GPC AND NEURAL GENERALIZED PREDICTIVE CONTROL

S. Chidrawar

1

Nikhil Bidwai

2

, L. Waghmare

2

and B. M. Patre

2

1

MGM’s College of Engineering, Nanded (MS) 431 602, India

2

SGGS Institute of Engineering and Technology, Nanded (MS) 431 606, India

Keyword: Neural network, Model predictive control, GPC, NGPC.

Abstract: An efficient implementation of Model Predictive Control (MPC) using a multilayer feed forward network as

the plants linear model is presented. This paper presents a comparison between the Generalized Predictive

Control and Neural Generalized Predictive Control with Newton-Raphson as minimization algorithm. Three

different linear models are taken and their performances are tested. Simulation result shows the effect of

neural network on Generalized Predictive Control for linear systems. The performance comparison of these

system configurations has been given in terms of ISE and IAE.

1 INTRODUCTION

Model predictive control (MPC) has found a wide

range of applications in the process, chemical, food

processing, automotive, aerospace, metallurgy, and

pulp and paper industries. (Qin and Badgwell, 2003;

Yu, Yu and Gomm, 2006; Lawrynczuk, 2007). In

recent years, the requirements for the quality of

automatic control in the process industries increased

significantly due to the increased complexity of the

plants and sharper specifications of product quality.

As a result, computer models that are

computationally expensive became applicable even

to rather complex problems. Intelligent and model

based control techniques were developed to obtain

tighter control for such applications. Neural network

techniques has been found to be particularly useful

for modeling and controlling highly uncertain

nonlinear and complex systems. (Noorgard, Ravn,

Poulsen and Hansen, 2000). The Model Predictive

Control (MPC) techniques found to be very effective

in control systems. MPC was introduced

successfully in several industrial plants. Some of the

most popular MPC algorithms that found a wide

acceptance in industry are Dynamic Matrix Control

(DMC), Model Algorithmic Control (MAC),

Predictive Functional Control (PFC), Extended

Prediction Self Adaptive Control (EPSAC),

Extended Horizon Adaptive Control (EHAC) and

Generalized Predictive Control (GPC). (Morari and

Lee, 1999, Rossiter, 2003). In this work, comparison

between GPC and Neural GPC has been carried out

for linear systems. The results show the efficacy of

NGPC for such plants.

2 GENERALIZED PREDICTIVE

CONTROL

The GPC method was proposed by Clarke et. al.

(Clarke, Mohatadi and Tuffs, 1987) and has become

one of the most popular MPC methods both in

industry and academia.

The basic idea of GPC is to calculate a sequence

of future control signals in such a way that it

minimizes a multistage cost function defined over a

prediction horizon. The index to be optimized is the

expectation of a quadratic function measuring the

distance between the predicted system output and

some reference sequence over the horizon plus a

quadratic function measuring the control effort. The

GPC scheme consists of the plant to be controlled, a

reference model that specifies the desired

performance of the plant, a linear model of the plant,

and the Cost Function Minimization (CFM)

algorithm that determines the input needed to

produce the plant’s desired performance. The GPC

system starts with the input signal, r(t), which is

presented to the reference model. This model

produces a tracking reference signal, w (t) that is

used as an input to the CFM block. The CFM

algorithm produces an output, which is used as an

input to the plant. Between samples, the CFM

266

Chidrawar S., Bidwai N., Waghmare L. and M. Patre B. (2008).

GPC AND NEURAL GENERALIZED PREDICTIVE CONTROL.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 266-270

DOI: 10.5220/0001476102660270

Copyright

c

SciTePress

algorithm uses this model to calculate the next

control input, u(t+1), from predictions of the

response from the plant’s model. Once the cost

function is minimized, this input is passed to the

plant.

