RAPID VIRTUAL DESIGN AND SYSTEM DEVELOPMENT

BASED ON EXTENDED MVC-BASED WEB APPLICATION

FRAMEWORK AND INTERACTIVE XML PRODUCT MODEL

Cao Yan

Mailbox 155, Advanced Manufacturing Engineering Institute, School of Mechatronic Engineering, Xi’an Technological

University, 710032, Xi’an, Shaanxi, P. R. China

Yang Lina

Xi’an University of Science and Technology, 710054, Xi’an, Shaanxi, P. R. China

Keywords: Virtual Design, Virtual Prototyping Simulation, MVC, Web Application, XML.

Abstract: To integrate multiple aspects of an enterprise to improve design decision-making and control at all process

levels, rapid virtual design based on virtual prototyping simulation (RVDBVPS) is put forward to carry out

distributed cooperative product design. Its architecture and key technologies are discussed. To develop the

system on Internet/Intranet, satisfy current requirements of Web applications and solve the existing

problems in web application development, an extended MVC-based web application framework based on

XML on J2EE platform is put forward that is more flexible, expansible and maintainable. According to the

characteristics of structured and unstructured product data in Web based distributed cooperative design

environment, product design information exchange based on Interactive XML product model is investigated

to realize interactive information transaction across heterogeneous platforms.

1 INTRODUCTION

Through virtual prototyping simulation, distributed

cooperative designers can gain unprecedented

insight into duty cycles that will ultimately be

imposed by users and refine the design before it is

locked into a hardware configuration (Chen, 2006;

Wu et al, 2006). It also permits the user to

participate in the product development process on

Internet/Intranet, as part of an integrated

multidisciplinary team, by letting him operate the

conceptual product in advance as if it were already

put into operation. Based on virtual prototyping

simulation and synthetic design evaluation, the

product designed can be evaluated from any number

of perspectives in multidisciplinary design

optimization in the virtual performance test

environment, virtual application environment, and

virtual manufacturing environment under the control

of a design management system, permitting

fundamental trade-offs to be made in product

performance, manufacturing processes, support

processes, product quality and cost

To satisfy current requirements of web

applications for enterprises and virtual enterprises

and solve the existing problems in web application

development (Yuan et al, 2004; Chung et al, 2002;

Li et al, 2002), web application framework based on

MVC mode in J2EE platform is adopted to develop

various applications on Internet/Intranet. Due to the

powerful data description capability of XML, many

methods of product data exchange based on XML

are applied to realize the description of product data,

graphic data, characteristics, and their relationship in

distributed cooperative design (Wu et al, 2006; Chen

et al, 2003). And, the method of exchanging design

semantics instead of 3D model data is adopted to

enormously reduce the transmission quantity

through network in distributed cooperative design.

202

Yan C. and Lina Y. (2008).

RAPID VIRTUAL DESIGN AND SYSTEM DEVELOPMENT BASED ON EXTENDED MVC-BASED WEB APPLICATION FRAMEWORK AND

INTERACTIVE XML PRODUCT MODEL.

In Proceedings of the Fourth International Conference on Web Information Systems and Technologies, pages 202-205

DOI: 10.5220/0001532202020205

Copyright

c

SciTePress

2 RAPID VIRTUAL DESIGN

SYSTEM

In the paper, rapid virtual design based on virtual

prototyping simulation (RVDBVPS) is put forward

to carry out distributed cooperative product design to

integrate multiple aspects of the enterprise to

improve design decision-making and control at all

process levels, to raise its competing capability, to

realize the common objective, and to accelerate the

shift to Internet/Intranet based product design.

On the basis of information integration, the

integration of product development processes are

realized by integrating organization, technologies,

physical resources, human resources and so on. It is

Concurrent Engineering (CE) oriented design based

on virtual prototypes, virtual environments and

simulation. The emphasis is put on rapid generation

and evolvement of the virtual prototypes in the

virtual environments. It is the application of virtual

manufacturing in product design, namely design

centered virtual manufacturing on Internet/Intranet.

The main functions of the RVDBVPS system

include:

(1) Integrate the product development processes.

(2) Realize close loop product development

based on virtual product design and virtual

prototyping simulation.

(3) Enhance design decision-making and control

at all design process levels.

(4) Raise the ability of the enterprise to

cooperate, improve, innovate, and develop.

