NEURAL NETWORK AND GENETIC ALGORITHMS FOR

COMPOSITION ESTIMATION AND CONTROL OF A HIGH

PURITY DISTILLATION COLUMN

J. Fernandez de Cañete, P. del Saz-Orozco and S. Gonzalez-Perez

System Engineering and Automation Dpt., University of Malaga, Malaga, Spain

Keywords: Distillation control, software sensors, neural networks, genetic algorithms.

Abstract: Many industrial processes are difficult to control because the product quality cannot be measured rapidly

and reliably. One solution to this problem is neural network based control, which uses an inferential

estimator (software sensor) to infer primary process outputs from secondary measurements, and control

these outputs. This paper proposes the use of adaptive neural networks applied both to the prediction of

product composition from temperature measurements, and to the dual control of distillate and bottom

composition for a continuous high purity distillation column. Genetic algorithms are used to automatically

choice of the optimum control law based on the neural network model of the plant. The results obtained

have shown the proposed method gives better or equal performances over other methods such fuzzy, or

adaptive control.

1 INTRODUCTION

Nowadays, advanced control systems are playing a

fundamental role in plant operations because they

allow for effective plant management. Typically,

advanced control systems rely heavily on real-time

process modelling, and this puts strong demands on

developing effective process models that, as a prime

requirement, have to exhibit real-time responses.

Because in many instances detailed process

modelling is not viable, efforts have been devoted

towards the development of approximate dynamic

models.

Approximate process models are based either on

first principles, and thus require good understanding

of the process physics, or on some sort of black-box

modelling. Neural network modelling represents an

effective framework to develop models when relying

on an incomplete knowledge of the process under

examination. Because of the simplicity of neural

models, they exhibit great potentials in all those

model-based control applications that require real-

time solutions of dynamic process models. The

better understanding acquired on neural network

modelling has driven its exploitation in many

chemical engineering applications.

For many reasons, distillation remains the most

important separation technique in chemical process

industries around the world. Therefore, improved

distillation control can have a significant impact on

reducing energy consumption, improving product

quality and protecting environmental resources.

However, both distillation modelling and control are

difficult task because it is usually a nonlinear, non-

stationary, interactive, and subject to constraints and

disturbances process. Nevertheless, process

identification and optimization (Bhat and McAvoy

1990) (Bulsari 1995), software sensor development

(Zamprogna et al 2001), fault analysis and process

control (Hussain 1999) (Xiong and Jutan 2002)

works have been successfully reported in this field.

Genetic algorithms (GA) are model machine

learning methodologies, which derive their

behaviour from a metaphor of the processes of

evolution in nature and are able to overcome

complex non-linear optimization tasks like non-

convex problems, non-continuous objective

functions, etc. (Michalewitz 1992). They are based

on an initial random population of solutions and an

iterative procedure, which improves the

characteristics of the population and produces

solutions that are closer to the global optimum. This

220

Fernandez de Cañete J., del Saz-Orozco P. and Gonzalez-Perez S. (2008).

NEURAL NETWORK AND GENETIC ALGORITHMS FOR COMPOSITION ESTIMATION AND CONTROL OF A HIGH PURITY DISTILLATION

COLUMN.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 220-224

DOI: 10.5220/0001498702200224

Copyright

c

SciTePress

is achieved by applying a number of genetic

operators to the population, in order to produce the

next generation of solutions. GAs have been used

successfully in combinations with neural and fuzzy

systems (Fleming and Purshouse 2002).

In this paper we describe the application of

adaptive neural networks to the estimation of the

product compositions in a binary methanol-water

continuous distillation column from available on-

line temperature measurements. This software

sensor is then applied to train a neural network

model so that a GA performs the searching for the

optimal dual control law applied to the distillation

column. The performance of the developed neural

network based estimator is further tested by

observing the performance of the designed neural

network based control system for both set point

tracking and disturbance rejection cases.

2 PROCESS DESCRIPTION

The distillation column used in this study is

designed to separate a binary mixture of methanol

and water, which enters as a feed stream with flow

rate F

vol

and composition X

F

between the rectifying

and the stripping section, obtaining both a distillate

product stream D

vol

with composition X

D

and a

bottom product stream B

vol

with composition X

B

. The

column consists of 40 bubble cap trays. The

overhead vapour is totally condensed in a water

cooled condenser (tray 41) which is open at

atmospheric pressure. The process inputs that are

available for control purposes are the heat input to

the boiler Q and the reflux flowrate L

vol

. Liquid

heights in the column bottom and the receiver drum

(tray 1) dynamics are not considered for control

since flow dynamics are significantly faster than

composition dynamics and pressure control is not

necessary since the condenser is opened to

atmospheric pressure.