3 NEURAL GENERALIZED

PREDICTIVE CONTROL

The ability of the GPC to make accurate predictions

can be enhanced if a neural network is used to learn

the dynamics of the plant instead of standard

nonlinear modeling techniques.(Noorgard, Ravn,

Poulsen and Hansen, 2000). The selection of the

minimization algorithm affects the computational

efficiency of the algorithm. In this work Newton-

Raphson method is used as the optimization

algorithm. The main cost of the Newton-Raphson

algorithm is in the calculation of the Hessian, but

even with this overhead the low iteration numbers

make Newton-Raphson a faster algorithm for real-

time control. (Soloway, 1996). The Neural

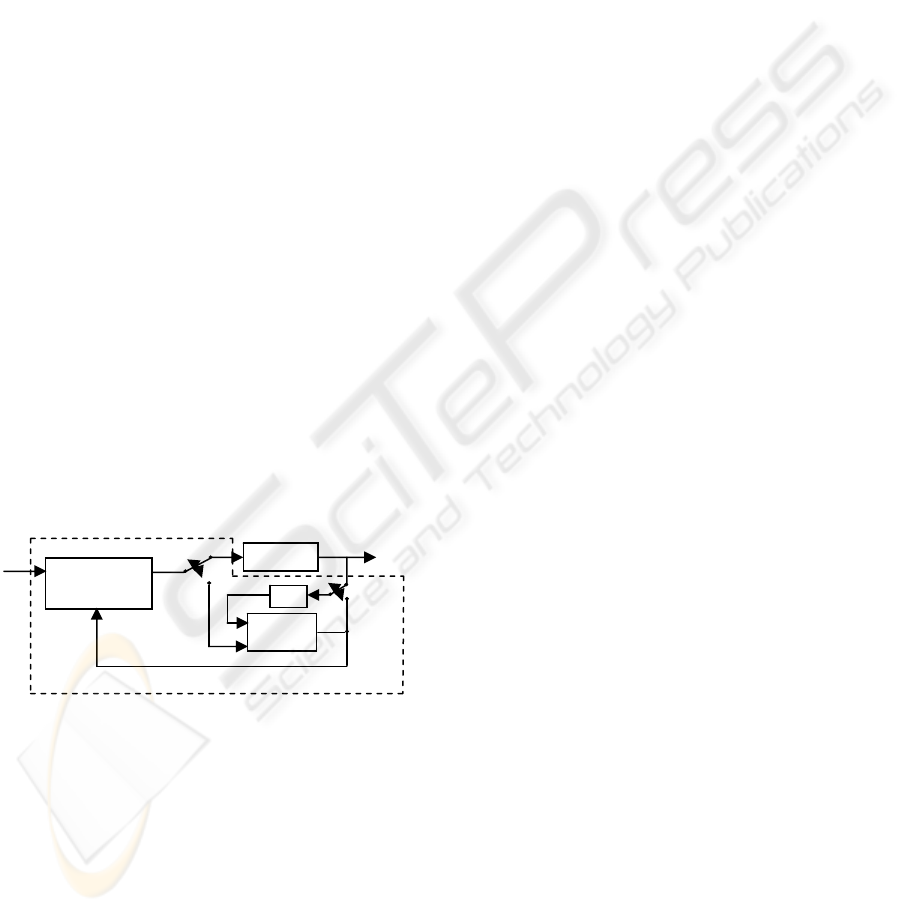

Generalized Predictive Control (NGPC) system can

be seen in Fig. 1. It consists of four components, the

plant to be controlled, a reference model that

specifies the desired performance of the plant, a

neural network that models the plant, and the Cost

Function Minimization (CFM) algorithm that

determines the input needed to produce the plant’s

desired performance. The NGPC algorithm consists

of the CFM block and the neural net block.

Figure 1: Block Diagram of NGPC System.

