DEVELOPMENT OF AN AMPEROMETRIC SENSOR FOR

POTASSIUM IONS

Marcos F. S. Teixeira, Alex S. Lima, Patricia Monteiro Seraphim

Dep. of Physical, Chemistry and Biology , Faculty of Science and Technology, University of State of Sao Paulo (UNESP)

Rua Roberto Simonsen, 305 - Presidente Prudente – SP - Brazil

Nerilso Bocchi

Department of Chemistry, Federal University of São Carlos

Via Washington Luiz, Km 235 - São Carlos – SP - Brazil

Keywords: Sensor for potassium ions, hollandite, voltammetry.

Abstract: Hollandite-type manganese oxides are nanofibrous crystals with sub-nanometer open tunnels that provide a

unique property for sensing applications. Sensor based on hollandite-type manganese oxide was investigated

for amperometric detection of potassium. With an operating potential of +0.63 V versus SCE, potassium

ions produce oxidation currents at the sensor, which can be exploited for quantitative determinations. The

amperometric signals are linearly proportional to potassium ions concentration in the range 2.7 × 10

−4

to 9.1

×10

−4

mol l

−1

with a correlation coefficient of 0.9990. The construction and renewal are simple and

inexpensive.

1 INTRODUCTION

Determination of potassium contents of serum,

urine, and foods is very important in clinical and

medical fields, since the potassium contents are

related to renal diseases. These diseases restrict

patients to a diet containing a large amount of

potassium. From the potassium determination,

medical information concerning physical conditions

of the patient can be obtained. In the case of

hypopotassemia, alkalosis, cirrhosis of liver, diuretic

drugs, etc. are suspected. On the other hand, when

potassium concentration in human serum becomes

higher than 9 mmol L

−1

, heart often stops (Harrison

et al., 1966). Hence, accurate, easy and rapid sensing

of potassium ions is very important.

The development of chemical sensors for non-

electroactive ions based with modified electrodes

has been based in the participation of non-

electroactive cations in redox reactions of metal

hexacyanoferrates (Karyakin, 2001). Other

compound with ability of accommodate non-

electroactive cations and promote the electroactivity

in function of the insertion cation is the manganese

oxide. Manganese oxides represent a large class of

materials that have layered and tunneled structures

consisting of edge-shared MnO

6

octahedral units.

They have attracted considerable interest due to

broad potential applications in heterogeneous

catalysis, chemical sensing, toxic wastewater

treatment, and rechargeable battery technology. In

our laboratories, we are also interested in developing

highly sensitive and selective methods for the

determination of non-electroactive using electrodes

modified with different allotropic forms of

manganese oxide (Teixeira et al., 2004 and Teixeira

et al., 2004).

In this paper, we propose a new sensor to

determine potassium ions.

2 EXPERIMENTAL

2.1 Apparatus

All voltammetric measurements were carried out in

a 30ml thermostated glass cell at 25

◦ C, containing

three electrodes: carbon-paste electrode as a working

electrode, saturated calomel as reference electrode

(SCE), and platinum wire as an auxiliary electrode.

During the measurements, the aqueous solution

(TRIS buffer solutions) in the cell was not stirred

198

F. S. Teixeira M., S. Lima A., Monteiro Seraphim P. and Bocchi N. (2008).

DEVELOPMENT OF AN AMPEROMETRIC SENSOR FOR POTASSIUM IONS.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 198-201

DOI: 10.5220/0001054001980201

Copyright

c

SciTePress

and deaerated. Voltammetric measurements were

performed with a micro-Autolab Type III controlled

by an appropriated software.

2.2 Reagents and Solutions

All solutions were prepared using a Millipore Milli-

Q water. All chemicals were analytical reagent grade

and were used without further purification. The

supporting electrolyte used for most of the

experiments was a 0.1 mol l

-1

Tris buffer solution

(pH = 8.30). A 0.01 mol l

-1

potassium ions solution

was prepared daily by dissolving potassium chloride

(Merck) in 100 ml of such Tris buffer solution.

