MODULARIZATION OF WEB-BASED COLLABORATION

SYSTEMS FOR MANUFACTURING INNOVATION

Kwangyeol Ryu

*

, Seokwoo Lee

**

and Honzong Choi

**

*

Department of Industrial Engineering, Pusan National University, San30, Geumjeong-gu, Busan 609-735, Korea

**

i-Manufacturing Center, KITECH, 7-47 Songdo-dong, Yeonsu-gu, Incheon 406-840, Korea

Keywords: Modularization, Collaboration, i-Manufacturing, Manufacturing Innovation.

Abstract: Unpredictable customer needs strongly require for manufacturing enterprises to produce quality products

satisfying cost and time constraints. To cope with such dynamically changing manufacturing environment

and to get higher competitiveness, the manufacturing industry needs to be equipped with advanced

technologies including IT as well as substantial infrastructure. On the one hand “i-Manufacturing” is the

name of the project funded by the Korea government, but on the other it is the strategy for achieving

manufacturing innovation in Korea. The most basic but important concept of the i-Manufacturing is

“collaboration”. As a part of the i-Manufacturing project, we are developing various kinds of web-based

collaboration systems, referred to as hub systems. Along with increase in the number of collaboration

systems and users every year, we have to modularize function modules for easy and synthetic application of

systems to other conglomerates or industries. Here, collaboration systems we developed are currently being

used by more than 300 companies in Korea. In this paper, therefore, we first introduce the i-Manufacturing

project and collaboration systems we have developed. The system architecture and composition of function

modules which has multi-level framework will be described in detail before concluding the paper.

1 INTRODUCTION

The manufacturing industry has been facing with

unpredictable challenges brought on mostly by

dynamically changing customer demands. To cope

with competitive market environment, the

manufacturing enterprises of today should equip

advanced technologies as well as corresponding

infrastructure. Due to widespread availability of the

Internet and over the past decade, business of the

enterprise has been evolving into e-business, which

innovates in business processes and systems such as

Enterprise Resource Planning(ERP), Supply Chain

Management(SCM), Product Lifecycle Management

(PLM), Customer Relationship Management(CRM),

and so forth. It has aided the acceleration of rapid

and smart production in manufacturing systems to

fulfill requirements of customer such as short

delivery, low cost, and quality products(Lee, 2003).

Because of sudden growth of IT, aforementioned

business areas or concepts are implemented in on-

line or web-based ones such as e-SCM, e-PLM, e-

CRM, etc., which is so called “e-” version of

concepts. On the other hand, recent fashion of

naming technologies or tools seems to add “u-”

because ubiquitous technologies are in the spotlight.

Even though any prefix is fine, but we have to note

that such technologies should be supported within

synthetic strategies in order to achieving innovation.

Enterprises must capture, manage, and leverage

their intellectual assets to differentiate themselves.

The best way is to use the right application which

supports collaboration. Collaboration is the most

important factor to increase a company’s flexibility

and agility to respond swiftly to changing market

pressures and competitors. Collaboration is being

viewed as the next big wave after e-Commerce,

digital commerce and several other variants that

have emerged over the last decade. According to the

outcomes of the i-Manufacturing project that we are

conducting, as illustrated from the following section,

collaboration systems can function as a good

extranet as well as an intranet especially for small

and medium sized companies who do not have

sufficient IT resources and infrastructure including

hardware, software, and experts.

For facilitating collaboration of manufacturing

companies in Korea, we develop various kinds of

174

Ryu K., Lee S. and Choi H. (2008).

MODULARIZATION OF WEB-BASED COLLABORATION SYSTEMS FOR MANUFACTURING INNOVATION.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - SAIC, pages 174-177

