NOVEL FIELD-EFFECT CONTROLLED SINGLE-WALLED

CARBON NANOTUBE NETWORK DEVICES FOR BIOMEDICAL

SENSOR APPLICATIONS

Udo Schwalke

Institute for Semiconductor Technology and Nanelectronics, Darmstadt University of Technology

Schlossgartenstrasse 8, 64289 Darmstadt, Germany

Keywords: Carbon nanotube (CNT), carbon nanotube field-effect sensor (CNTFES), carbon nanotube field-effect

transistor (CNTFET), functionalization, virus-detection, integrated circuit, CMOS, hybrid CNT-CMOS

integrated circuit, atomic force microscopy (AFM).

Abstract: In this position paper we propose a novel method for the realization of carbon nanotube field-effect sensors

(CNTFESs) which will most likely have a strong impact on the next-generation of sensors. CNTFESs are

ideally suitable for biomedical sensor applications due to their excellent inherent properties such as ultra

small size, high specific surface area and extremely high sensitivity. CNTFESs are based on carbon

nanotube field-effect transistors (CNTFETs) which are optimized for sensor applications. We have

succeeded to develop a simple, reproducible fabrication process to grow individual CNTs and CNT-

networks directly within the specified device area. No tedious manual manipulation and alignment of the

CNTs is necessary. Electrical results of the fabricated fully functional CNTFETs are presented and the use

of these devices as single-walled CNT-based field-effect controlled sensors for virus detection is discussed.

1 INTRODUCTION

Carbon nanotubes (CNTs) are hollow cylinders of

graphene with a diameter of approximately 1 nm and

lengths up to 100 µm. Multi-walled carbon

nanotubes (MWNTs) consist of several

concentrically arranged cylinders of graphene and

were observed for the first time in 1991 (Iijima

1991). MWNTs are always metallic with very good

conductivity. Single-walled carbon nanotubes

(SWNTs), however, can be either metallic (m-

SWNTs) or semiconducting (s-SWNTs) depending

on the arrangement of the carbon atoms within the

hexagonal network, i.e. their chirality.

Since 1998 (Martel 1998; Bezryadin 1998) it is

known that s-SWNTs can be used to realize carbon

nanotube field-effect transistors (CNTFETs) which

are promising candidates for future nanoelectronic

applications to replace Si-CMOS. Furthermore, only

a change in the charge state is needed to alter the

device characteristics via the field effect (i.e. just by

the presence of the charge and not via current flow),

so that extremely sensitive sensors are feasible, i.e.

carbon nanotube field-effect sensors (CNTFESs).

In addition, the inner and outer surface of the

single-walled CNT is equal to the whole tube itself

and thus the CNTFES will be extremely sensitive to

the immediate environment, i.e. ideally suited for

biomedical sensor applications. In fact, excellent

electronic response properties of CNTFETs to their

chemical (Someya 2003) and biological (Staii 2005)

environments have been demonstrated already. The

response times of CNT-sensors are at least one order

of magnitude faster than those based on solid-state

sensors. CNT-based nanosensors have the

advantages that they are thousands of times smaller

than even MEMS sensors and consume much less

power. Therefore, CNT-based nano-sensors are

highly suitable as implantable sensors. Apart from

their small size, semiconducting SWNTs operate at

room temperature with a sensitivity as high as 10

3

(Kong 2000). This enables them to perform better in

many of the biomedical sensing applications.

Currently CNTFETs and CNTFESs are

fabricated and investigated by several research

groups. However, the fabrication processes used are

often complicated, including both separate growth

(Barreiro 2006) and tedious manual manipulation of

99

Schwalke U. (2008).

NOVEL FIELD-EFFECT CONTROLLED SINGLE-WALLED CARBON NANOTUBE NETWORK DEVICES FOR BIOMEDICAL SENSOR APPLICA-

TIONS.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 99-102

DOI: 10.5220/0001055900990102

Copyright

c

SciTePress

the CNTs (Kong 200; Someya 2003; Staii 2005).

Obviously, commercial large scale integration

remains a major challenge to the realization of CNT-

based nanoelectronics and nanosensor technology as

well.

At our institute we have developed a novel

process to overcome the limitations of manual

fabrication of CNTFETs and hence CNTFESs as

well (Rispal 2006; Rispal 2007; Schwalke 2007).

