ACTIVE SECURITY SYSTEM FOR AN INDUSTRIAL ROBOT

BASED ON ARTIFICIAL VISION AND FUZZY LOGIC PRINCIPLES

B. Fevery, B. Wyns, L. Boullart

Department of Electrical Energy, Systems and Automation, Ghent University, Ghent, Belgium

J. R. Llata Garc

´

ıa, C. Torre Ferrero

Control Engineering Group, Electronic Technology and Automatic Systems Department

University of Cantabria, Santander, Spain

Keywords:

Active security, application, artificial vision, fuzzy logic, real-time, robot control.

Abstract:

An active security system assures that interacting robots don’t collide or that a robot operating independently

doesn’t hit any obstacle that is encountered in the robots workspace. In this paper, an active security system

for a FANUC industrial robot is introduced. The active security problem where one robot needs to avoid

a moving obstacle in its workspace is considered. An obstacle detection and localization mechanism based

on stereoscopic vision methods was successfully developed. To connect the vision system, an operator’s pc

and the robot environment a real-time communication is set up over Ethernet using socket messaging. We

used fuzzy logic for intelligent trajectory planning. A multitask oriented robot application in the KAREL

programming language of FANUC Robotics was implemented and tested.

1 INTRODUCTION

In industrial settings, robots often work on valuable

products and with expensive tools. When more robots

are working together on one assignment, a collision

free interaction of the robot arms needs to be guar-

anteed at all time. Systems that establish collision

free robot interaction are identified as Active Security

Systems (ASSYS). ASSYSs can also be situated in

the domain of interaction between industrial manipu-

lators and human operators, where the physical safety

of the operator, rather than an economical concern,

constitutes the necessity for the design of an appro-

priate security system.

The key principle of ASSYSs is the vigilance of

the work area of cooperating robots and the streaming

of information about events that are unexpected for

each robot. This contrasts with a strategy where every

robot is seperately programmed to execute its task and

where interaction signals are sent between robots over

rigid communication media.

Safe robot motion is typically guaranteed by the

use of a sensor system. A camera network based

human-robot coexistence system was already pro-

posed in (A.J. Baerveldt, 1992) and a safety system

also using a network of cameras and with path re-

planning in an on-line manner was presented in (D.

Ebert et al., 2005). In this paper, we present the setup

of a basic vision system to detect and positionally

reconstruct obstacles in the robot’s workspace. The

stereoscopic vision techniques applied in the design

of the vision system will be presented in section 2.

In literature, some researchers focus on the direct

kinematics of robot manipulators. Using the differ-

ences between actual and goal angular configuration

of every axis, output actions for every axis’s motor are

produced taking into account an obstacle’s configura-

tion in the two or three dimensional space. In this

paper, we will present a security system that controls

the motional actions of an industrial FANUC Robot

Arc Mate 100iB with six degrees of freedom and a

circular range of 1800 millimeters. Instead of giving

commands to every axis’s motor, positional and ro-

tational configuration of the robot arm will be calcu-

lated along the nodes of an alternative path around one

detected obstacle. Intelligent path planning is done by

using a fuzzy logic control system. A rule base com-

posed of linguistic if-then implications is used to sim-

ulate human reasoning in decision taking. The fuzzy

system produces a set of alternative positions and ro-

tational configurations that assure collision free mo-

tion continuation towards a final location. Fuzzy logic

17

Fevery B., Wyns B., Boullart L., R. Llata García J. and Torre Ferrero C. (2008).

ACTIVE SECURITY SYSTEM FOR AN INDUSTRIAL ROBOT BASED ON ARTIFICIAL VISION AND FUZZY LOGIC PRINCIPLES.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 17-23

DOI: 10.5220/0001477300170023

Copyright

c

SciTePress

is popular due to its simplicity and hands-on, intuitive

design of the control strategy and was successfully ap-

plied by preceding authors, e. g. in (Bischoff, 1999),

to build active safety systems for robots. In this paper,

a three dimensional obstacle avoidance strategy will

be introduced that is founded on the idea of repelling

and attracting forces (P. Zavlangas et al., 2000). The

design of a fuzzy logic controller will be highlighted

in section 3.

Although specialised solutions exist for each com-

ponent of the proposed ASSYS, the goal in this paper

was to build such a system using only basic compo-

nents communicating over an Ethernet network. No

multiple robot interaction was assumed and due to the

early stage of the investigation, the vision system was

only designed to make the robot avoid collision with

a single, however dynamically moving, obstacle. At-

tention was also given to the time performance of the

vision system.