DOI: 10.5220/0001717601740177

Copyright

c

SciTePress

collaboration systems every year. We first applied

them into injection-mold industry as it is considered

to deal with the root and core parts for making

products. From the statistics in 2006, five different

collaboration systems were developed and 239

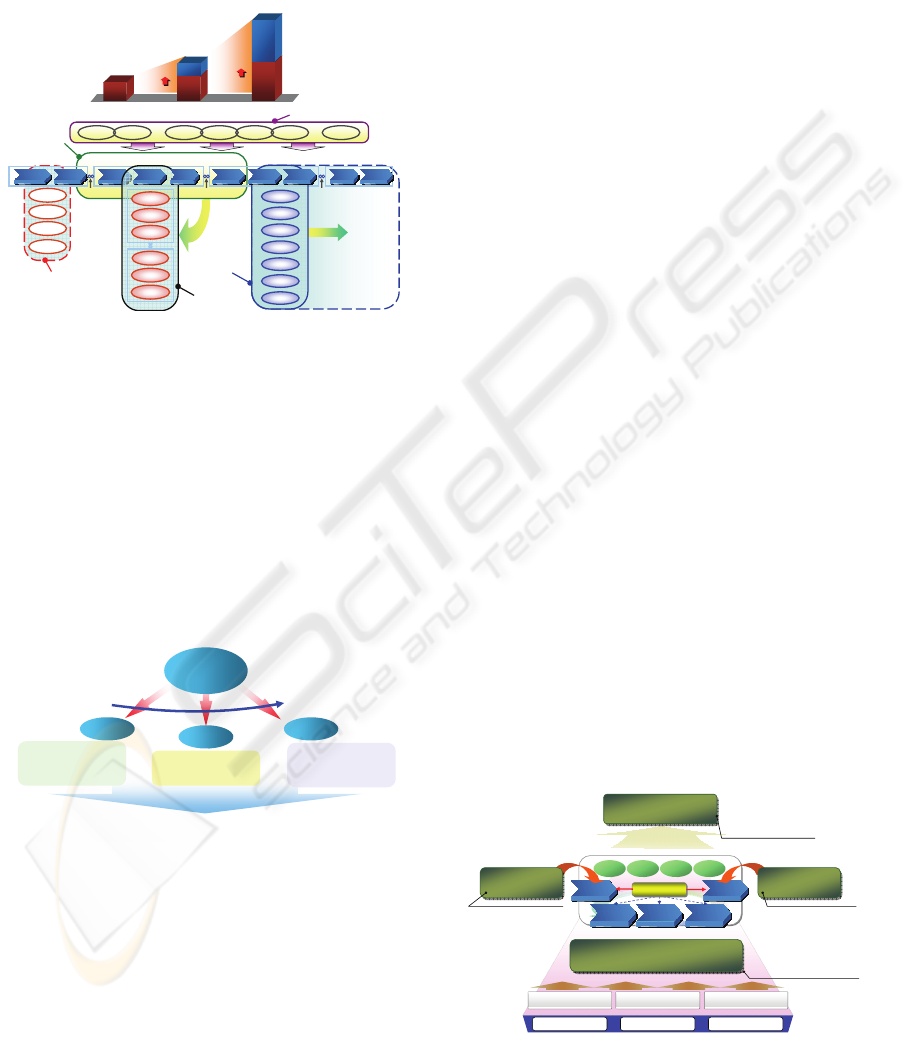

companies used them as illustrated in Figure 1.

Expansion

of covering

Processes

(2006)

Design_Hub

Technology

Collabor ation

Mold Design & Production Extrusion / Mass ProductionProduct Design

Inverse

Design

Design

Mock-up

CAS

Conferencing

Photo

Clinic

Automold_Hub

(2006 brand-new)

Production_Hub

CAM

Standard

Machining

Discharge

Electricity

Core

Machining

Precise

Machining

Assembly

Maintenance

Concept

Design

Concept

Design

Blow_Hub

Trouble

Shooting

Trial Shoot

Blowing

Parison-mold

Design

Blow-mold

Design

Assembly &

Inspection

Engineering_Hub

CAE Analysis

3D

Inspection

Trial Shoot

Quality

Approval

Novel

Technology

Defection

Consulting

Consulting/

Experts

Design

Collabor ation

Collabor ation with

Drawings and Technology

Styling

Styling

Part

Design

Part

Design

Design

Review

Design

Review

Pilot

Product

Pilot

Product

Mold

Design

Mold

Design

Production

of Mold

Production

of Mold

Assembly

& Inspection

Assembly

& Inspection

Trial

Shoot

Trial

Shoot

Extrusion

Extrusion

Conceptual Product Design

specialized hub

according to

the product type

2004 2005

45

61

21

2006

97

142

Participated

companies

Additionally

Involved companies

45

82

239

To t a l No . o f

companies

Ye a r

82%

191%

Figure 1: Composition of collaboration systems and users.

