PRODUCTION CONFIGURATION OF PRODUCT FAMILIES

An Approach based on Petri Nets

Lianfeng Zhang, Brian Rodrigues

Department of Operations, University of Groningen, Landleven 5, Groningen, The Netherlands

Lee Kong Chian School of Business, Singapore Management University, Singapore

Jannes Slomp, Gerard J. C. Gaalman

Department of Operations, University of Groningen, Landleven 5, Groningen, The Netherlands

Keywords: Production configuration, Timed Petri nets, Colored Petri nets, Transition synchronization.

Abstract: Configuring production processes for product families has been acknowledged as an effective means of

dealing with product variety while maintaining production stability and efficiency. In an attempt to assist

practitioners to better understand and implement production configuration, we study the underlying logic for

configuring production processes for product families by means of dynamic modelling and visualization.

Accordingly, we develop a formalism of nested colored timed Petri nets (PNs) to model production

configuration. To cope with the modelling difficulties resulting from the fundamental issues in production

configuration, three types of nets, namely process nets, assembly nets and manufacturing nets, together with

a nested net system are defined by integrating the principles of colored PNs, timed PNs and nested PNs. An

industrial example of electronics products is used throughout the whole paper to demonstrates how the

proposed formalism is applied to specify production processes at differently levels of abstraction to achieve

production configuration.

1 INTRODUCTION

Facing a high variety of customized products often

required in small quantities and with short delivery

lead-times, manufacturing companies nowadays

strive to provide quickly diverse products at low

costs so as to survive the intense global competition.

It has been recognized that the key for companies to

achieving efficiency in the resulting high variety

production lies in an ability to maintain it to be as

stable as possible (Martinez et al., 2000). In this

respect, process configuration contributes to

obtaining manufacturing stability by generating

similar manufacturing processes for parts

(Schierholt, 2001). It, de facto, is an alternative

computer-aided process planning and thus does not

lend itself to achieve efficiency in producing product

families, where both assemblies and parts are

involved. In response to the limited research in

product family production , production configuration

has been proposed for companies to produce product

variety while achieving mass production efficiency

(Zhang, 2007). The rationale is to plan and utilize

similar, yet optimal, production processes as these

existing on shop floors to fulfil customized products.

Production configuration entails a conceptual

structure and overall logical organization of

producing a family of individualized products. It

provides a generic umbrella to capture and utilize

commonality, within which each new product

fulfilment is instantiated and extended, and thereby

anchoring planning to a common structure of a

product family (Zhang et al., 2007). Underpinned by

the common structure, production configuration

involves such common elements as operations and

processes concepts for parts and assemblies,

operations and their precedence, and manufacturing

resources. Also involved are diverse optional

process elements in accordance with optional parts

and assemblies. Production configuration entails a

process of 1) selecting proper elements for given

products; 2) subsequently arranging the selected

elements into production processes; and 3) finally

evaluating the configured multiple alternatives to

5

Zhang L., Rodrigues B., Slomp J. and J. C. Gaalman G. (2008).

PRODUCTION CONFIGURATION OF PRODUCT FAMILIES - An Approach based on Petri Nets.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - ISAS, pages 5-11

DOI: 10.5220/0001669400050011

Copyright

c

SciTePress

determine appropriate ones. In such selection,

arrangement and evaluation processes, a number of

configuration rules, i.e., constraints or restrictions

imposed by manufacturing capabilities, capacity

limits, desired objectives that measure productivity

and efficiency, etc. must be satisfied. Consequently,

decision making in production configuration is

deemed to be very complex.

With an attempt to assist practitioners to better

understand and implement production configuration,

in this study, we tackle the underlying logic for

configuring production processes for product

families. In view of the potential of dynamic

modelling and visualization in shedding light on

process logic, we propose to model production

configuration graphically. In relation to fundamental

issues in production configuration (Zhang, 2007),

the resulting difficulties in modelling production

configuration have been identified. They include 1)

handling a high product and process variety; 2)

accommodating many process variations resulting

from design changes; 3) dealing with configuration

at different abstraction levels; 4) satisfying a number

of constraints/restrictions describing, for example,

the connections between product and process

elements; and 5) selecting process elements/

processes from multiple alternatives.

Owing to their executability, graphical

representation and mathematic support, Petri nets

(PNs) have been well recognized as a powerful

modelling, simulation and evaluation tool for

complex flows and processes (Peterson, 1981). A

number of extensions have been made to classic PNs

in order to satisfy different modelling requirements.

Among all, colored PNs (CPNs; Jensen, 1995),

timed PNs (TPNs; Ramachandani, 1974) and nested

PNs (NPNs; Lomazova, 2000) are of particular

interest in this study. CPNs are able to provide a

concise, flexible and manageable representation of

large systems by attaching a variety of colors to

tokens. By including timing, TPNs can capture

systems physical behaviours through assuming

specific durations for various activities. By

considering PNs as tokens, NPNs is expected to

model large and complex system through refinement

and abstraction.

In this paper, we apply PN techniques to model

production configuration by taking into account the

difficulties imposed by the fundamental issues.

Accordingly, a formalism of NCTPNs (nested

colored timed PNs) has been developed by

integrating the basic principles of CPNs, TPNs and

NPNs. Product/process variety and configuration

constraints are handled by attaching various data

describing product items and process elements to

tokens, resulting colored tokens. A reconfiguration

mechanism is incorporated into the modelling

formalism to cope with process variations. Timing is

introduced to facilitate the selection of proper

machines, operations and processes. Moreover, a

multilevel net system is further developed based on

net nesting in NPNs to tackle explicitly the

granularity issue in production configuration.

The next section introduces an industrial

example of vibration motors for mobile phones,

which is used throughout the rest of this paper to

demonstrate the proposed formalism and the

modelling of production configuration.

2 INDUSTRIAL EXAMPLE

The industrial example adopted is the production of

vibration motors for mobile phones. The increasing

variations in mobile phones design lead to large

numbers of customized vibration motors to be

produced. Together with other factors, e.g., short

delivery lead times, the high variety of vibration

motors complicate the planning of their production

processes.

