ULTRASONIC MOTION TRACKING OF INSTRUMENTS IN

OPERATING THEATRE

Alejandro Ibarz, Roberto Casas, Álvaro Marco, Héctor Gracia, Rubén Blasco and Jorge Falcó

Instituto de Investigación en Ingeniería de Aragón,(Tecnodiscap Group)

Universidad de Zaragoza. María de Luna 1, Zaragoza, Spain

Keywords: Indoor positioning, motion tracking, ultrasound ranging, accurate localization.

Abstract: The purpose of this paper is to address the design of a system to track surgical instrument’s movement

during an operation. Motion tracking of surgical instruments is one of the most interesting methods to

survey the data needed for medical robotics, computer-aided surgery, skills assessment and training progress

applications. Over the wide range of tracking technologies, low frequency ultrasound was selected to meet

the system’s requirements. Factors that bring about measurement inaccuracies are analysed and taken into

account when developing the system. Furthermore, a localization algorithm that calculates three-

dimensional position using one-dimensional distances and overriding signal blockage is presented.

Moreover, experimental results of a resectoscope mock up motion tracking are shown.

1 INTRODUCTION

With the spread of minimally invasive surgery and

training in this field, development of metrics for

medical robotics, computer-aided surgery, skills

assessment and training progress has become

increasingly important.

There is a wide range of technologies for motion

tracking: computerized tomography, nuclear

magnetic resonance imaging, video-based imaging,

ultrasound imaging, optical tracking systems,

electromagnetic tracking systems, inertial,

ultrasound positioning, etc. They can be

characterized according its price, complexity,

accuracy and drawbacks. Most of these technologies

are not suitable for designing a indoor positioning

system meant for operating theatres (Tatar, 2006;

Bianchi 2007). However, low frequency ultrasound

positioning offers promising perspective measuring

one-dimensional distances. Moreover, a more

thorough analysis will be done to use low frequency

ultrasound for motion tracking purposes.

The purpose of this paper is to design an

ultrasound indoor positioning system. It has to be

able to track the motion of a surgical instrument

during the operation. Furthermore, system’s

requirements are low-cost, low-complexity and

accuracy enough to track instrument’s position

properly. The final and most important requirement

is that devices placed on the instrument can not

restrict surgeon’s movements or put the patient in

risk.

Concerning the exactitude of the system, the

design of the electronics will be analysed, as well as

the method of time of flight measurement to obtain

an accuracy of millimetres. In order to obtain this

accuracy, it will be necessary to analyse the

influence of environmental factors and correct its

effects. The ultimate goal is to objectively assess

instrument localization in a realistic environment;

i.e., the operating room.

2 ULTRASONIC TRACKING

Generally speaking, ultrasonic positioning systems

are based on different subsystems: transducers on

the mobile that needs to be located, transducers

places on known positions and one or several

computing units (PC, microprocessor or DSP). In

order to obtain mobile’s unknown position; one-

dimensional distances from fixed transducers to

mobile transducers have to be surveyed. After

obtaining the one-dimensional data, mobile’s

coordinates can be calculated by a computing unit

using a location algorithm.

186

Ibarz A., Casas R., Marco Á., Gracia H., Blasco R. and Falcó J. (2008).

ULTRASONIC MOTION TRACKING OF INSTRUMENTS IN OPERATING THEATRE.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 186-189

DOI: 10.5220/0001053301860189

Copyright

c

SciTePress

A generic ultrasound positioning system has

been described. Afterwards, the system has to be

adapted to the operating theater characteristics.

