RE-USING 3D MODELING DATA FOR

CONSTRUCTING 3D SIMULATION DATA

Jonggeun Kwak

Department of Industrial Information & Systems Engineering, Ajou University

San 5, Woncheon-dong, Yeongtong-gu, Korea

Min. S. Ko, Sang C. Park, Gi-Nam Wang

Department of Industrial Information & Systems Engineering, Ajou University

San 5, Woncheon-dong, Yeongtong-gu, Korea

Keywords: CAD, CAM, Modelling, Simulation, Manufacturing system design, PLC.

Abstract: With the aid of the powerful computational ability and software tools, we undergo rapid change in a whole

product manufacturing process. In a traditional way, it took long time and cost to build real manufacturing

line. The behind time change for the manufacturing process ends up with supplementing large amount of

budget. Therefore early detecting the errors on manufacturing process saves quite a big amount of time and

money. As a result, the need for plant simulations rises. When we simulate manufacturing line on a virtual

environment, it is not easy to acquire 3D data. If we have 3D CAD data, we can reuse them for each tools,

products and equipments for the manufacturing line. Even in this case, the size matters. The large size of

CAD data makes it difficult for us to directly use CAD data for simulation. As the CAD data and simulation

data differs in their own purpose, we can reduce the size of the CAD data without losing simulation purpose.

In this paper we propose effective methods for reducing the size of the CAD data and re-using them for

simulation, assuming the 3D CAD data are already available.

1 INTRODUCTION

As the computer hardware gets faster, we can deal

with large data which needs huge computation. In a

product design, the commercial CAD software is

widely used to model the products. Preparing 3D

simulation data from the scratch takes enormous

efforts and time which is not applicable for most

cases. The importance of the availability of CAD

information in product and process design and

process visualization is increasing rapidly. If we

already have CAD data for each component used in

the manufacturing process, we can reuse the CAD

data for simulation.

To build the simulation data, we need to

integrate the CAD information with manufacturing

models such as machining process simulation

models upstream with concurrent engineering

activities. In this case, there are two problems. One

is the data interfacing problem due to various CAD

data format (Iyer, Arjun, 2002). The other is the size

of the integrated CAD data. For the data format

problem, we used simple STL (Stereolithography)

format as a data interface. For the data size, we will

discuss in this paper.

Simulation data for the production line consists

of hundreds of CAD data for each device, robot and

part. Each CAD data can be some hundred

megabytes when represented in STL format. Even

for a small cell, the size of direct sum of CAD data

can reach several gigabytes. As a matter of fact, this

approach is not applicable for production line or

whole plant even we take consideration of the high

performance of the modern computer hardware.

The purpose of the CAD data is different from

that of the simulation data. The main purpose of

CAD data is to produce the model by verifying the

shape and checking the static interference between

assembled parts. It contains very detailed level of

geometry like small sized holes and small parts like

bolts and nuts, which results in a big size of the data.

On the other hand, simulation data needs not be

94

Kwak J., S. Ko M., C. Park S. and Wang G. (2008).

RE-USING 3D MODELING DATA FOR CONSTRUCTING 3D SIMULATION DATA.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 94-98

DOI: 10.5220/0001492500940098

Copyright

c

SciTePress

described so detail. Though, it depends on the

simulation purpose, generally speaking, simulation

data needs far less level of detail compared to that of

the CAD data. In a large scale simulation like

manufacturing process simulation or whole plant

simulation, we assume that the operations which

need high accuracy already have been verified on a

cell level using OLP(off line programming). It

means, the error tolerance of the geometry for the

simulation data can be larger than that of CAD data.

Using the increased error tolerance, we can reduce

the size of CAD data. In this paper, we assume that

1) 3D CAD data is available for simulation.

2) In some cases, we assume that OLP program

data is available, like IGRIP or RobCAD for

the devices which has kinematic information

like robots or jig fixtures.

3) Triangular mesh is used for solid geometry

handling for various CAD data interface.

4) We do not assume any restriction for the

relationship between original CAD data and

converted triangular mesh geometry

hierarchy by IGRIP or RobCAD.

