DATA EVALUATION FOR DEPTH CALIBRATION OF A

CUSTOMARY PMD RANGE IMAGING SENSOR CONSIDERING

OBJECTS WITH DIFFERENT ALBEDO

Jochen Radmer

Institut f

¨

ur Werkzeugmaschinen und Fabrikbetrieb (IWF), Technische Universit

¨

at Berlin, Berlin, Germany

Alexander Sabov and J

¨

org Kr

¨

uger

Institut f

¨

ur Produktionsanlagen und Konstruktionstechnik (IPK), Fraunhofer Gesellschaft, Berlin, Germany

Keywords:

Range Imaging Camera, Photo Mixer Device (PMD), Depth Calibration, Albedo, Reflectance Properties.

Abstract:

For various applications, such as object recognition or tracking and especially when the object is partly oc-

cluded or articulated, 3D information is crucial for the robustness of the application. A recently developed

sensor to aquire distance information is based on the Photo Mixer Device (PMD) technique. This article

presents an easy but accurate data acquisition method for data evaluation of a customary sensor. Data evalu-

ation focuses on the detection of the over- and underexposured data under consideration of objects with two

different albedos.

1 INTRODUCTION

Since we are living in a three-dimensional world, for

various applications, such as object recognition or

tracking, 3D information is crucial for the robust-

ness of the application, especially when the object

is partly occluded or articulated. Due to its signifi-

cance, the field of depth data acquisition has attracted

many researchers working on sensors or sensor sys-

tems respectively. A recently developed sensor is

based on the Photo Mixer Device (PMD) technique

which works on modulated, coherent infrared light

using the Time of Flight (ToF) approach and rely on

a technology that correlates reference and received

signals directly on the chip. It was first mentioned

by (Lange, 2000) and (Schwarte, 1999). This sensor

provides direct depth information for a whole image,

for which reason such sensors are called range imag-

ing sensors. Additionally to the depth data the cam-

era provides two other channels. One channel corre-

sponds to the luminance of the scene and the other

channel is the amplitude as it is described in section

(Lange, 2000) and corresponds to the signal strength

of the incoming signal. The PMD range imaging cam-

era is shown in figure 1 with infrared LED matrices on

both sides of the camera.

Since this sensor is based on a rather new technol-

ogy, data evaluation and depth calibration has to be

Figure 1: This figure shows the examined PMD Range

Imaging Camera of model PMD [vision] 19k with the in-

frared LED matrices on both sides of the camera.

carried out for it. (Lindner and Kolb, 2006) did a lat-

eral and depth calibration on a modified research sen-

sor. In this work the non-linearity of the depth data

was coped by a distance deviation plot. (Kahlmann

et al., 2006) additionally considered the dependency

on the integration time. But since the sensor emits

light for ToF and is dependent on the amount of inci-

dent light, the integration time is not the only param-

eter affecting the depth measurement. It is just one

parameter influencing the amount of incident light.

The incident light can also vary with the infrared re-

flectance properties of the looked at object, the dis-

tance to it and the LEDs properties. Therefore the

data evaluation for the depth calibration has to be car-

169

Radmer J., Sabov A. and Krüger J. (2008).

DATA EVALUATION FOR DEPTH CALIBRATION OF A CUSTOMARY PMD RANGE IMAGING SENSOR CONSIDERING OBJECTS WITH DIFFERENT

ALBEDO.

In Proceedings of the Third International Conference on Computer Vision Theory and Applications, pages 169-173

DOI: 10.5220/0001076701690173

Copyright

c

SciTePress

ried out considering the amount of incident light. In

addition, in order to guarantee a certain exactitude

of the data, over and underexposed data has to be

identified. For this reason this paper focuses on data

evaluation and improvement considering different re-

flectance properties in combination with the distance

and the integration time for a customary sensor. On

account of the fact that the reflectance properties of

an object vary greatly with its material and orienta-

tion, the measurement will be simplified. Instead of

the reflectivity we will rather consider different albe-

dos. Albedo is a unitless measure indicative of an ob-

ject’s diffuse reflectance properties. Nevertheless, a

comprehensive investigation has to be done for many

reflectance properties so that this work can be seen

as some starting point. Thus, the main contribution

of this paper is the analysis of the data provided by

the PMD range camera under consideration of objects

with different albedos and to give method for distance

measuring improvement.