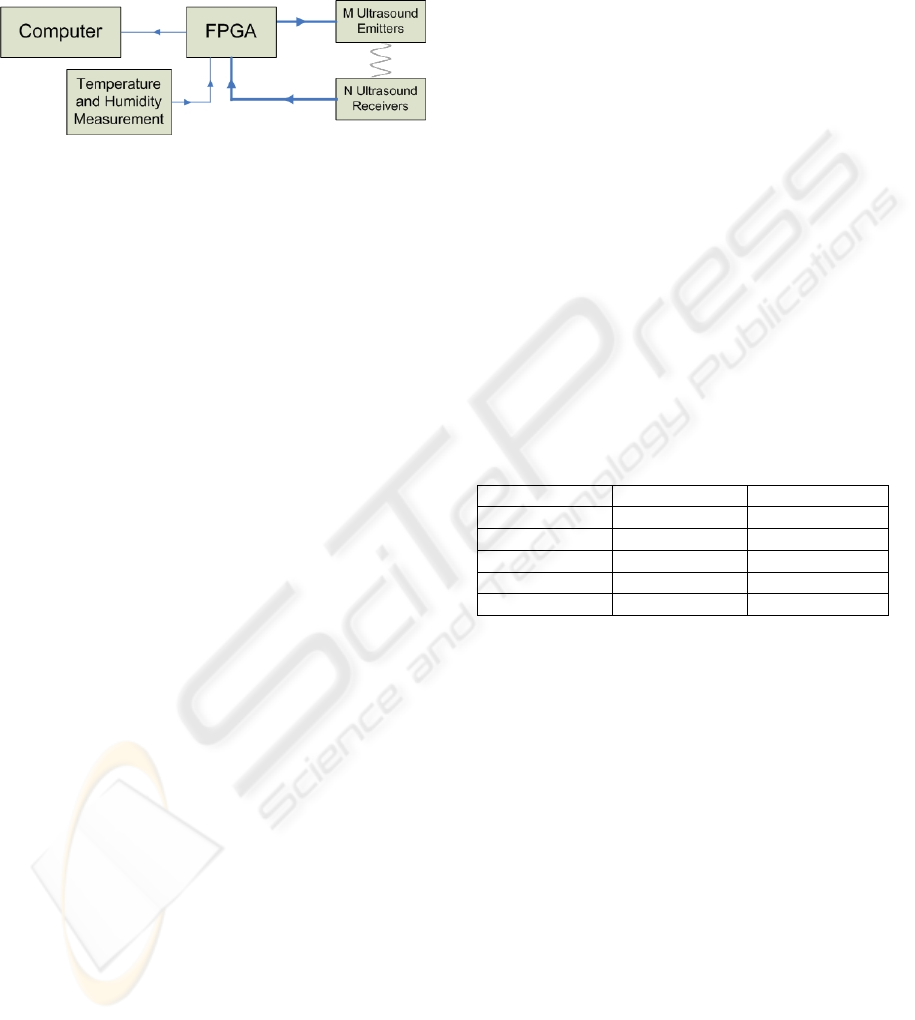

The system’s architecture is as follows:

Figure 1: System’s architecture.

Emitting transducers (at least 3 to determine

mobile’s position) need to be placed on the surgical

instrument on known position (in order to compute

the instrument’s position).

Receiving transducers have to be placed on the

ceiling to avoid non-line of sight issues. To ensure

good performance of the system, the coordinates of

receiving transducer should be known as much

accurate as possible.

The FPGA assigns a temporal interval to each

emitter module. It commands the emitter to generate

ultrasound chirps; simultaneously the ultrasonic time

of flight (TOF) to the receiving transducers will be

computed and stored (as well as ambient

temperature and humidity). After the FPGA sends

all surveyed data, the computer will obtain the

coordinates of all emitting transducers and the

instrument’s position.

2.1 Ambient Influence in Operating

Rooms

In this sub chapter, several factors that may affect

system’s performance will be analysed. This

analysis will take into account operating room (OR)

ambient characteristics and several others

considerations that may bring about measurement

inaccuracies.

Update rate: The frequency of the

measurements reported by the tracking system. The

higher this parameter the better tracking results are

obtained. The TOF system has a low update rate

caused by the low speed of sound and the sequential

triple emission of pulses.

Misalignment between transducer pairs: Due

to the quantity of receiving transducers and the wide

range of mobile’s movements, we cannot expect to

have perfect alignment between transducers pair

(emitter-receiver). It has been stated (Lamancusa,

1990) that misalignment between transducer pairs

will bring about a distance measurement error.

Ultrasound wave reflection on surfaces:

Reflections on surfaces has been used in ultrasound

distance measurement systems, using echoes to

determine distances to surfaces. Nevertheless,

considering the number of medical instruments in

OR (lamps, monitors, tables), echoes might bring

about measurement errors to our system and affect

system’s robustness. Therefore, reflection on

surfaces should be analyzed and taken into account

in system’s design.

