A REAL TIME EXPERT SYSTEM FOR FAULTS

IDENTIFICATION IN ROTARY RAILCAR DUMPERS

Osevaldo S. Farias, Jorge H. M. Santos, João V. F. Neto, Sofiane Labidi, Thiago Drumond

Department of Electrical Engineering, Federal University of Maranhão

Av. dos Portugueses, s/n, São Luís, Brazil

José Pinheiro de Moura, Simone C. F. Neves

Companhia Vale do Rio Doce, Retorno do Itaqui, SN, São Luís, Ma, Brazil

Keywords: Expert System, Knowledge Base, Industrial Process, Rotary Railcar Dumper.

Abstract: This paper describes the development of a real-time Expert System applied to the ore extraction Industrial

branch, specifically used to assist the decision making and fault identification on rotary railcar dumpers of

the operational productive system located at Ponta da Madeira Dock Terminal, built and operated by

Companhia Vale do Rio Doce (now referred just as VALE) in São Luis-MA. The Expert System is built on

JESS (Java Expert System Shell) platform and provides support to engineers and operators during the ore

unloading as soon as supplying on-line information about faults triggered by device sensors of the rotary

railcar. The system’s conception involves the application of CommonKADS methodology, knowledge

engineering and artificial intelligence techniques at the symbolic level for representing and organizing the

knowledge domain in which the system is applied.

1 INTRODUCTION

In a great deal of industrial production mechanisms

approaches able to turn automatic a wide range of

processes have being used. Such applications

demand from high control pattern to decision taking,

where Artificial Intelligence (AI) presents wide

applicability of those approaches implementing their

concepts under the form of Expert Systems (Su et

al., 2005). Applications with this architecture allow

the machine to be structured into a model apt to

behave in the most similar way a human specialist

uses its reasoning when facing a decision taken

problem (Feigenbaum, 1992).

The VALE production system comprehends

several mining complexes, among which is

notorious the Ponta da Madeira Dock Terminal

(PMDT). In this complex, processes such as

Unloading, Storing and Minerals Shipping are

conducted, supervised by the Operational Control

Center (OCC). This article discusses the

development of a real time Expert System applied to

decision making when facing faults occurred in the

VV311-K01 rotary railcar dumper system used to

unload minerals at the VALE’s PMDT. Besides, we

apply some information technologies such as: the

JESS, the JAVA language and also XML

(eXtensible Markup Language) aiming the real time

running of the Expert System.

This paper is organized as follows: Section 2

describes the particularities and the operation of the

rotary railcar dumper system. In Section 3 are

detailed the Expert System Development steps, such

as knowledge acquisition, representation and

system’s implementation. Section 5 summarizes

some remarks and the conclusion.

2 THE ROTARY RAILCAR

DUMPER SYSTEM

The minerals unloading mechanism initiates at the

rotary railcar dumper with the arrival of the

locomotive pulling behind it 102 to 104 rail-wagons

that will be positioned in the dumper.

To attain the rotation a positioner car fixes the rail-

wagons in the rotary and this, consequently, unloads

347

S. Farias O., H. M. Santos J., V. F. Neto J., Labidi S., Drumond T., Pinheiro de Moura J. and C. F. Neves S. (2008).

A REAL TIME EXPERT SYSTEM FOR FAULTS IDENTIFICATION IN ROTARY RAILCAR DUMPERS.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 347-350

DOI: 10.5220/0001497603470350

Copyright

c

SciTePress

the material by performing a 160° rotation, in the

conveyor belts (Fonseca Neto et al., 2003). The

Operational Process is monitored by the Supervisory

Control and Data Acquisition (SCADA). This

supervision is also conducted by means of the

programmable logic controllers (PLCs) which

receive all the information from the dumper

hardware through input cards.

Thus, the rail-wagons dumper’s hardware is one

important middleware for the communication

between the Expert System and the VV311-K01

hydraulic and mechanical components at the

operation time.