5) We assume developing our own simulation

software to adopt our simulation data.

2 REUSING 3D CAD DATA

We are developing manufacturing process

simulation software called PlcStudio. It is divided

into two major modules called generic kernel and

graphic module. The generic kernel is used to build

logical model of the manufacturing process. It uses

either software PLC(Programmable Logic Control)

or hardware PLC to control and verify the

manufacturing process, and interfaces graphic

module to display the simulation results and/or to

get the sensory information (Chang Mok Park, 2006).

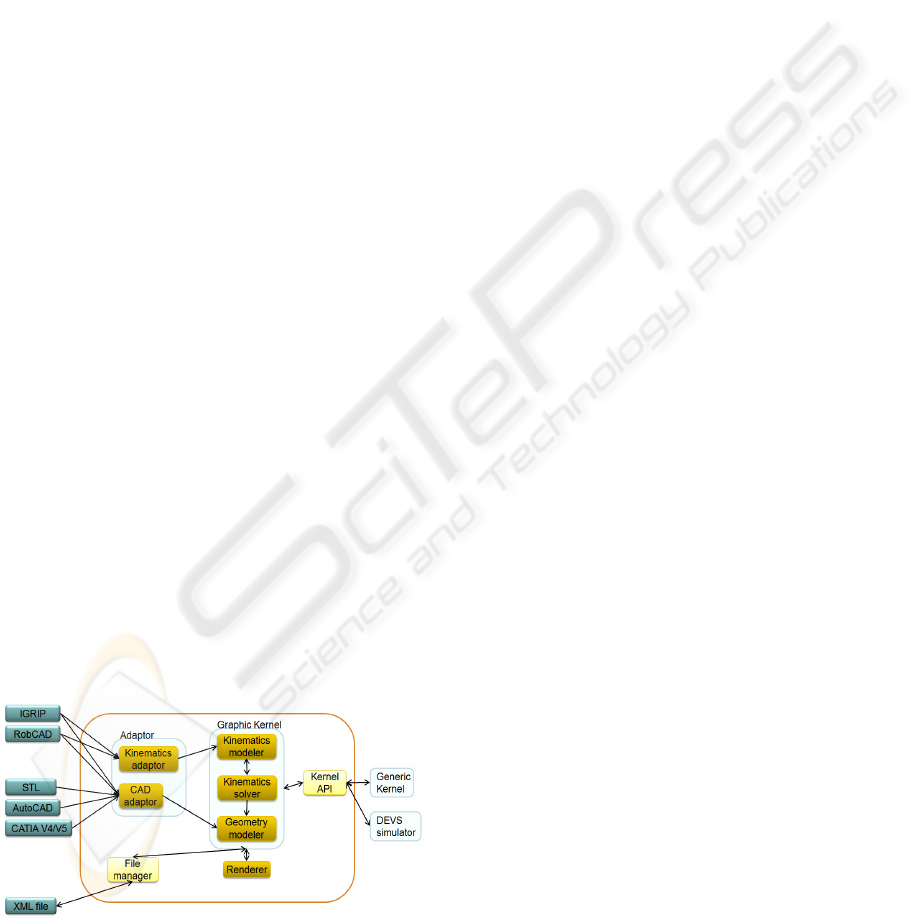

Figure 1: Graphic module architecture.

Graphic module gets the geometry information

from the CAD file generated by the CAD software

like AutoCAD or CATIA. Similarly, it can get both

the geometry information and kinematic information

from various OLP software like IGRIP or RobCAD.

2.1 Background and Related Work

There were many research for simplifying mesh for

the curved surface. Michael et el. summarized these

efforts into 3 classes (GarlandM, 1997). Vertex

decimation, vertex clustering and iterative edge

contraction. They suggested pair contraction method

using a quadric error calculation. The

implementation of the idea is available as an open

source, and it shows nice performance for the curved

surface. In many cases, the geometry of device for

the production line does not contain curved surface.