To make the industrial FANUC robot move along

an alternative path in an on-line manner, a robot ap-

plication needed to be programmed in the proper pro-

gramming language KAREL of FANUC Robotics. A

multitask oriented design in the KAREL language

assures that alternative positions can be read in by

the robot’s system and subsequently moved to by the

robot arm. The architecture of the robot application,

as well as details on the real-time communication sys-

tem established over Ethernet, will be commented in

section 4. In section 5 results and drawbacks of the

designed ASSYS are commented.

2 ARTIFICIAL VISION

2.1 3D Object Reconstruction

Stereoscopic vision applications intent to reconstruct

the 3D location of characteristic object points. From

(Torre Ferrero, 2002) an analytical method was taken

that allows for a unique 3D reconstruction of an object

point P, knowing the pixel sets (u

1

, v

1

) and (u

2

, v

2

) of

P’s projection into two different image planes I

1

and

I

2

. The camera’s projection matrices, that are com-

posed of the camera’s extrinsic and intrinsic parame-

ters (Gonzal

´

ez Jim

´

enez, 1999), are also needed for re-

construction. These parameters were obtained for ev-

ery camera by applying a camera calibration method

based on (J. Heikkil

¨

a et al., 1997). For more details on

camera projection principles and reconstruction meth-

ods, please consult (Gonzal

´

ez Jim

´

enez, 1999) and

(Torre Ferrero, 2002).

2.2 Camera Setup of the Vision System

A triplet of network cameras was installed to watch

the robot’s workspace. Camera images can be ob-

tained by sending an image request signal to their IP

address over a Local Area Network (LAN). For ev-

ery camera, a video stream of images using ActiveX

components is activated. Images are taken out of the

video stream and saved as image matrices of dimen-

sion 480x640x3 in the Red Green Blue (RGB) image

space. A pc is used to perform image processing op-

erations. The cameras were collocated in a triangular

pattern and mounted on the ceiling above the robot’s

workspace.

2.3 Object Detection and

Reconstruction Methods

In industrial settings, image processing times need to

be small. Preliminary knowledge about the object’s

color and shape is therefore often used to detect obsta-

cles in the robot’s workspace as quickly as possible.

For the experimental setup of our vision system, we

worked with a foam obstacle of parallelepiped struc-

ture. The motion of the obstacle is achieved by simply

dragging the foam into the robot’s workspace with a

rope. Because it is not within the scope of this paper,

no attention was given to the detection of the robot’s

arm, nor to the detection of humans or objects of other

form than a parallelepiped. In the next sections, we

will introduce the vision techniques that were used

for the detection of a moving obstacle and for the re-

construction of its 3D position. The reconstruction

method is based on the technique of epipolar lines,

which form a useful geometric restriction in vision

applications.

2.3.1 Obstacle Observation

The obstacle of parallelepiped form is detected in an

image by converting this image to binary form and

subsequently check for the presence of contours of

squared form, using a simple criterion that relates a

square’s perimeter to its area. The presence of the ob-

stacle is checked by drawing the image of one camera

out of the activated video stream every 50 millisec-

onds and by applying the square detection criterion.

When a moving obstacle is detected for the first

time in the workspace, the ASSYS halts all robot mo-

tion. Only if the obstacle stops moving within a cer-

tain number of time frames after it had first been de-

tected, the robot will resume its motion, now moving

around the obstacle. By taking subsequent images out

of the video stream of the same camera and resting

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

18

.

.

.

.

.

.

.

.

C

3

I

l

p

1

C

1

C

2

p

2

P

21

P(x, y, z)

P

2m

E

2

E

3

p

3

E

31

E

3m

E

3j

I

3

I

2

Figure 1: Pixel correspondence algorithm.

two subsequent image matrices, the system checks if

the object has stopped moving. As soon as this condi-

tion holds, images are drawn out of the video stream

of the two other cameras and the 3D reconstruction

of the obstacle is initiated. We typically reconstruct

the 3D location of the obstacle’s four upper corners.

These characteristic object points are determined by

applying a Canny edge detector (Gonzal

´

ez Jim

´

enez,

1999) and a corner detection operator on the three im-

ages.