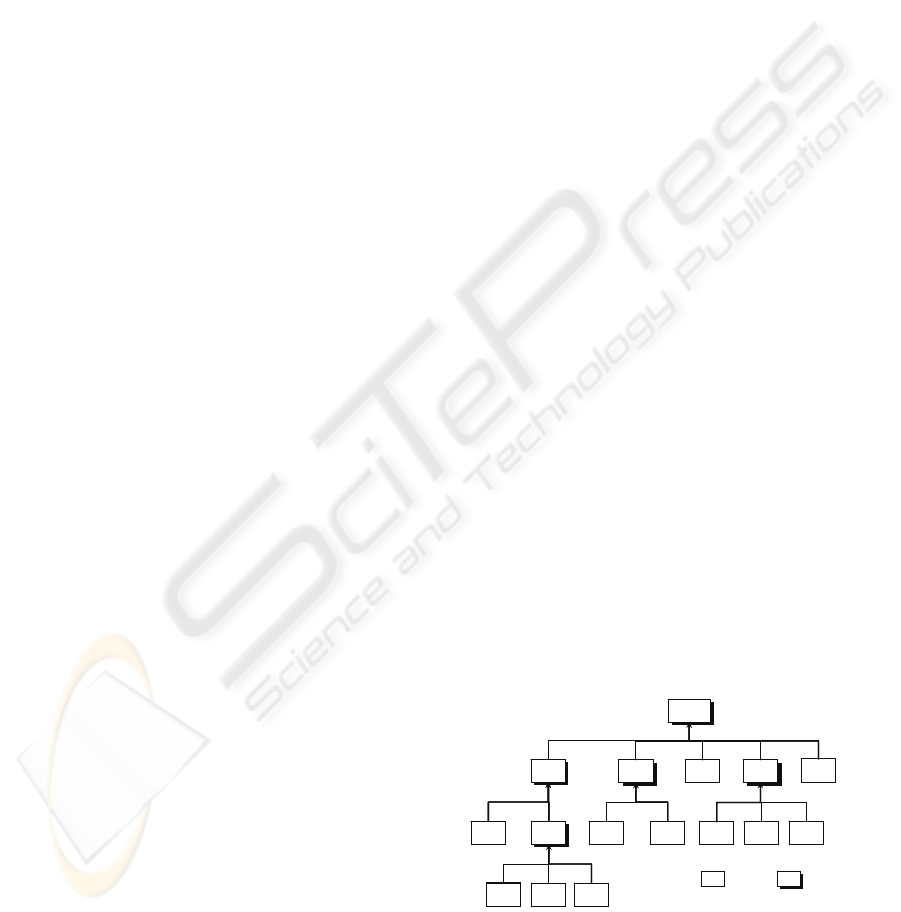

Modelling production configuration of a

vibration motor family using the proposed NCTPNs

is presented in this study. Figure 1 shows the

common product structure of the motor family. This

motor family assumes several part types, as shown

in the figure. According to the design requirements,

individual motors may not contain a specific variant

from each part family. In other words, not all part

types are assumed by each individual motor variant.

While the company produces all assembly families

and final motors, among all they manufacture

several part families, e.g., Ba family, Bb family, Tl

family.

VM

Rh

BA

AA

FA

CA

St Mt

Fm

Cl

Tp

Ct

Wt

Ba

Bb

Tl

: Part; : Assembly

FA: Frameassy; BA: Bracketassy; Rh: Rubber holder; Wt: Weight

VM: Vibration motor; AA: Armatureassy

CA: Coilassy; St: Shaft; Fm: Frame; Mt: Magnet; Ba: Bracket a

Bb: Bracket b; Tl: Terminal; Ct: Commutator; Cl: Coil; Tp: Tape

VM

Rh

BA

AA

FA

CA

St Mt

Fm

Cl

Tp

Ct

Wt

Ba

Bb

Tl

: Part; : Assembly

FA: Frameassy; BA: Bracketassy; Rh: Rubber holder; Wt: Weight

VM: Vibration motor; AA: Armatureassy

CA: Coilassy; St: Shaft; Fm: Frame; Mt: Magnet; Ba: Bracket a

Bb: Bracket b; Tl: Terminal; Ct: Commutator; Cl: Coil; Tp: Tape

Figure 1: The common product structure.

ICEIS 2008 - International Conference on Enterprise Information Systems

6

3 NET DEFINITIONS

Production configuration entails a process of

configuring a complete production process for a

product along with the product hierarchy, i.e., at

different levels of abstraction. Being located at the

highest level, the more abstract production process

involving the product’s immediate child items only

is configured first. Subsequently, the assembly

processes and/or manufacturing processes for

producing these immediate child items are

configured at the second level, and so on. The

manufacturing processes for parts at the lowest level

of each branch of the hierarchy are configured at

last. Bearing in mind the similarities embedded in

processes of any type, e.g., adoption of buffers and

alternative machines, involvement of WIPs, we

define a basic PN structure first, which reflects the

generalized common process elements that are

assumed by different types of nets defined in the

proposed formalism.

3.1 Basic Net Structure

Definition 1: A basic PN structure is a directed

bipartite graph

()

h,A,T,PG = , where

CRRIB

P

P

P

P

P

∪∪∪= is a finite set of places

with 4 disjoint subsets:

B

P

representing buffers (be it

for raw materials, parts, assemblies, or final

products),

I

P

items ready to be processed (be it a

raw material, part, assembly, or WIP),

R

P

machines,

and

CR

P

the conceptual machines for alternative

machines that can complete same tasks using

different operations;

φ

=∩∪∪= TP,TTTT

TRL

is a finite set of

transitions with 3 disjoint subsets:

L

T

denoting a set

of logical transitions,

R

T

a set of reconfigurable

transitions, and

T

T

a set of timed transitions;

PTTPA ×∪×⊆

is a finite set of arcs that

connect places/transitions to transitions/places; and

φ

=∩×⊆ Ah,TPh

RCR

is a finite set of inhibitor

arcs that connect a conceptual machine place to a

reconfigurable transition.

()

RCR

Tt,Pp,1t,ph ∈∈∀=

indicates that there is a token in the conceptual

machine place; and the associated reconfigurable

transition is disabled and cannot fire. When

()

,0t,ph = no token resides in the conceptual

machine place; and the associated reconfigurable

transition can fire if it is enabled.

Attempting to capture and model multiple

alternative machines in relation to same tasks,

CR

P

is defined in the formalism to represent the

corresponding conceptual machines in addition to

R

P

, which is defined to denote specific machines. In

conjunction with

CR

P

, h and

R

T

are introduced to

model the situations, where multiple machines can

perform same tasks and only one is used eventually.

The firing of

R

T

leads to the reconfiguration of

proper machines. In this way,

CR

P

,

R

T

and h can

address process variations in system models without

rebuilding new ones when machines are added

and/or removed.

