EFFICIENT PLANNING OF AUTONOMOUS ROBOTS USING

HIERARCHICAL DECOMPOSITION

Matthias Rungger, Olaf Stursberg

Institute of Automatic Control Engineering, Technische Universit¨at M¨unchen, 80333 Munich, Germany

Bernd Spanfelner, Christian Leuxner, Wassiou Sitou

Software and System Engineering, Technische Universit¨at M¨unchen, 80333 Munich, Germany

Keywords:

Hierarchical Planning, Autonomous Robots, Context Adaptation, Hybrid Models, Predictive Control.

Abstract:

This paper considers the behavior planning of robots deployed to act autonomously in highly dynamic envi-

ronments. For such environments and complex tasks, model-based planning requires relatively complex world

models to capture all relevant dependencies. The efficient generation of decisions, such that realtime require-

ments are met, has to be based on suitable means to handle complexity. This paper proposes a hierarchical

architecture to vertically decompose the decision space. The layers of the architecture comprise methods for

adaptation, action planning, and control, where each method operates on appropriately detailed models of the

robot and its environment. The approach is illustrated for the example of robotic motion planning.

1 INTRODUCTION

The spectrum of applications for future robots will

continuously grow, and an increasing percentage will

be employed in dynamic environments. Examples

are service robots which assist elderly or disabled

persons and rescue robots which operate in hostile

areas that are devastated by earthquakes or similar

incidents. A characteristic of such applications is

that an autonomous planning of actions must consider

changing environment conditions and include reliable

and immediate decisions on which available resources

should be employed to fulfill a momentary task. In

particular, if the environment includes dynamic ob-

jects with non-deterministic or partly unpredictable

behavior, the representation of the constraints for a

planning problem becomes complex and has a signif-

icant impact on the realtime-computability of action

plans. Another difficulty encountered in this case is

that environment models which are purely identified

based on data series measured over a short period of

time for a specific situation are merely suitable to re-

flect the behavior of the environment sufficiently well.

In order to cope with the issues of model complex-

ity and quality of prediction within action planning,

this paper proposes a planning architecture which

combines multi-layer decision making with the use of

a knowledge base for storing learned goal-attaining

action strategies. Of course, the idea of hierarchi-

cal planning architectures is not new in general, and

corresponding approaches can be found, e.g., in (Nau

et al., 1998), (Galindo et al., 2007), (Barto and Ma-

hadevan, 2003). However, the novel contribution of

this paper is that a three-tier scheme is suggested

which separates the planning task into steps of config-

uring the system structure, of planning a sequence of

actions, and refining these actions into locally optimal

control trajectories. The configuration step allocates

the set of resources (sensors, actuators, or algorithms

for planning and control) that seem most appropriate

to accomplish a given task. By employing reinforce-

ment learning, the action planning on a medium layer

produces a sequence of discrete actions that qualita-

tively accomplish the task. The third layer refines an

action plan by generating control trajectories which

correspond to the action plan and establish a quanti-

tative setting for the actuators over time. The overall

concept setting is explained in the following section.

262

Rungger M., Stursberg O., Spanfelner B., Leuxner C. and Sitou W. (2008).

EFFICIENT PLANNING OF AUTONOMOUS ROBOTS USING HIERARCHICAL DECOMPOSITION.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 262-267

DOI: 10.5220/0001502202620267

Copyright

c

SciTePress

2 HIERARCHICAL PLANNING

APPROACH

The proposed hierarchy vertically decomposes a com-

plex planning task for reduction of complexity wher-

ever possible, and consists of the layers shown in

Fig.1: The adaptation-layer perceives and evaluates

the current situation based on measured data and de-

cides on the configuration, i.e. the resources selected

to solve a current task. The planning layer consid-

ers the allocated resources and existing constraints for

calculating an action plan that accomplishes the task.