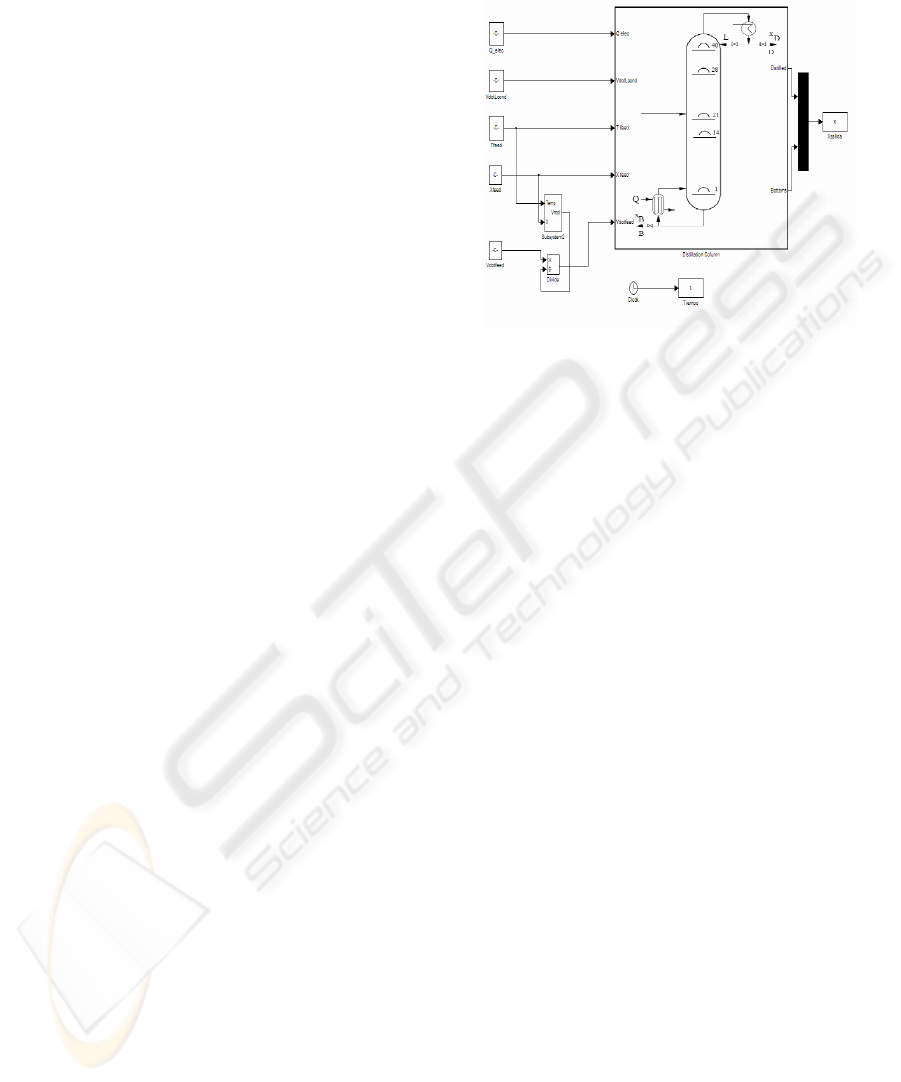

The model of the distillation column used

throughout the paper is developed by (Diehl et al

2001), composed by the mass, component mass and

enthalpy balance equations used as basis to

implement a SIMULINK model (figure 1) which

describes the nonlinear column dynamics as a 2

inputs (Q , L

vol

) and 2 output (X

D

, X

B

).

Implementations details for the overall column

dynamics are given in (Fernandez de Canete et al

2007).

Figure 1: Schematic of the SIMULINK model of the

distillation.

3 NEURAL ESTIMATOR AND

CONTROLLER

The complete neural network based estimation and

control system is described below (Figure 2).

3.1 Neural Composition Estimator

In order to infer the composition from temperature a

neural network is used. Previously, a sensitivity

study is performed in order to choose the correct set

of temperatures to infer top and bottom

compositions, resulting a three temperature vector

T[k] = [T

41

[k],T

21

[k],T

1

[k]] selected as input to the

neural network predictor which outputs the predicted

values of composition vector

]][

ˆ

],[

ˆ

[][

ˆ

kXkXky

BD

=

.