3 SYSTEM ARCHITECTURE

AND ITS KEY

TECHNOLOGIES

3.1 System Architecture

The architecture for the RVDBVPS system is put

forward, as shown in Figure 1. As an engineering

information management system, it can provide

information for enterprise product strategies,

business search and project management. At the

same time, it can also be used as a product design

decision support system at all design levels. For

integrated product and process development, it is a

testbed for design decisions. For production, it is a

monitor, control, management, maintenance and

simulation system to improve production plan

scheduling and control.

Figure 1: The system architecture.

3.2 Master Model Technology

As the basic challenges to achieving RVDBVPS are

the creation of product and design process

representations and their implementation in the

virtual design environment. Virtual product design

master model technology is put forward for product

data management and design process management in

the rapid virtual design environment to implement

timely design assessments, trade-off analyses, and

iterative design optimizations. To carry out

distributed cooperation during all product

development phases, it is based on a blackboard

control system which consists of a design knowledge

base containing product models, relations, and

constraints, a blackboard where design sources are

controlled and coordinated, and a number of design

knowledge sources performing simulation, analysis,

evaluation and cooperative decision-making.

Management and control of product development

processes is based on integrated process modeling.

According to the changes of the virtual product

master model, the functions of design activities and

relations among them are analyzed using function

models and object-oriented method. Then, based on

process activity networks in different layers, the

product development processes are produced or

modified dynamically. And then, human resources

and physical resources are organized and allocated

reasonably in accordance with existing resources

and subjective and objective conditions. Finally, the

processes are simulated, analyzed, modified and

optimized using Petri-nets and so forth.

The data structure of the virtual product master

model representing the product being designed is

realized with a dynamic feature representation

structure to reflect the changes of product design

information.

RAPID VIRTUAL DESIGN AND SYSTEM DEVELOPMENT BASED ON EXTENDED MVC-BASED WEB

APPLICATION FRAMEWORK AND INTERACTIVE XML PRODUCT MODEL

203

3.3 Multi-Level, Multi-Perspective and

Multi-Phrase Synthetic Design

Evaluation

In order to assess the product design concurrently

and comprehensively, it is needed to dynamically

generate lifecycle oriented evaluation models for

product design during product development and to

carry on multi-level, multi-perspective, and multi-

phrase synthetic design evaluation.

Under the support of computer network systems

and various databases, the product design process

management and control module administrates

product design synthetic evaluation activities that

provide product related evaluation information based

on the virtual environments and virtual prototyping

to cooperating designers, realizing the integration of

product design and synthetic evaluation. The

implementation of product design synthetic

evaluation includes the following four aspects:

(1) Product design synthetic evaluation planning

and control.

(2)Dynamically generation of evaluation models.

(3) Synthetic analysis and evaluation functions.

(4) Product redesign and optimization process

based on synthetic evaluation information of the

product design.