The NGPC system starts with the input signal, r(t),

which is presented to the reference model. This

model produces a tracking reference signal, w(t+k),

that is used as an input to the CFM block. The CFM

algorithm produces an output that is either used as

an input to the plant or the plant’s model. The

double pole double throw switch, S, is set to the

plant when the CFM algorithm has solved for the

best input, u(t), that will minimize a specified cost

function. Between samples, the switch is set to the

plant’s model where the CFM algorithm uses this

model to calculate the next control input, u(t+1),

from predictions of the response from the plant’s

model. Once the cost function is minimized, this

input is passed to the plant. The computational

performance of a GPC implementation is largely

based on the minimization algorithm chosen for the

CFM block. Models using neural networks have

been shown to have the capability to capture

nonlinear dynamics. Improved predictions affect rise

time, over-shoot, and the energy content of the

control signal.

3.1 Formulation of NGPC

3.1.1 Cost Function

As mentioned earlier, the NGPC algorithm

(Soloway, 1996) is based on minimizing a cost

function over a finite prediction horizon. The cost

function of interest to this application is

[][]

2

22

ˆ

(, , ) ()( |) ( ) () ( 1)

12

1

1

N

N

u

JNNN jytjt wtj j utj

u

jN j

δλ

=+−++Δ+−

∑∑

==

(1)

N

1

= Minimum Costing Prediction Horizon

N

2

= Maximum Costing Prediction Horizon

N

u

= Length of Control Horizon

()yt kt

∧

+

⏐

= Predicted Output from Neural;

Network,

()ut kt

+⏐

= Manipulated Input

()wt k

+

= Reference Trajectory

δ and λ = Weighing Factor

When this cost function is minimized, a control

input that meets the constraints is generated that

allows the plant to track the reference trajectory

within some tolerance. There are four tuning

parameters in the cost function, N

1

, N

2

, N

u

, and λ.

The predictions of the plant will run from N

1

to N

2

future time steps. The bound on the control horizon

is N

u

. The only constraint on the values of N

u

and N

1

is that these bounds must be less than or equal to N

2

.

The second summation contains a weighting factor,

λ that is introduced to control the balance between

the first two summations. The weighting factor acts

as a damper on the predicted u(n+1).

3.1.2 Cost Function Minimization Algorithm

The objective of the CFM algorithm is to minimize J

in Equation (1) with respect to [u(n+l), u(n+2), ...,

u(n+N

u

)]

T

, denoted as U. This is accomplished by

setting the Jacobian of Equation (1) to zero and

solving for U. With Newton-Rhapson used as the

CFM algorithm, J is minimized iteratively to

Cost Function

Minimization

(CFM)

Plant

Neural

Plant Model

z

-1

y(t)

()

n

yt kt

∧

+⏐

()wt k+

u(t)

s

s

NGPC Algorithm

GPC AND NEURAL GENERALIZED PREDICTIVE CONTROL

267

determine the best U. An iterative process yields

intermediate values for J denoted J(k). For each

iteration of J(k) an intermediate control input vector

is also generated and is denoted as:

(1)

(2)

.

()

.

.

()

u

ut

ut

Uk

ut N

Δ

+

⎡⎤

⎢⎥

+

⎢⎥

⎢⎥

=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

+

⎢⎥

⎣⎦

k=1,....N

u

(2)

Using this Newton-Raphson update rule,

(1)Uk

+

is

1

2

2

(1) () () ()'

JJ

Uk Uk k k

UU

−

⎛⎞

∂∂

+= −

⎜⎟

∂∂

⎝⎠

where

()

J

fx

U

∂

=

∂

(3)

where the Jacobian is denoted as

(1)

.

.

()

.

()

u

J

ut

J

k

U

J

ut N

∂

⎡⎤

⎢⎥

∂+

⎢⎥

⎢⎥

∂

⎢⎥

≡

⎢⎥

∂

⎢⎥

⎢⎥

∂

⎢⎥

⎢⎥

∂+

⎣⎦

(4)

and the Hessian as

22

2

2

2

22

2

..

(1) (1)( )

....

() .

....

..

()(1) ()

u

uk u

JJ

ut ut ut N

J

k

U

JJ

ut N u t ut N

⎡⎤

∂∂

⎢⎥

∂+ ∂+∂+

⎢⎥

⎢⎥

∂

≡

⎢⎥

∂

⎢⎥

⎢⎥

∂∂

⎢⎥

∂+ ∂ + ∂+

⎢⎥

⎣⎦

(5)

The each element of the Jacobian is calculated by

partially differentiating (4) with respect to vector U.

