VISUAL BASIC APPLICATIONS FOR SHAPE MEMORY

ELEMENTS DESIGN USED IN INTELLIGENT SYSTEMS

Sonia Degeratu, Petre Rotaru, Horia Octavian Manolea

Faculty of Electromechanical Engineering and Faculty of Physics, University of Craiova, Romania

Faculty of Dentistry, University of Medicine and Pharmacy, Craiova, Romania

Gheorghe Manolea, Anca Petrisor, Bizdoaca Nicu George

Faculty of Electromechanical Engineering and Faculty of Automation, University of Craiova, Romania

Keywords: Shape memory alloy, austenite phase, martensite phase, cantilever strip, helical spring.

Abstract: The paper presents the design strategies for two typical configurations of intelligent systems, using as active

elements the Shape Memory Alloy (SMA) cantilever strip and the SMA helical spring. Based on the

advantages and unique properties of shape memory alloys the authors defined the operating mode, the

mechanical considerations and the design assumptions for these two examples. It also includes the

experimental results of thermal analysis in order to determine the transformation temperatures for studied

SMA elements. A comprehensive graphical interface, which runs under Visual Basic environment, has been

developed for each design strategy. Each one provides a user friendly environment that allows intelligent

system parameters configuration as well as the choice of the most adapted analysis methods and data

displaying. At this moment, these two Visual Basic applications are used for engineering purposes as well

as didactical ones.

1 INTRODUCTION

The shape memory alloys (SMA's) possess the

ability to undergo shape change at low temperature

and retain this deformation until they are heated, at

which point they return to their original shape (Van

Humbeeck, 2001), (Waram, 1993).

The unique behavior of SMA’s (e.g. shape

memory effect, pseudo-elasticity) is based on the

temperature-dependent austenite-to-martensite phase

transformation on an atomic scale, which is also

called thermoelastic martensitic transformation.

The SMA’s can exist in two different

temperature-dependent crystal structures (phases)

called martensite (lower temperature) and austenite

or parent phase (higher temperature).

When martensite is heated, it begins to change

into austenite and the temperatures at which this

phenomenon starts and finishes are called austenite

start temperature (As) and respectively austenite

finish temperature (Af). When austenite is cooled, it

begins to change into martensite and the

temperatures at which this phenomenon starts and

finishes are called martensite start temperature (Ms)

and respectively martensite finish temperature (Mf).

SMA’s have been extensively studied as

functional materials for a wide range of applications:

robotics, actuators, automobiles, aerospace, military

field, medicine, toys, electronics, optical industry,

constructions, agroalimentary sector (Degeratu,

2003), (Dolce, 2001), (Van Humbeeck, 1999).

The use of SMA’s can sometimes simplify a

mechanism or device, reducing the overall number

of parts, increasing reliability and therefore reducing

associated quality costs. Moreover, their functioning

can be scheduled and controlled by establishing an

adequate strategy in respect to the operating mode

(Bizdoaca, 2006), (Petrisor, 2007).

2 CHARACTERISTICS OF SMA’S

The thermoelastic martensitic transformation causes

the folowing main properties of SMA’s: one-way and

two-way shape memory effect, hysteresis behavior,

superelasticity, vibration damping capacity (Dolce,

207

Degeratu S., Rotaru P., Octavian Manolea H., Manolea G., Petrisor A. and Nicu George B. (2008).

VISUAL BASIC APPLICATIONS FOR SHAPE MEMORY ELEMENTS DESIGN USED IN INTELLIGENT SYSTEMS.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 207-210

DOI: 10.5220/0001500802070210

Copyright

c

SciTePress

2006), (Waram, 1993), (Van Humbeeck, 2001). The

two applications presented in this paper are mainly

using the two-way shape memory effect representing

the ability of SMA's to recover a preset shape upon

heating above the transformation temperatures and to

return to a certain alternate shape upon cooling.

3 DESIGN STRATEGIES FOR

SMA ELEMENTS

The first step an engineer should take when

undertaking a design involving shape memory

material is to clearly define the design requirements.

This article includes the design strategies for the

SMA cantilever strip and for a SMA spring working

against a conventional steel spring (referred to in

this case as the “biasing” spring). In both design

models the friction effect is neglected and a linear

stress-strain behavior is assumed (Nasser, 2005).