Once characteristic points -true and also false ob-

ject corners due to image noise or nearby objects- are

detected, an algorithm is applied to determine corre-

sponding corners. This problem boils down to finding

for every upper corner of the obstacle in a first image,

the location of the same corner in the second and third

image.

2.3.2 Calculation of Pixel Correspondences

The applied algorithm is based on the geometric re-

striction of the epipolar line: an image point P that

is projected onto a pixel in a first image can only be

projected onto one line of pixels in a second image.

We aim to find three pairs of pixel coordinates of one

point in space that is projected into three images I

1

,

I

2

and I

3

. This problem is identified as the search for

pixel correspondences. The algorithm can briefly be

explained as follows, according to the notations of fig-

ure 1. The image point p

2

in the second image I

2

that

corresponds to the point p

1

in the first image I

1

has

to be situated on the epipolar line E

2

associated to p

2

.

Characteristic pixels of I

2

that are located sufficiently

close to this epipolar line are selected as correspon-

dence candidates P

2i

in I

2

. When the epipolar lines

E

3 j

associated to all correspondence candidates P

2i

are constructed in a third image I

3

, this results in a

number of intersections p

3k

in I

3

between the epipolar

lines associated to the set P

2i

and the epipolar line E

3

associated to p

1

. The intersection that coincides or is

located sufficiently close to one of the characteristic

points in I

3

, results in the unique corresponding pixel

triplet {p

1

, p

2

, p

3

}. Epipolar line pixel equations from

(Torre Ferrero, 2002) were used to construct epipolar

lines.

As soon as the corresponding corner pixels are

found in the three camera images, the pixel correspon-

dences are used to calculate the obstacle’s 3D location

in space, as described in section 2.1. False pixel cor-

respondences, that originated from detected corners

not belonging to the object, can be discarded because

the resulting 3D positions don’t fall within the range

in which the obstacle is expected to be encountered.

The obstacle’s 3D location in space is used as an input

of the fuzzy logic controller that calculates an alterna-

tive trajectory.

3 FUZZY LOGIC CONTROL

3.1 Introduction

A Fuzzy Logic Controller (FLC) is a useful tool to

transform linguistic control strategies based on exper-

tise into an automatic control strategy (O. Cordon et

al., 2001). The basic idea is to assign linguistic la-

bels to physical properties. The process that converts

a numerical value into a linguistic description is the

fuzzification process. Using a rule base that simulates

human reasoning in decision taking, a number of lin-

guistic control actions is computed and subsequently

defuzzified or converted to numerical control actions.

For more information and a detailed description on

FLCs, please consult (O. Cordon et al., 2001).

A pneumatically controlled tool was mounted on

ACTIVE SECURITY SYSTEM FOR AN INDUSTRIAL ROBOT BASED ON ARTIFICIAL VISION AND FUZZY

LOGIC PRINCIPLES

19

the robot arm. The term End Effector is used to indi-

cate this tool, that is depicted in figure 2 for different

configurations. In robot terminology, the central point

of the End Effector is called the Tool Center Point

(TCP). The dots between the ends of the End Effector

in figure 2 represent this TCP.

3.2 Fuzzy Avoidance Strategy

A fuzzy rule containing two types of actuating forces

was designed. An attracting force proportional to the

1D distance differences between actual TCP coordi-

nates and final location coordinates causes the FLC to

output distance increments towards the final location.

A repelling force describing the distance to the obsta-

cle’s sides deactivates the attracting force and invokes

specific avoidance actions that have to be undertaken

by the robot’s End Effector to avoid collision with the

obstacle.

Further on, it will be explained how safety zones

are constructed around the obstacle, based on the dis-

tance differences between the TCP and the obstacle’s

sides. When the robot’s TCP enters one of these

safety zones around the obstacle, two types of avoid-

ance actions are undertaken. Rotational actions guar-

antee the End Effector’s orthogonal position to the ob-

stacle’s sides and translational actions assure an accu-

rate avoidance in position. This idea is depicted in

figure 2.

5

4

3

2

.

.

.

.

.

1

+90° y

-

90° y

Very Close

Figure 2: Fuzzy avoidance strategy.

3.3 Inputs to the Fuzzy Logic Controller

The inputs of the FLC consist of two types. A first

type describes 1D distance differences between actual

TCP coordinates and final location coordinates, while

the second input indicates if the TCP is near to one of

the obstacle’s sides. The first input is related to the at-

tracting influence and the second one to the repelling

influence. It will now be explained how both types of

inputs to the FLC are composed.

