Comparison of Defuzzification Methods: Automatic

Control of Temperature and Flow in Heat Exchanger

Carlos A. Cosenza

1

, Alvaro J. Rey Amaya

2

, Omar Lengerke

3

, Max Suell Dutra

3

and Magda J. M. Tavera

2

1

Production Engineering, COPPE, Federal University of Rio de Janeiro – UFRJ

Cidade Universitária - CT, Bloco F, sala 108 - Ilha do Fundão

Rio de Janeiro, RJ – Postal Box: 68507, Brazil

2

Energy and Automation Laboratory, Autonomy University of Bucaramanga – UNAB

Calle 48 Nr. 39 -234, Bucaramanga - Colombia

3

Robotic and Automation Laboratory – COPPE/UFRJ

Federal University of Rio de Janeiro – UFRJ

Postal Box 68.503 – CEP 21.945-970 – Rio de Janeiro, RJ, Brazil

Abstract. The objective of this work is to analyze the behavior of the tradi-

tional control and the fuzzy control, applying them in the flow and temperature

control to the load of current of a heat exchanger, as well as the analysis of dif-

ferent methods of defuzzification, utilized just as itself this carrying out the

fuzzy control. Acting on the structure of the fuzzy controller some changes of

form are carried out such that this tune in to be able to obtain the answer but

optimum. In the same way proceeds on the traditional controller, and in this

way comparisons on these two types of controls are established. Inside the

changes that are carried out on the fuzzy controller this form of defuzzification

the information, that is to say the methods are exchanged defuzzification in or-

der then to realize comparisons on the behavior of each one of these.

1 Introduction

In many of the sectors of the industry where include itself thermal processes, is im-

portant the presence of a heat exchanger [1] [2]. Said processes do part of the every-

day life of an engineer that has as field of action the control, therefore is considered

interesting to realize a control to this type of tools. This work in its content studies

two large aspects: A comparison between the traditional control and the fuzzy con-

trol, and an analysis between some of the different methods of defuzzification that are

utilized in the fuzzy logic [3], doing an analysis of each one of they taking in consid-

eration contribute them that other authors have done and leaving always in clear, that

the alone results obtained will be applicable al moment of doing control on an ex-

changer of heat [4]. The system this composed one for two exchangers of heat [5],

one of concentric pipes and the other of hull and pipes, to which implemented them

an automatic control of the temperature and the flow to the load of the current of

heating (Fig. 1).

A. Cosenza C., J. Rey Amaya A., Lengerke O., Suell Dutra M. and J. M. Tavera M. (2008).

Comparison of Defuzzification Methods: Automatic Control of Temperature and Flow in Heat Exchanger.

In Proceedings of the 4th International Workshop on Artificial Neural Networks and Intelligent Information Processing, pages 107-116