The distance measuring methods used be the PMD

range imaging camera is the Time of Flight (ToF)

method. The article of (Lange, 2000) offers a de-

tailed description of the functional way of the PMD

range imaging camera. A short overview of the dis-

tance calculation can be found in (Sabov and Kruger,

2007).

The paper is structured as follows. First the data

acquisition and data evaluation is described. The ba-

sic methods for the improvement of the data are given.

Within section three results are presented and dis-

cussed and finally this article is concluded in section

five.

2 DATA EVALUATION

2.1 Data Acquisition Method

For the data evaluation fixed targets were considered,

a black and a white wall, with diffuse, Lambertian re-

flectance model like characteristics. We have selected

a white and a black wall as objects because of their

contrariness in their albedo.

The measuring setup for the data acquisition ex-

isted of the PMD range camera, two lasers to distance

measuring instruments (range finder), a camera con-

struction to arm the distance measuring instruments

on the PMD range camera, two markers, a tripod and

the object, the wall. The measurement range of the

distance measuring instrument was 0.2m to 30m me-

ter with an accuracy of ±2.0mm. Those range finders

were aimed at the ends of the camera construction in

parallel in the direction of the camera. With every

Figure 2: This figure shows the measurement setup as de-

scribed in the text.

measurement the camera was aimed with both dis-

tance measuring instruments showing the same dis-

tance. The distance measured by both instruments

was taken as the nominal distance to the object. In

addition, the laser points of the distance measuring in-

struments were directed upon two marks on the wall

to verify the parallelism of the distance measuring in-

struments. The base distance b between the marks on

the wall as well as the distance between both range

finders is identical. To guarantee the orientation of

the camera also in vertical direction, the marks were

appropriated by the same height like the range finders.

The base distance b can be seen in the figure 2, which

shows the whole measurement setup. The parallelism

and the same distances measured by the instruments

guaranteed the horizontal orientation α of the cam-

era towards the wall to be perpendicular. This is done

to reduce perspective influence on the measurement.

Based on this measuring setup and with the base dis-

tance b = 0.4m the maximum angle error ∆α

max

of

the adjustment of the camera arises to ∆α

max

≈ 0.6

◦

using the following equation:

∆α

max

= arctan

|∆d

1

| + |∆d

2

|

b

= arctan

0.004m

0.4m

(1)

This assumes that the wall is plane and arming of the

range finders was performed in a precise way. The

maximum distance error ∆d

max

can be calculated re-

garding the direction of the distances with equation 2.

The maximum ∆d

max

then arises to ±2.0mm.

∆d

max

=

∆d

1

+ ∆d

2

2

(2)

The measurement was carried out in different dis-

tances of the camera to the wall in intervals between

the single measurements of 0.1m. The measurement

was applied about the whole measuring space of the

camera. Ten measurements were carried out in every

measuring distance and in each case the local neigh-

borhood of the centre was captured to get more sta-

ble data. The centre was determined before by the

determination of the intrinsic parameters. This lat-

eral calibration was done using the method described

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

170

in (Bouguet, 1999). The measurements per measur-

ing distance were performed for different integration

times. The span of the used integration times reached

from 500µs to 20000µs which were gone through in

500µs steps.

(Kahlmann et al., 2006) showed that the sensor

’SwissRanger’ heats up self-induced and that this af-

fects the captured data. This process stabilizes a few

minutes after having started the data acquisition. To

avoid these effects of self-induced heating, the data

acquisition for the data evaluation was started after

20 minutes of sensor run-time.

Although the distance measurement accuracy vary

over the sensor and every measuring point must be

considered individually for improvement (Kahlmann

et al., 2006), in this work only the central measuring

points are considered, because the focus on the dis-

tance data improvement lies in relation for the inte-

gration time, the nominal distance and the albedo of

the objects.

2.2 Distance Measurement, Amplitude

and Object Albedo

In this section distance measuring results regarding

integration time and nominal distance are considered.