In the opposite direction, information about the ex-

istence of a feasible plan for the chosen configura-

tion is transmitted from the planning to the adaptation

layer. The control layer refines the action sequences

received from the planning layer by computing a con-

trol trajectory for each action. The control trajectory

is then passed to the corresponding actuators of the

system. If no feasible trajectory is found for an ac-

tion (or a part of the action sequence), this informa-

tion is passed by to the planning layer and triggers

replanning. Thus, the three layers continuously inter-

act during the online execution to compute a task ac-

complishing strategy. To enable this computation, the

system must have the capability to predict the behav-

ior of itself and its environmentup to a point of time in

which the task is accomplished or cannot be accom-

plished anymore. These predictions are obtained from

evaluating the models shown in Fig. 1 for a choice of

configurations, action sequences, and control strate-

gies.

The hierarchy implements a nested feedback loop

also in the following sense: as soon as a current sit-

uation changes (e.g. because either a task changes

or a relevant change of the environment is detected)

the previously generated configuration, action plan, or

control trajectory is re-evaluated and possibly modi-

fied. The reactivity to the behavior of the environ-

ment requires continuous update of the models based

on measurement signals from the sensors of the au-

tonomous system. On each layer, appropriate identi-

Models

Configurations

State transition

systems

Hybrid Automata

Adaptation Layer

Planning Layer

Control Layer

Knowledge

base

Figure 1: The hierarchical architecture.

fication techniques are included to reparametrize the

models to the momentarily perceived situation.

In summary, the main objective of the three-tier

architecture is (a) to decompose the decision making

into three qualitatively distinct categories, (b) to se-

lect components, algorithms, and behavior in a top-

down manner to reduce the search effort in the deci-

sion space, and to (c) include a knowledge-base by

which already ’experienced’ (or learned) behavior is

used as heuristics for efficiently deciding which strat-

egy is goal-attaining. For this scheme, the claim is

not to outperformsingle state-of-the-art algorithms on

a particular layer, but to provide an architecture for

proper integration of different algorithms to solve a

broad variety of complex planning tasks.

3 ADAPTATION LAYER

The term adaptation is here understood as the capa-

bility of an autonomous system to react to changing

tasks or varying aspects of the context in which the

system is embedded. The term ’context’ refers to the

state of the system environment, as e.g. the proximity

of obstacles to a moving robot (the ’system’). The

adaptation on the uppermost layer of the hierarchy

means here to deduce from the current context and

a task to be accomplished a suitable configuration,

which is a subset of available components, i.e. avail-

able hardware devices (e.g. actuators) or software

algorithms for action planning and control.

Components. On the adaptation layer, the system

and its environment are described in terms of com-

municating units called components. Formally, a

system is defined as a pair (C,CH) with C as a set

of components and CH as a set of channels. The

components communicate through directed channels,

which are defined by ch = C×C× Id with Id as a set

of unique names. A system is completely determined

by a network of components connected via channels,

and the components send messages along channels

and thereby express their behavior. Different ways

to describe such behavior exist, like e.g. process

algebras or relations on inputs and outputs like

FOCUS (Broy and Stoelen, 2001) or COLA (Haberl

et al., 2008). The behavior of a component is here

specified by a sequence of data msg ∈ MSG which

is received and sent over the ports I and O of the

component.

Adaptation Mechanism. To formalize the adapta-

tion of a component-based model, the notion of Mode

Switch Diagrams (MSD) is introduced. An MSD is

EFFICIENT PLANNING OF AUTONOMOUS ROBOTS USING HIERARCHICAL DECOMPOSITION

263

a tuple (M,map,δ,m

0

) defining a transition system

with a set of modes M, a transition function δ, a func-

tion map : m → C that relates modes to components,

and m

0

is the initial mode. The transitions are defined

by δ : M× P → M with predicates P depending on the

inputs i ∈ I of the components assigned to a mode.

The function δ encodes the transition of the MSD be-

tween two modes m

i

and m

i+1

, and it represents the

adaptation. An example of an adaptation is shown in

Fig. 2. An activated mode m

i+1

determines the com-

ponents of the system which are selected until a new

context change triggers another transition. The mode

constitute the frame for the action planning carried

out on the medium layer.

m

1

m

2

c

1

c

2

c

3

δ

1

I

I

O

O

Figure 2: Transition between two modes m

1

and m

2

of an

MSD example.