DOI: 10.5220/0001490701070116

Copyright

c

SciTePress

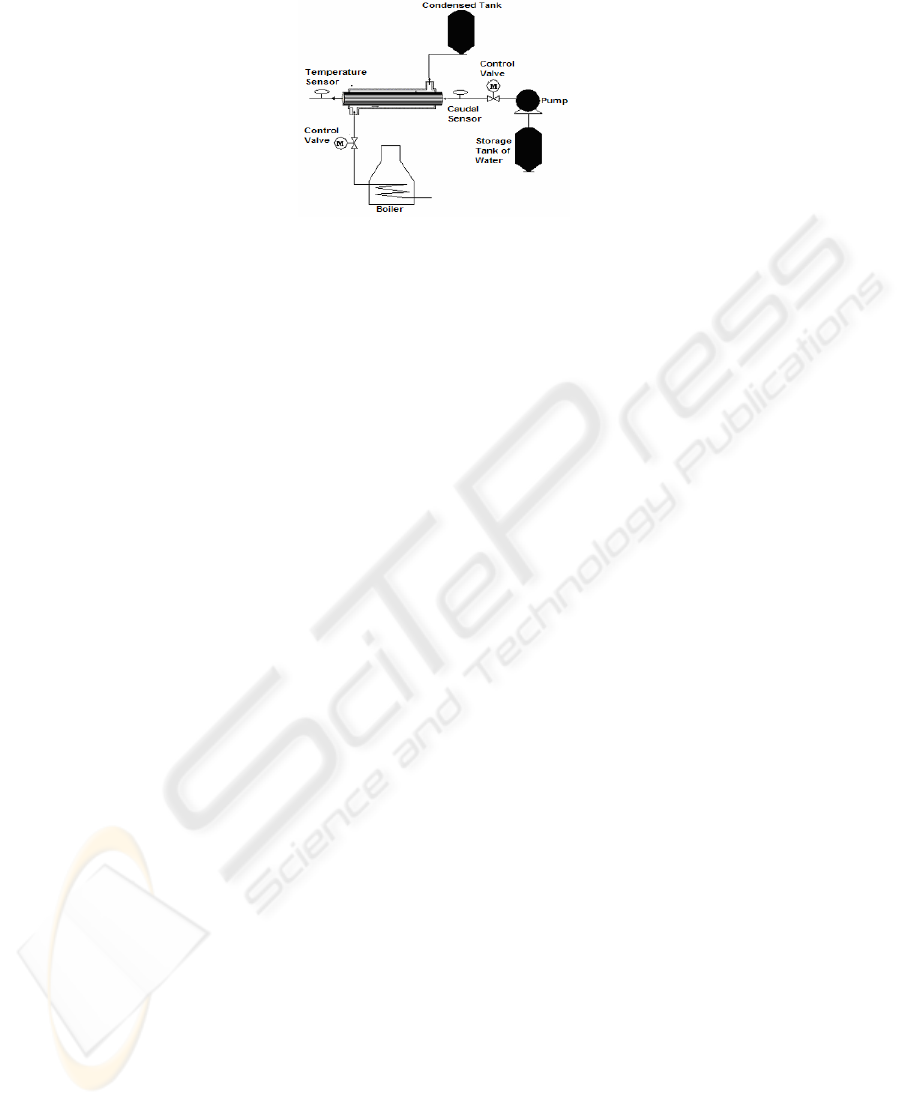

Fig. 1. Assembly of the system.

This control is realized through two proportional valves, one to the input of the water,

that is the responsible for maintaining the value of order of the water and the other

installed in the line of input of the vapor (source of heat), that is responsible of main-

taining the quantity of necessary vapor to obtain the target temperature. The meas-

urement of the flow [6] is realized by means of a sensor of rotary palette and the

measurement of the temperature by means of thermocouples [7] [8] [9]. The signals

supplied by these sensors are acquired by means of the FieldPoint systems of Na-

tional Instruments [10], the same one that takes charge of sending the signal to the

valves of control, after to be processed the data by the controller [11].

2 Software of Fuzzy and Classic Control

The software of control designed, is formed of two sections, the program of fuzzy

control, and the program of the PID (Proportional/Integral/ Derivative) control. These

controllers are elaborate in environment Labwindows/CVI, software of the company

National Instruments, which permits to realize the pertinent operations with the data

captured through the modules of FieldPoint, and that, are utilized in the control of the

system. The fuzzy control interface, is the responsible for taking the data of the sen-

sors, so much of temperature, for the case of the control of temperature, as of the

sensor of flow, for the control of the same one, to process, and according to an order

established, to determine an response, which is sent to the actuators. Basically, this

program is responsible of: to schematize the fuzzy sets, according to established by

the user, defuzzification of the inputs, to realize the inference of these inputs in the

rules, to realize the aggregation in the outputs sets, and to execute the process of de-

fuzzification, to determine the response that help to the system to obtain the stable

state. The program of the classic control PID, is the responsible for taking the data of

the sensors, so much of temperature, for the case of the control of temperature, as of

the sensor of flow, for the control of the same one, to process, and according to an

order established, to determine an response, which is sent to the actuators. Basically,

this program is entrusted of to execute the three actions of control, proportional, de-

rivative and integral to determine the responses that help to the system to obtain its

target state. The PID control system general is represented in figure 2, where R(s), is

the signal target or set point, U(s), is the output of the PID controller that goes toward

108

the plant G(s), and Y(s), is the value taken of the variable to control, which reduces to

the reference and the error is determined (controller input).