Normally, in a plant operation, both real values are

measured off-line in the laboratory. In this study, the

neural network parameter update is made accepting

the simulation results as same with the actual plant

data. Training set for a 3-layer net (3-15-2 units) is

generated by selecting 1200 temperature data points

obtained by during column open loop operation with

range for L

Vol

(0-5E-06 m3/h) and heat flow Q (0-

2000 J/s) for fixed feed rate conditions F

Vol

= 1 E-06

m3/h, X

F

= 0.3, where the Levenberg-Marquardt

training algorithm has been applied.

NEURAL NETWORK AND GENETIC ALGORITHMS FOR COMPOSITION ESTIMATION AND CONTROL OF A

HIGH PURITY DISTILLATION COLUMN

221

Figure 2: Estimation and control neural network based structure.

An additional temperature data set consisting of 150

data points was used to test the neural predictor

afterwards. The error in the training phase is under

0.001% and 0.002% in the validation phase. For

training pattern generation we assume an initial

steady state for the column after a start-up process.

3.2 Neural Model

Prior to the design of the controller, a neural

network has been used as an identification model of

the distillation column dynamics. To obtain

representative training data, varying feed flows,

initial liquid composition values both in the column,

boiler and condenser along with input values for the

control actions were imposed on the model. The a 3-

layer net (4-10-2 units) with vector input

])[],2[

ˆ

],1[

ˆ

],[

ˆ

(][

~

kukykykyfky

−

−=

and vector

output u[k] = [L

Vol

[k],Q[k]] with

][

ˆ

ky

regularly

spaced covering the same range as defined in the

former. As the model’s dynamic will be modified

with unknown perturbations, this neural network

based model will be updated with the real plant

response.

3.3 Neural GA Controller

As the estimation of the composition vector

][

~

ky

in

the next simulation step according the present and

previous states of

][

ˆ

ky

and the input to the system

u[k] can be achieved using the neural net, the control

problem can be implemented as an optimization

problem in which the function to minimize is the

difference between the desired output

][ky

d

and the

estimated one

][

~

ky

in the next step. As a result, the

optimum control law u[k] is elicited for the

distillation control problem.

In order to search for the optimum for the highly

non-linear function a genetic algorithm is used with

75 members fixed population, 75 generations and

random mutation. If an error under 0.01% is

achieved, the algorithm is stopped in order to

accelerate the simulations.

4 RESULTS

The aim in the design of the composition neural

estimator is to use together with Neural-GA

controller for dual composition control of the

distillation column. Therefore, the composition

NEURAL

MODEL

GA

CONTROLLER

DISTILLATION

COLUMN

NEURAL

ESTIMATOR

TDL

][

ˆ

ky

]1[ +ky

d

][

~

ky

][ku

][ke

][kT

TDL : Tapped Delay Line

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

222

estimator is tested by using the SIMULINK model

before it is used for control (Figure 3).