L

T

is defined to capture the logic of the system

running. Their firing indicates the satisfaction of

preconditions of operations, for example, the

presence of material items and machines to be used.

T

T

is defined to represent operations, which take

certain time durations to complete. Thus, the firing

of timed transitions incurs time delays. Both logic

and reconfigurable transitions are untimed. Their

firing is instantaneous and takes 0 time delay.

Figure 2 shows a basic PN structure and the

corresponding graphical formalism. Based on the

basic PN structure, 3 types of PNs, namely

manufacturing nets (

MNets ), assembly nets ( ANets )

and a process net (

PNet ) are defined to address the

granularity issue in production configuration. These

nets are defined as a type with a marking, with each

type following the basic PN structure and includes

additional information.

: Place;

: Logical transition

: Arc;

: Reconfigurable transition

: Inhibitor arcs;

: Timed transition;

1

p

2

p

1

t

2

t

4

t

3

p

6

p

5

p

4

p

3

t

: Place;

: Logical transition

: Arc;

: Reconfigurable transition

: Inhibitor arcs;

: Timed transition;

1

p

2

p

1

t

2

t

4

t

3

p

6

p

5

p

4

p

3

t

Figure 2: A basic PN structure.

3.2 Manufacturing Net (MNet)

Definition 2: A manufacturing net is defined as a

tuple

(

)

μ

,ToMMNet

=

, where

MNet is a manufacturing net representing the

processes of manufacturing a part family;

(

)

τΕβαΣ

,,,,,GToM

M

= is a manufacturing type

with

−

G is the basic PN structure;

−

M

Σ

is a finite set of color sets or token types;

−

M

MP

Σ

α

6: is a color assignment function that

maps a place,

p

, to a set of colors,

()

p

α

;

PRODUCTION CONFIGURATION OF PRODUCT FAMILIES - An Approach based on Petri Nets

7

−

(

)

{

}

(

)

εΣΣβ

∪×:

MM

T 6 is a color assignment

function that maps a transition,

t , to a set of color

pairs,

()

t

β

such that each pair declares the transition,

t , must be synchronized externally with transitions

of the net where this manufacturing net resides,

except if the pair is

(

)

εΣ

,

M

, indicating no

synchronization is required;

−

()

τΣΕ

ΣΣΣ

+→∧∨∪∨×:

MMM

M@MMA

M

6 is

an arc expression function that defines the timed and

untimed arc expressions for arcs with respect to

transition colors;

∧

∨ / denote Exclusive OR

(XOR)/AND relationships; and

→ represents “if–

then”;

−

+

ℜ∈

τ

is a set of positive real numbers

representing time delays;

()

Pp,MP

p

∈∀:

α

μ

6 is a marking function

specifying the distribution of colored tokens in all

places of an

MNet .

While tokens in idle machine places are defined

to represent machines, tokens in busy machine

places are defined according to the items to be

produced. When there is a token residing in the

conceptual machine place, the conceptual machine is

instantiated to the specific machine represented by

the token. Cycle times are used to accommodate

selection of proper processes elements. Thus, time

delays,

τ

, are defined in the formalism to represent

operations cycle times.

To cope with the difficulties in modelling diverse

cycle times, an arc expression function,

Ε

, is

introduced in the formalism. It defines both timed

arc expressions and untimed arc expressions. A

timed arc expression is a set of antecedent-

consequent statements with XOR relationships. It

specifies input items, machines to be used, output

items and the cycle times to be incurred. Untimed

arc expressions are defined to specify 1) the input

tokens for firing any transitions; and 2) output

tokens after firing timed and reconfigurable

transitions.

6

p

1

p

9

p

1

t

7

t

321

AAAAAA ∨∨

32

1

ABAB

AB

∨

∨

10

p

()

()

()

()

()

()

()

12@ABmBAAA

9@ABmBAAA

13@ABmBAAA

11@ABmBAAA

15@ABmBAAA

12@ABmBAAA

10@ABmBAAA

3333

3233

2322

2122

1311

1211

1111

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

2

p

4

p

3

p

2

t

3

t

4

t

8

p

3

2

1

m

m

m

∨

∨

6

t

5

p

() ( )( )( ){}

3322112

BA,BA,BA,BA,BA,BAt =

β

() ( )( )( ){}

;AA,AA,AA,AA,AA,AAt

3322111

=

β

() () ( )( )( ){}

;AB,,AB,,AB,tt

32173

εεεββ

==

9

t

16

p

12

t

17

p

11

p

8

t

21

FAFA ∨

12

p

3

m

2

m

1

m

32

1

MBMB

MB

∨

∨

()

()

()

()

7.11@MBmFAAB

6.10@MBmFAAB

2.14@MBmFAAB

8.12@MBmFAAB

3423

2522

1511

1411

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

()

(

)

{

}

14

m,t

εβ

=

() ( ){}

;m,t

25

εβ

=

()()()()(){}

;MB,,MB,,MB,tt

321129

εεεββ

==

() ( )( ){}

;FA,FA,FA,FAt

22118

=

β

10

t

14

p

15

p

5

4

m

m ∨

4

m

5

m

11

t

13

p

4

m

5

m

4

m

5

m

18

p

()

()

()

8.7@VMmRhWtMB

7.6@VMmRhMB

2.6@VMmWtMB

16111

3623

2622

+→∧∧∧

∨+→∧∧

∨

+

→

∧

∧

5

t

7

p

6

m

19

p

6

m

20

p

21

p

13

t

14

t

321

AAAAAA ∨∨

321

BABABA ∨∨

321

BABABA ∨∨

32

1

AAAA

AA

∨

∨

32

1

BABA

BA

∨

∨

3

m

2

m

1

m

3

m

2

m

1

m

32

1

ABAB

AB

∨

∨

32

1

ABAB

AB

∨

∨

21

FAFA ∨

2

1

FA

FA ∨

32

1

VMVM

VM

∨

∨

32

1

VMVM

VM

∨

∨

(

)

22

11

RhWt

RhWt

∨

∨∧

32

1

MBMB

MB

∨

∨

32

1

MBMB

MB

∨

∨

() ( ){}

;m,t

36

εβ

=

(

)( ){}

;m,t

410

εβ

=

() ( ){}

;m,t

511

εβ

=

() () ( )

(

)