Fig. 2. System of Control PID.

The control of Temperature, have as an objective to obtain that the water that the

exchanger of heat leaves achieve the value of the target temperature and then to keep

it in the value even with external disruptions. That is to say, should operate on the

valve of control who is the one that supplies the quantity of vapor that heats the wa-

ter. The input to this system of control will be the error of temperature, obtained since

the thermocouple placed on the exit of the exchanger, and the exit will control the

quantity of necessary current to open or to close the proportional valve (Plant). This

control is realized through a PID controller. The flow control has as an objective to

obtain that the mass flow of water that enters to the exchanger of heat, achieve the

target value, and can to keep it during its operation, and even with disruptions. This

means that should operate on the valve of control, who is the one that strangles the

quantity of water that enters to the system. The input of the system will be the error

obtained through the sensor of flow installed in the input of the system, and the PID

controller will control the quantity of necessary current to manipulate the proportional

valve. Both processes begin, calculating the difference between the measured tem-

perature and the temperature target or of the flow measured and the flow desired. In

this form, know the error. Then, the values of the parameters of control are taken, and

the output is calculated that goes toward the plant. This output, will obtain values

since 0 to 20 mA, they will represent angles of opening of the proportional valve.

3 System of Fuzzy Control

The input to this system of control will be the error of temperature and the gradient,

obtained since the sensor placed on the way out of the exchanger, and the exit will

control the quantity of necessary current to open the proportional valve. The rules of

the system and function of membership are obtained in the table 1 and figure 3, re-

spectively.

Table 1. Temperature control rules assembly.

Error

Δ Error

Negative Zero Positive

Negative

Open Open Not operation

Zero

Open Not operation Close

Positive

Not operation Close Close

109

Functions of membership for

the current at the outset

Functions of membership for the

variable derived from the Error

Functions of membership or the

variable Error

Fig. 3. Functions of membership temperature control.

The control of flow has as objective to obtain that the mass flow of water that enters

to the exchanger of heat, achieve the value of order, and can to keep it during its

operation, and even before disruptions. This means that should act on the valve of

control who is the one that strangles the quantity of water that enters to the system.

The input of the system, they will be the error obtained through the sensor of flow

installed to the entrance of the system, and the change of the error in the time, and the

output will control the quantity of necessary current to manipulate the proportional

valve. Both processes begin, calculating the difference between the measured tem-

perature and the temperature desired, or of the flow measured and the flow desired. In

this form know the Error. Then, calculate the gradient, reducing the new error of the

previous one. Once known these variables, that constitute the inputs of the fuzzy

logic controller, proceeds to realize the fuzzification, the inference and the defuzzifi-

cation to obtain the output of the controller. This output, will obtain values since 0 to

20 mA, who will represent angles of opening of the proportional valve. The rules of

the system and function of membership are obtained in the table 2 and figure 4, re-

spectively.

Table 2. Flow control rules assembly.

Error

Δ Error

Negative Zero Positive

Negative

Close Close Not operation

Zero

Close Not operation Open

Positive

Not operation Open Open

Functions of membership for the

variable Error

Functions of membership for the

variable derived from the Error

Functions of membership for

the current at the outset

Fig. 4. Functions of membership flow control.