Graphite powder (1–2 μm particle size from

Aldrich) and mineral oil (Aldrich) of high purity

were used for the preparation of the sensor.

2.3 Preparation of Hollandite-Type

MnO

2

Hollandite-type manganese(IV) oxide was prepared

using a reflux method according to literature (Ching

et al. 1997). For conversion to hollandite-type

manganese oxide, a KMn

2

O

4

sample was treated in

an aqueous diluted sulfuric acid solution kept under

constant stirring during 120 min. When the pH of

this mixture was stabilized at a particular value, the

solution was decanted and the remaining solid

material washed by decantation with deionized

water, filtered and dried in air at 90

ºC.

2.4 Sensor Construction

Sensors with hollandite-type MnO

2

were prepared

by carefully mixing the dispersed graphite powder

with manganese oxide

at varying ratio. Exactly 1 g

of this mixture was subsequently added to 0.200 g of

mineral oil (20% m/m) and mixed in a 50 ml beaker

containing 20 ml of hexane. The final paste was

obtained with the solvent evaporation. The carbon-

paste electrode was finally obtained packing the

paste into a plastic tube (1 ml insulin plastic syringe)

and arranged with a copper wire serving as an

external electric contact.

3 RESULTS AND DISCUSSION

3.1 Electrochemical Behavior

First, the voltammetric behavior of the CPEM with

hollandite-type manganese oxide in Tris buffer

solution (pH 8.3) containing 5.0 x 10

-4

mol L

-1

potassium ions was investigated. The cyclic

voltammograms obtained with the sensor (see Fig.

1) presented one anodic peak (peak I = 0.63 V vs.

SCE) and another cathodic peak (peak II = 0.08 vs.

SCE). This electrochemical activity is due to the

extraction topotactic process of the potassium ions

from the hollandite structure, which occurs in two

steps to the electrochemical insertion/extraction

processes of the potassium ions (Feng et al., 1995):

4

4

2

3

OMnMnK

+

−

+

xxx

(s)

→ 2.MnO

2(s)

+ x K

+

(aq)

+ x e

-

(1)

2.MnO

2(s)

+ x K

+

(aq)

+ x e

-

→

4

4

2

3

OMnMnK

+

−

+

xxx

(s)

(2)

-0.2 0.0 0.2 0.4 0.6 0.8 1.0

-200

-100

0

100

200

300

peak II

peak I

I / μA

E (V) vs. ECS

Figure 1: Cyclic voltammogram of the sensor in 5.0 x 10

-4

mol L

−1

of potassium ions, at a scan rate of 50 mV s

−1

between − 0.15 and 1.00 V versus SCE.

The enhanced response to potassium ions occurs

because the cathodic polarization of the sensor with

hollanditel-type manganese oxide is quite enough to

reduction the manganese in the solid. Consequently,

the potassium ions from the adjacent solution are

able to diffuse though the hollandite structure to

maintain the electroneutrality principle.

In the absence of potassium ions, no voltammetric

response was observed for the sensor, confirming

that the response of the sensor is a function of the

insertion reaction of potassium ions in the hollandite

structure as mentioned previously (see Eq. 3):

2.MnO

2(s)

+ x K

+

(aq)

+ (x/2) H

2

O

(l)

→

4

4

2

3

OMnMnK

+

−

+

xxx

(s)

+ x H

+

(aq)

+ (x/4) O

2(g)

(0 < x < 1)

(3)

where is vacant site (tunnel) of the manganese

oxide.