Therefore this approach is not effective for device

CAD model. For device CAD model, it is more

plausible to use geometric features only if we can

extract them.

2.2 Classification of CAD Data

If we have to build simulation data from the CAD

files, the size of total simulation data grows

exponentially. We can effectively reduce the size of

CAD data based on the features

Conceptually, CAD data can be divided into two

groups. The one is manufacturing devices like robots,

jigs, conveyors etc., which contains few curved

surfaces. The other is parts or workpieces, which

contains lots of curved surface. For the convenience,

we call the former as device CAD model and the

latter as workpiece CAD model.

2.2.1 Device CAD Model

Device CAD model data has the following

characteristics.

1) Has few curved surface :

In almost case, it can be represented with the

combination of box, cylindrical frustum,

sphere etc.

2) Has lots of primitives :

Contains lots of cylinders, boxes etc.

3) Has lots of small part :

It contains lots of small parts like bolts and

nuts, which are not necessary for simulation

purpose.

4) Has lots of holes :

The purpose of the device CAD model is to

manufacturing the device itself, so it

contains lots of holes for bolts and nuts for

part assembly.

RE-USING 3D MODELING DATA FOR CONSTRUCTING 3D SIMIULATION DATA

95

5) It contains inner part data :

In many cases, device CAD model data

contains invisible inner part data, which are

not necessary for simulation purpose.

2.2.2 Workpiece CAD Model

In many cases, workpieces have lots of curved

surface. For car assembly line, almost every

workpieces have smooth surface, like body, side,

door, hood, fender etc. The CAD model for this

workpieces are far more bigger than that of the

device CAD model, because it represents smooth

surface using triangular mesh. Typically, CAD

model for car door exceeds some hundreds mega-

bytes, while the size of device CAD model for

robots is some mega-bytes.

Due to the different characteristics, we apply

different methods to reduce the size of CAD model.

2.3 Reducing Device CAD Model Size

After converted by various software, the structural

information for the geometry data can be lost. This

makes it difficult to go further processing for

geometry handling. However, it is relatively easier

to detect geometric features from device CAD model

rather than workpiece CAD model.

We used the geometric features extracted from

device CAD model to reduce data size.

2.3.1 Replacing the Primitives

In many cases, the device CAD model contains lots

of primitives like cylinder, sphere etc. For replacing

cylinders, we assume that a n-side cylinder

representation in the CAD model is an

approximation of the pure logical cylinder which has

infinitely large n.

A cylinder consists of top, bottom and n-side faces,

where n ≥ 3. A cylinder with n-side consists of 4n-4

triangles. A cylinder contained in the device CAD

model typically has large n value. By detecting this

cylinder geometry and reducing the n, we can reduce

the size of data.

Figure 2: Calculation of n-side for cylinder.

Figure 2 shows how many number of cylinder

sides we can reduce, when the final error tolerance e

for simulation data is given. Using the radius r of the

pure logical cylinder and error tolerance e, we can

calculate maximum θ for reduced cylinder. The

reduced cylinder has 360/θ side faces.

Though this method is quite effective, it is

difficult to apply in real situation, because it is hard

to identify cylinder geometry from unstructured

triangular meshes. For sphere, it is more difficult to

identify. So this method is only applicable when the

CAD data contains structural information and we

can identify them.

Another problem for this method is after

replacing into the simple geometry, some parts

attached to the original cylinder side surface can be

dangling on a replaced cylinder.

2.3.2 Removing Small Parts

The device CAD model contains lots of small

components needed for part assembly. Small bolts

and nuts are one of those things. If these parts are so

small that the size is less than the error tolerance for

the simulation, we can safely remove them.

But in this case, it is not always possible to

identify small parts from unstructured triangular

meshes.

2.3.3 Removing Small Holes

The effect of removing holes from the geometry is

quite potential. A cube without hole can be

represented with 12 triangles, while a cube with one

hole of n side needs 4n + 8 triangles. (n+4 for top,

n+4 for bottom, 2n for side) If a hole is consists of

20 sides, the number of triangles reaches 4*20+8 =

88, which is more than 7 times of 12. If number of

holes increases, the number of triangles increases

rapidly.