3 THE EXPERT SYSTEM

DEVELOPMENT

In order to develop the Expert System we

highlighted its stages based on JESS and

CommonKADS methodologies.

The JESS architecture involves cognition

components defined as: Inference Engine, Agenda

and Execution Engine. All these structures catch

assertions or domain facts and also create new

assertions. The inference JESS engine (based on the

Rete algorithm) is constituted by the Pattern-

Matching mechanism that decides which rules will

be activated. The Agenda programs the order in

which the activated rules will be fired, and the

Execution Engine is in charge of the triggering shot

(Friedman-Hill, 2003). In JESS the reasoning

formalism presents rules composed by if...then

patterns, represented by the LHS (Left-Hand Side)

and RHS (Right-Hand Side), respectively.

CommonKADS is a methodology for building

knowledge based systems (Labidi, 1997). Products

arisen from Expert Systems development that use

this methodology are the result of the performed

phases modelling activities, and characterize the

input artefacts for the successive refinements

undergone in the next steps of the CommonKADS

life cycling.

The steps of the system with actions such as

Acquisition and Knowledge representation are

summarized– also including the Analysis phase–

Rules representation– attending the Design phase –

and the System’s codification – satisfying the phase

Implementation.

3.1 Acquisition and Knowledge

Representation

All the knowledge acquisition was done by means of

interviews with the expert through information kept

in the operational reports. The knowledge

representation was built based upon production rules

that map the knowledge of the VV311-K01

operation expert.

There were observed the main concepts related

with the dumper’s positioner car along activities in

the operational productive system, aiming at getting

knowledge elements description to elaborate the

organizational model that complements the

CommonKADS.

The domain facts deal with the equipment

situation and the potential causes that promote the

main system stopping or the reduction of its

productivity. Thus, by correlating problems and

opportunities that can be solved or enhanced by the

Expert System from which there were extracted the

identified slots for building the VV311-K01

templates, it was elaborated the organizational

model presented in Table 1.

Table 1: Organization Model.

The slot called ‘Situation’ is one of the units for

representing the knowledge in the JESS inference

engine. The causes that lead the dumper to reach

certain circumstances are pointers for guiding what

must be done as to specify derivations that constitute

a method for the positioner car problem resolution,

and the strategies to attain this solution. These

efforts are described through the knowledge model

shown in Table 2.

Table 2: Knowledge Model.

SLOT OPPORTUNITIES PROBLEMS

Vibration

Broken Rollers

Spin

Lack of voltage

Short-circuit

Broken fixing

screws

Situation

Positioner car

Broken Counter-

bolts

SLOT INFERENCE

LEVEL

TASK LEVEL

Motor basement snap

Resonance

Vibration

Bend axle

Terminal out of order

Low isolation

Cause

Short-circuit

Falling’s wire material

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

348

According to Labidi (1997), the inference and task

levels are layers that describe the expert Knowledge;