(

){}

3211413

VM,,VM,,VM,tt

εεεββ

==

6

p

1

p

9

p

1

t

7

t

321

AAAAAA ∨∨

32

1

ABAB

AB

∨

∨

10

p

()

()

()

()

()

()

()

12@ABmBAAA

9@ABmBAAA

13@ABmBAAA

11@ABmBAAA

15@ABmBAAA

12@ABmBAAA

10@ABmBAAA

3333

3233

2322

2122

1311

1211

1111

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

2

p

4

p

3

p

2

t

3

t

4

t

8

p

3

2

1

m

m

m

∨

∨

6

t

5

p

() ( )( )( ){}

3322112

BA,BA,BA,BA,BA,BAt =

β

() ( )( )( ){}

;AA,AA,AA,AA,AA,AAt

3322111

=

β

() () ( )( )( ){}

;AB,,AB,,AB,tt

32173

εεεββ

==

9

t

16

p

12

t

17

p

11

p

8

t

21

FAFA ∨

12

p

3

m

2

m

1

m

32

1

MBMB

MB

∨

∨

()

()

()

()

7.11@MBmFAAB

6.10@MBmFAAB

2.14@MBmFAAB

8.12@MBmFAAB

3423

2522

1511

1411

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

()

(

)

{

}

14

m,t

εβ

=

() ( ){}

;m,t

25

εβ

=

()()()()(){}

;MB,,MB,,MB,tt

321129

εεεββ

==

() ( )( ){}

;FA,FA,FA,FAt

22118

=

β

10

t

14

p

15

p

5

4

m

m

∨

4

m

5

m

11

t

13

p

4

m

5

m

4

m

5

m

18

p

()

()

()

8.7@VMmRhWtMB

7.6@VMmRhMB

2.6@VMmWtMB

16111

3623

2622

+→∧∧∧

∨+→∧∧

∨

+

→

∧

∧

5

t

7

p

6

m

19

p

6

m

20

p

21

p

13

t

14

t

321

AAAAAA ∨∨

321

BABABA ∨∨

321

BABABA ∨∨

32

1

AAAA

AA

∨

∨

32

1

BABA

BA

∨

∨

3

m

2

m

1

m

3

m

2

m

1

m

32

1

ABAB

AB

∨

∨

32

1

ABAB

AB

∨

∨

21

FAFA ∨

2

1

FA

FA ∨

32

1

VMVM

VM

∨

∨

32

1

VMVM

VM

∨

∨

(

)

22

11

RhWt

RhWt

∨

∨∧

32

1

MBMB

MB

∨

∨

32

1

MBMB

MB

∨

∨

() ( ){}

;m,t

36

εβ

=

(

)( ){}

;m,t

410

εβ

=

() ( ){}

;m,t

511

εβ

=

() () ( )

(

)

(

){}

3211413

VM,,VM,,VM,tt

εεεββ

==

Figure 3: The PNet of the motor family.

By following the common routing of the motor

family, the

PNet is constructed, as shown in Figure

3. In the

PNet , the involved items include AAs,

FAs, BAs, ABs (abassies; WIPs formed by AAs and

BAs), MBs (mainbodies; WIPs formed by ABs and

FAs) and VMs. The places, represented system

elements and contained colored tokens/lower level

nets are listed in Table 1 (not exhaust due to place

constraints). The color pairs assigned to each

transaction are shown in the figure. For illustrative

simplicity, the colored tokens in relation to 3 motor

variants (

21

VM,VM and

3

VM ) are given in Figure 3

and Table 1, and in the following figures and tables

as well. Take the timed arc expression of arc

(

)

2013

p,t as an example. It shows that

1

VM assumes

both Wt and Rh;

2

VM contains a Wt; and

3

VM

includes an Rh. Also shown are the machines used

and the corresponding cycle times.

Table 1: The places, represented system elements and

colored tokens/nets.

Places System Elements Nets/Colored Tokens

11/4/1

p

Input buffers for

AAs/Bas /FAs

ANets for producing

assembly

families AA/BA/FA

2

p

AAs are ready to be

processed

(){ }

3212

AA,AA,AAp =

α

3

p

BAs are ready to be

processed

(){ }

3212

BA,BA,BAp =

α

… … …

21

p

A buffer for final motors

(){ }

32121

VM,VM,VMp =

α

3.3 Assembly Net (ANet)

Definition 3: An assembly net is defined as a tuple

(

)

μ

,ToAANet =

, where

ANet is an assembly net representing the

processes of producing a family of assembly

variants;

(

)

τΕβαΣ

,,,,,SoTma,GToA

A

= is an assembly

type with

−

G is the basic PN structure;

−

SoTma is a set of manufacturing types and

assembly types;

−

A

Σ

is a finite set of color sets or token types;

−

A

MSoTmaP

Σ

α

∪: 6 is an assignment function

that maps a place,

p

, to manufacturing or assembly

types or a set of colors;

−

{

}

(

)

(

)

{}

(

)

εΣΣεΣβ

∪××∪:

AAA

T 6 is an

assignment function that maps a transition,

t , to a set

of color triples,

(

)

t

β

, such that each triple declares

ICEIS 2008 - International Conference on Enterprise Information Systems

8

the transition,

t , must be synchronized 1) internally

with transitions of the nested net; and 2) externally

with transitions of the host net where this assembly

net is contained, except if the triple is

(

)

εΣε

,,

A

;

−

()

τΣΕ

ΣΣΣ

+→∧∨∪∨×:

AAA

M@MMA

A

6 is

an arc expression function that defines the timed and

untimed arc expressions for arcs with respect to

transition colors; and

−

+

ℜ∈

τ

is a set of positive real numbers

representing time delays;

()

Pp,MP

p

∈∀:

α

μ

6 is a marking function

specifying the distribution of colored tokens,

manufacturing and assembly nets in all places of an

ANet .

Unlike raw buffer places in an

MNet , buffer

places in an

ANet are defined for the immediate child

items of assemblies. Tokens in such

part/subassembly buffers are

MNets / ANets of child

items. The assignment function,

α

, specifies the

allocation of such

MNets / ANets to buffer places and

colored tokens to other places.

Same as specifying the

PNet , four

ANets

have

been constructed for 4 assembly families of the

motor family in Figure 1. Figure 4 shows the

ANet

of BA family. The color triples assigned to each

transition are also shown. According to these

colored triples, transitions of this

ANet fires

autonomously, or simultaneously with either the

transitions of the nested nets residing in places

2522

p,p

and

31

p

or the transitions of the PNet in

Figure 3. Table 2 lists the set of places, represented

system elements and colored tokens/

MNets .