Users got really beneficial influences by using

collaboration systems in terms of productivity, profit,

and product quality. Based on such results, we

decided to extend the usage of our systems to other

injection-mold companies or other industrial

sections such as press-mold(even though it is still in

mold industry), automobile, machinery, and

electronics as depicted in Figure 2. To cover all

industrial divisions, however, we need to develop

and deploy novel technologies because of several

limitations as illustrated in Figure 2.

Comprehensive and systematic

Manufact uring innovation strategy

Automobile

Mac hine ry

Electronics

spreading

collaboration

systems

Confront with limitations

of technologies for enlarging

application domains

e- Manufacturing

Inj ec t io n Mold

Limitation for supporting

manufacturing process

such as procurement,

logistics, etc.

Need to develop

manufacturing system

technologies

Limitation on product

development

technologies wit h very

short delivery

Figure 2: Limitations in propagating collaboration system.

We also need to define and implement common

platforms in order to extend systems previously

developed to other users. Specifically speaking, we

have to modularize basic function modules for

common usage and to leave some parts as

customizing areas for satisfying new users, thereby

rapid and easy development of a collaboration

system is possible. For this, we define 3-layer

architecture including presentation, business, and

data layers, and develop collaboration systems.

2 i-MANUFACTURING

i-Manufacturing is a government-led project that

combines IT to conventional manufacturing and

design to production, where i in i-Manufacturing

contains meanings of information, intelligence, and

innovation. The project offers support to

manufacturing companies by strengthening the

competitiveness of the Korean manufacturing

industry and nurturing new innovation. Before

launching the i-Manufacturing project in 2007, there

was a pilot project referred to as e-Manufacturing. It

was started from 2004 by both central and regional

governments to build up infrastructure promoting

collaboration and technology development among

companies. For realization of the manufacturing

innovation, we reorganize the pilot project to more

comprehensive one by adding other innovation

categories. That is i-Manufacturing project. The core

strategy of the project is referred to as a middle-

updown innovation. It means both bottom-up and

top-down innovations occur together by intensifying

competitiveness of middle sized companies. By

doing so, they lead improvement of technical power

of small sized companies by spreading out high-

level technologies and knowledge. They also have a

role to strengthen the relations between small and

big sized companies as a mediator between them.

Four main categories are included in the i-

Manufacturing project such as the development of

collaborative infrastructure, innovation in both

manufacturing process and system, and innovation

for developing brand-new products as illustrated in

Figure 3. Each category will be conducted as sub-

projects of the i-Manufacturing step by step, and the

project will be continued to 2015.

Syne rg y Ef f ec t s by

integrating product

lifecycle of mfg. companies

Development of

brand- new products

De v e l o p m e n t o f

Development of

brand

brand

-

-

new products

new products

y Center for providing experts,

tec hnologies, and enginee r ing

services to SMEs'

y Project year : 2011 ~ 2015

Informatization

(e- Manuf acturing)

Informatization

Inf o r mat izat io n

(e

(e

-

-

Manufacturing)

Manufacturing)

Virtual Enterprise Model Collabor ation Net works Mfg. Innovation Exper t s

information innovation intelligence

De s ig n

collaboration

De s ig n

collaboration

Qu a l i t y

collaboration

Quality

collaboration

Production

collaboration

Pro duction

collaboration

Mf g. Pro ce s s

Mfg. Proc e ss

Pr o c u r e m e n t /

Lo g i s t i c s

Pr o c u r e m e n t /

Lo g i s t i c s

y Co l l ab o r a t iv e PLM

y Adapting IT/UT to

manufact uring processes

y Sustainable mfg, etc.

y Project year : 2008 ~ 2015

Manuf ac t ur ing

Process

Manuf ac t ur ing

Manuf act ur ing

Process

Process

Integrated

Manufacturing

Integr ated

Manufacturing

y Highly distributed and intelligent

manufact ur ing system

y Self- reconf igurable

manufact ur ing system

y Project year : 2009 ~ 2015

Manuf ac t ur ing

Sys t em

Manufacturing

Manuf ac t ur ing

Sys t em

Sys t e m

automobile molds electronics machinery

y Development of collaboration

models and systems

y Project year : 2005 ~ 2015

Figure 3: Innovation categories in i-Manufacturing.