The distance between final location and TCP can

be described in linguistic terms as e.g. Close or Far.

Close

Neg

Far

Neg

VClose

Neg

VClose

Pos

Close

Pos

Far

Pos

∆r

Figure 3: MFs for fuzzy sets of attracting influence.

For a given numeric value of distance to the final lo-

cation, each of the linguistic labels will be true with

a certain value in the range [0, 1]. This value will

be determined by the Membership Function (MF) of

the specified linguistic distance label. Figure 3 illus-

trates the MFs of the labels that describe the distance

difference ∆r in x, y and z direction between the coor-

dinates of the Tool Center Point and the final location

coordinates. MFs of triangular and open trapezoidal

form were chosen because they are easy to implement

in programming applications and require small evalu-

ation times. The central triangular represents the MF

for Contact with the obstacle. Table 1 indicates the

1D distance descriptions in coordinates r = x, y and z

towards the final desired configuration.

Table 1: Labels for attracting influence.

Linguistic label Short notation

Goal Far Negative GFar Neg r

Goal Close Negative GCl Neg r

Goal Very Close Negative GVCl Neg r

Goal Reached Goal r

Goal Very Close Positive GVCl Pos r

Goal Close Positive GCl Pos r

Goal Far Positive GFar Pos r

The second FLC input is related to the repelling

force. To understand how these FLC inputs originate,

we make the following consideration. If the robot’s

TCP is Very Close to the positive x side of the obsta-

cle, this means it is close to the positive x bound of

the obstacle AND: within the y and z range OR within

the y range and very close to the positive z bound OR

... . Figure 4 illustrates this idea for the construction

of the label Very Close Positive x.

The distance differences ∆s (s = x, y and z-

dimension) represent the distances of the TCP to the

closest obstacle bound in the considered coordinate.

For the example of figure 4, the considered label

needs to be evaluated using AND and OR logical oper-

ators. Table 2 represents distance difference descrip-

tions towards the sides of the obstacle.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

20

Z

Y

X

VCl Pos ∆y

VCl Neg ∆z

VCl Pos ∆y

Contact ∆z

VCl Pos ∆y

VCl Pos ∆z

Contact ∆y

VCl Neg ∆z

Contact ∆y

Contact ∆z

Contact ∆y

VCl Pos ∆z

VCl Neg ∆y

VCl Neg ∆z

VCl Neg ∆y

Contact ∆z

VCl Neg ∆y

VCl Pos ∆z

VCl Pos ∆x

Figure 4: Construction of label Very Close Positive x.

Table 2: Labels for repelling influence.

Linguistic label Short notation

Far Negative Far Neg ∆s

Not Close Negative NCl Neg ∆s

Close Negative Cl Neg ∆s

Very Close Negative VCl Neg ∆s

Contact Contact ∆s

Very Close Positive VCl Pos ∆s

Close Positive Cl Pos ∆s

Not Close Positive NCl Pos ∆s

Far Positive Far Pos ∆s

Note that, according to the idea of figure 4, the

labels of table 2 have three-variable MFs, because

they are all composed of one dimensional MFs for

coordinate differences ∆r (r = x, y and z) towards the

obstacle’s boundary coordinates. These 1D MFs are

similar to the ones for the attracting forces depicted

in figure 3. Next step is to construct safety zones

around the obstacle, as shown in figure 2 for the label

Very Close. Analogously, zones Close and Not Close,

and an outer region Far, complementary to the inner

zones, are constructed.

To fuzzify the entrances of the Fuzzy Inference

System, we used a singleton fuzzificator (J. R. Llata

Garc

´

ıa et al., 2003).

3.4 Design of a Rule Base

The basic principle of the rule base is the deactivation

of the attracting influence -determined by the distance

to the final location- when the repelling influence is

triggered. Taking this into account, logical rules for

closing up to the final location can be constructed.

For the rules related to the repelling influence, we

can state that the designer of the rule base is free to

choose the direction and sense of the avoidance ac-

tions. We decided to undertake an avoidance action

in positive z direction when the TCP closes up to the

(Very) Close x or y, Negative or Positive side of the

obstacle.