4 PLANNING LAYER

The planning layer comprises algorithms that search

for a sequence of actions which transfers the ini-

tial state of the system or environment into a desired

goal state. The specific algorithm to be used for a

given task, the available set of actions, and the rel-

evant model is determined by the mode information

received from the adaptation layer. The model used

on the planning layer is specified as a state transition

system Σ = (S,A, δ) consisting of a set of states S =

{s

1

,s

2

,... ,s

n

}, a set of actions A = {a

1

,a

2

,... ,a

m

},

and a transition function δ : S× A → 2

S

. The planning

task is mapped into a goal state s

G

(or a set of goal

states S

G

⊆ S, respectively) which has to be reached

from a current state s

0

∈ S. A plan is a sequence of

actions that evokes a state path ending in s

G

(or an

s ∈ S

G

).

The planning techniques on the medium layer fol-

low the principle of reinforcement learning. In order

to formulate the planning problem as optimization, an

utility function r : S× S → R is introduced, which de-

fines the reward of taking a transition of Σ. The goal

is encoded implicitly by assigning a high reward to a

state sequence via which a goal state is reached, and

by producing a negative reward for undesired behav-

ior of Σ. Reinforcement learning represents learning

from interaction, i.e. the system learns a strategy (as a

state-to-action mapping) based on the reward. At time

t, the system observes the state s ∈ S, and for a cur-

rent policy π = P(a|s) an action a ∈ A is chosen. The

system moves from state s to s

′

according to the tran-

sition function, and it receives the reward r. The goal

is to learn a policy π which maximizes the cumulative

discounted future reward. By introducing the action-

value function Q(s,a), a measure is available which

estimates the profit of taking an action a in state s.

The action-value function under policy π is given by

the Bellman equation:

Q

π

(s,a) = [R(s

′

|s,a) + γ

∑

a

′

π(s

′

,a

′

)Q

π

(s

′

,a

′

)],

where s

′

and a

′

denote state and action at the next time

instant. γ is the discount factor and is given by 0 <

γ < 1. R(s

′

|s,a) denotes the reward for taking action

a in state s, resulting in the new state s

′

. If the reward

function as well as the system dynamics are known,

the optimal policy

Q

∗

= max

π

Q

π

(s,a)

can be calculated explicitly, resulting in a system of

|S| · |A| equations. Since this is often computation-

ally intractable (in addiion to some dynamics may not

be known before-hand) approximations to the optimal

action-value function are used.

One possible algorithm to estimate Q

∗

(s,a) is

called SARSA (Takadama and Fujita, 2004), which

learns the current state-value function Q(s,a) by up-

dating the function with the observed reward, while

interacting with the environment:

Q(s,a) ← Q(s,a) + α[r + γQ

π

(s

′

,a

′

) − Q(s,a)],

where α is the learning rate. SARSA is a so called on-

policy RL algorithm, which updates the action-value

function while following a policy π. The policy is ε-

greedy, where the greedy action a

∗

= argmax

a

Q(s,a)

is selected most of the time. Once in a while, with

probability ε, an action is chosen randomly. SARSA

is used here as RL technique in order to reduce the

“risk” by avoiding negative rewards while paying

with a loss of optimality (Takadama and Fujita, 2004).

5 CONTROL LAYER

The control layer ensures the correct execution of the

action sequence derived on the planning layer. It es-

tablishes a connection of the discrete actions received

from the medium layer to the real world by apply-

ing continuous signals to the system’s actuators. The

combination of discrete actions with continuous dy-

namics motivates the use of hybrid automata (Hen-

zinger, 1996) to model the behavior on the control

layer. Hybrid automata (HA) do not only establish

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

264

an adequate interface to the higher layers, but also

provide the necessary expressivity required to model,

e.g. robot-object-interaction. For each component se-

lected by the adaptation layer, one hybrid automaton

is introduced, and the various automata can interact

via synchronization or shared variables.