The hole removing algorithm is difficult to

implement, because it is not always possible to

identify holes from unstructured meshes. For this

reason, first we detect small inner circle from a

surface. It is relatively easy to implement even if we

don’t have structural information.

Step 1: Group faces which exists in a same plane.

That means, the faces has the same plane equation,

and they are inter-connected.

Step 2: merge the grouped faces

Step 3: Trace boundary edges from the merged

face

Step 4: Identify outmost boundary edges

Step 5: Using the boundary edges, re-triangulate

the surface.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

96

By applying these steps, we can easily remove

any circle in a plane, but it can only remove top or

bottom of the hole, whereas the wall of the cylinder

still remains. Theses cylinder walls are hard to

identify from unstructured set of meshes. These

walls can be further removed by visibility check

routine explained later.

2.3.4 Removing Invisible Parts

In many cases, CAD model contains invisible parts.

Components or parts of a component placed below

other component are invisible from user. For

example, the engine installed in a car is not visible to

the user unless the hood is open. In a simulation,

these invisible components need not be rendered.

After applying hole removal process, the cylinder

walls of the hole geometry are not removed, yet.

These wall are invisible to the user, so it can be

removed by applying visibility checking, too.

Deciding whether a given geometry is visible

from a given camera position or not requires quite

large computation and the implementation of the

algorithm is not simple. With the aid of modern

graphic card functionality, we can successfully

distinguished invisible parts from visible parts (Sang

C. Park, 2005). This method is easy to implement

and it is fast enough to apply, because it uses

hardware function.