MODULARIZATION OF WEB-BASED COLLABORATION SYSTEMS FOR MANUFACTURING INNOVATION

175

3 COLLABORATION SYSTEMS

3.1 System Architecture

The collaboration systems have been independently

implemented according to their specific objectives.

As illustrated in Figure 1, we have developed

Design_Hub, Production_Hub, Blow_Hub,

Engineering_Hub and Automold_Hub until 2006.

All functions of the collaboration systems are

provided as a type of ASP (application service

provider) so that users can use them at anytime and

anywhere. For more details about collaboration

systems, refer to Ryu et al. 2007a and Ryu et al.

2007b.

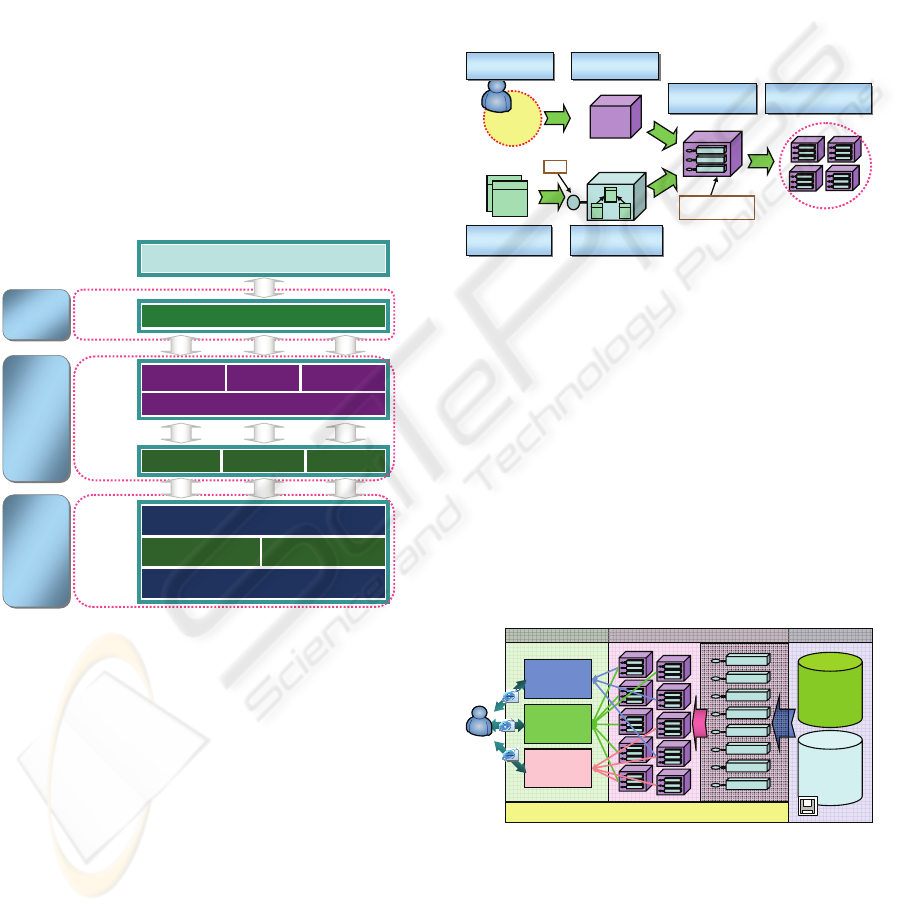

The architecture of collaboration systems

includes 3 layers – presentation, business, and data.

Note that the business layer consists of function and

service layers, and data layer includes OS, storage

and developer layers as illustrated in Figure 4.