thus, the model in Table 2 constitutes a set of

knowledge instances on the VV311-K01 positioner

car component. In Table 2, in order to better

characterize the system’s knowledge mechanism in

agreement with the CommonKADS methodology,

the activities organized in the inference model

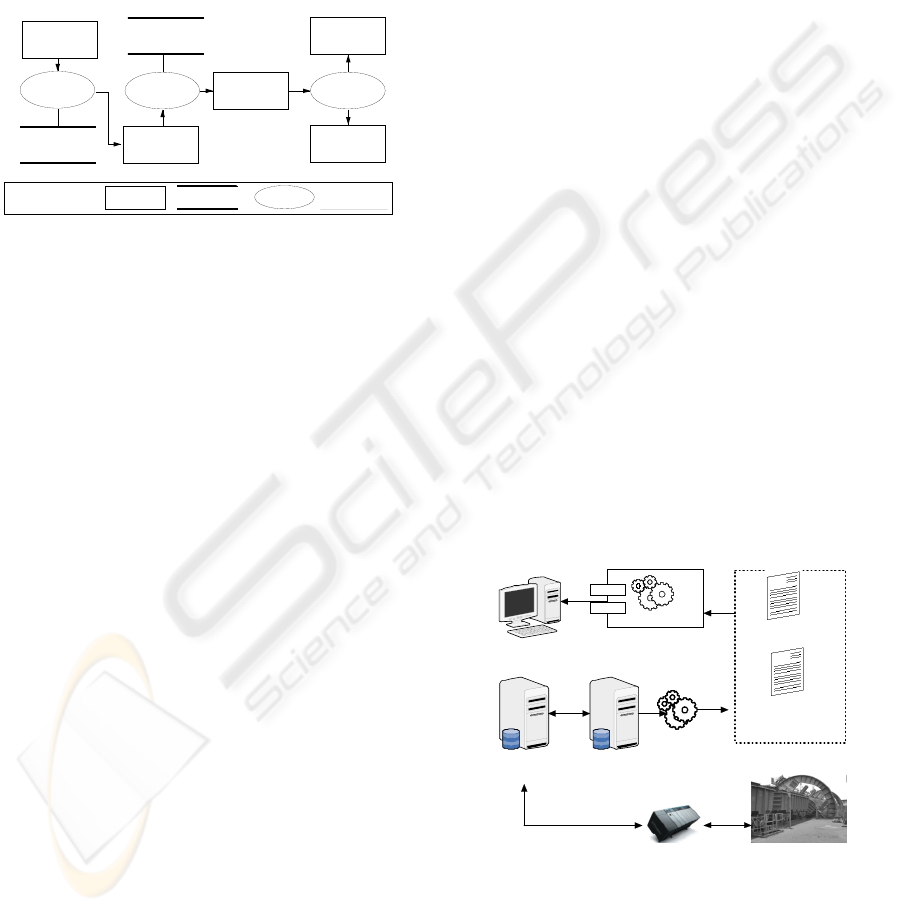

presented in Figures 1, were decomposed.

COMPARE

situation

rules

decision

rules

current

result

situation

COVER

hypothesis

(probable)

PREDICT

expected

result

result

dumper brake

module do not work

Causal Model

Manifestation Model

command=not acted

different results

command=acted

lack voltage

Data flux and

Knowledge

Knowledge

role

Static role Inference

Legend

Figure 1: Inference Model.

The knowledge’s roles, described in Figure 1, are

functional names that capture the elements

participant in the reasoning process. Inference

actions assume as inputs static roles, represented by

the manifestation and causal models. Within the

causal model, the rules relate the positioner car fault

modes taking into account their attribute’s values,

while in the manifestation model are reunited the

production rules that express their responsibilities

through the attributes’ values, which satisfy some

given conditions. The inference concepts represent

reasoning axioms that will be mapped by the JESS

inference engine used in the Expert System.

3.2 System Implementation

The Expert System decision module performs a

scanning on the faults detected by the sensors

present in the VV311-K01 instrumentation.

Through the checking of these faults addresses,

which are generated by the PLCs and mapped into

faults tagnames stored in the relational database, the

Expert System rules are activated or not in the

working memory of the JESS inference engine.

Tagnames (e.g.

AFF_CEP_F01@VV311K01) are

part of historical registry from PIMS (Plant

Information Management System). In the Expert

System they play the role of input data for the rules

that deduce the situation the VV311-K01

components pass through, that is why they form the

LHS rules pattern in the JESS language syntax, as

can be seeing in the excerpt bellow:

(defrule rule198

(test(eq TRUE(actedTag

"AFF_CEP_F01@VV311K01")))

=>

(store RESULT198 "Loose-Wire-

Connection")

(assert (decision(decCausa Loose-Wire-

Connection))))

The ‘actedTag’ function returns true for 1 and false

for 0, according to the result read in the XML file

generated by the stored procedure into the PIMS

oracle database server (see Figure 2). The function

‘test’ is a conditional JESS instruction responsible

for determining that this pattern will only be unified

if the result of the ‘actedTag’ function returns true.