First it is looked at the measuring results without vary-

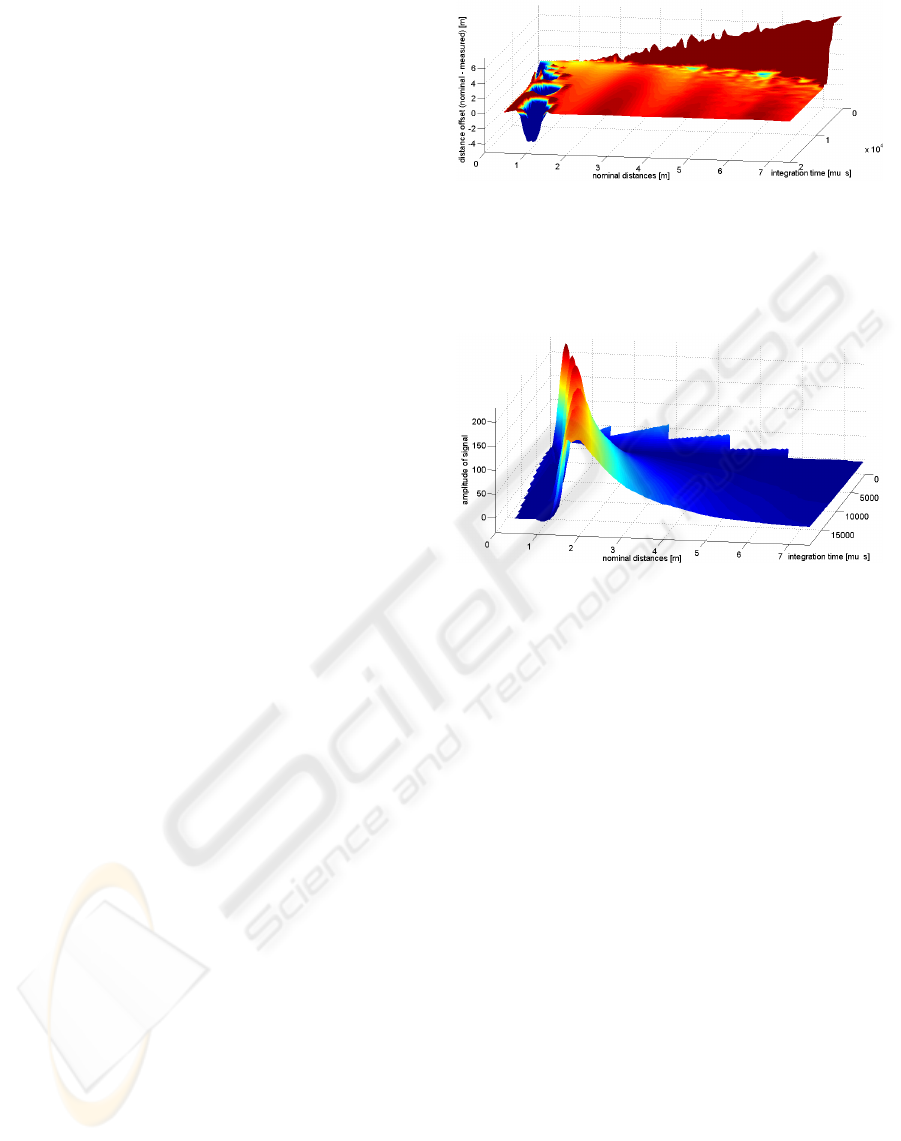

ing the albedo of the object. In figure 3 the deviation

of the measured to the nominal distance for a white

wall can be seen. The deviations are applied for in-

tegration time and nominal distance. As can be seen

clearly, low integration times and high nominal dis-

tances result in erroneous distance measurements. In

this connection must be mentioned that the low inte-

gration times which yield erroneous distance measur-

ing values play only one very low role in the practi-

cal use of the sensor. The same can be ascertained

for long integration times in combination with low

nominal distances. Since distance measurements with

under- and overexposure do not include any useful in-

formation, these distances have to be detected first be-

fore improving the distance data.