Using a variant of HA with inputs according to

(Stursberg, 2006), a hybrid automaton modeling the

system is given by HA = (X,U,Z,inv, Θ,g, f), with

X as the continuous state space, U the input space,

Z the set of discrete locations, inv the assignment

of invariance sets for the continuous variables of

the discrete locations, and Θ the set of discrete

transitions. A mapping g : Θ → 2

z

associates a

guard set with each transition. The discrete-time

continuous dynamics f defining the system dynamics

is x(t

j+k

) = f(z(t

k

),x(t

k

),u(t

k

)). At any time t

k

, the

pair of continuous and discrete state forms the current

hybrid state s(t

k

) = (z(t

k

),x(t

k

)). Hybrid automata

for modeling relevant components of the environment

introduced without input sets U (since not directly

controllable).

Model Predictive Control. In order to generate con-

trol trajectories for the HA, the principle of model pre-

dictive control (MPC) is used (Morari et al., 1989).

Considering the control problem not only as a motion

planning problem like typically done in the robotic

domain, e.g. (LaValle, 2006), but as an MPC prob-

lem has the following advantages: (1) an optimal so-

lution for a given cost function and time horizon is

computed, (2) model-based predictions for the behav-

ior of the system and the environment lead to more

reliable and robust results, and (3) a set of differential

and dynamic constraints can be considered relatively

easy. The MPC scheme solves, at any discrete point

of time t

h

, an optimization problem over a finite pre-

diction horizon to obtain a sequence of optimal con-

trol inputs to the system. The optimization problem

considers the dynamics of the system and the follow-

ing additional constraints: a sequence of forbidden re-

gions φ

F,k

= {F

k

,F

k+1

, ·· · ,F

k+p

}, and a sequence of

goal regions φ

G,k

= {G

k

,G

k+1

, · ·· ,G

k+p

} are speci-

fied over the prediction horizon p·(t

k

−t

k−1

). Here, F

k

denotes a state region that the system must not enter,

and G

k

is the state set into which the system should

be driven. The constrained optimization problem can

be formulated as:

min

φ

u,k

J(φ

s,k

,φ

e,k

,φ

u,k

, p,φ

G,k

)

s.t. s(t

j

) /∈ F

j

∀ j ∈ {k, ...,k + p}

u

min

≤ u(t

j

) ≤ u

max

φ

s,k

∈ Φ

s

and φ

e,k

∈ Φ

e

where φ

s,k

and φ

e,k

are the predicted state trajectories

of the system and the environment, which must be

contained in the sets of feasible runs Φ

s

and Φ

e

. No

state s(t

j

) contained in φ

s,k

must be in a forbidden

region F(t

j

). u

min

and u

max

are the limitations for the

control inputs u(t

j

) and thus for the control trajectory

φ

u,k

. A possible solution technique for the above

optimization problem is the following sequential

one: (1) an optimizer selects a trajectory φ

u,k

, (2)

the models of system and environment are simulated

for this choice leading (possibly) to feasible φ

s,k

and φ

e,k

, (3) the cost function J is evaluated for

these trajectories, and (4) the results reveals if φ

u,k

should be further modified for improvement of the

costs or if the optimization has sufficiently converged.

Knowledge Base and Learning. In order to improve

the computational efficiency, the MPC scheme is en-

hanced by a knowledge-base, in which assignments

of action sequences to situations is stored. The ob-

jective of the learning unit with a knowledge base

is to reduce the computational effort by replacing

or efficiently initializing the optimization. The sit-

uations in the knowledge base are formulated as tu-

ple δ = (φ

s,k

,φ

e,k

,φ

G,k

,φ

F,k

,φ

u,k

,J), where s(t

k

) and

e(t

k

) again denote the current state of the system and

the environment, and φ

u,k

, φ

G,k

, and φ

F,k

are the se-

quences of control inputs, the goal, and forbidden

sets, respectively. For a given situation at the current

time t

k

, by using similarity comparison

1

, the learning

unit infers a proper control strategy φ

L

u,k

if it exists.