3.1.3 Neural Network Architecture

In NGPC the model of the plant is a neural network.

This neural model is constructed and trained using

MATLAB Neural Network System Identification

Toolbox commands and Control System Design

Toolkit (Noorgard, Ravn, Poulsen and Hansen,

2000).

The output of trained neural network is used as

the predicted output of the plant. This predicted

output is used in the Cost Function Minimization

Algorithm. If y

n

(t) is the neural network’s output

then it is nothing but plant’s predicted output

()

n

yt kt

∧

+

⏐

.

The initial training of the neural network is typically

done off-line before control is attempted

3.1.4 Prediction using Neural Network

The NGPC algorithm uses the output of the plant's

model to predict the plant's dynamics to an arbitrary

input from the current time, t, to some future time,

t+k.

4 SIMULATION RESULTS

The objective of this study is to show how GPC and

NGPC implementation can cope with linear systems.

GPC is applied to the systems with changes in

system order. The Neural based GPC is

implemented using MATLAB Neural Network

Based System Design Toolbox (Noorgard, Ravn,

Poulsen and Hansen, 2000).

4.1 GPC and NGPC for Linear

Systems

The GPC and NGPC algorithm was applied to the

different linear models with varying system for

simulation purpose. For all the systems Prediction

Horizon N

1

=1, N

2

=7 and Control Horizon (N

u

) is 2

have been considered. The weighing factor λ for

control signal is kept to 0.3 and δ for reference

trajectory is set to 0. The same controller setting is

used for all the systems simulation. The following

simulation results are obtained showing the plant

output when GPC and NGPC are applied. Also the

required control action for different systems is

shown.