Our group has succeeded to develop a simple,

reproducible fabrication process to grow individual

SWNTs and SWNT networks as wells in order to

fabricate fully functional CNTFETs and single-

walled CNT-based field-effect controlled sensors.

In this position paper we will first present a brief

summary of our research results on CNTFETs and

subsequently discuss the use of this technology for

possible biomedical CNT-based sensor applications.

2 RESULTS AND DISCUSSION

2.1 CNTFET & CNTFES Fabrication

The process is based on chemical-vapor-deposition

(CVD) growth of CNTs using an aluminum/nickel

‘sacrificial’ catalyst which transforms itself after

CNT growth into a high-k dielectric (i.e. Al

x

O

y

)

covered with dispersed Ni-nanoclusters (Rispal

2007). SWNTs are grown uniformly across the

wafer surface and subsequently contacted with

palladium for S/D contacts and the Si-substrate acts

as a gate electrode as illustrated in Fig. 1. The

process contains neither complicated manipulations

of the SWNTs nor multi-step lithography and is Si-

CMOS compatible. We choose the in-situ growth

method because it appears the most practical

approach for future use in high-volume fabrication

of advanced integrated nano-sensors at low cost.

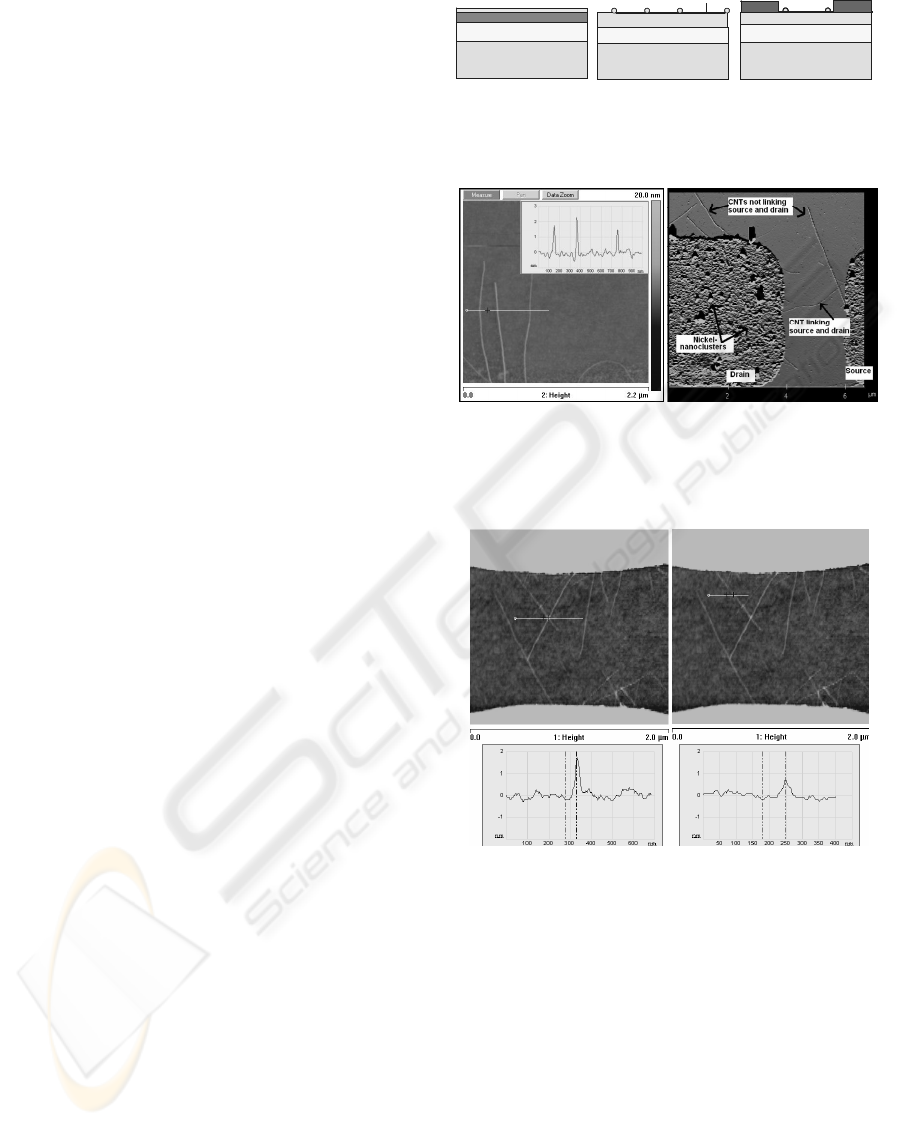

For the development of this novel process we

have extensively used atomic force microscopy

(AFM) for process control and to optimize the

CNTFET fabrication technology as well. The role of

the Al/Ni films as “sacrificial” catalyst to stimulate

SWNT growth is evident from the AFM images of

Fig. 2 where the SWNTs always start to grow from a

Ni-cluster and extend on the SiO

2

. With topographic

AFM the SWNTs with a diameter of approximately

1 - 2 nm are clearly detectable on smooth thermally

grown SiO

2

. Examples of simple CNT network

structures are shown in Fig. 3.

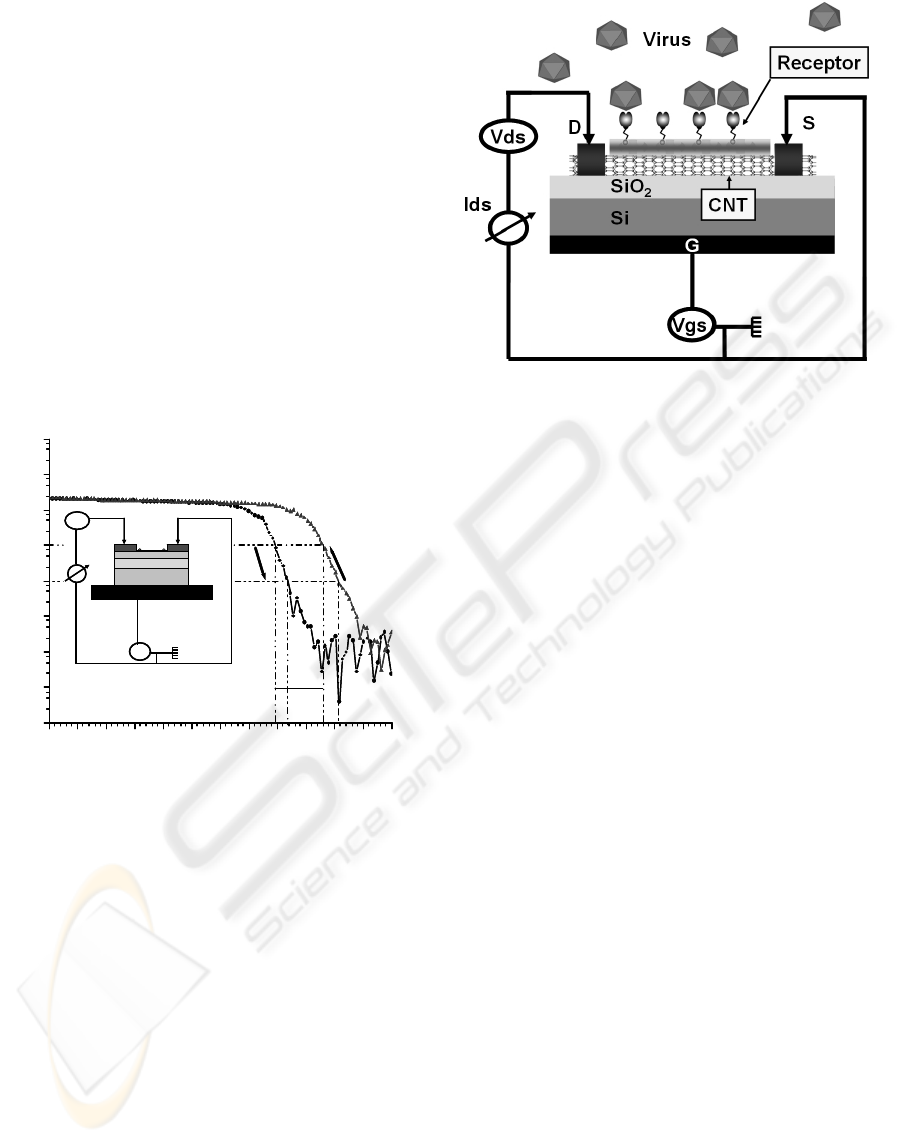

2.2 Electrical CNTFET Device

Characteristics

Once the electrical connection with the S/D contacts

is established, the electrical characteristics of the

CNTFETs can be obtained as shown in Fig. 4. In a

CNTFET the electric field applied via the gate

electrode modulates the charge carrier density in the

nanotube and thus the current between the source (S)