Otherwise, the optimization is carried out and the re-

sult is stored in the knowledge-base.

6 APPLICATION TO A KITCHEN

SCENARIO

The presented hierarchical architecture is applied to

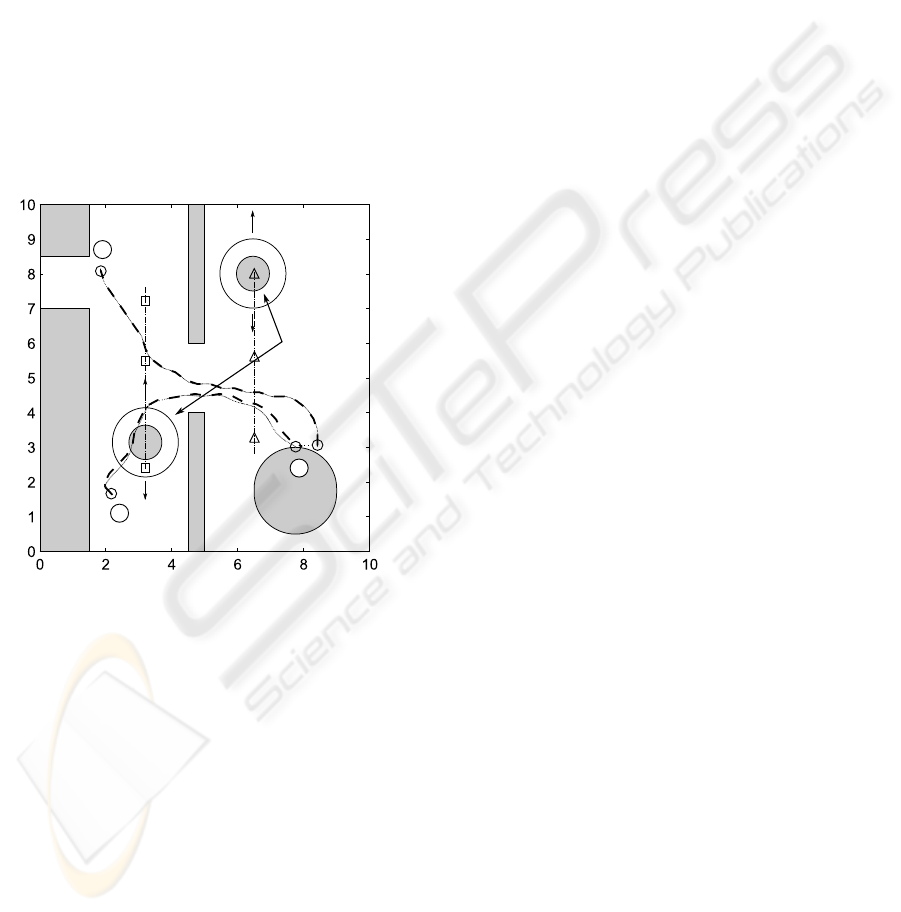

a service robot in a kitchen scenario. The task of the

robot is to lay a table (see Fig 3), i.e. the robot is

expected to drive back and forth between a table and

a kitchenette for positioning plates and cutlery on

the table. The scenario obviously formulates a very

challenging planning task, as the robot has to decide

which object to take, how to move to the desired place

at the table, and how to avoid collision with humans

moving in the same space – this is the motivation

for employing a decomposition-based planning

approach. To simplify the upcoming presentation, the

1

Similarity is here defined by small distances of the

quantities specifying a situation in the underlying hybrid

state space.

EFFICIENT PLANNING OF AUTONOMOUS ROBOTS USING HIERARCHICAL DECOMPOSITION

265

Figure 3: Setting of the kitchen scenario.

further discussion is here restricted here to the part of

robot motion planning only.