3.1 Operating Modes of SMA’s

The most used operating modes of SMA's are: free

recovery, constrained recovery and work production.

The two Visual Basic applications presented in

this paper use a work production operating mode. In

this kind of operating mode a shape memory

element (SME), such as a strip or a helical springs,

works against a constant or varying force to perform

work. The element therefore generates force and

motion upon heating.

3.2 Transformation Temperatures

SMA’s exhibit a large temperature dependence on the

material shear modulus, which increases from low to

high temperature. Therefore, as the temperature is

increased the force exerted by a SME increases

dramatically (Dolce, 2001), (Nasser, 2005).

This section presents the transformation

temperatures obtained for the studied SMA elements

(strip and helical spring) using Thermal Analysis

Methods. Ni-Ti-Cu (Raychem proprietary alloy) is

the material used for the two SMA elements.

Thermogravimetric Analysis (TGA), Differential

Thermal Analysis (DTA) and Differential Scanning

Calorimetry (DSC) methods were used to determine

the required parameters. The measurements were

carried out on a Perkin Elmer Thermobalance in

dynamic air atmosphere, showing that the sample’s

mass does not undergo any changes at heating and

cooling. In consequence, the TGA curves are ignored.

SMA strip transformation temperature

The temperature control program used for SMA

strip measurements contains the following sequences:

heating from 30°C to 160°C at 5°C/min;

holding for 10min at 160°C;

cooling from 160°C to 20°C at 5 °C/min.

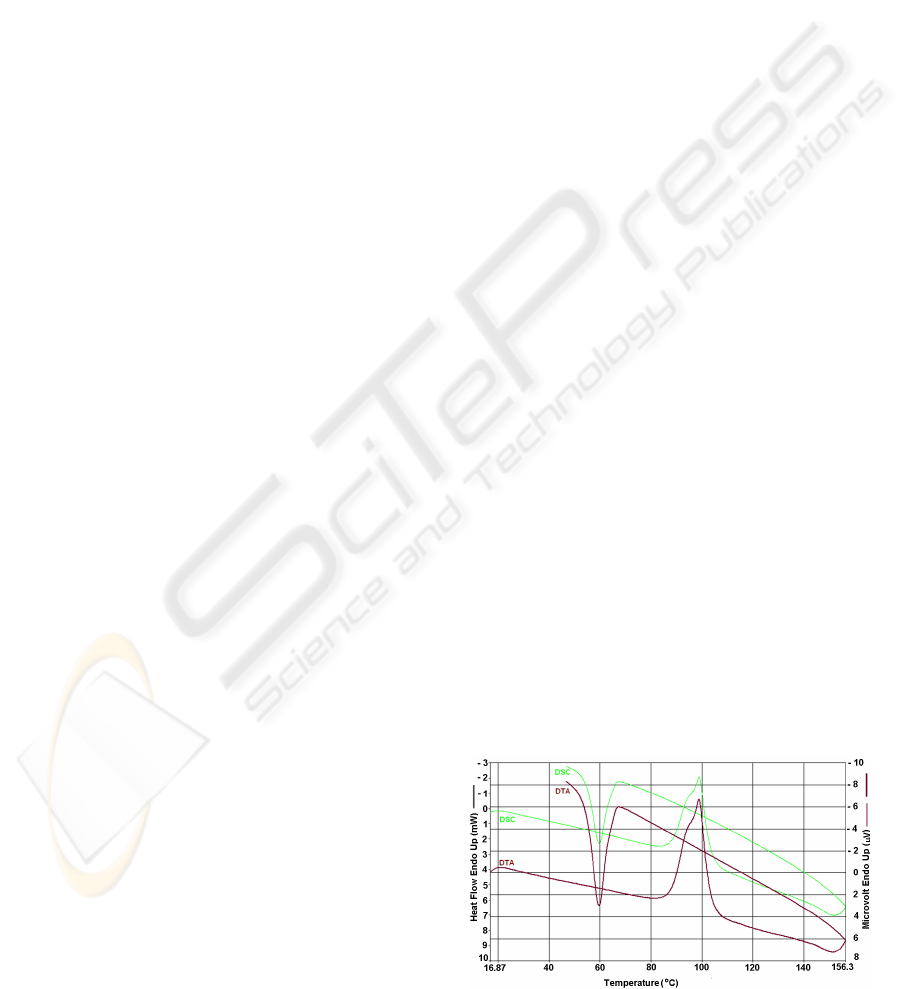

The DTA and DSC curves are presented in Figure

1. By analyzing this figure we can observe two phase

transitions. The first occurs during the heating while

the second one appears during the cooling process.