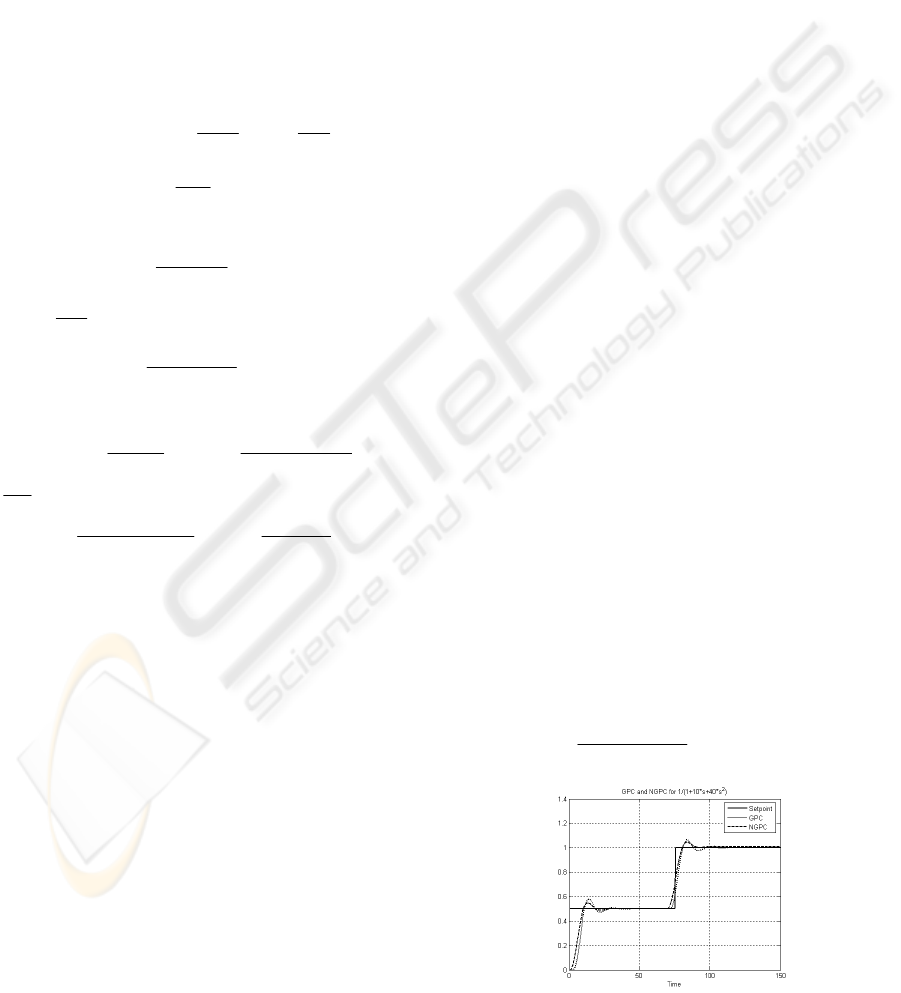

System I. The GPC and NGPC algorithms are

applied to a second order system (6). Fig. 2 shows

the plant output with GPC and NGPC. Fig. 3 shows

the control efforts taken by both controllers.

2

1

()

110 40

Gs

s

s

=

++

(6)

Figure 2: System I Output using GPC and NGPC.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

268

Figure 3: Control Signal for System I.

System II. A simple first order system (7) is

controlled. Fig. 4 and Fig. 5 show the system output

and control signal.

1

()

110

Gs

s

=

+

(7)

Figure 4: System II Output using GPC and NGPC.

Figure 5: Control Signal for System II.