Adaptation. On the uppermost layer, the set of

components C comprises the relevant physical com-

ponents of the setting and the choice of algorithms

being available on the planning and control lay-

ers. Thus, the kitchen K, the table T, the kitch-

enette KN, the refrigerator R, the robot dynam-

ics B1, the quantized robot dynamics B2, the per-

sons P

1

and P

2

, the reinforcement learning algorithm

alg

1

, the MPC algorithm alg

2

, the learning algo-

rithm alg

3

, and the knowledge base kb are elements

of the set of components for the motion scenario:

C = {K,T,KN,R,B1,B2,P

1

,P

2

,alg

1

,alg

2

,alg

3

,kb}.

Modes are defined for the component structure like

described above, i.e. they represent a particular sub-

set of C according to map : m → C. Note that modes

may only affect parts of the system and that nesting

of modes is possible (leading to alternative choices).

For the different steps in the motion planning

problem, the adaptation chooses appropriate algo-

rithms by switching to a corresponding mode. For the

motion of the robot from one point to another within

the kitchen, only one mode m

1

has to be be defined. It

encodes the path planning by reinforcement learning

for the planning layer and the calculation of the

corresponding input trajectories to the dynamic

system (including learning about situations) for the

control layer. For this example, adaptation (in the

sense of a switch between modes) occur only if the

goal changes due to the current one being achieved

or becoming unreachable.

Planning. The states s ∈ S of the state transition sys-

tem Σ for this particular example represent different

positions of the robot within the kitchen. The ac-

tions a ∈ A on the planning layer denote constant in-

puts u

i

, i ∈ {1,.. .,n} (applied for a fixed time T)

for the HA modeling the robot motion on the con-

trol layer. A discrete state of Σ represents the motion

for time T, and it correspond to the trajectory obtained

from integrating the resulting dynamics f

z

(x,u

i

) spec-

ified on the control layer. Five constant inputs u

1

=

(1,0)

T

, u

2,3

= (0,±π/4)

T

, u

4,5

= (1,±π/4)

T

encode

pure translation, pure rotation, and curve transition re-

spectively. The state set S of Σ represents a discretiza-

tion of the floor space of the kitchen (modeled by two

continuous variables x

1

,x

2

on the lower layer). The

discretization follows implicitly from the solution of

the continuous dynamics on the control layer.

Choosing a reward of r = −1 for every taken

action, the SARSA algorithm results in a sequence

with a minimum number of actions. If the robot hits a

static obstacle a reward of r = −10 is used to update

the action-value function Q(s,a). The outcome of

the algorithm is depicted by the bold dashed line in

Fig. 5, resulting from the concatenation of the action

primitives. Σ consists in about 1000 states in this

particular setup and the RL algorithm converges after

approx. 80 runs (see Fig. 4), leading to a trajectory

consisting about 20 actions. For a faster convergence,

the action-value function Q(s,a) is suitably initialized

by a solution that leads to the goal position for the

case that no dynamic obstacles are present.

0 50 100 150

−800

−600

−400

−200

0

reward per run

number of runs

Figure 4: Reward improvement over repetitions of the mo-

tion.

Control. The HA used to model the robot that is

regarded in the simulation scenario is defined with

two locations z

1

and z

2

. Location z

1

defines the

kitchen domain, and location z

2

represents that the

robot enters a circular region around one of the

two moving persons being present in the kitchen;

in z

2

the speed of the robot is reduced. Thus,

the dynamics in the two locations are f

1

= x(t

k

) +

(sin(ϕ)u

1

(t

k

), cos(ϕ)u

1

(t

k

), u

2

(t

k

))

T

· ∆t and f

2

= x(t

k

) +

0.5(sin(ϕ)u

1

(t

k

), cos(ϕ)u

1

(t

k

), u

2

(t

k

))

T

· ∆t with a time-

step ∆t, a position vector x and a heading angle ϕ. The

objective function for the MPC algorithm specifies

the deviation from the trajectory y obtained from the

planning layer: J =

∑

H

p=1

kx(t

k+p

) − y(t

k+p

)k

2

2

with

the prediction horizon H. For the computation, a step

size of ∆t = t

k+1

− t

k

= 0.1 seconds and horizon of

H = 10 is chosen. The forbidden regions are defined

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

266

as circles around the persons and the goal set follows

from the trajectory y.

