

Because not all of the possible actions can be

explained in this text, the planning of a new batch

should exemplify the work with OOPUS.

To create a new batch the user has to know the

time and the AL where he wants to generate the new

batch. After right-clicking at the background at the

intended time and AL an menu appears where the

user can decide whether he wants to create the new

batch with the chosen time as start or as end date.

The combo boxes for the possible parts and sorts

are filled dynamically at the start of the dialogue

(Figure 5) and contain only the parts which can be

produced on the chosen AL. After choosing the part

number, information for this part, like the calculated

maximum quantity in this gap, are shown on the

right side of the dialogue.

If a batch size is entered the beginning and end

time of the batch is calculated and a virtual batch is

displayed in the Gantt chart.

If the desired batch size is bigger than the capacity

of the chosen gap, the user has the possibility to start

Figure 5: Dialogue to create new batches.

ICEIS 2007 - International Conference on Enterprise Information Systems

428

Figure 6: Example of creating a batch semi-automatically.

an automatic search via the dialogue. For that he can

specify in the upper left area of the dialogue if the

search for a gap should be done forward or

backward or in both directions around a number of

days. There is also a decision at which AL’s the

algorithm should search if there is more than one AL

that can produce that part. By pushing the Start-

Button the algorithm searches for a gap and

proposes one if possible.

The virtual batch will be redrawn whenever the

batch parameters changes and becomes the new

batch if the user confirms the dialogue.

As shown above the user has many possibilities

to adapt the plan according to his preferences. Each

action regards the restrictions for the part number as

well as the capacities and inactive times to ensure

that a current plan is always valid according to the

master data.

Additionally the planning table gives the user an

overview of the actual production progress by

showing batch progresses in real time. Thereby the

user can always compare the planned with the actual

progress and adapt the plan if necessary.

5.3 Interaction of both interfaces

Using both modules at once offers maximum

information transparency to the user. He sees both

the calculated cumulative quantities and the batches

which these quantities are calculated of. Whenever a

change is done in the planning table the CQT is

updated, thus the user can see the impacts of his

actions immediately. To see both modules at once a

dual monitor mode is recommended.

In Figure 6 a semi-automatic function is presented

as an example to show the interaction of both

modules. Down left in the new batch dialogue (see

Figure 5) is a button which offers a proposal based

on open demands for the part number in the selected

gap. The CQT in Figure 6 shows a deficit of 134 on

2006-11-13.

After pushing the proposal button, OOPUS checks

if there is a deficit at the chosen gap and in the case

of a deficit checks whether the whole deficit can be

planned in the gap or not. If the deficit can be

eliminated, a batch with the size of the deficit will be

proposed; otherwise the whole gap will be filled to

reduce the deficit to a minimum. In this example

OOPUS - A Production Planning Information System to Assure High Delivery Reliability under Short-term Demand

Changes and Production Disturbances

429

OOPUS generates a proposal of 134 to eliminate the

deficit.

Down in Figure 6 is the result after confirming the

proposal. By creating the new batch there are no

more deficits for the part number in the time from

2006-11-13 till 2006-11-17.

6 CONCLUSION

The software OOPUS, presented in this paper,

is used by an international automobile manufacturer

to plan and control his engine production in two

manufacturing plants. Thereby OOPUS replaced

different isolated applications to unite all aspects

needed for the production planning and control in

one application. Additionally OOPUS automated

many processes which where handled manually and

without IT support before.

OOPUS guarantees a higher planning reliability

by taking every required data into account to create a

production plan that is valid and efficient.

By using two integrated interfaces, the CQT and

the planning table, OOPUS guarantees maximum

information transparency. The user gets a

compressed, but complete overview of all the

relevant data he needs to plan and manipulate the

production plan. The CQT gives an overview of the

situation for the complete planning horizon by

comparing cumulative quantities based on customer

requests with cumulative quantities based on the

already produced parts and the planned parts of the

current plan. The planning table shows this plan and

offers many actions to change it manually, semi-

automatically or automatically. Every change of the

plan leads to a recalculation of the CQT, to ensure

that both interfaces always show the same updated

information.

This maximum information transparency leads to

a big saving of time for the production planner who

no longer needs to change between different

applications to create and control the production

plan.

OOPUS was developed based on the specific

requirements of an automobile manufacturer, so it is

integrated into the system architecture of this

customer. This leads to the idea of developing a

system called OOPUS-WEB which is a platform

independent web application and inherits the main

ideas of OOPUS. Therefore OOPUS-WEB can be

used by smaller companies as well as being

integrated into complex information system

infrastructures at large companies.

REFERENCES

Harjes, I.-M.; Bade, B.; Harzer, F., 2004.

Anlaufmanagement – Das Spannungsfeld im

Produktentstehungsprozess. In: Industrie

Management.

Holland, C., Light, B, 1999. A critical success factors

model for ERP implementation. In: IEEE Software,

vol. 16, no. 3.

Tempelmeier, H., 2006. Inventory Management in Supply

Networks. Problems, Models, Solutions. Books on

Demand GmbH, Norderstedt.

Stammen-Hegener, C., 2002. Simultane Losgrößen- und

Reihenfolgeplanung bei ein- und mehrstufiger

Fertigung. Dt. Univ.-Verl., Wiesbaden.

Katok, E.; Lewis, H. S.; Harrison, T. P., 1998. Lot sizing

in general assembly systems with setup costs, setup

times, and multiple constrained resources.

Management Science, no. 44.

Tempelmeier, H., 2003. Material-Logistik. Springer,

Berlin, 5

th

edition.

Maes, J., McClain, O.J., Van Wassenhove, L.N., 1991.

Multilevel capacitated lotsizing complexity and LP-

based heuristics. European Journal of Operational

Research, no. 53.

Wilson, James M., 2003. Gantt Charts: A Centenary

Appreciation. European Journal of Operational

Research 149, no. 2.

Schönsleben, P., 2004. Integrales Logistikmanagement -

Planung und Steuerung der umfassenden Supply

Chain. Springer, Berlin, 4

th

edition.

Kurbel, K., 2005. Produktionsplanung und -steuerung im

Enterprise Resource Planning und Supply Chain

Management. Oldenbourg Wissenschaftsverlag,

München.

Dangelmaier, W.; Henkel, S.; Holtkamp, R., 1997.

OOPUS - eine objektorientierte PPS-Plattform. In: wt

- Produktion und Management.

Dangelmaier, W.; Brockmann, K.; Hamady, M.;

Holtkamp, R.; Langemann, T., 1999. OOPUS-PSCM -

Ein Werkzeug zum Produktions- und Supply-Chain-

Management. In: Logistik Management: Intelligente I

+ K Technologien. Springer, Berlin.

Dangelmaier, W.; Holtkamp, R.; Hamady, M.;

Langemann, T.; Krebs, W., 1999. Produktions- und

Supply-Chain-Management bei größeren Stückzahlen.

In: PPS-Management.

Dangelmaier, W., Klöpper, B., Timm, T. Brüggemann, D.;

A Modelling Approach for Dynamic and Complex

Capacities in Production Control Systems, BIS 2007,

Lecture Notes of Computer Science 4439, pp. 626-

637, Springer Verlag, Berlin Heidelberg

ICEIS 2007 - International Conference on Enterprise Information Systems

430