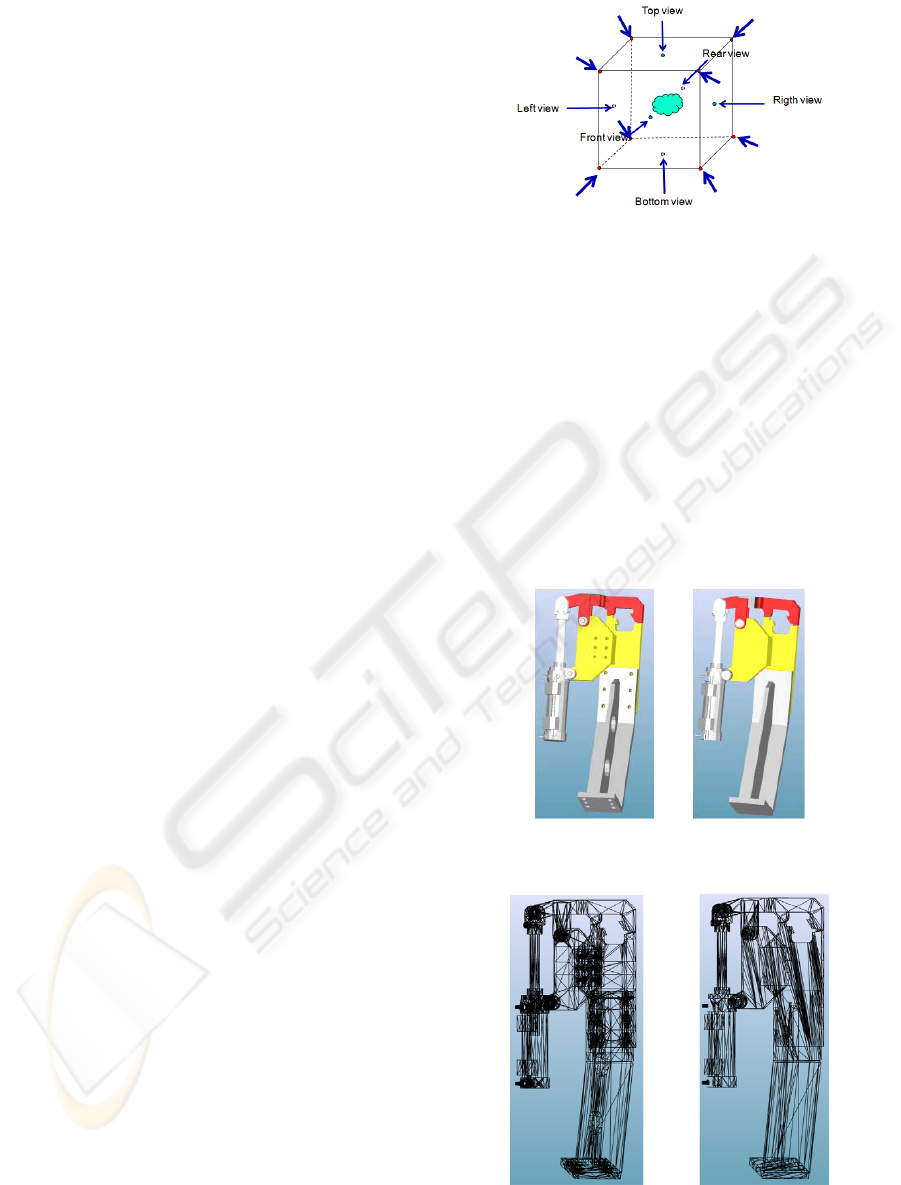

We take a shot for the scene while moving the

camera position. The typical camera positions

looking at the scene are 6 cubic directions plus 8

corner positions. Cubic directions are TOP,

BOTTOM, FRONT, REAR, LEFT and RIGHT

directions. Corner directions are top-front-left, top-

front-right, top-rear-left, top-rear-right, bottom-

front-left, bottom-front-right, bottom-rear-left and

bottom-rear-right directions as depicted in figure 3.

After taking shots at a given camera positions,

we collectively combine all shots, and

mark(remember) all visible parts. On the whole

scene, parts which is not marked as visible forms

invisible parts. The camera positions are

heuristically determined, and there are cases that

given camera positions can’t distinguish invisible

parts. But in many cases, 6 cubic angle point and 8

additional corner point is enough to distinguish

visibility property.

These process can be implemented by drawing

each entities with unique color onto the back-buffer,

while moving the camera positions, and read each

pixel value back from back-buffer, and checking the

color value as a unique key.

Figure 3: Camera positions to view the scene.

By using graphic hardware for deciding visibility,

we need not implement the visibility algorithm and

it can be computed very fast. The visibility checking

algorithm implemented in a graphic card is widely

tested by vendor for a long period of time, so it is

well verified algorithm. We can use the algorithm

almost for free. In addition, modern graphic card can

draw millions of triangles in a second. It means that

we can compute the visibility for a large scene in a

very short time.