The solution of the optimization problem φ

u

, is

stored in the knowledge base together with the ob-

served situation. The similarity measure of situations,

needed to extract a previously calculated control in-

put, is defined in terms of the Euclidean distances of

the current state of the system and position of the per-

sons.

Fig. 5 shows by the dotted line as outcome of the

MPC algorithm the motion of the service robot from

the kitchenette (1) to the table (2) and further to the

refrigerator (3). The underlying map represents the

kitchen in 2D and is used for the localization of the

robot. For three time stamps t

1

,t

2

, and t

3

the posi-

tions of the robot and the two persons are marked by

a circle, and by a square / triangle respectively. The

dash-dotted lines mark the motion of the two persons.

2

People in motion

with safety margin

1

3

t

0

t

0

t

0

t

1

t

1

t

1

t

2

t

2

t

2

Figure 5: Trajectories of the robot moving between kitch-

enette (1), table (2), and refrigerator (3).

For each varying goal positions, the knowledge

base is filled with information on goal-attaining

strategies for future use. Employing the knowledge

base reduces the calculation time essentially. The ser-

vice scenario is simulated in the Player/Stage/Gazebo

(PSG) environment.

7 CONCLUSIONS AND

OUTLOOK

The aim of the presented concept is to provide an ar-

chitecture by which the combination of control meth-

ods applied to hybrid systems, techniques from artifi-

cial intelligence, and vertical decomposition of tasks

is realized. Simultaneously, the approach intends to

cover the whole perception-reasoning-action loop of

an autonomous system that has to make decisions for

goal-oriented behavior in new situations. While the

considered example is quite simple, it illustrates the

mechanism of task decomposition and improves ef-

ficiency of computing suitable control trajectories by

the use of machine learning techniques.

Current work is focussed on extending the plan-

ning hierarchy to different learning and control algo-

rithms.

ACKNOWLEDGEMENTS

Partial financial support of this investigation by the

DFG within the Cluster of Excellence Cognition for

Technical Systems is gratefully acknowledged.

REFERENCES

Barto, A. G. and Mahadevan, S. (2003). Recent advances

in hierarchical reinforcement learning. Discrete Event

Dynamic Systems, 13(1-2):41–77.

Broy, M. and Stoelen, K. (2001). Specification and De-

velopment of Interactive Systems: Focus on Streams,

Interfaces, and Refinement. Springer.

Galindo, C., Fernandez-Madrigal, J., and Jesus, A. G.

(2007). Multiple abstraction hierarchies for mobile

robot operation in large environments. Studies in

Computational Intelligence, Springer.

Haberl, W., Tautschnig, M., and Baumgarten, U. (2008).

Running COLA on Embedded Systems. In Proceed-

ings of The International MultiConference of Engi-

neers and Computer Scientists 2008.

Henzinger, T. (1996). The theory of hybrid automata. In

Proceedings of the 11th Annual IEEE Symposium on

Logic in Computer Science (LICS ’96), pages 278–

292.

LaValle, S. M. (2006). Planning Algorithms. Cambridge

University Press.

Morari, M., Garcia, C., and Prett, D. M. (1989). Model

predictive control: Theory and practice-A survey. Au-

tomatica, 25(3):335–348.

Nau, D. S., Smith, S. J. J., and Erol, K. (1998). Control

strategies in HTN planning: Theory versus practice.

In AAAI/IAAI, pages 1127–1133.

Stursberg, O. (2006). Supervisory control of hybrid systems

based on model abstraction and refinement. Journal

on Nonlinear Analysis, 65(6):1168–1187.

Takadama, K. and Fujita, H. (2004). Lessons learned from

comparison between q-learning and sarsa agents in

bargaining game. In Conference of North American

Association for Computational Social and Organiza-

tional Science, pages 159–172.

EFFICIENT PLANNING OF AUTONOMOUS ROBOTS USING HIERARCHICAL DECOMPOSITION

267