110

3.1 Comparative Results between the Methods of Defuzzification

Implemented

The methods of defuzzification chosen were five; these are know in the area of the

control by the names, central gravity weighted by the height, central gravity weighted

by the area, average of centers, points of maximum criterion weighted by the height

and points of maximum criterion weighted by the area. When refers to the control of

a system, the main term on which refers is to the stability that this can offer, for this is

necessary to take into consideration, the time that delayed the system in being stabi-

lized, the margin of error between the value desired, (Vc), and the values of stabiliza-

tion, (Ve) of the system and the influence of the inertia of the system. For the tests of

temperature and flow control, is defined a set point of 25 [Lts / min] and 40 [ºC]. The

parameters and equations used are observed in the table 3 and the table 4 the different

responses are shown in each one of the methods, according to the parameters estab-

lished in the table 3.

Table 3. Methods and models of defuzzification.

METHODS EQUATIONS

1. Central gravity weighted

by the height

∑

∑

=

=

=

n

i

i

n

i

ii

h

wh

x

1

1

*

Where, w is the center gravity of the

resultant assembly after realized the

fuzzy operation chosen, and h is the

height of the same assembly.

2. Central gravity weighted

by the area.

∑

∑

=

=

=

n

i

i

n

i

ii

s

ws

x

1

1

*

Where, w is the center gravity of the

resultant assembly after realized the

fuzzy operation chosen and s is the

area of the same assembly.

5. Points of maximum

criterion weighted by the

area.

∑

∑

=

=

=

n

i

i

n

i

ii

s

Gs

x

1

1

*

Where, G is the point of maximum

criterion of the resultant set after to

realize the fuzzy4 operation chosen

and s is the area of the same set.

3. Points of maximum

criterion weighted by the

height.

∑

∑

=

=

=

n

i

i

n

i

ii

h

Gh

x

1

1

*

Where, G is the point of maximum

criterion of the resultant set after to

realize the fuzzy operation chosen and

h is height of the same set.

4. Average of centers

Where y

-l

represents the center of the

fuzzy set G

l

(defined as the point V in

which μ

G

l

(y) reaches its value maxi-

mum), and μ

B

(y) this defined for the

degrees of membership resultant of the

fuzzy inference.

()

`

1

`

1

(())

()

M

ll

B

l

M

l

B

l

yy

y

y

μ

μ

−−

=

−

=

=

∑

∑

111

Table 4. Response in each one of the methods established.

FLOW CONTROL

0 10 20 30 40 50 60 70 80

0

5

10

15

20

25

30

Centro de gravedad ponderado por la altura

Ciclos de 5 seg

Caudal [ Lt s / min ]

25.2

24.5

22.9

Central gravity weighted by the height

0 10 20 30 40 50 60 70 80

8

10

12

14

16

18

20

22

24

26

28

Centro de gravedad ponderado por el area

Ciclos de 5 s e

g

Caudal [ Lts / min ]

26.8

23.7

25.2

25.2

24.5

Central gravity weighted by the area

0 10 20 30 40 50 60 70 80

8

10

12

14

16

18

20

22

24

26

28

30

Media de c entros

Ciclos de 5 seg

Caudal [ Lts / min ]

25.2

24.5

23.7

Average of centers

0 10 20 30 40 50 60 70 80

0

5

10

15

20

25

Puntos de maximo criterio ponderados por la altura

Ciclos de 5 seg

Caudal [ Lts / min ]

25.2

24.5

23.7

Points of maximum criterion weighted by the

height

0 10 20 30 40 50 60 70 80

0

5

10

15

20

25

30

Puntos de maximo criterio ponderados por el area

Ciclos de 5 seg

Caudal [ Lts / min ]

25.2

24.5

Points of maximum criterion weighted by the area.

112

Table 4. Response in each one of the methods established (continued).