The avoidance action for the (Very) Close z, Pos-

itive or Negative side, is decided upon by a criterion

that checks the distance difference in x and y coordi-

nate of the TCP’s current position and the final loca-

tion coordinates. If the distance difference is bigger

in the x direction, then an avoidance action in x is un-

dertaken, otherwise in y direction.

As soon as the TCP enters the safety zone Not

Close, a rotation of -90

◦

or +90

◦

around the appro-

priate axis of a fixed coordinate system needs to be

undertaken, to prevent the End Effector from hitting

the obstacle (see figure 2).

To resolve the fuzzy intersection operator used for

the composition of rule premises and for the impli-

cation on rule consequents, we used a T-norm of the

product type. In the aggregation of rule consequents

an S-norm for the fuzzy union operator was chosen.

We implemented a maximum operator as this S-norm

to save in processing time.

Given an initial and final position and an obsta-

cle’s location supplied by the vision system, the FLC

outputs a set of positional and rotational configura-

tions that guarantee collision free motion towards the

final location.

3.5 Outputs of the FLC

Fuzzy outputs of the Sugeno singleton type (J. R.

Llata Garc

´

ıa et al., 2003) were used for defuzzifica-

tion. Depending on the output of a rule, a specific

value can be assigned to the considered system out-

put. The designer of the FLC is free to determine the

size of the output actions.

Upon detection of an obstacle and halting of robot

motion, the TCP’s current position is sent by the

robot’s operational system over a socket connection

to the artificial intelligence system as a start point

for the calculation of an alternative path. Alternative

positions and rotational configurations are then sent

back over the socket in data packages that contain the

desired coordinates of the TCP and the desired rota-

tional configuration of the End Effector with respect

to the fixed coordinate system.

ACTIVE SECURITY SYSTEM FOR AN INDUSTRIAL ROBOT BASED ON ARTIFICIAL VISION AND FUZZY

LOGIC PRINCIPLES

21

4 EXPERIMENTAL SETUP

4.1 Real-time Communication

Robotic control applications often have cycle times

of typically hundreds of microseconds. When oper-

ational data needs to be exchanged between a robot

and an operator’s pc, the fastness and the guarantee

of data transmission is of utmost importance. For

many years, Ethernet was banned as a communication

medium from the industrial work floor, for data pack-

ages that are sent over the Ethernet by devices con-

nected to a same Local Area Network can collide and

be lost, due to the network’s media access control pro-

tocol CSMA/CD (Van Moergestel, 2007). Nowadays,

Fast Ethernet switches can be used to isolate network

devices into their own collision domain, hereby to-

tally eliminating the chance for collision and loss of

data packages. Ethernet switches together with the

development of Fast Ethernet (100Mbps) and Giga-

bit Ethernet (1Gbps) have made Ethernet popular as

a real-time communication medium in industrial set-

tings (Decotignie, 2005).

To establish the Ethernet communications in the

ASSYS, we used so called Ethernet sockets. Sockets

are software entities that are assigned to a combina-

tion of communication port and IP address, so that

they can be used by a client and a server device to

communicate over a LAN. In our setup, this LAN was

created by a Fast Ethernet switch. The exchange of all

data packages between the industrial FANUC Robot

Arc Mate 100iB and a pc running the vision and fuzzy

logic applications is performed by socket messaging.

4.2 Multitask Robot Application

A multitask oriented active security application was

developed and tested in KAREL, the programming

language of FANUC Robotics for advanced user ap-

plications. A motion task executes a normal opera-

tion trajectory until a condition handler is triggered

by the detection signal that was received through an

Ethernet socket by a concurrently running communi-

cation task. When this condition handler is triggered,

robot motion is halted within a time that is accept-

ably small and the TCP’s current position is sent by

the communication task to the operator’s pc, where

the FLC calculates the first alternative positions and

sends them back over the opened socket connection to

the communication task. An interrupt routine for mo-

tion along the alternative path is then invoked in the

motion task. The robot axes’s motors start accelerat-

ing immediately. Meanwhile, the communication task

completes the reading in of subsequent alternative po-

sitions and rotational configurations. Motion contin-

ues until the original final location is reached. The

KAREL application is written in a non-cyclic way.

Upon reaching the final position, program execution

is aborted. Coordination between the motion task and

the communication task was realised by the use of

semaphores. The artificial vision system, the FLC and

the robot control application in KAREL were tested in

an integrated way.