and drain (D) electrodes. Figure 4 shows the

measured drain-current (Ids) as a function of the

gate voltage (Vgs) which is swept between positive

and negative values. Our fabricated devices are fully

Si

Metal Catalyst Deposition

SiO

2

Al (8 nm)

Ni (1 nm)

Si

Metal Catalyst Deposition

SiO

2

Si

Metal Catalyst Deposition

SiO

2

Al (8 nm)

Ni (1 nm)

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

Si

SiO

2

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

(Gate)

(S) (D)

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

Si

SiO

2

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

(Gate)

(S) (D)

SWNT

Cluster Formation + CVD

Ni clusters

Si

SiO

2

AlxOy

SWNT

Cluster Formation + CVD

Ni clusters

Si

SiO

2

SiO

2

AlxOy

Si

Metal Catalyst Deposition

SiO

2

Al (8 nm)

Ni (1 nm)

Si

Metal Catalyst Deposition

SiO

2

Si

Metal Catalyst Deposition

SiO

2

Al (8 nm)

Ni (1 nm)

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

Si

SiO

2

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

(Gate)

(S) (D)

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

Si

SiO

2

Si

SiO

2

AlxOy

Pd

Pd

Pd S/D Contacts (Lift-Off)

(Gate)

(S) (D)

SWNT

Cluster Formation + CVD

Ni clusters

Si

SiO

2

AlxOy

SWNT

Cluster Formation + CVD

Ni clusters

Si

SiO

2

SiO

2

AlxOy

Figure 1: Process flow of CNTFET and CNTFES

fabrication based on CVD with sacrificial catalyst.

nmnm

Figure 2: AFM scan of SWNTs with a diameter o

f

approximately 1 to 2 nm on test structure (left). Top view

of CNTFET/CNTFES with CNT connecting source and

drain electrodes (right).

Figure 3: Example of CNT network structures with cross-

over points.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

100

functional and the drain-current is well controlled by

the gate voltage. Similar to conventional MOSFETs,

the CNTFET device can be properly turned on and

off. In fact, the on/off current ratio is in the 10

5

range

and exceeds the values of previously published

“hand made” CNTFETs (Martel 1998; Bezryadin

1998). The transistor characteristic is unipolar and

PMOS-like, i.e. a negative gate bias is required for

turn-on.

The gate controlled drain current shown in Fig. 4

exhibits a strong hysteresis effect which is well

reproducible. It has been found (Rispal 2007) that

the hysteresis is caused by trapped charges and the

related charge transfer at the interface between the

gate dielectric and s-SWNT. With respect to CNT-

sensor applications, the hysteresis effect confirms

that any attached charges will have clearly

detectable signatures on the device characteristics of

Figure 4: Measured transfer characteristics of fabricated

CNTFET device structure. In this example the CNTFET

contains just one s-SWNT. Device characteristics of

CNTFETs containing multiple SWNTs (CNT-network)

are similar, except for the increased drain current drive

(Ids) proportional to the number of SWNTs in parallel.

CNTFETs. Since only the change in the charging

state will be needed to alter the device

characteristics via the field effect, extremely

sensitive sensors are feasible.

These CNTFET devices form the basis of the

technology platform of the proposed nano-sensors

for biomedical applications.

3 PROPOSAL: BIOMEDICAL

CNTFES

Taking advantage of the above mentioned hysteresis

effect which we observe in our CNTFET devices,

extremely sensitive nano-sensors (i.e. CNTFES)

well suitable for biomedical applications can be

realized. For example, the detection and

identification of single viral particles may be

possible using functionalized CNTFETs as sensors

as illustrated in Fig. 5: The binding of a virus to a

suitably functionalized s-SWNT will measurably

affect the gate-dependent electrical current-voltage

characteristics of the s-SWNT via charge transfer

between the CNT and the virus. The virus detection

is thus performed electronically via the CNTFET

(cf. Fig. 4) which will alter its electrical device

characteristics in presence of a virus. The sensitivity

can be enhanced further by using CNT-networks (cf.