TEMPERATURE CONTROL

0 20 40 60 80 100 120 140 160 180 200

20

25

30

35

40

45

50

Centro de gravedad ponderado por la altura

Ciclos de 5 s eg

Temperatura [ ºC ]

35.37

39.7

46.358

Central gravity weighted by the height

0 20 40 60 80 100 120 140 160 180 200

20

25

30

35

40

45

Centro de gravedad ponderado por el area

Ciclos de 5 se

g

Temperatura [ ºC ]

44.49

34.187

Central gravity weighted by the area

0 20 40 60 80 100 120 140 160 180 200

20

25

30

35

40

45

Media de centros

Ciclos de 5 seg

Temperat ura [ ºC ]

44.086

39.6

Average of centers

0 20 40 60 80 100 120 140 160 180 200

25

30

35

40

45

Puntos de maximo criterio ponderados por la altura

Ciclos de 5 seg

Temperat ura [ ºC ]

39.7

44.21

38.482

Points of maximum criterion weighted by the

height

0 20 40 60 80 100 120 140 160 180 200

20

25

30

35

40

45

50

Puntos de maximo c rit erio ponderados por el area

Ciclos de 5 seg

Temperatura [ ºC ]

45.922

39.447

35.837

Points of maximum criterion weighted by the area

A summary of the results obtained in the different methods is shown in the table 5 for

the control of flow and the table 6 for the control of temperature.

113

Table 5. Response of the methods of defuzzification in the control of flow.

Defuzzification

Method

Time of

stability

[sec]

Margin of error

(Vc - Ve)

Influence of the inertial of

system

Central gravity

weighted by the

height

105

0.8% above of the set point

2% underneath of the set point

0.8% above of the set point

8.4% underneath of the set

point

Central gravity

weighted by the

area

125

0.8% above of the set point

2% underneath of the set point

7.2% above of the set point

5.2% underneath of the set

point

Average of

centers

85

0.8% above of the set point

2% underneath of the set point

4% above of the set point

5.2% underneath of the set

point

Points of maxi-

mum criterion

weighted by the

height

230 2% underneath of the set point

0.8% above of the set point 5.2%

underneath of the set point

Points of maxi-

mum criterion

weighted by the

area

120

0.8% above of the set point

2% underneath of the set point

0.8% above of the set point

2% underneath of the set point

Table 6. Response of the methods of defuzzification in the control of temperature.

Defuzzification

Method

Time of

stability

[sec]

Margin of error

(Vc - Ve)