5 RESULTS AND DISCUSSION

The obstacle is dragged into the robot’s workspace

when the robot arm is close to the leftmost or right-

most point of its regular trajectory. Absence of the

robot’s arm in the central zone of the workspace is

necessary for correct obstacle detection because the

robot arm would deform the binary image of the ob-

stacle’s squared contour. Further development of the

vision system is therefore needed to distinguish the

robot arm from the obstacle in order to be able to sig-

nal obstacle presence in all operational situations. In

an advanced stadium, detection criteria for human op-

erators can also be elaborated.

However, if the robot arm is occulting one of the

obstacle’s upper corners in one of the three images,

performing an accurate reconstruction of the obsta-

cle’s 3D location is still possible, since a free view on

three of the four upper corners in all images is suffi-

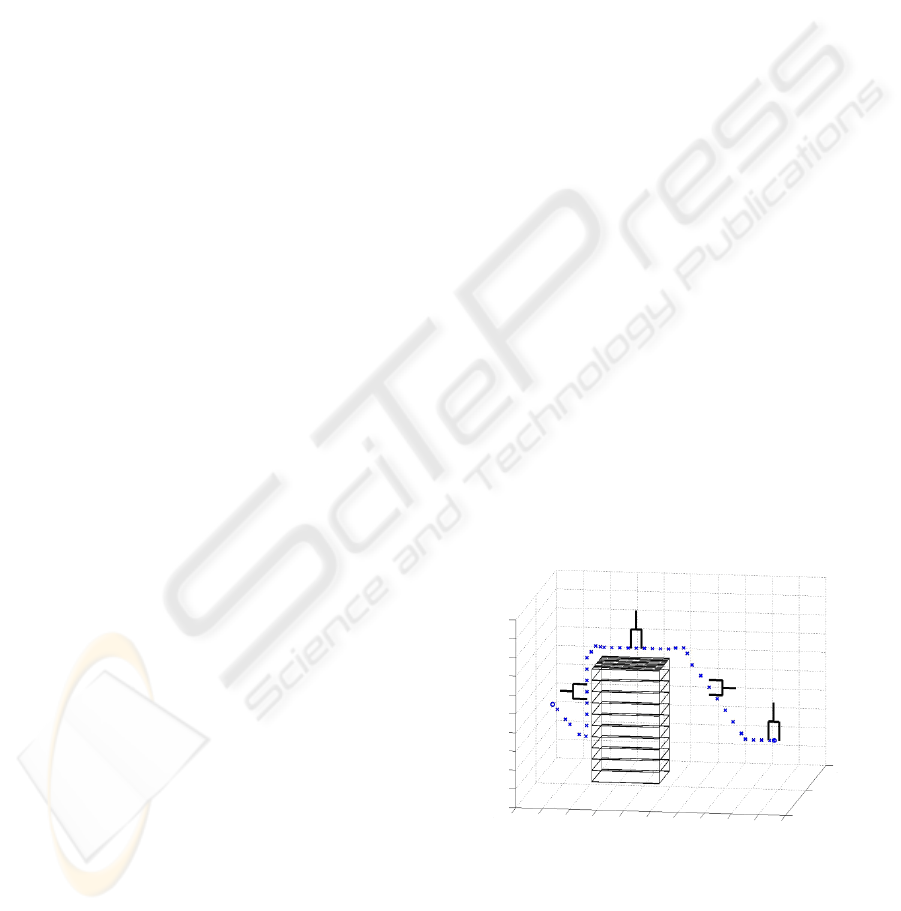

cient for the reconstruction. The parallelepiped in fig-

ure 5 depicts the result of the vision system and fuzzy

logic path planning.

Figure 5: Alternative trajectory around reconstructed obsta-

cle.

With distance increments of 50 millimeter in the

FLC we typically obtained a number of 40 alterna-

tive positions. The designer of the FLC is free to

choose the size of the translational increments larger

or smaller and in a rather intuitive way. However, a

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

22

thorough study can be performed making a trade-off

between small increments and thus larger calculation

times and larger robot processing times or large dis-

tance increments and thus smaller calculation times

and robot processing times. This last option impli-

cates however that the safety zones around the obsta-

cle need to be bigger and that longer trajectories have

to be completed by the robot tool before it reaches

the final location. For industrial settings, where small

robot motion execution times are of utmost impor-

tance, this trade-off study is an interesting topic for

future research. More specifically, a time efficient and

distance optimal path construction algorithm can be

designed.