The apparent electrochemical rate constant k

e and

the electron-transfer coefficient α

anodic

were calculated

for the sensor according to the method described by

Larivon (Larivon, 1979). It has been shown by

Laviron that for a surface redox couple, α

anodic

and ke

can be determined from the variation of Epa with

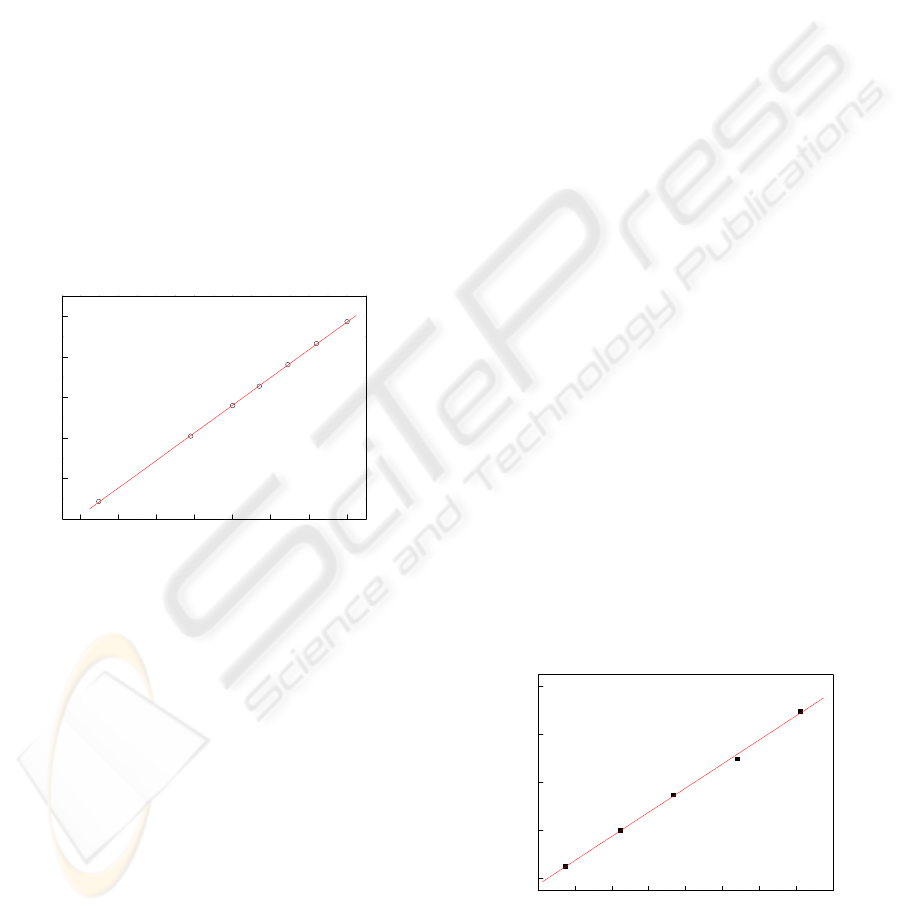

scan rate. Figure 2 presents the plot of E

pa (V)

DEVELOPMENT OF AN AMPEROMETRIC SENSOR FOR POTASSIUM IONS

199

versus log ν (V s

−1

) of the sensor in Tris buffer

solution (pH 8.3) containing 5.0 x 10

-4

mol L

-1

potassium ions. For large enough values of scan rate

the E

p − log ν plots gave one straight line with

slopes of 2.303RT/(1− α

anodic

)nF for the anodic

branch, where R is the gas constant, T the absolute

temperature, F the Faraday constant and n number of

electrons involved in the redox couple. Considering

that the number of electrons involved in the redox

process is 1, the calculated value for the coefficient

α

anodic

was 0.83. These results suggest the redox

process tends towards an irreversible system. The

apparent electrochemical rate constant can then be

determined applying the equation k

e =

2.303α

anodic

nFν

o

/RT, in which the value of scan rate

(ν

o

) is determined by extrapolation of the linear

branch at higher scan rates and its intersection with

the constant peak potential, represented by the peak

of the voltammogram at the lower scan rate. The

observed value was k

e = 32.2 s

−1

.

-2.4 -2.2 -2.0 -1.8 -1.6 -1.4 -1.2 -1.0

0.4

0.5

0.6

0.7

0.8

E

pa

/ V vs. ECS

log v (V/s)

Figure 2: Dependence of E

pa

with log(ν) for the sensor in

Tris buffer solution (pH 8.3) containing 5.0 x 10

-4

mol L

-1

potassium ions.