Influence of the inertial of

system

Central gravity

weighted by the

height

670

0.75% underneath of the

set point

40.895% above of the set point

11.575% underneath of the

set point

Central gravity

weighted by the area

Not stabi-

lized

Not stabilized

11.25% above of the set point

14.5325% underneath of the

set point

Average of centers

710

1% underneath of the

set point

10.215% above of the set point

12.5% underneath of the set point

Points of maximum

criterion weighted

by the height

745

0.75% underneath of the

set point

10.525% above of the set point

3.795% underneath of the

set point

Points of maximum

criterion weighted

by the area

735

1.38% underneath of the

set point

14.805% above of the set point

10.4075% underneath of the

set point

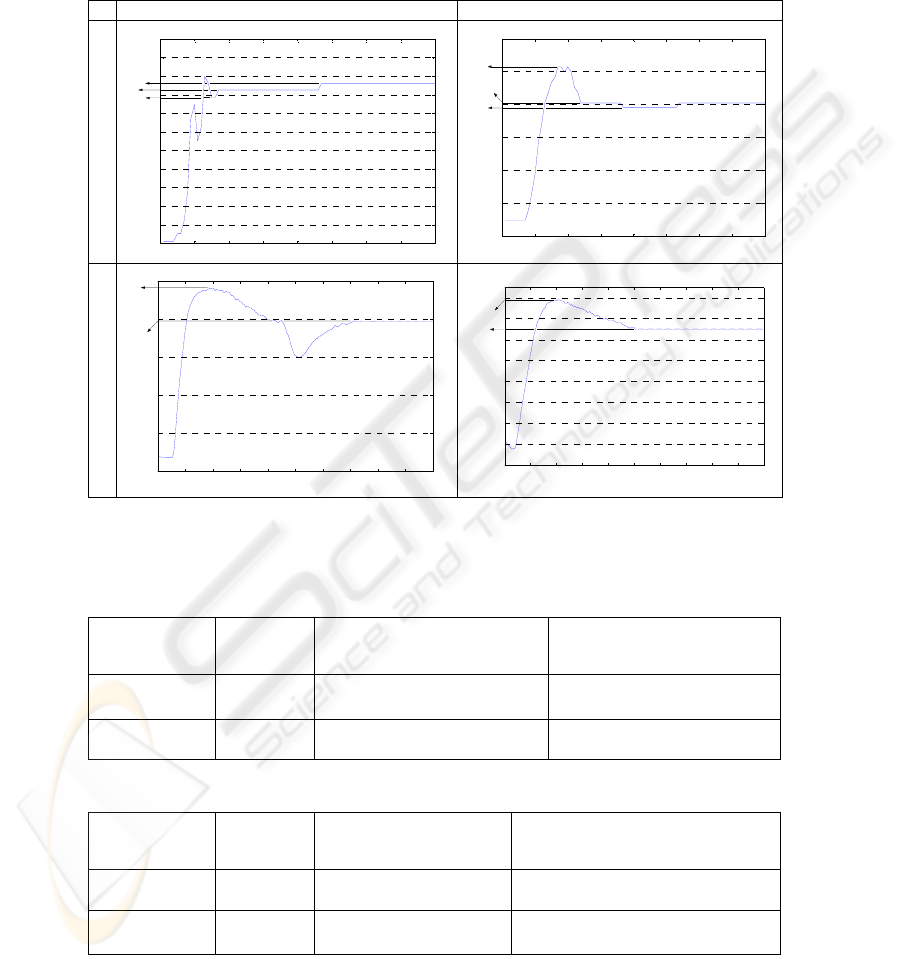

3.2 Comparative Analysis between the Classic Controller and Fuzzy

Controller

To be able to realize this analysis should make use of concepts that be fundamental at

the moment of to evaluate the efficiency of a controller. The concepts to take into

consideration in this case are, the time that delayed the system in being stabilized,

margin of error between the value of order, (Vc), and the values of stabilization (Ve),

114

of the system and the Influence of the inertia of the system. For the comparative

analysis between the fuzzy controller and the PID controller in the control of flow

made use of the tests realized to each one of these controllers, with a set point of 25

[Lts / min] and 40 [ºC]. The results obtained are shown in the table 7.

Table 7. Response of the controllers.

FUZZY CONTROLLER PID CONTROLLER

FLOW CONTROL

0 10 20 30 40 50 60 70 8

0

8

10

12

14

16

18

20

22

24

26

28

30

Media de c entros

Ciclos de 5 seg

Caudal [ Lts / min ]

25.2

24.5

23.7

0 10 20 30 40 50 60 70 80

5

10

15

20

25

30

35

Control PID

Ciclos de 5 seg

Caudal [ Lts / min ]

25.2

24.5

30.7

TEMPERATURE CONTROL

0 20 40 60 80 100 120 140 160 180 200

20

25

30

35

40

45

Media de cent ros

Ciclos de 5 seg

Temperatur a [ ºC ]

44.086

39.6

0 20 40 60 80 100 120 140 160 180 200

26

28

30

32

34

36

38

40

42

Control PID

Cicl os de 5 s eg

Temperatura [ ºC ]

41.782

38.9

A summary of the results obtained in the different methods is shown in the table 8 for

the control of flow and the table 9 for the control of temperature.

Table 8. Response of the methods of defuzzification in the control of flow.