Airflows: Most of these systems are based on

calculating the ultrasound TOF and multiplying it by

the sonic air speed to obtain the distance. Therefore,

airflow will modify the speed which the ultrasound

moves in the air.

Temperature: The temperature is an

environmental factor to consider when designing an

accurate ultrasound positioning system, as it affects

the speed of sound (Liao et al, 2004).

Relative Humidity: The relative humidity

modifies the speed of sound, affecting distance

measurement (Liao et al, 2004).

Table 1: Inaccuracies due to ambient factors.

Parameter Accuracy Max. Error

Temperature 0.3 º C 1.77 mm

Humidity 1.8 % RH 0.4 mm

Misalignment --- 1 mm

Airflows --- 1.3 mm

Total --- 4.4 mm

2.2 Distance Measurement

Once analysed the environmental factors (table 1)

that influence distance measurements, we will

analyse the measurement process. This part includes:

generation of ultrasonic chirps, reception and

treatment of the signals; and determination of TOFs.

TOF is the time elapsed between the

transmission of a pulse and its reception, from which

the target distance can be calculated multiplying

speed of sound in air by TOF. Using TOF to

measure the distance, the system errors are primarily

due to amplitude degradation of the received signal,

and uncertainty in the speed of sound.

There is a close relation between generation of

ultrasonic chirps and the method to determine TOFs

and distances (Tatar, 2006; Huang et al, 2002).

Moreover, the chirp generation method can affect

system’s performance. For example, some methods

require longer chirps, lowering system’s update rate

ULTRASONIC MOTION TRACKING OF INSTRUMENTS IN OPERATING THEATRE

187

and making them less robust to reflections on

surfaces.

The chosen method of emission was based on

self-interference (Cai, 1993), using short chirps and

giving the signal in reception a specific form that

will take be used to determine TOF and afterwards

the one-dimensional distance. Allocating an event on

the signal close to its start will make the method

more robust to reflections on surfaces.

The method implemented in the FPGA consists

on storing several time stamps of the moments when

the signal exceeds a predefined threshold. These

data are processed through an algorithm in the

FPGA to determine where the event is located, and

afterwards this time is corrected to obtain the TOF.

Experimental tests were done to assess the

precision of determining the TOF using this method.

Placed both emitter and receiver at a fixed distance,

the distances obtained had a standard deviation of

300 μm and a resolution of 7 μm. The system was

also able to measure distance between transducers

with a high degree of misalignment.

2.3 Location Calculation

2.3.1 Problem formulation

We have to solve the classic multilateration

problem. Calculate the position of the transmitter

(x

P

,y

P

,z

P

) from the estimation of several distances

(d

i

) to emitters having known coordinates

(x

bi

,y

bi

,z

bi

). Distances have been estimated as

indicated in previous subsection.

At least three distances are required to solve the

aforementioned trilateration problem.

Unfortunately, this is not typically the case in real

operations where one or more of the distances may

contain large errors produced by multipath effects

and the blockage of the ultrasonic signal.

2.3.2 Location Algorithm

Our aim is to solve the proposed problem when it is

not possible to use any prior information to solve the

multilateration. It is not possible to identify the

measurements affected by error, or whether there are

any. In the end, there is redundant data within

unidentified, erroneous information, which must be

filtered out to compute the best solution.

Robust estimators provide methods for detecting

outliers, and they obtain trustworthy results even

when a certain amount of data is contaminated. The

LMedS method used (Casas, 2006) searches in the

space of solutions obtained from subsets of the

minimum number of data. As we require a minimum

of three distances to compute the location and there

are a total of n, we make m subsets of three

distances:

()

!n!

n!

=m

33 −

(1)

For each subset Si of distances (du, dv, dw), we

compute a location Pi (xi, yi, zi) by solving the

system of equations of using any traditional

technique such as least squares:

where i = 1,…,m and (xBSj, yBSj, zBSj) are the

coordinates of BSj being j = u, v, w.