The details of these thermal effects are presented in

figures 2 and 3 (reported from the DSC curve).

Figure 2 shows that the determined transformation

temperatures at heating are A

s

=80°C and A

f

=111°C.

The enthalpy of the endothermal transition process is

ΔH

h

=36.8858J/g. The temperature corresponding to

maximum transformation speed is 98.79°C.

The transformation temperatures at cooling result

from Figure 3: M

s

=69°C and M

f

=48.25°C. The

enthalpy of the exothermal transition process is

ΔH

c

=-28.7792J/g and the temperature corresponding

to maximum transformation speed is 59.75°C.

SMA helical spring transformation temperature

The transformation temperatures of SMA helical

spring are obtained by similar measurements as in

the case of SMA strip, using the following

temperature-control sequences:

heating from 30°C to 100°C at 5°C/min;

holding for 10 min at 100°C;

cooling from 100°C to 20°C at 5 °C/min.

The form of DTA and DSC curves is similar to

the ones represented in Figure 1, for 6.849mg SMA

spring sample. The experimental transformation

temperatures at heating are A

s

=58.89°C and

A

f

=67.93°C. The enthalpy of the endothermal

transition process is ΔH

h

=9.2J/g and the temperature

corresponding to maximum transformation speed is

60.42°C. The transformation temperatures at cooling

are M

s

=45°C and M

f

=33°C, the enthalpy of the

exothermal transition process is ΔH

c

= -5.03J/g and

the temperature corresponding to maximum

transformation speed is 39.07°C.

Figure 1: DTA and DSC curves for 18.275mg SMA strip.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

208

Figure 2: Detail of DSC curve for computation transition

at heating of SMA strip.

Figure 3: Detail of DSC curve for computation transition

at cooling of SMA strip.

4 VISUAL BASIC APPLICATIONS

Two Visual Basic applications were implemented

for SMA cantilever and SMA helical spring with

biasing spring. This section details these

applications.

Visual Basic application for SMA cantilever strip

Cantilevers made from SMA strip can be used to

provide a lifting force and a nominal amount of

motion by heating.

For the design example, assume that a cantilever

is required to lift a force F=2N (at electrically

energized) for a distance of 5mm (required motion)

and that the maximum allowable width is 3.8mm.

The high temperature stress is σ=140MPa. The

operational temperatures, at heating and cooling, are

those determined at section 3.2, that are 111°C and

respectively 48.25°C. For these temperatures the

experimental determined values of Young’s modulus

are E

h

=59000MPa and respectively E

l

=6900MPa.

A Visual Basic project SMA cantilever strip was

implemented. The application background computations

are entirely presented in (Degeratu, 2003).

After providing the initial parameters in the

dialogue boxes of the user interface (Figure 4), by

pressing the compute button the designed parameters

are being displayed in the upper part of the window:

cantilever length, thickness and width, reset force,

high and low temperature deflections. The middle of

the window displays the typical SMA cantilever

configuration as well as all design parameters.

SMA cantilever strip can be used to provide

thermal control of a microswitch or automatic control

of a cooling fan (Waram, 1993, Bizdoaca, 2006).

Visual Basic application for SMA spring with

biasing spring. In the work production operation

mode the SMA helical spring can work against

varying forces such as a steel spring, fluid presure or

a magnetic force. In this application the varying

force is produced by a steel spring.

For the design example, assume the following

requirements: a Ni-Ti-Cu spring/biasing spring

combination is required which provides a net force

F

n

=3N with a 8mm stroke; the maximum cavity length

and diameter are 38mm and respectively 5.5mm.