Controller

Time of

stability

[sec]

Margin of error

(V

c

- V

e

)

Influence of the inertial

of system

FUZZY

CONTROL

85

0.8% underneath of the set point

2% above of the set point

4% underneath of the set point -

5.2% above of the set point

PID CONTROL 115

0.8% underneath of the set point

2% above of the set point

22.8% underneath of the set

point 2% above of the set point

Table 9. Response of the methods of defuzzification in the control of temperature.

Controller

Time of

stability

[sec]

Margin of error

(V

c

- V

e

)

Influence of the inertial of system

FUZZY

CONTROL

710

1% underneath of the set

point

10.215% above of the set point

12.5% underneath of the set point

PID CONTROL 505

2.75% underneath of the

set point

4.455% above of the set point

2.75% underneath of the set point

115

4 Conclusions

The results obtained in this work show the technical viability of the utilization of the

fuzzy logic in the control of flow and temperature to the warming-up current input of

an exchanger of heat. With respect to the control of flow and temperature implement-

ing fuzzy logic, can tell that possesses the advantages of need not a mathematical

model of precision of the control system. As disadvantage can tell itself, that the de-

sign should be realized generally with the method of test and error. Is possible to

control through fuzzy techniques industrial process, with the greater facility and with

the minimum of errors, suffices with knowing its general behavior to structure a se-

ries of fuzzy sets and its respective rules. The tuning of the fuzzy controller, besides

depending on the rules matrix, also, depends on the size of the sets of the variable,

already itself of input or output. This depends on the same behavior of the system.

For the implementation of a fuzzy control, is necessary, the establishment of the

methods and alternatives utilized in each one of the blocks that conform it. In this

form, can be obtained best results, at the moment of the tuning of the system. The

answer of the fuzzy controller does not depend on the method of defuzzification util-

ized, if not of the adequate utilization of the functions of membership, and of the

numbers of linguistic variables utilized for each one of the variables of input and

output of the system. Also, depends on the type and of the size of the sets utilized.

References

1. Ruan, D.: Fuzzy Logic Foundations and Industrial Applications. International Series in

Intelligent Technologies. Kluwer Academic Publishers, Boston (1996).

2. Harris, J.: An introduction to fuzzy logic applications. Kluwer Acad. Pub., Boston (2000).

3. Ruan D. and Huang C.,: Fuzzy sets and fuzzy information-granulation theory: key selected

papers by Lotfi A. Zadeh. International Series on Advances in Fuzzy Mathematics and En-

gineering. Beijing Normal University Press, Beijing (2000).

4. Alotaibi, M., Sen, B., Goodwine and Yang, K.T.: Controllability of cross-flow heat ex-

changer. Int. J. Heat Mass Transfer 47, (2004) 913–924.

5. Xia, L., De Abreu-Garcia, J.A. and Hartley, T.T.: Modeling and simulation of a heat ex-

changer. IEEE International Conference on Systems Engineering. (1991) 453–456.

6. McMillan, G.K.; Considine, D.M.: Process / Industrial Instruments and Controls Hand-

book. 5th Edition, McGraw-Hill, New York, USA (1999).

7. Youden, W. J.: Experimentation and Measurement. Dover Publications. Mineola, New

York. (1998).

8. Morris, A. S.: Measurement and Instrumentation Principles, Third Edition, Butterworth-

Heinemann, Great Britain (2001),

9. Michalski, L., Eckersdorf, K., Kucharski, J., and McGhee, J.: Temperature Measurement.

2nd edition, John Wiley, England (2001).

10. Archila, J.F., Dutra, M.S., Lengerke, P. O. and Vega, T.J.: Design and implementation of a

control system in closed-loop using the communication system FIELD POINT for a hydro-

static transmission. Published in RESET: Journal Specialized in informatics and electronics

systems of Telecommunications Systems. Vol.1, (2006) 48–53.

11. Park, J. and Mackay S.: Practical Data Acquisition for Instrumentation and Control Sys-

tems. Newnes Elsevier. Great Britain (2003).

116