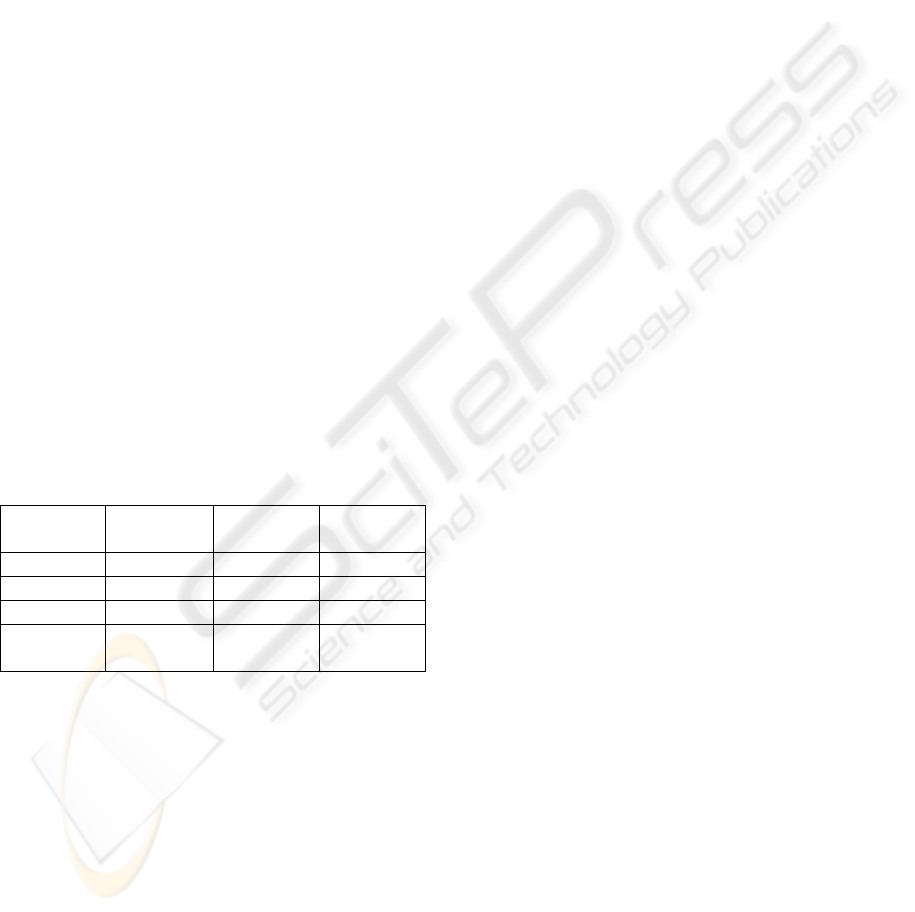

Next figure shows the result of data reduction by

removing invisible parts after removing small parts

and holes.

# triangles = 8220 # triangles = 1845

Figure 4: Processing result: before and after.

Figure 5: Mesh view: before and after.

RE-USING 3D MODELING DATA FOR CONSTRUCTING 3D SIMIULATION DATA

97

2.4 Reducing Workpiece CAD Model

Size

Workpiece CAD model which contains very

complicated surface is not proper to apply the

proposed algorithm. The proposed algorithm is

based on the features extracted from 3D CAD model.

It is almost impossible to identify features from the

workpiece CAD model containing curved surfaces.

So we can use well known mesh simplification

methods like decimation to the curved surface.

3 RESULT AND DISCUSSION

The proposed methods are based on the feature

extraction of the CAD model. Extracting primitives

from the CAD is not always successful. If the CAD

keeps the information about the primitive, we can

easily extract them and we can apply the methods.

But in general case, we can’t assert that information

is available. Identifying small parts has the same

problem. But, identifying the holes and removing

invisible parts works very well even the CAD data

does not keep any information about the feature. It

can even be extracted from raw triangular mesh.

The next table shows the result of reducing cell data

which contains 16 devices. We only applied non

curved surface reduction algorithm for this result.

Table 1: CAD data reduction result.

Original

data

Reduced

data

Ratio(%)

# devices 16 16 100

# solid 4,567 2,966 64.94

# mesh 86,833 24,170 27.84

#

triangles

3,316,146 600,478 18.11

4 CONCLUSIONS

When we have to construct 3D simulation data from

CAD data, we have difficulties for the size of the

CAD data. In the proposed method, we used an hole

removal and visibility checking algorithm to reduce

the data size. This method is easy to implement and

very fast because it utilizes graphic hardware

functionality. If the original CAD data contains

more information for solid identification, we can

further apply the methods by replacing the

geometries. These methods applied to non-curved

surface do not distort the original shape except that it

removes the holes and small parts, which are smaller

than the simulation tolerance error. Using these

methods, we can reduce the size of the sample

production line by 20% of the original data. In our

future work, we plan to develop improved method to

identify features from unstructured triangular mesh.

REFERENCES

Sang C. Park: Pencil curve detection from visibility data.

Computer-Aided Design 37(14): 1492-1498 (2005)

Chang Mok Park : Development of Virtual Simulator for

Visual Validation of PLC program. In CIMCA 2006

Iyer, Arjun, 2002. CAD data visualization for machining

simulation using the STEP standard. In Journal of

Manufacturing Systems. 2001/2002.

GarlandM, Heckbert P. Surface simplification using.

quadric error metrics. In proceedings of SIGGRAPH

1997,. August 1997. p. 209–16.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

98