Storage

Layer

OS

Function

Layer

Service

Layer

Presentation

Layer

Developer

Layer

Manager Library

Business

Transactions

Access

Control

Object-Relation

Mapping

Windows & Office Desktop with Browser

Client System

Windows Service

Directory, Security, etc

Web Storage System

Storage

SQL Server 2005

Storage

.Net Application Framework 2.0

ASP.Net 2.0, Web Controls, Web Services, CLR

Web Server (IIS 6.0)

Core Business

Library

Core Data

Library

Value Object

Library

Presentation

Presentation

Business

Business

Data &

Base

Environment

Data &

Base

Environment

Figure 4: System architecture of collaboration systems.

3.2 Modularization of Function

Modules

In order to apply collaboration systems already

developed into other companies as well as industrial

sections, it is very useful to implement main

functions into modules. This is because several

functions are essentially used by almost companies,

but some of them are not necessary on the other

hand. Following this idea, we now can develop a

new system very quickly by assembling function

modules previously developed like assembling

LEGO blocks. Additional implementations are also

needed if we cannot find the proper functions that

customers want.

To define and implement basic function modules,

we first gather customers needs (VoC; Voice of

Customers) and define services they want after

analyzing VoC as depicted in Figure 5. On the other

hand, unit function libraries are developed by

integrating unit classes and connecting API. In order

to realize services, we find proper function libraries

and merge them into a block, referred to as a unit

technology library. Then we are now ready to

develop a new collaboration system. After building

up specific user interface, we just connect several

technology libraries.

Class

Class

Class

Class

Class

API

Apply Unit

Function Libraries

Define Unit Class

Impl. of Basic Functions

Unit Function Library

Devl. Of Function Modules

Unit Technology I/F

Define Service

Unit Technology Lib.

Service Implementation

Set of Unit Technologies

Collaboration Systems

VoC

Acquisition of VoC

Analyze Customer Needs

Figure 5: Unit function modules and technology libraries.

From the view of aforementioned 3 layers, we

have integrated database and file repository in the

data layer as illustrated in Figure 6. There are many

kinds of function libraries in the function layers and

technology libraries in the service layer. In the

presentation layer, several UIs are implemented

according to business models of collaboration

systems. For example, if we have 10 collaboration

systems, then we already have 10 different basic UIs.

Every basic UI can be accommodated by each user if

he or she wants to use some functions of the system.

Most functions and services are implemented based

on .Net application framework 2.0.

i-Manufacturing

Integrated

Database

UI for Design

Collaboration

System

UI for Production

Collaboration

System

UI for Blow-mold

Collaboration

System

Presentation

Business Data

i-Manufacturing

Integrated

File Repository

.Net Application Framework 2.0

ASP .Net 2.0, Web Control s, Web Serv ices, CLR

User

Figure 6: Conceptual framework of collaboration systems.

3.3 Illustration of Functions and

Services in a Collaboration System

As described in Section 3.2, a collaboration system

consists of many services containing multi-function

modules. Among several collaboration systems,

ICEIS 2008 - International Conference on Enterprise Information Systems

176

Design_Hub is the system to support collaborative

design of molds by providing useful tools including

CAD conference, visualizer for 3D CAD drawings,

collaborative project manager, etc. As illustrated in

Figure 7, users of the Design_Hub wanted to use

functions such as collaboration supports between

customer and company, sales support, efficient data

and schedule management, monitoring of production

processes in real time, etc. Based on such VoC, we

defined many services including customer support,

sales support, data management, etc., and developed

function modules as depicted in Figure 7.

Design Collaboration

System Management

System Management

User Information Mgnt.

User Information Mgnt.

Partnershi p Mgnt.

Partnershi p Mgnt.

Information Center

Information Center

Web Log Mgt.

Web Log Mgt.

Standard Process Mgnt.

Standard Process Mgnt.

Standard Class Mgnt.

Standard Class Mgnt.

Unit Cost Management

Unit Cost Management

Standard Parts Mgnt.

Standard Parts Mgnt.

Facilities M anagement

Facilities M anagement

Work-templates Mgnt.

Work-templates Mgnt.

Process-templates Mgnt.

Process-templates Mgnt.

Part-templates Mgnt.

Part-templates Mgnt.

Reporting & Simulation

Reporting & Simulation

Message Management

Message Management

e-Mail

e-Mail

Electronic Distribution

Electronic Distribution

Printing Matter Mgnt.

Printing Matter Mgnt.