For each location Pi, we obtain the residues Ri

as:

(

)

(

)( )

22 2

11 22

ˆˆ ˆ

,,,

iinin

dd dd dd

⎛⎞

=− − −

⎜⎟

⎝⎠

i

R K

()()()

22

2

ˆ

1,...,

ik i BSk i BSk i BSk

dxx yy zz

kn

=− +− +−

=

(3)

And compute the median Mi of the residues Ri.

The final solution P (x, y, z) is that with the

minimum median Mi.

2.4 Instrument’s Localization

As an experimental implementation (figure 2), a

motorized resectoscope mock up have been used.

The distances between emitters and receivers were

processed by the computer through the localization

algorithm in order to obtain the instrument’s

unknown position.

According the results (figure 3), can be stated

that the system has a good dynamic behavior.

Moreover, can be stated the good performance of

localization algorithms and solution filtering.

()()()

()()()

()()()

222

222

222

u i BSu i BSu i BSu

v i BSv i BSv i BSv

w i BSw i BSw i BSw

dxx yy zz

dxx yy zz

dxx yy zz

⎫

=− +− +−

⎪

⎪

⎪

=− +− +−

⎬

⎪

⎪

=− +− +−

⎪

⎭

(2)

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

188

3 CONCLUSIONS

As result of this research, a low-cost and low-

complexity indoor positioning system has been

designed. It meets the requirements stated

previously, to fit in a motion tracking application.

The method of determining TOF has a good

precision for fixed distances (300 µm) and good

performance with high misalignment between

transducer pairs. Adding all sources of one-

dimensional distances’ inaccuracies (worst case

scenario), the error might reach 5 mm. This error

translated to three-dimensional positioning would

mean 8 mm.

Regarding the reliability of the system, with the

inclusion of the controlled emission, the system has

been able to create signals in reception with a

characteristic form. This effect brings about

advantages when dealing with reflection on surfaces,

important factor in an operating room. In addition,

the system will be more robust to external noises in

the work frequency. In terms of scalability, the

developed system is able to capture the data from up

to 20 receiving modules. Observing the obtained

results, we can conclude that the system performs in

a satisfactory way the motion tracking of the

instrument’s position and movement.

ACKNOWLEDGEMENTS

This work has been partially supported by the

Spanish Ministry of Science and Technology under

CICYT project numbers TIC2003-07766 and

TIN2006-15617-C03-02. Also by the EU under

project MonAmi (IST-5-0535147).

REFERENCES

Bianchi, G., 2007. Exploration of augmented reality

technology for surgical training simulators, Diss.,

Eidgenössische Technische Hochschule ETH Zürich,

Nr. 16876

Cai, C., Regtien, Paul P. L. , 1993. Accurate Digital Time

of flight Measurement Using Self-Interference, IEEE

Transactions on Instrumentation and Measurement

.Vol. 42, No.6, December 1993, Pag. 990-994

Casas, R., et al, 2006. Robust Estimator for Non-Line-of-

Sight Error Mitigation in Indoor Localization,

EURASIP Journal of Applied Signal Processing,

2006, Article ID 43429, pp. 1-8.

Casas, R., et al, 2007. Hidden Issues in Deploying an

Indoor Location System ,Pervasive Computing, IEEE,

Vol.6, Iss.2, April-June 2007 Pages:62-69

Huang. S.S et al, 2002. A high accuracy ultrasonic

distance measurement system using binary frequency

shift-keyed signal and phase detection. American

Institute of Physics, Review of Scientific Instruments,

Volume 73, Issue 10, pp. 3671-3677.

Lamancusa, John S., Figueroa, J.Fernando, 1990. Ranging

errors caused by angular misalignment between

ultrasonic transducer pairs, The Journal of the

Acoustical Society of America, Volume 87, Issue 3,

March 1990, pp.1327-1335

Liao et al, 2004. A new ultrasonic temperature

measurement system for air conditioners in

automobiles. Insttitute of Physics, Meas. Sci. Technol.

15 413-419

Tatar, F., 2006. Ultrasound 3D positioning system for

surgical instruments, Doctoral Dissertation,

Technische Universiteit Delf.

Figure 3: Motion tracking.

Figure 2: Mock up implementation.

ULTRASONIC MOTION TRACKING OF INSTRUMENTS IN OPERATING THEATRE

189