22

p

29

p

15

t

20

t

321

BaBaBa ∨∨

32

1

BabBab

Bab

∨

∨

30

p

()

()

()

()

()

()

3.6@BabmTlBbBa

3.5@BabmTlBbBa

1.6@BabmTlBbBa

6.5@BabmTlBbBa

9.4@BabmBbBa

3.4@BabmBbBa

38233

37233

28122

27122

1811

1711

+→∧∧∧

∨+→∧∧∧

∨+→∧∧∧

∨+→∧∧∧

∨+→∧∧

∨+→∧∧

23

p

25

p

24

p

16

t

17

t

23

t

34

p

36

p

11

10

9

m

m

m

∨

∨

25

t

33

p

() ( )( )( ){}

;,Ba,Ba,,Ba,Ba,,Ba,Bat

33221115

εεεβ

=

22

t

37

p

26

t

38

p

31

p

21

t

21

TlTl ∨

32

p

10

m

()

()

()

()

()

()

()

2.4@BAmTlBab

0.3@BAmTlBab

5.3@BAmTlBab

9.3@BAmTlBab

8.2@BAmTlBab

2.3@BAmTlBab

0@BABab

31123

31023

3923

21112

21012

2912

11

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→

18

t

27

p

28

p

8

7

m

m ∨

7

m

19

t

26

p

8

m

24

t

35

p

321

BbBbBb ∨∨

11

m

9

m

32

1

BABA

BA

∨

∨

() ( ){}

;,m,t

819

εεβ

=

321

BaBaBa ∨∨

321

BbBbBb ∨∨

32

1

BaBa

Ba

∨

∨

32

1

BbBb

Bb

∨

∨

7

m

8

m

7

m

8

m

10

m

11

m

9

m

10

m

11

m

9

m

32

1

BabBab

Bab

∨

∨

32

1

BabBab

Bab

∨

∨

21

TlTl ∨

2

1

Tl

Tl ∨

32

1

BABA

BA

∨

∨

() ( )( )( ){}

;,Bb,Bb,,Bb,Bb,,Bb,Bbt

33221116

εεεβ

=

() () ( )

(

)

(

){}

εεεεεεββ

,Bab,,,Bab,,,Bab,tt

3212017

==

() ( )( )( ){}

;,Tl,Tl,,Tl,Tl,,Tl,Tlt

33221121

εεεβ

=

()()()(){}

;,BA,,,BA,,,BA,t

32122

εεεεεεβ

=

(

)

(

)

{

}

εεβ

,m,t

923

=

() ( )( )

(

){}

23221126

BA,BA,,BA,BA,,BA,BA,t

εεεβ

=

() ( ){}

;,m,t

718

εεβ

=

() ( ){}

;,m,t

1024

εεβ

=

() ( ){}

;,m,t

1125

εεβ

=

22

p

29

p

15

t

20

t

321

BaBaBa ∨∨

32

1

BabBab

Bab

∨

∨

30

p

()

()

()

()

()

()

3.6@BabmTlBbBa

3.5@BabmTlBbBa

1.6@BabmTlBbBa

6.5@BabmTlBbBa

9.4@BabmBbBa

3.4@BabmBbBa

38233

37233

28122

27122

1811

1711

+→∧∧∧

∨+→∧∧∧

∨+→∧∧∧

∨+→∧∧∧

∨+→∧∧

∨+→∧∧

23

p

25

p

24

p

16

t

17

t

23

t

34

p

36

p

11

10

9

m

m

m

∨

∨

25

t

33

p

() ( )( )( ){}

;,Ba,Ba,,Ba,Ba,,Ba,Bat

33221115

εεεβ

=

22

t

37

p

26

t

38

p

31

p

21

t

21

TlTl ∨

32

p

10

m

()

()

()

()

()

()

()

2.4@BAmTlBab

0.3@BAmTlBab

5.3@BAmTlBab

9.3@BAmTlBab

8.2@BAmTlBab

2.3@BAmTlBab

0@BABab

31123

31023

3923

21112

21012

2912

11

+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→∧∧

∨+→

18

t

27

p

28

p

8

7

m

m ∨

7

m

19

t

26

p

8

m

24

t

35

p

321

BbBbBb ∨∨

11

m

9

m

32

1

BABA

BA

∨

∨

() ( ){}

;,m,t

819

εεβ

=

321

BaBaBa ∨∨

321

BbBbBb ∨∨

32

1

BaBa

Ba

∨

∨

32

1

BbBb

Bb

∨

∨

7

m

8

m

7

m

8

m

10

m

11

m

9

m

10

m

11

m

9

m

32

1

BabBab

Bab

∨

∨

32

1

BabBab

Bab

∨

∨

21

TlTl ∨

2

1

Tl

Tl ∨

32

1

BABA

BA

∨

∨

() ( )( )( ){}

;,Bb,Bb,,Bb,Bb,,Bb,Bbt

33221116

εεεβ

=

() () ( )

(

)

(

){}

εεεεεεββ

,Bab,,,Bab,,,Bab,tt

3212017

==

() ( )( )( ){}

;,Tl,Tl,,Tl,Tl,,Tl,Tlt

33221121

εεεβ

=

()()()(){}

;,BA,,,BA,,,BA,t

32122

εεεεεεβ

=

(

)

(

)

{

}

εεβ

,m,t

923

=

() ( )( )

(

){}

23221126

BA,BA,,BA,BA,,BA,BA,t

εεεβ

=

() ( ){}

;,m,t

718

εεβ

=

() ( ){}

;,m,t

1024

εεβ

=

() ( ){}

;,m,t

1125

εεβ

=

Figure 4: The ANet of the bracketassy family.