The part of XML document is shown as the

following structure:

<?xml version="1.0" encoding="UTF-8" ?>

- <tags>

- <tagname id="ASC_B11@VV311K01">

<value>0</value>

</tagname>

- <tagname id="AIN_ALI_001@VV311K01">

<value>1</value>

</tagname>

Aiming at present the system’s global solution,

Figure 2 describes the Expert System architecture

and the nodes distribution that form its structure in

order to summarize the Expert System solution.

Once the architecture is formulated, in the

following parcel of the system’s decision rule, it is

possible to observe that the cause ‘Loose-Wire-

Connection’ deduces that the ultrasound on VV311-

K01 must be made.

PIMS

Relational Database Server

PLC Historical

Database Server

PLC

VV311-K01

Knowledge Base

ExpertSystem.jar

Rules File

(vv311-01.clp)

XML File

(tagNam es.xml)

Client

engine JESS

Figure 2: Expert System Architecture.

The RHS pattern of the rule’s parcel below stores

the result through the command store, and next

inserts in the ‘decision’ template, the action to be

done.

A REAL TIME EXPERT SYSTEM FOR FAULTS IDENTIFICATION IN ROTARY RAILCAR DUMPERS

349

(defrule rule204

(decision (decCause Loose-Wire-

Connection))

=>

(store RESULT204 "Do ultrasound on

VV311-K01")

(assert (decision

(decDecision Do-ultrasound-on-

VV311-K01))))

At the end of the performed deductions, in the shell

JESS working memory is shown a window with the

recommendations that were stored by the command

store, based in the causes that led to the inference

process pointed out by the system, along the

responses given by the user. Figure 3 shows the

decision taking delivered by the system.

Figure 3: Expert System Recommendations.

The recommendations viewed in Figure 5, represent

the rules that were activated in the working memory

of the JESS engine and were triggered (shot) only

because they got the unification of patterns present

in its structure, deduced by the Rete algorithm. The

control structure used for the Expert System rules

chaining was based on backward chaining

(Friedman-Hill, 2003).

4 CONCLUSIONS

The system developed in this work presented the

conception and automation of the strategic

knowledge required by VALE’s mineral unloading

system activities. The building of the Expert System

in JESS, turned available the use of existing and

well succeeded methods for the developing of

systems based on knowledge, like the

CommonKADS, and the direct handling of JAVA

technology objects.

The system’s performance while processing

information in the JESS inference engine was

considered satisfactory once the search frequency of

such information elements was tested at 5 s. interval

for the deduction of 250 rules, in order to update the

expert system the events triggered by the PIMS

server. The speed and proper timing obtained in

terms of the updating processes of the expert system

rules base was due to the use of the XML

technology as to feed the system’s knowledge base.

Finally, this system furnished enhancement and

relative readiness to the knowledge processing, as a

guide for the decision taking of the VALE’s rail-

wagon unloading system experts.

ACKNOWLEDGEMENTS

The authors express their thanks to

FAPEMA/CAPES, Intelligent Systems

Laboratory/UFMA, Automation and Control

Laboratory/UFMA and VALE.

REFERENCES

Feigenbaum, A.E. Expert Systems: principles and practice.

In: Encyclopedia of computer science and engineering,

1992.

Friedman-Hill, E. J. Jess in Action: Rule-based systems in

java. USA: Manning Press, 2003.

Su, K.W. Hwang, S.L. Chou Y.F. Applying knowledge to

the usable fault diagnosis assistance system: A case

study of motorcycle maintenance in Taiwan. Elsevier

Science Ltd, 2005.

Fonseca Neto, J. V. da., Moura, J.P. de. Um Sistema

Especialista para Identificação de Falhas e Tomada de

Decisão em Correias Transportadoras de Minério, VI

SBAI, 2003.

Labidi, S. CommonKADS Extension for Supporting

Multi-Expertise. In: The 17th International Conference

of the British Computer Society on Expert Systems,

(ES'97), 1997, Cambridge. Proceedings of the 17

th

,

International Conference of the British Computer

Society on Expert Systems, (ES'97), 1997.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

350