The FLC only takes the TCP’s position as an in-

put. Collision of the robot’s arm is prevented by ro-

tating the End Effector +90

◦

or -90

◦

when it enters

the first safety zone Not Close. For the majority of

practically executable robot trajectories, this preven-

tive action has proven to be sufficient. In future re-

search however, the distance to the obstacle of extra

points on the robot’s arm will have to be monitored to

guarantee safer motion.

In this design, a parameter to take into account

is the processing time needed by the robot’s system

to handle new motion instructions. The robot system

is able to continue program execution after launching

a motion instruction. Moreover, a continuous transi-

tion between two separate motion instructions is pos-

sible using the appropriate clauses in the motion com-

mands. Nevertheless, we chose to keep the number

of motion commands as limited as possible and de-

cided to only send every fourth alternative position as

an effective motion instruction to the robot. Given the

fact that alternative positions are situated close to each

other (see figure 5), this strategy still results in accu-

rate obstacle avoidance and in a smooth, continuous

robot motion.

The time needed to draw images out of the video

stream and save them as pixel matrices for further

image processing could be restricted to 15 millisec-

onds. The computational time to identify pixel corre-

spondences and make a 3D reconstruction is also very

small. Regarding processing time, the bottleneck of

the vision system, and thus of the entire ASSYS, has

proven to be the identification of characteristic object

pixels, in our case corner pixels of the parallelepiped.

Improvements have to be made. Remark that during

3D reconstruction of the obstacle the robot is motion-

less, thus no unsafe situation is created due to the high

processing times of the vision system.

6 CONCLUSIONS

An active security system for an industrial FANUC

robot was designed. With special attention for real-

time performance of the constituting subsystems, sat-

isfying experimental results were obtained. The setup

of the Ethernet communication through sockets, the

fuzzy obstacle avoidance mechanism and the vision

system open wide perspectives for future investiga-

tion on active security. More attention can be given

to distinguishing the robot arm from foreign objects,

to optimizing image processing times, to searching

cost optimized alternative paths and to automating the

robot application in a cyclic way.

REFERENCES

A. J. Baerveldt (1992). A safety system for close interaction

between man and robot. Proceedings of IFAC Confer-

ence on Safety Security Reliability SAFECOMP 1992.

Bischoff, A. (1999). Echtzeit Kollisionsvermeidung f

¨

ur

einen Industrieroboter durch 3d-Sensor

¨

uberwachung.

D. Ebert et al. (2005). Safe human-robot-coexistence:

Emergency-stop using a high-speed vision-chip. 2005

IEEE/RSJ International Conference on Intelligent

Robots and Systems, pages 1821–1826.

Decotignie, J.-D. (2005). Ethernet-based real-time and in-

dustrial communications. IEEE, 93:1102–1117.

Gonzal

´

ez Jim

´

enez, J. (1999). Visi

´

on por computador.

Paraninfo.

J. Heikkil

¨

a et al. (1997). A four-step camera calibra-

tion procedure with implicit image correction. 1997

IEEE Computer Society Conference on Computer Vi-

sion and Pattern Recognition.

J. R. Llata Garc

´

ıa et al. (2003). Introducci

´

on a las T

´

ecnicas

de Inteligencia Artificial. Grupo de Ingenier

´

ıa de Con-

trol, Departamento de Tecnolog

´

ıa Electr

´

onica e In-

genier

´

ıa de Sistemas y Autom

´

atica, Universidad de

Cantabria.

O. Cordon et al. (2001). Genetic fuzzy systems: Evolu-

tionary tuning and learning of fuzzy knowledge bases.

World Scientific.

P. Zavlangas et al. (2000). Industrial robot navigation and

obstacle avoidance employing fuzzy logic. Journal of

Intelligent and Robotic Systems, 27:85–97.

Torre Ferrero, C. (2002). Reconstrucci

´

on de piezas en 3d

mediante t

´

ecnicas basadas en visi

´

on estereosc

´

opica.

Van Moergestel, L. J. M. (2007). Computersystemen en Em-

bedded Systemen, 2nd reviewed print. Academic Ser-

vice, Den Haag.

ACTIVE SECURITY SYSTEM FOR AN INDUSTRIAL ROBOT BASED ON ARTIFICIAL VISION AND FUZZY

LOGIC PRINCIPLES

23