43

p

30

t

44

p

(

)

()

()

()

()

()

8.4@2.Bam1.Ba

4.4@2.Bam1.Ba

5.4@2.Bam1.Ba

7.3@2.Bam1.Ba

9.5@2.Bam1.Ba

3.5@2.Bam1.Ba

3133

3123

2132

2122

1131

1121

+→∧

∨+→∧

∨+→∧

∨+→∧

∨+→∧

∨+→∧

27

t

45

p

()()()()(){}

;,2.Ba,,2.Ba,,2.Batt

3213027

εεεββ

==

31

t

46

p

32

t

(

)

(

)

{

}

;,mt

1228

εβ

=

28

t

41

p

42

p

13

12

m

m ∨

12

m

29

t

40

p

13

m

14

m

(

)

(

)

{

}

;,mt

1329

εβ

=

1.Ba1.Ba

1.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

(

)

()

()

5.1@Bam2.Ba

7.1@Bam2.Ba

1.1@Bam2.Ba

3143

2142

1141

+→∧

∨+→∧

∨+→∧

32

1

BaBa

Ba

∨

∨

32

1

BaBa

Ba

∨

∨

14

m

12

m

13

m

12

m

13

m

() ( )( )( ){}

;,Ba,,Ba,,Bat

32131

εεεβ

=

() ( )

(

)

(

){}

33221132

Ba,Ba,Ba,Ba,Ba,Bat =

β

39

p

47

p

43

p

30

t

44

p

(

)

()

()

()

()

()

8.4@2.Bam1.Ba

4.4@2.Bam1.Ba

5.4@2.Bam1.Ba

7.3@2.Bam1.Ba

9.5@2.Bam1.Ba

3.5@2.Bam1.Ba

3133

3123

2132

2122

1131

1121

+→∧

∨+→∧

∨+→∧

∨+→∧

∨+→∧

∨+→∧

27

t

45

p

()()()()(){}

;,2.Ba,,2.Ba,,2.Batt

3213027

εεεββ

==

31

t

46

p

32

t

(

)

(

)

{

}

;,mt

1228

εβ

=

28

t

41

p

42

p

13

12

m

m

∨

12

m

29

t

40

p

13

m

14

m

(

)

(

)

{

}

;,mt

1329

εβ

=

1.Ba1.Ba

1.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

2.Ba2.Ba

2.Ba

32

1

∨

∨

(

)

()

()

5.1@Bam2.Ba

7.1@Bam2.Ba

1.1@Bam2.Ba

3143

2142

1141

+→∧

∨+→∧

∨+→∧

32

1

BaBa

Ba

∨

∨

32

1

BaBa

Ba

∨

∨

14

m

12

m

13

m

12

m

13

m

() ( )( )( ){}

;,Ba,,Ba,,Bat

32131

εεεβ

=

() ( )

(

)

(

){}

33221132

Ba,Ba,Ba,Ba,Ba,Bat =

β

39

p

47

p

Figure 5: The MNet of the bracket a family.

Table 2: The places, represented elements and colored

tokens/nets.

Places System Elements Nets/Colored Tokens

31/25/22

p

Input part buffers for

Bas/Bbs/Tls

MNets for producing

part families Ba/Bb/Tl

23

p

Bas ready to be processed

(){ }

32123

Ba,Ba,Bap =

α

24

p

Bbs ready to be processed

(){ }

32124

Bb,Bb,Bbp =

α

…. … …

37

p

Alternative mach.

processing Babs&Tls

(){ }

32137

BA,BA,BAp =

α

38

p

A buffer for BAs

(){ }

32138

BA,BA,BAp =

α

3.4 Process Net (PNet)

Definition 4: A process net is defined as a tuple

(

)

μ

,ToPPNet

=

.

PNet is a process net representing more abstract

production processes of producing a family of end-

products.

(

)

τΕβαΣ

,,,,,SoTma,GToP

P

= is a process

type (a special assembly type) with symbols carrying

similar meanings as with an

ANet , except

{

}

(

)

(

)

PP

T

ΣεΣβ

×∪: 6 , which is defined as an

assignment function that maps a transition,

t

, to a

set of color pairs,

(

)

t

β

, such that a pair declares the

transition,

t

, must be synchronized internally with

transitions of the nested nets, except if the pair is

(

)

P

,

Σε

. Essentially, a PNet is a special kind of

ANets . It involves only the child items at the

immediate lower level of the end-products in the

BOM structures.

In a similar way,

MNets have been constructed

in accordance with part families produced in house.

Figure 5 shows the

MNet of Ba family. Table 3 lists

the places, represented system elements and colored

tokens.

4 NESTED NET SYSTEM

4.1 Nested Net System

Definition 5: A multilevel nested net system is

defined as a triple,

()

A,M,PNetMlNNS =

, where

MlNNS is the multilevel nested net system for

modelling the complete production processes of end-

products;

PRODUCTION CONFIGURATION OF PRODUCT FAMILIES - An Approach based on Petri Nets

9

Table 3: The places, represented elements and colored

tokens/nets.

Places System Elements Colored Tokens

39

p

A raw material buffer

for Bas

(

)

{

}

1.Ba,1.Ba,1.Bap

32139

=

α

40

p

A conceptual machines

for manufacturing Bas

(){ }

131240

m,mp =

α

42/41

p

Alternative idle

machines for

manufacturing Bas

(

)

{

}

(

)

{

}

13421241

mp/mp ==

αα

… … …

46

p

The second machine

processing Ba WIPs

(){ }

32146

Ba,Ba,Bap =

α

47

p

A buffer for Bas

(){ }

32147

Ba,Ba,Bap =

α

PNet

is the process net describing the abstract

production processes of end-products;

{}

M

N

i

MNetM = is a finite set of MNets ; and

{}

A

N

i

ANetA =

is a finite set of ANets .

Performing as an abstraction mechanism,

MlNNS facilitates the configuration of processes

with right amount of details. Within

MlNNS , the

highest level is the

PNet

, while a number of MNets

and

ANets are located at the second level. Each of

these nets provides more details for processes of

input items involved in the

PNet

. At the lowest level

of each path, all nets are

MNets , whilst a mixture of

MNets and ANets can be found at any arbitrary

level.

For the motor family, based on the constructed

MNets , ANets and PNet , the multilevel system of

production configuration is obtained, as shown in

Figure 5.