In the area in which the measured distances de-

viate only slightly from the nominal ones a period-

ical dependence of the distance offset can be ascer-

tained to the nominal distance. This periodic error

in the depth measurement agrees with mathematical

predictions due to the shape of the correlation func-

tion of the reference and the received signals. Be-

side this periodical dependence the distance measur-

ing error increases with an enlargement of the integra-

tion time. The error measured for different integration

times tending downwards has a range of about 50mm

up from 2m nominal distances. For closer distances

Figure 3: This figure shows the absolute deviation of nomi-

nal to measured distances in meter regarding the integration

times in µs10

4

and nominal distance in meter. A white wall

with diffuse, Lambertian reflectance model like characteris-

tics had been considered as object.

Figure 4: This figure shows the amplitude of the signal used

for distance determination regarding the integration times in

µs and nominal distance in meter. A white wall was used as

object.

the error introduced by the near field effect caused

by different ToF from the left and the right LED ar-

rays dominates over the error introduced by the anhar-

monic signals. For these areas which can be described

about integration time and nominal distance a correc-

tion can be achieved about Look-up-tables (LUT). Ac-

cording to (Kahlmann et al., 2006) these LUT’s have

to contain an individual offset for each data point. A

better knowledge of the received LED and the refer-

ence signal likely would provide a more robust ba-

sis for depth calibration. However, with the practi-

cal application of the sensor the nominal distance is

unknown. Hence, we take into consideration for the

detection of the useless distance values, in addition,

the amplitude Ampl. In figure 4 the accompanying

Ampl is shown. Likewise with regard to the integra-

tion time and the nominal distance. A connection can

be noticed between distance measuring error and the

accompanying Ampl. Through a simple threshold the

underexposed data can be identified, when Ampl falls

below a certain threshold.

The area in which on account of low nominal dis-

tance, high reflectance property and long integration

time it comes to an overexposure cannot be detected

simply about a threshold. In this case the standard

DATA EVALUATION FOR DEPTH CALIBRATION OF A CUSTOMARY PMD RANGE IMAGING SENSOR

CONSIDERING OBJECTS WITH DIFFERENT ALBEDO

171

Figure 5: This figure shows the standard deviation in meter

regarding the integration times in µs10

4

. A white wall was

considered as object with a nominal distance of 0.9m. It

can be noticed that the standard deviation can be used for

the detection of overexposure.

deviation of the distance is considered giving a direct

quality measurement for the measured distances. Ex-

emplary the standard deviation for the distance mea-

surement at a nominal distance of 0.9m is shown in

figure 5. It was computed out of ten measured dis-

tances. The nominal distance of 0.9m was selected

because it yields correctable distance values at short

integration times and arbitrary distance values at long

ones, which are not correctable (cp. figure 3). Fig-

ure 5 shows that the standard deviation is high when

an overexposure occurs and low instead. Therefore

the standard deviation of measured distances can be

used for the detection of overexposure. It can be seen

that the standard deviation in spite of the very small

number of ten samples being used for the calculation

achieves a high discriminatory power. Comparable

results can be achieved by calculating the standard

deviation of the local neighborhood and therefore us-

ing a spatial instead of a temporal window. A spa-

tiotemporal consideration is not necessary because of

the high discriminatory power of one approach.

By the detection of over- and underexposure useless

measured distances can be neglected. The remaining

measured distances then can be corrected by a LUT,

which is based upon the nominal to measured distance

measurements.

In the following the measuring results are exam-

ined under consideration of a different albedo of the

object. For measurements with a black wall as object

the distance offset can be seen in figure 6. Of course

these measurements also show areas with erroneous

measured distances due to underexposure, since the

albedo of a black wall is lower than the one of a white

wall. The recently described method for the detection

of measured distance in case of over- or underexpo-

sure show good results also with this object, when

using the same global thresholds. The periodicity

has the same period length over the nominal distance.

This is due to the shape of the correlation function

of the reference and the received signals, which does

not change. But in comparison to the measurements

with the white wall, a bigger distance offset can be

Figure 6: This figure shows the absolute deviation of nomi-

nal to measured distances in meter regarding the integration

times in µs10

4

and nominal distance in meter. A black wall

was used as object.

Figure 7: This figure shows the amplitude of the signal used

for distance determination regarding the integration times in

µs and nominal distance in meter. A black wall was used as

object.

noticed. Therefore the albedo must be identified for

the improvement of the distance measuring data.