4 SYSTEM DEVELOPMENT

BASED ON EXTENDED

MVC-BASED WEB

APPLICATION FRAMEWORK

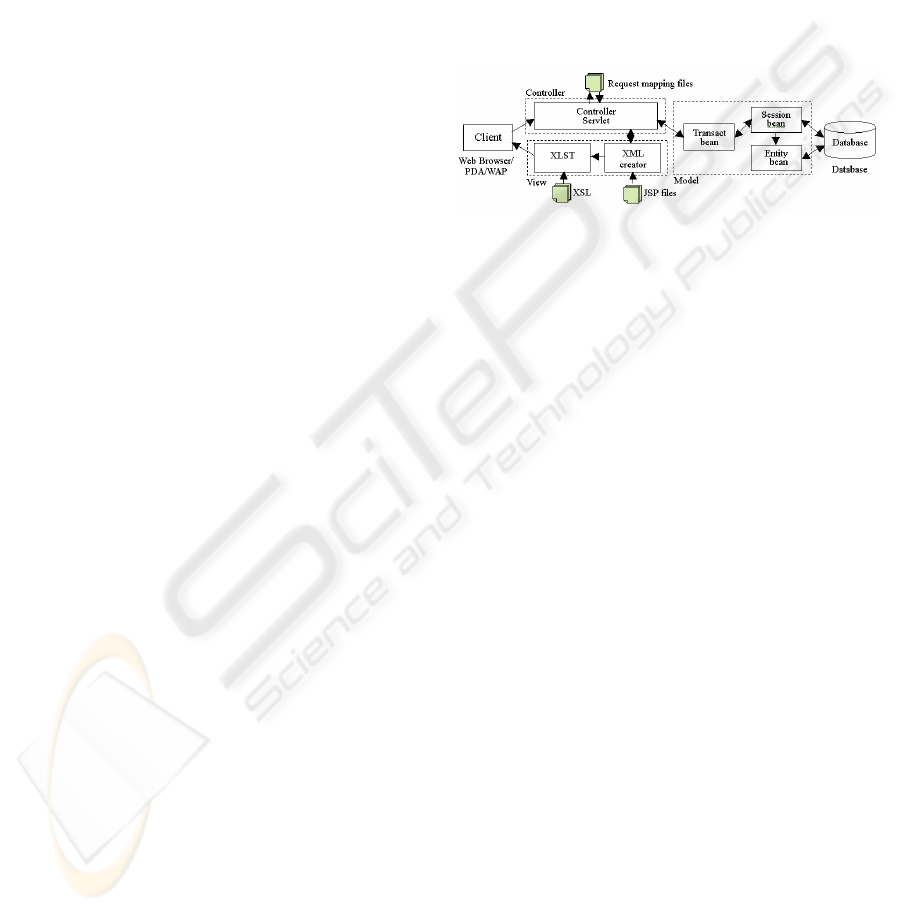

In order to develop the system on Internet/Intranet,

an MVC-based web application framework is

extended with XML to make it more flexible,

expansible and maintainable. An XML style

interface and mapping interface mechanism are

adopted to realize interactive information transaction

across heterogeneous platforms. To validate the

extended MVC-based web application framework

and XML interoperable information model, both are

applied to develop a machine tool distributed

cooperative design system for virtual enterprises.

The scheme to extend the framework with the

technologies of XML, XSLT and Xbean is

presented. The standard format of XML and the

powerful conversion function of XSLT can help

extend the limited function of the View part in the

MVC-based web application framework.

The data in XML format can be represented in

any other required form by combining XML with

XSL. An extending scheme for the MVC-based web

application framework is presented as follows.

Firstly, an XML creator is set up using XBean to

transform the data gathered from user’s request

interfaces or JSP feedback pages into XML

document. Then, the extendable stylesheet list is

programmed according to the special requirement of

terminal equipment. Finally, the prepared XML

document can be transformed into the corresponding

data format as terminal client equipment requires

using XSLT. The extended MVC-based web

application framework is shown in figure 2.

Figure 2: Extended MVC-based web application

framework.