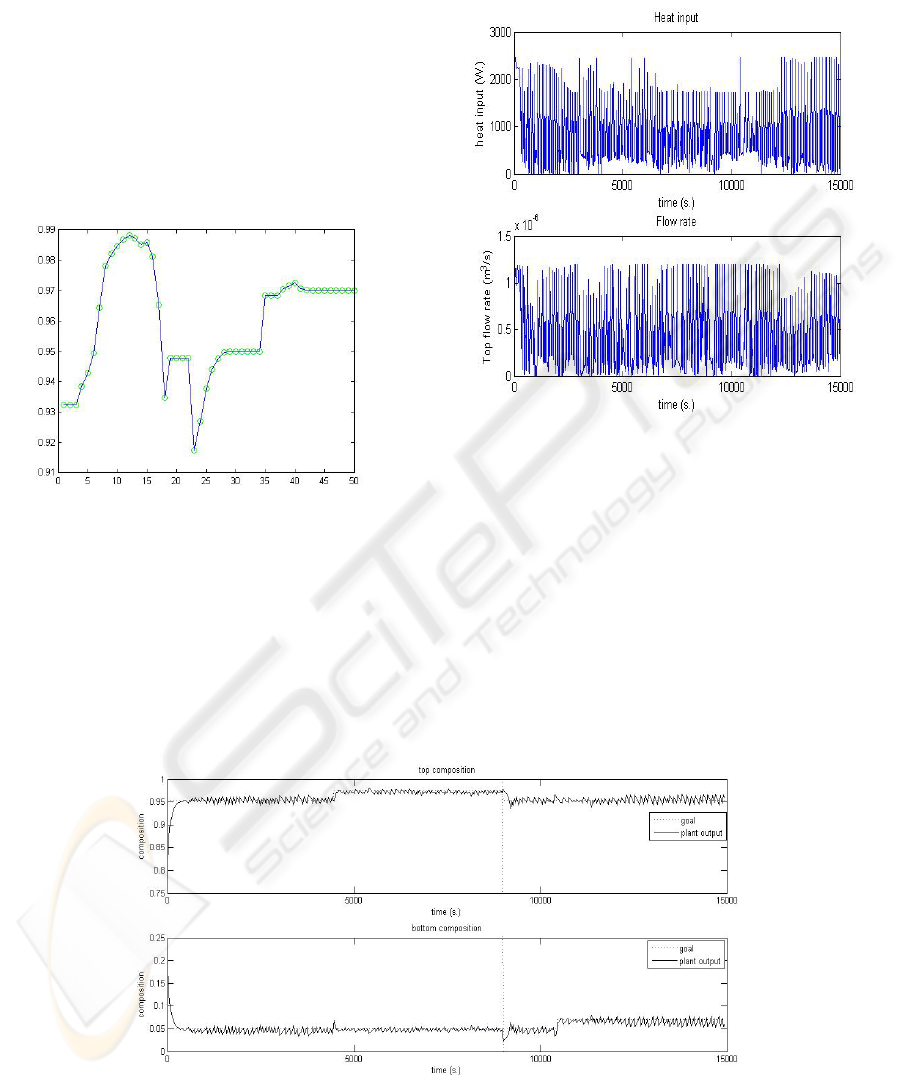

Changes in the reflux and heat flow are determined

by the neural network based controller for the

column (Figure 4). The performance of the control

structure is checked for a 95% to 98% (5% to 7%)

pulse change in the distillate (bottom) composition

set-point at t = 4600 s together with a 40% to 30%

change in feed composition X

F

at t = 9050 s, this

variable taken as a disturbance (Figure 5). The

results obtained demonstrate the potential use of this

control strategy in this field.

Figure 3: Composition estimation for the neural predictor.

5 CONCLUSIONS

We have proposed a neural network design

methodology to dual composition control in a

multivariable binary distillation column. A neural

network has been employed both for prediction of

composition profiles from temperatures and design

of optimum control law using a GA search

technique, by using a neural model based fitness

function. The results obtained point to the potential

Figure 4: Heat flow and reflux flow rate for a pulse set-

point change in top (bottom) product purity and

disturbance in X

F

.

use of this control strategy in areas of design related

to operability and control in process engineering.

Future works are actually directed towards the

application of the proposed methodology to a real

small scale pilot plant DELTALAB DC-SP (web

http//www.isa.uma.es/C4/Control%20Neurob

orroso/

Document%20Library/index.htm)

Figure 5: Performance of the Neural-GA controller for a pulse set-point change in top (bottom) product purity and

disturbance in X

F

NEURAL NETWORK AND GENETIC ALGORITHMS FOR COMPOSITION ESTIMATION AND CONTROL OF A

HIGH PURITY DISTILLATION COLUMN

223

REFERENCES

Bhat N, McAvoy T., 1990. Use of neural nets for dynamic

modeling and control of chemical process systems.

Computers and Chemical Eng , v. 14, n. 4, pp. 573–

583.

Bulsari A.,1995. Neural networks for chemical engineers.

Elsevier, Amsterdam.

Zamprogna, E.; Barolo, M.; Seborg, D.E., 2001.

Composition estimations in a middle-vessel batch

distillation column using artificial neural networks.

Chemical Engineering Research and Design, v.79,

n.6, pp. 689-696.

Hussain, M. A., 1999. Review of the applications of neural

networks in chemical process control. Simulation and

on-line implementations, Artificial Intelligence in

Eng., v. 13, pp. 55-68.

Xiong, Q., Jutan, A., 2002. Grey-box modelling and

control of chemical processes”, Chem. Eng. Science, v.

57, pp. 1027-1039.

Michalewitz, Z., 1992. Genetic Algorithms + Data

Structures = Evolution Programs, Springer, Berlin,

Germany.

Fleming, P., Purshouse, R., 2002. Evolutionary algorithms

in control systems engineering: a survey. Control

Engineering Practice, v. 10, pp. 1223–1241.

Diehl, M., Uslun I., Findeisen, R., 2001. Real-time

optimization for large scale processes: Nonlinear

predictive control of a high purity distillation column,

On Line Optimization of Large Scale System: State of

the Art, Springer-Verlag, 2001

Fernandez de Canete, J., Gonzalez-Perez, S., Del Saz-

Orozco, P., 2007. A development of tools for

monitoring and control of multivariable

neurocontrolled systems with application to distillation

columns, Proeedings of the EANN 2007 International

Conference, Thesaloniki, Greece, pp. 296-305.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

224