Order Management

Order Management

Estimates Management

Estimates Management

Try-out Management

Try-out Management

Measurement Mgnt.

Measurement Mgnt.

Project Management

Project Management

Document/Drawing Mgnt.

Document/Drawing Mgnt.

Parts Management

Parts Management

CAD Data Exchange

CAD Data Exchange

Production Schedule Mgnt.

Production Schedule Mgnt.

CAD Conference

CAD Conference

Work Assignment

Work Assignment

Process Results Mgnt.

Process Results Mgnt.

Change History Mgnt.

Change History Mgnt.

Progress Status

Progress Status

Issue Management

Issue Management

Failure Management

Failure Management

My Job Management

My Job Management

Module Service Service ModuleCollaboration Hub

Collaboration Supports

b/w Customer and Company

Collaboration Supports

b/w Customer and Company

Sales Support

Sales Support

Design and Technical Info.

management

Design and Technical Info.

management

Data Transfer & Sharing

Data Transfer & Sharing

Monitoring of

Manufacturing Process

Monitoring of

Manufacturing Process

Management of

Manufacturing Execution

Management of

Manufacturing Execution

Production Result Management

Production Result Management

Product oriented Integration

of Collaboration Projects

Product oriented Integration

of Collaboration Projects

System

Management

Company

Information

Projects

Management

Schedule

Management

Data

Management

Distribution

Management

Change

Management

Reporting &

Simulation

My Work

Manufacturing

Execution

Sales

Support

Customer

Support

Engineering

Conference

Global

Collaboration

Process Change Mgnt.

Process Change Mgnt.

Schedule Management

Schedule Management

Figure 7: Composition of functions and services in the

Design_Hub.

According to the user’s purpose for using the

system, function modules can be reorganized in each

service by them. Furthermore, users can choose

proper or modify services. Figure 8 shows the screen

shot of the page that user can modify UI, services,

and functions. By developing flexibly restructurable

systems, users can use them with higher satisfaction.

Se r vi ce La ye r

Function Layer

Presentation Layer

Figure 8: Menu management in collaboration systems.

4 CONCLUSIONS

Led by the Korean government, the i-Manufacturing

project creates new value for the manufacturing

industry through collaboration among companies.

Through the project, Korean companies have

overcome the limitations of time and space to carry

out seamless production with overseas facilities and

clients, and manage the entire production process in

real-time. By using the system, they can reduce

delivery time and enhance product quality. In the

case of a conglomerate composed of nine small and

medium sized companies using Production_Hub,

average delivery time for molds has been reduced

from 44.7 days in 2004 to 24.6 days in 2006. Their

net profit has also increased 369.6% from 270

million won to 1.27 billion.

To widely enlarge the application areas of

collaboration systems rapidly and easily, we define a

common platform with pre-defined services

containing basic function modules. With this system

architecture and platform, we are developing two

brand-new systems and restructuring Production_

Hub for new conglomerates.

The easiest way to raise competitiveness and

realize manufacturing innovation is to develop and

to provide collaboration infrastructure especially for

small and medium sized companies. However, lots

of novel technologies regarding manufacturing

processes and systems also have to be developed and

combined with infrastructure to achieve innovation.

The i-Manufacturing project, we hope, will be the

answer of manufacturing innovation in Korea.

ACKNOWLEDGEMENTS

This paper is supported by the i-Manufacturing

projects funded by the Ministry of Commerce,

Industry and Energy(MOCIE) of Korea. The authors

would like to thank for their support.

REFERENCES

Lee, J., 2003. e-Manufacturing – fundamental, tools, and

transformation, Robotics and Computer Integrated

Manufacturing, 19: 501-507.

Ryu, K., Lee, S., and Choi, H., 2007a. Strategies based on

collaboration for manufacturing innovation in Korea.

In 37

th

International Conferences on Computers and

Industrial Engineering. Egypt. 954-960.

Ryu, K., Lee, S., Hong, W., Lee, D., and Choi, H., 2007b.

Business Innovation via Collaboration. In ICEIS2007.

Portugal. 198-201.

MODULARIZATION OF WEB-BASED COLLABORATION SYSTEMS FOR MANUFACTURING INNOVATION

177