Since the range camera works with a globally set in-

tegration time, the method for the improvement of the

data needs to take into consideration the amount of

incident light. That can be achieved by directly con-

sidering Ampl. Figure 7 shows Ampl of the measure-

ments with the black wall. Results for the identifi-

cation of the albedo with a case-based measured dis-

tance improvement are presented in the next section.

3 RESULTS

In this section the results of the work are presented,

meaning that the identification of the albedo with a

case-based distance value improvement are presented

for a black and white wall. In figure 8 is shown on the

left side the distance offset in meter and on the right

side the according amplitude Ampl at central data

points along a central column. The left side shows

the black wall and the right side the white wall show-

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

172

ing a lower distance measuring error. The crossover

between black and white can be seen clearly. The re-

sult after applying the LUT’s for black and white on

the distance measurement data is shown in figure 9

showing the distance offset in meter. It can be noticed

that the distance offsets were decreased significantly

from up to 0.3m down to about 0.02m. The difference

of the distance offset between the white and the black

wall was nearly completely eliminated. At data points

where the different albedo contact a bigger distance

offset can be noticed. This is caused by the interme-

diate values for which no LUT exist.

Figure 8: In the left figure the distance offset in meter and

on the right side the according amplitude Ampl at central

data points along a central column is shown. The crossover

between the two albedos can be seen clearly.

Figure 9: This figure shows the distance offset in meter af-

ter applying the LUT’s for black and white on the distance

measurement data. The distance offsets were decreased

from up to 0.3m down to about 0.02m. The difference be-

tween the offset was nearly completely eliminated. At the

crossover a bigger distance offset can be noticed. This is

caused by the intermediate values for which no LUT exist.

4 CONCLUSIONS

This article presents an easy but accurate data acquisi-

tion method for data evaluation of a customary sensor.

Data evaluation focuses on the detection of the over-

and underexposed data under consideration of objects

with two different albedos. This improves the exacti-

tude of the data for the study of the systematic errors

of this sensor. Therefore the work of this article can

be seen as an intermediate result on the way to a PMD

range imaging sensor calibration. We showed that

the object’s reflectance properties affects the distance

measuring. Therefore we proposed a basic method for

the identification of the albedo of the considered ob-

jects so that an albedo according LUT can be applied

for the correction. These LUT’s have to be created for

a set of reference objects with different albedos. The

example in the previous section shows that a correc-

tion can be achieved about LUT’s. Because of their

contrariness in their albedos, we selected a white and

a black wall as objects. A statement about the be-

haviour of the sensor can thereby be done only for

those extreme albedos. Apart from these albedos a

statement cannot occur for general reflectance proper-

ties. Further work has to be done in the field of inter-

polation between LUT’s when unknown albedos are

detected and how to handle crossovers between dif-

ferent albedo. Additionally, objects which reflectance

properties cannot be described by a Lambertian re-

flectance model need to be investigated.

REFERENCES

Bouguet, J. (1999). Visual methods for three-dimensional

modeling. PhD thesis, California Institute of Technol-

ogy.

Kahlmann, T., Remondino, F., and Ingensand, H. (2006).

Calibration for increased accuracy of the range imag-

ing camera swissranger. In International Archives of

Photogrammetry, Remote Sensing and Spatial Infor-

mation Sciences, ISPRS Commission V Symposium,

volume XXXVI, pages 136–141.

Lange, R. (2000). 3D Time-of-Flight Distance Mea-

surement with Custom Solid-State Image Sensors in

CMOS/CCD-Technology. PhD thesis, University

Siegen.

Lindner, M. and Kolb, A. (2006). Lateral and depth calibra-

tion of pmd-distance sensors. In ISVC (2)- Advances

in Visual Computing, Second International Sympo-

sium, volume 4292 of Lecture Notes in Computer Sci-

ence, pages 524–533. Springer Verlag.

Sabov, A. and Kruger, J. (2007). Improving the data quality

of pmd-based 3d cameras. In Proc. Vision, Modeling

and Visualization (VMV).

Schwarte, R. (1999). Handbook of Computer Vision and

Applications, chapter Principles of 3-D Imaging Tech-

niques. Academic Press.

DATA EVALUATION FOR DEPTH CALIBRATION OF A CUSTOMARY PMD RANGE IMAGING SENSOR

CONSIDERING OBJECTS WITH DIFFERENT ALBEDO

173