22

p

29

p

15

t

20

t

31

p

23

p

25

p

24

p

16

t

17

t

23

t

34

p

36

p

25

t

33

p

22

t

37

p

26

t

38

p

30

p

21

t

32

p

18

t

27

p

28

p

19

t

26

p

24

t

35

p

1

p

9

p

1

t

7

t

10

p

2

p

4

p

3

p

2

t

3

t

4

t

6

p

8

p

6

t

5

p

9

t

16

p

13

t

17

p

11

p

8

t

12

p

10

t

14

p

15

p

11

t

13

p

18

p

5

t

7

p

19

p

20

p

21

p

14

t

PNet

60

p

62

p

41

t

57

p

56

p

58

p

37

t

38

t

63

p

39

t

61

p

40

t

59

p

familyAA

ofANet

familyBA

ofANet

48

p

49

p

33

t

51

p

53

p

35

t

50

p

32

t

54

p

36

t

55

p

34

t

52

p

familyFA

ofANet

54

t

87

p

57

t

79

p

82

p

83

p

53

t

56

t

88

p

85

p

55

t

84

p

81

p

80

p

86

p

52

t

family

CAof

ANet

27

t

43

p

30

t

44

p

39

p

28

t

41

p

42

p

29

t

40

p

45

p

46

p

47

p

32

t

31

t

familyBaofMNet

42

t

68

p

45

t

69

p

64

p

43

t

66

p

67

p

44

t

65

p

70

p

71

p

72

p

47

t

46

t

familyBbofMNet

75

p

48

t

77

p

51

t

78

p

73

p

49

t

76

p

50

t

74

p

family

TlofMNet

58

t

93

p

61

t

94

p

89

p

59

t

92

p

60

t

90

p

91

p

familyTp

ofMNet

62

t

97

p

63

t

98

p

95

p

96

p

99

p

100

p

101

p

65

t

64

t

familyClofMNet

22

p

29

p

15

t

20

t

31

p

23

p

25

p

24

p

16

t

17

t

23

t

34

p

36

p

25

t

33

p

22

t

37

p

26

t

38

p

30

p

21

t

32

p

18

t

27

p

28

p

19

t

26

p

24

t

35

p

22

p

29

p

15

t

20

t

31

p

23

p

25

p

24

p

16

t

17

t

23

t

34

p

36

p

25

t

33

p

22

t

37

p

26

t

38

p

30

p

21

t

32

p

18

t

27

p

28

p

19

t

26

p

24

t

35

p

1

p

9

p

1

t

7

t

10

p

2

p

4

p

3

p

2

t

3

t

4

t

6

p

8

p

6

t

5

p

9

t

16

p

13

t

17

p

11

p

8

t

12

p

10

t

14

p

15

p

11

t

13

p

18

p

5

t

7

p

19

p

20

p

21

p

14

t

PNet

1

p

9

p

1

t

7

t

10

p

2

p

4

p

3

p

2

t

3

t

4

t

6

p

8

p

6

t

5

p

9

t

16

p

13

t

17

p

11

p

8

t

12

p

10

t

14

p

15

p

11

t

13

p

18

p

5

t

7

p

19

p

20

p

21

p

14

t

PNet

60

p

62

p

41

t

57

p

56

p

58

p

37

t

38

t

63

p

39

t

61

p

40

t

59

p

familyAA

ofANet

60

p

62

p

41

t

57

p

56

p

58

p

37

t

38

t

63

p

39

t

61

p

40

t

59

p

60

p

62

p

41

t

57

p

56

p

58

p

37

t

38

t

63

p

39

t

61

p

40

t

59

p

familyAA

ofANet

familyBA

ofANet

48

p

49

p

33

t

51

p

53

p

35

t

50

p

32

t

54

p

36

t

55

p

34

t

52

p

familyFA

ofANet

48

p

49

p

33

t

51

p

53

p

35

t

50

p

32

t

54

p

36

t

55

p

34

t

52

p

48

p

49

p

33

t

51

p

53

p

35

t

50

p

32

t

54

p

36

t

55

p

34

t

52

p

familyFA

ofANet

54

t

87

p

57

t

79

p

82

p

83

p

53

t

56

t

88

p

85

p

55

t

84

p

81

p

80

p

86

p

52

t

family

CAof

ANet

27

t

43

p

30

t

44

p

39

p

28

t

41

p

42

p

29

t

40

p

45

p

46

p

47

p

32

t

31

t

familyBaofMNet

27

t

43

p

30

t

44

p

39

p

28

t

41

p

42

p

29

t

40

p

45

p

46

p

47

p

32

t

31

t

27

t

43

p

30

t

44

p

39

p

28

t

41

p

42

p

29

t

40

p

45

p

46

p

47

p

32

t

31

t

familyBaofMNet

42

t

68

p

45

t

69

p

64

p

43

t

66

p

67

p

44

t

65

p

70

p

71

p

72

p

47

t

46

t

familyBbofMNet

42

t

68

p

45

t

69

p

64

p

43

t

66

p

67

p

44

t

65

p

70

p

71

p

72

p

47

t

46

t

42

t

68

p

45

t

69

p

64

p

43

t

66

p

67

p

44

t

65

p

70

p

71

p

72

p

47

t

46

t

familyBbofMNet

75

p

48

t

77

p

51

t

78

p

73

p

49

t

76

p

50

t

74

p

family

TlofMNet

75

p

48

t

77

p

51

t

78

p

73

p

49

t

76

p

50

t

74

p

75

p

48

t

77

p

51

t

78

p

73

p

49

t

76

p

50

t

74

p

family

TlofMNet

58

t

93

p

61

t

94

p

89

p

59

t

92

p

60

t

90

p

91

p

familyTp

ofMNet

58

t

93

p

61

t

94

p

89

p

59

t

92

p

60

t

90

p

91

p

58

t

93

p

61

t

94

p

89

p

59

t

92

p

60

t

90

p

91

p

familyTp

ofMNet

62

t

97

p

63

t

98

p

95

p

96

p

99

p

100

p

101

p

65

t

64

t

familyClofMNet

62

t

97

p

63

t

98

p

95

p

96

p

99

p

100

p

101

p

65

t

64

t

62

t

97

p

63

t

98

p

95

p

96

p

99

p

100

p

101

p

65

t

64

t

familyClofMNet

Figure 5: The multilevel nested net system of production

configuration.

As shown in the figure, the PNet is at the

highest level; 3

ANets for producing assembly

families AA, BA and FA are located at the second

level; 1

ANet for producing CA family and 3 MNets

for manufacturing part families Ba, Bb and Tl are at

the third level; and 2

MNets for fabricating part

families Tp and Cl are located at the lowest level.

Each lower level nested net is linked with the

corresponding tokens residing in the places of the

higher level nets.

4.2 System Evolution

Complying with production practice, in the

MlNNS ,

MNets nest in places of ANets and/or

PNet

; and

ANets nest in places of higher level ANets and/or

PNet

. Consequently, configuration of a complete

production process for an end-product necessitates

interaction of the nested nets and the host nets. In

this study, transition synchronization is introduced to

enable interaction of nets at different levels.