Fig. 3) or array structures with multiple SWNTs.

Furthermore, complete electronic integrated sensor

circuits based on hybrid CNT-CMOS technology are

envisioned which will perform data analysis on-chip

(smart biosensors).

However, the main challenge for the realization

of this biomedical sensor will be the proper

functionalization of the CNT in order to be highly

selective to the desired type of virus. This

knowledge is outside of the scope of our own

-3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0

1E-13

1E-12

1E-11

1E-10

1E-9

1E-8

1E-7

1E-6

1E-5

On-current: 210 nA

Hysteresis:

850 mV

300

mV/dec

250 mV/dec

Vds = 400 mV

SiO2 thick. = 30 nm

ABS (Ids) (A)

Vgs (V )

SiO

2

AlxOy

PdPd

Vgs

Vds

Gate

Drain Source

Ids

SiO

2

AlxOy

PdPd

SiO

2

SiO

2

AlxOy

PdPd

Vgs

Vds

Gate

Drain Source

Ids

-3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0

1E-13

1E-12

1E-11

1E-10

1E-9

1E-8

1E-7

1E-6

1E-5

On-current: 210 nA

Hysteresis:

850 mV

300

mV/dec

250 mV/dec

Vds = 400 mV

SiO2 thick. = 30 nm

ABS (Ids) (A)

Vgs (V )

SiO

2

AlxOy

PdPd

Vgs

Vds

Gate

Drain Source

Ids

SiO

2

AlxOy

PdPd

SiO

2

SiO

2

AlxOy

PdPd

Vgs

Vds

Gate

Drain Source

Ids

Figure 5: Illustration of proposed CNTFET-sensor for

virus detection. The semiconducting single-walled CNT

is functionalized with a suitable receptor to allow

selective bonding via its protein. Extremely sensitive

sensors for virus detection are feasible, since any change

in the charging state introduced by the virus will alte

r

the device characteristics via the field-effect.

NOVEL FIELD-EFFECT CONTROLLED SINGLE-WALLED CARBON NANOTUBE NETWORK DEVICES FOR

BIOMEDICAL SENSOR APPLICATIONS

101

expertise (nanoelectronics). For a successful

realization of these biomedical nano-sensors

additional expertise from the biochemical and

biomedical area is needed through collaborations

with experts from the respective fields via research

projects (e.g. EU FP7). In these projects we will

provide the CNTFET-sensor devices and will be

able to perform all necessary electrical

characterization.

4 CONCLUSIONS

In this position paper we have proposed a novel

method for the fabrication of carbon nanotube field-

effect sensors (CNTFESs). These nano-sensors are

ideally suitable for biomedical sensor applications

due to their excellent inherent properties such as

ultra small size, high specific surface area and

extremely high sensitivity. Results have been

presented on the novel fabrication process to grow

individual CNTs and CNT-networks directly within

the specified device area. This is the most practical

approach for future use in high-volume fabrication

of advanced integrated nano-sensors at low cost

since tedious manual manipulations and alignment

procedures of CNTs are obsolete. As a proof of

concept electrical results on the fabricated fully

functional CNTFETs suitable for sensor applications

have been presented.

We are offering the biomedical device

community our CNT-sensor technology in order to

realize next-generation of nano-sensors within a

joint project and to evaluate their potential in

biomedical applications.

REFERENCES

Barreiro, A., et al., 2006, Applied Physics A, 82 (4), 719

Bezryadin, A., et al., 1998, Phys. Rev. Lett., 80, 4036.

Iijima, S., 1991, Nature, 354, p. 56-58

Kong, J., et al., 2000, Science 287, 622

Martel, R., et al., 1998, Appl. Phys. Lett., 73, 2447.

Rispal, L., et al. 2006, Japanese J. Appl. Physics, 45, 3672

Rispal, L., et al. 2007, International Conference on Solid

State Devices and Materials (SSDM2007), Tsukuba,

Japan.

Schwalke, U., 2007, ECS Transactions, 10, in print.

Someya, T. et al., 2003, Nano Lett. 3, 877

Staii, C., et al., 2005, Nano Lett. 5, 1774

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

102