Assume that the force exerted by the biasing

spring F

h

=2N, the maximum corrected shear stress

T

c

=175MPa, the SMA spring index c=6 and the low

temperature shear strain γ

l

=0.015 (in order to ensure

a good cyclic life of 50000 cycles). The operational

temperatures, at heating and cooling, are those

determined at section 3.2, that are 67.93°C and

respectively 33°C. For these temperatures the

experimental determined values of shear modulus are

G

h

=16890MPa and respectively G

l

=3759MPa. Also

assume that the two springs are separated by a plug

of thickness 2.5mm.

A Visual Basic project SMA spring with biasing

spring was implemented. The application

background computations are entirely presented in

(Degeratu, 2003) and (Degeratu, 2007).

Using standard steel spring design procedure,

assume that the maximum shear stress for the wire

T = 675MPa and the shear modulus G = 79300MPa.

When the VISUAL BASIC project for SMA

spring with biasing spring design is run, a user

interface is displayed, Figure 5.

First the user has to provide the initial parameters

in the dialogue boxes in the lower part of the

interface. By clicking on the Compute button, the

designed parameters are being displayed for both

SMA spring and biasing spring in the upper part of

the interface. The total actuator system comprised of

SMA spring and biasing spring is shown in the

middle part of the interface.

This configuration is frequently used for SMA

Controlled Valves (Bizdoaca, 2006) and SMA

Latching Mechanisms and SMA Bell Crank

Mechanisms (Nesser, 2005, Waram, 1993).

VISUAL BASIC APPLICATIONS FOR SHAPE MEMORY ELEMENTS DESIGN USED IN INTELLIGENT SYSTEMS

209

Figure 4: Dialog interface for SMA cantilever design.

Figure 5: Dialog interface for SMA spring with biasing

spring

5 CONCLUSIONS

The paper presents two design strategies for SMA

cantilever and SMA spring with biasing spring. For

these two design strategies the authors defined: the

operating mode, the mechanical considerations and

the design assumptions.

Using Thermal Analysis Methods the authors

determined the experimental transformation

temperatures for the studied SMA elements. These

temperatures were necessary to precisely establish

the shear modulus values for a high-quality design.

In addition, for each design strategy, a Visual Basic

application was developed, providing:

adequate dialogue boxes for fast and easy initial

parameters configuration;

fast computation and display of all required

information for a complete SMA element design;

remarkable facilities to analyze results and

choose an optimal solution.

These two Visual Basic applications are already

used by ICMET Craiova for engineering purposes

and by the Faculty of Electromechanical

Engineering of Craiova for didactical ones.

REFERENCES

Bizdoaca, N., G., Degeratu, S., Pana, C., Vasile, C., 2006.

Fuzzy Logic Controller for Hyperredundant SMA

Tendons Actuated Robot. 7

th

International Carpathian.

Control Conference. Ostrava Beskydy, Czech Republic.

Bizdoaca, N., G., Degeratu, S., Diaconu, I., Petrisor, A.,

Patrascu, D., 2006. Demining Robots: Behavior Based

Control Strategy. Annals of University of Craiova,

Craiova, Romania.

Degeratu, S., Bizdoaca, N., G., 2003. SMA’s.

Fundamental Notions, Design and Applications.

Universitaria Press, Craiova, Romania.

Degeratu, S., Manolea, H., O., Bizdoaca, N., G., 2007.

Shape Memory Elements Design for Intelligent

Systems, University Annuars from Oradea, Romania

Dolce, M., Cardone, D., 2001. Mechanical Behavior of Shape

Memory Alloys for Seismic Applications 2: Austenitic

NiTi Wires Subjected to Tension. Int. Met. Schi, 43.

Nasser, S., N., Choi, J., Y., Guo, W., Issacs, J., B., Taya,

M., 2005. High Strain-Rate, Small Strain Response of

NiTi Shape Memory Alloy. Journal of Engineering

Materials and Technology, vol.127.

Petrisor A., Rosca D., Bizdoaca N., G., Degeratu S., 2007,

Mathematical Model for Walking Robot with SMA

Ankle, ISI Proceedings ICINCO, Angers, France.

Van Humbeeck, J., 1999. Non-Medical Applications of

Shape Memory Alloys. Matter. Sci. Eng. 237A-275A

Van Humbeeck, J., 2001. Shape Memory Alloys: A

Material and a Technology. Adv. Eng. Mater., 3.

Waram, T., C., 1993. Actuator Design Using Shape

Memory Alloys. Ontario, Canada.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

210