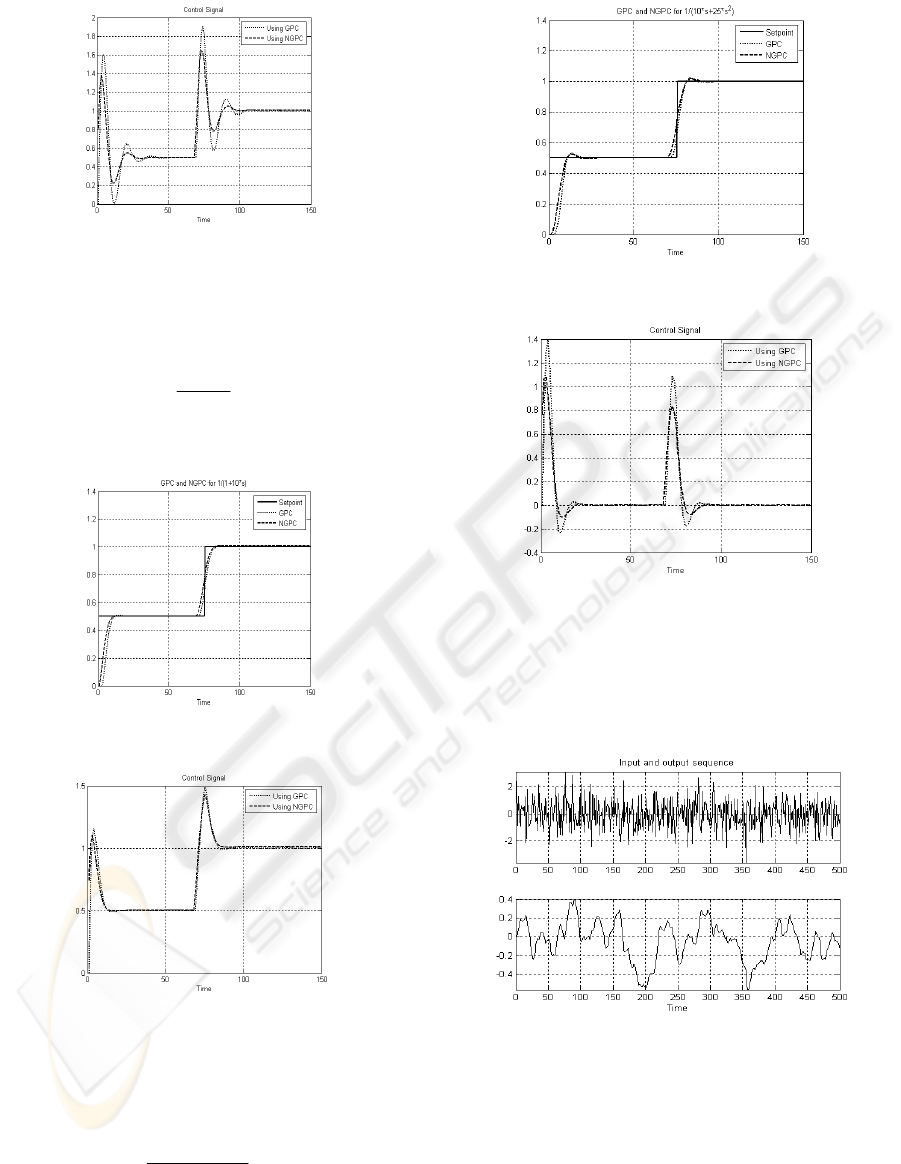

System III. A second order system (8) is controlled

using GPC and NGPC. Fig.6 and Fig.7 Show the

predicted output and control signal.

1

()

10 (1 2.5 )

Gs

s

s

=

+

(8)

Figure 6: System III Output using GPC and NGPC.

Figure 7: Control Signal for System III.

Initially systems were trained using Levenberg-

Marquardt learning algorithm. Fig. 8 shows input

data applied to the neural network for offline

training purpose and corresponding neural network

output.

Figure 8: Input and output data for NN.

Performance evaluation of both the controller is

carried out using ISE and IAE criteria. Table 1 gives

ISE and IAE values for both GPC and NGPC

implementation for all the linear systems considered.

It was observed that for each system ISE and IAE

using NGPC is smaller or equal to GPC.

GPC AND NEURAL GENERALIZED PREDICTIVE CONTROL

269

Table 1: ISE and IAE Performance Comparison of GPC

and NGPC for Linear System.

GPC NGPC Systems Setpoint

ISE IAE ISE IAE

0.5 1.827 4.4107 1.6055 3.6351 I

1 0.2567 1.4492 0.1186 1.4312

0.5 1.1803 3.217 0.7896 2.6894 II

1 0.1311 0.767 0.063 1.017

0.5 1.4639 3.7625 1.1021 3.3424 III

1 0.1759 0.9065 0.0957 0.7062

5 CONCLUSIONS

In this paper a comparison between GPC and NGPC

is carried out for linear systems. The performance of

NGPC is better that GPC in terms of ISE and IAE

Performance index.

REFERENCES

Qin, S. J., Badgwell, T., 2003. A survey of industrial

model predictive control technology. Control

Engineering Practice. Vol. 11. no. 7. pp. 733-764.

Yu, D. L., Yu, D. W., Gomm, J. B., 2006. Neural model

adaptation and predictive control of a chemical rig.

IEEE Transaction on Control Systems Technology.

Vol. 14. no. 5. pp. 828-840.

Lawrynczuk, M., 2007. An efficient nonlinear predictive

control algorithm with neural models based on

multipoint on-line linearization. EUROCON 2007.

The International Conference on “Computer asa Tool.

Warsaw. September 9-12. pp. 777-784

Noorgard, M., Ravn, O., Poulsen, N. K., Hansen, L. K.

2000. Neural networks for modeling and control of

dynamical systems. Springer, London.

Morari, M., Lee, J. 1999. Model predictive control: past,

present and future. Computers and Chemical

Engineering. Vol. 23. no. 4/5. pp. 667- 682

Rossister, J. A. 2003. Model based predictive control.

CRC Press. Boca Raton.

Clarke, D. W., Mohtadi, C., Tuffs, P. S. 1987. Generalized

predictive control- Part I, The basic algorithm.

Automatica. Vol. 23. pp. 137-148.

Soloway, D. 1996. Neural generalized predictive control.

Proceedings of the 1996 IEEE International

Symposium on Intelligent Control. Dearborn,

September, 15-18. pp. 227-282.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

270