The effect of the carbon paste composition in the

amperometric response of the sensor was evaluated

in Tris buffer solution (pH 8.3) containing 5.0 x 10

-4

mol L

-1

potassium ions. The anodic peak current

increased with the amount of manganese oxide in

the paste up to 25% (

m

/

m

). The anodic peak current

decreased significantly when more than 25% is used

in the electrode preparation. This probably occurs

due to a decrease in the conductive area at the sensor

surface. According to these results a sensor

composition of 25% (

m

/

m

) modified hollandite-type

manganese oxide, 55% (

m

/

m

) graphite and 20% (

m

/

m

)

mineral oil was used in further studies.

3.2 Analytical Curve and Repeatability

After optimizing the best operating conditions for

the sensor (scan rate of 20 mV s

−1

), cyclic

voltammetries were carried out in Tris buffer

solution containing different potassium ion

concentrations in order to obtain the analytical curve

for such electrode. This curve, illustrated in the

Figure 3, was constructed using the anodic peak

currents resulting a linear relationship with the

potassium ion concentrations from 2.7 × 10

−4

to 9.1

×10

−4

mol l

−1

(I

pa

(μA) = 2.07 + 200.8 [K

+

] (mol

L

−1

); r = 0.9990) with a detection limit of 1.5 × 10

−4

mol L

−1

potassium ions. The precision of the method

was also tested by analyzing five replicates

containing 5.0 x/10

−4

mol L

−1

potassium ions. For

each voltammogram, the surface of the sensor was

renewed. The variation coefficient was 2.0 %.

4 CONCLUSIONS

As shown above, a sensor based on the hollandite-

type manganese oxide exhibits an obvious response

to potassium ions. It is necessary to investigate the

interaction mechanism between potassium ion and

the hollandite-type manganese oxide. The presence

of Mn

3+

in hollandite may increase its activity for

the reaction. During the amperometric detection,

potassium ions diffuse through the hollandite

structure to produce Mn

+3

, which can be

electrochemically reoxidized to Mn

+4

. The oxidative

current is directly related to the concentration of

potassium ions. In view of its sensitivity, stability,

low working potential and simplicity and low cost of

construction, the sensor based on the hollandite-type

manganese oxides exhibits prospects for future

biosensor work.

0.3 0.4 0.5 0.6 0.7 0.8 0.9

2.12

2.16

2.20

2.24

2.28

I

pa

/ μA

[potassium ions] / mmol L

-1

Figure 3: The curve analytical obtained from the anodic

currents using sensor based hollandite-type manganese

oxide.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

200

ACKNOWLEDGEMENTS

The research support from FAPESP under contract

no. 05/01296-4 and also grant by CNPq (no.

372010/2006-7) to A.S.L. are gratefully

acknowledged (SJT).

REFERENCES

Ching, S., Roark, J.L., Duan, N., Suib, S.L., 1997. Chem.

Mater. 9, 750.

Feng, Q., Kanoh, H., Miyai, Y., Ooi, K., 1995. Chem.

Mater. 7, 148.

Harrison, T.R., Adams, R.D., Bennett, I.L., Resnik, W.H.,

Thorn, G.W., Wintrobe M.M., (Eds.), 1966. Principles

of Internal Medicine, 5

th

edn., McGraw-Hill, New

York.

Larivon, E., 1979. J. Electroanal. Chem. 101, 19.

Karyakin, A.A., 2001. Electroanalysis 13, 813.

Teixeira, M.F.S., Cavalheiro, E.T.G., Bergamini, M.F.,

Moraes, F.C., Bocchi, N., 2004. Electroanalysis 16,

633.

Teixeira, M.F.S., Bergamini, M.F., Bocchi, N., 2004.

Talanta 62, 603.

DEVELOPMENT OF AN AMPEROMETRIC SENSOR FOR POTASSIUM IONS

201