5 PRODUCT DESIGN

INFORMATION EXCHANGE

BASED ON XML-BASED

INTERACTIVE MODEL

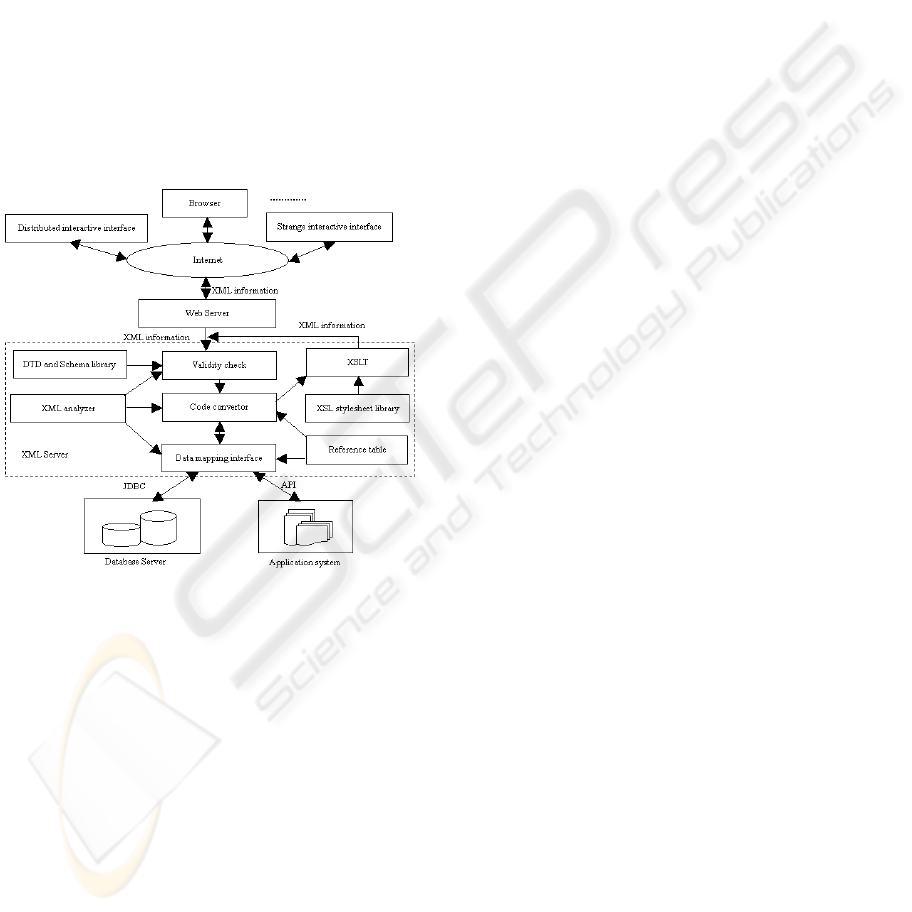

XML models of product design information are

mainly applied to two fields. On the one hand, in the

process of cooperative design, by XSL stylesheet

mapping, the same design information can be

displayed diversely on different application

platforms to provide favorable man-machine

interaction interface. On the other hand, through the

data mapping interface programmed with Java, the

product design information can be transformed and

operated in different application systems, such as

relational database systems, CAD/CAM systems, or

post-processing equipments.

The XML information model and its multiply

displaying as well as interactive information

processing are realized in machine-tool distributed

cooperative design system that is designed for

virtual enterprises. The interactive information

processing model based on XML is shown in figure

3.

At the customer layer, the designers input the

related characteristic parameters of machine-tool

design through man-machine interactive interface.

The design information is stored in network as XML

document tree structure. The intermediate layer is

WEBIST 2008 - International Conference on Web Information Systems and Technologies

204

composed of XML server and Web server. Web

server transfers the XML information according to

HTTP. It can be parsed and transformed by XML

server to generate the operation instruction for the

local graphic software such as AutoCAD, and then

the corresponding design drawing can be plotted

according the feature parameters and displayed on

the interactive design interface in time by the data-

mapping interface and XSL stylesheet. The

designers can vary the product design parameters to

modify the design drawing and store the current

result into a relational database in the database layer.

The result can then be consulted or edited by other

designers. The efficiency of distributed cooperative

design can be greatly improved by transmitting the

design semantics expressed with XML data rather

than 3D solid model data.

Figure 3: XML data exchange.

6 CONCLUSIONS

Rapid virtual design based on virtual prototyping

simulation is put forward to carry out distributed

cooperative product design on Internat/Intranet. Its

architecture and key technologies are discussed. To

overcome the deficiency of the View part at the

client end caused by the limitation of JSP, the MVC-

based web application framework based on

JSP/Servlet/EJB on J2EE platform is extended with

XML. The key technologies and method to create,

transform and display XML documents are

expatiated. XML is applied to the description of

structured and unstructured elements, characteristics

and their relationship in distributed cooperative

product design. A method of product data exchange

based on XML is put forward to exchange design

semantics instead of the 3D model data. Thus, the

display and modeling requirements can be satisfied

in distributed cooperative design. The extended

framework and data exchange method based on

XML are proved feasible and valid by system

development of the machine tool distributed

cooperative design system for virtual enterprises.

REFERENCES

Chen, L., 2006. Design of collaborative virtual

environment based on PC. In Computer Integrated

Manufacturing Systems. CIMS, Beijing, China.

Wu, B., Huang, H., Tao, Y., 2006. Digital design of virtual

prototype based on multidisciplinary design

optimization. In Journal of Wuhan University of

Technology. Wuhan University of Technology, Wuhan,

China.

Yuan, Z., Zhang, Q., Yang, J., 2004. Solution on

enterprise application integration based on web

services. In Computer Integrated Manufacturing

Systems. CIMS, Beijing, China.

Chung, J., Lee, K., 2002. A framework of collaborative

design environment for injection molding. In

Computers in Industry. Elsevier Science B.V.

Li, M., Cheng, Y., Zhao, B., 2002. Collaborative

application platform for small and medium-sized

enterprise. In Computer Integrated Manufacturing

Systems. CIMS, Beijing, China.

Wu, B., Wu, Y., Xi, L., Fu, S., 2006. Research on XML-

based typical parts and components design system. In

Computer Integrated Manufacturing Systems. CIMS,

Beijing, China.

Chen, Q., Hua, J., Zhang, Y., Ying, K., 2003. Design of an

XML-based collaborative documents model. In

Journal of Software. Chinese Academy of Sciences,

Beijing, China.

RAPID VIRTUAL DESIGN AND SYSTEM DEVELOPMENT BASED ON EXTENDED MVC-BASED WEB

APPLICATION FRAMEWORK AND INTERACTIVE XML PRODUCT MODEL

205