Transition synchronization is declared by the color

pairs/triples of net transitions. More specifically, two

or more transitions with same color pairs and/or

triples must be synchronized, i.e., fire

simultaneously. To enable transition

synchronization, several rules for enabling and firing

transitions are defined in the net system.

Rule 1: A transition,

t

, of an MNet is enabled

with respect to a color pair,

cp , and fires

autonomously without additional conditions if

(

)

(

)

(

)

pcp,t,p,p

μΕ

⊆∀

and

(

)

εΣ

,cp

M

= .

Rule 2: A transition,

t

, of an MNet is enabled

and fires simultaneously with an output transition of

the place, where the

MNet is nested, of the higher

level

ANet or PNet if

()()()

pcp,t,p,p

μ

Ε

⊆

∀

and

(

)

MM

,cp

ΣΣ

= .

Rule 3: A transition,

t , of an ANet is enabled

with respect to a color triple,

ct , and fires

autonomously without additional conditions if

(

)

(

)

(

)

pct,t,p,p

μΕ

⊆∀

and

(

)

εΣε

,,ct

A

= .

Rule 4: A transition,

t

, of an ANet is enabled

and fires simultaneously with a transition bearing a

(

)

AA

,cp

ΣΣ

= or

(

)

AA

,,ct

ΣΣε

= of the lower level

MNet or ANet that nests in an input place of t , if

(

)

(

)

(

)

pct,t,p,p

μ

Ε

⊆

∀

and

(

)

εΣΣ

,,ct

AA

= .

Rule 5: A transition,

t , of an ANet is enabled

and fires simultaneously with an output transition of

a place, where the

ANet is nested, of the higher

level

ANet or PNet , if

()()()

pct,t,p,p

μ

Ε

⊆

∀

and

(

)

AA

,,ct

ΣΣε

=

.

Rule 6: A transition,

t , of a PNet is enabled

with respect to a color pair,

cp , and fires

ICEIS 2008 - International Conference on Enterprise Information Systems

10

autonomously without additional conditions if

()()()

pcp,t,p,p

μΕ

⊆∀ and

(

)

P

,cp

Σε

= .

Rule 7: A transition,

t

, of a PNet is enabled and

fires simultaneously with a transition bearing a

(

)

MM

,cp

ΣΣ

= or

(

)

AA

,,ct

ΣΣε

= of the lower level

MNet or ANet that nests in an input place of t , if

()()()

pcp,t,p,p

μ

Ε

⊆∀ and

(

)

PP

,cp

ΣΣ

= .

While the firing of transitions of any net does not

provoke the transfer of nested nets, that is, the nested

nets remain in the same places before and after

simultaneous transition firing, the tokens, other than

the nested nets, are created and removed as follows:

Rule 8: The firing of an enabled transition,

t

, in

nets at all levels modifying the marking through 1)

generating tokens in the output places by following

()()

cp,p,t

Ε

or

()()

ct,p,t

Ε

; and 2) removing tokens

in the input places by following

()()

cp,t,p

Ε

or

()()

ct,t,p

Ε

.

5 APPLICATION RESULTS

For the 3 motor variants:

21

VM,VM and

3

VM in

Figure 3 and Table 1, more than one production

process consisting of different combination of

machines is feasible to fulfil each motor variant. In

this regard, minimizing the completion time of the

last operation of producing three motor variants is

chosen as the production objective and, the selection

of appropriate ones is made based on this objective.

In the application, we adopt the shortest delay times

to fire transitions, which are enabled by alternative

colored tokens. Table 5 list the corresponding

processes with respect to the selected machines. Due

to the space constraints, this table is truncated.

6 CONCLUSIONS

This study addresses the logic for configuring

production processes of product families with an

attempt to assist practitioners to better understand

and implement production configuration. In view of

the significance of PN techniques in modelling

complex systems/processes, we propose a formalism

of NCTPNs to model production configuration. By

integrating the basic principles of several well-

defined PN extensions, the NCTPNs are able to

capture and reflect the complex process of

configuring complete production processes for end

products. The industrial example has shown

Table 5: The configured production processes for the 3

motor variants.

Machine(Operation; Output item)

1

VM

2

VM

3

VM

13

m (Manufacturing

operation;

1

Ba )

13

m (Manufacturing

operation;

2

Ba )

12

m (Manufacturing

operation;

3

Ba )

14

m (Manufacturing

operation;

1

Ba )

14

m (Manufacturing

operation;

2

Ba )

14

m (Manufacturing

operation;

2

Ba )

… … …

5

m

(Assembly

operation;

1

MB )

5

m

(Assembly

operation;

2

MB )

4

m (Assembly

operation;

3

MB )

6

m (Assembly

operation;

1

VM )

6

m (Assembly

operation;

2

VM )

6

m (Assembly

operation;

3

VM )

the potential of the NCTPNs formalism to reveal the

logic of production configuration.

REFERENCES

Dash, S., Kalagnanam, J., Reddy, C., Song, S.H., 2007.

Production design for plate products in the steel

industry, IBM Journal of Research & Development,

51, 354-362.

Jensen, K., 1995. Colored Petri nets: Basic concepts,

analysis methods and practical Use

. Vol. 2, New

York, Springer.

Lomazova, I.A., 2000. Nested Petri nets: A formalism for

specification and verification of multi-agent

distributed systems, Fundamenta Informaticae, 43,

195-214.

Martinez, M.T., Favrel, J., Ghodous, P., 2000. Product

family manufacturing plan generation and

classification, Concurrent Engineering: Research and

Applications

, 8, 12-22.

Peterson, J.L., 1981.

Petri net theory and the modelling of

Systems, Prentice-Hall, Englewood Cliffs, N.J.

Ramachandani, C., 1974. Analysis of asynchronous

concurrent systems by timed Petri nets, Technical

Report MAC TR 120, MIT, Cambridge.

Schierholt, K., 2001. Process configuration: Combining

the principles of product configuration and process

planning, Artificial Intelligence for Engineering

Design, Analysis and Manufacturing

, 15, 411-424.

Zhang, L., 2007. Process Platform-based Production

Configuration for Mass Customization, PhD

Dissertation, Division of Systems and Engineering

Management, Nanyang Technological University,

Singapore.

Zhang, L., Jiao, J., Helo, P., 2007. Process platform

representation based on unified modelling language,

International Journal of Production Research, 45,

323-350.

PRODUCTION CONFIGURATION OF PRODUCT FAMILIES - An Approach based on Petri Nets

11