A SCALABLE AND OPEN SOURCE LINEAR POSITIONING

SYSTEM CONTROLLER

M. C. Medeiros, A. J. A. Fernandes, C. A. Teixeira and M. Grac¸a Ruano

Centre for Intelligent Systems, University of Algarve, Gambelas, Faro, Portugal

Keywords:

Automatic Positioning, Open Source Software, Scalable Systems, Ultrasound Measurements.

Abstract:

This paper is on the implementation of a dual axis positioning system controller. The system was designed

to be used for space-dependent ultrasound signal acquisition problems, such as pressure field mapping. The

work developed can be grouped in two main subjects: hardware and software. Each axis includes one stepper

motor connected to a driver circuit, which is then connected to a processing unit. The graphical user interface

is simple and clear for the user. The system resolution was computed as 127µm with an accuracy of 2.44µm.

Although the target application is ultrasound signal acquisition, the controller can be applied to other devices

that has up to four stepper motors. The application was developed as an open source software, thus it can be

used or changed to fit different purposes.

1 INTRODUCTION

In the scientific field precision is everything. A

scientist cannot conduct a responsible scientific expe-

riment if the precision of the process is not controlled.

Laboratory experiments involving ultrasound deals

normally with space-dependent parameters, such as

time-of-flight or pressure. Manual adjustment can in-

duce human errors, that can be eliminated by using

a reliable and automatic positioning system. In the

scientific community, the open-source software con-

cept is often referred. It refers to computer appli-

cations whose source code is available and under an

open-source license to study, change or tune the soft-

ware, and to redistribute in the modified or unmodi-

fied form.

This paper presents the necessary hardware and

software to control a linear positioning system. The

main application of this system is the acquisition of

space-dependent ultrasound signals. The developed

controller is an evolution to the system supplied by the

manufacturer. The proposed controller is supported

in Unix/Linux operating systems (OSs) and the con-

nection with the personal computer is accomplished

through an USB interface, instead of the nowadays

rare parallel port (Arrick Robotics, nd).

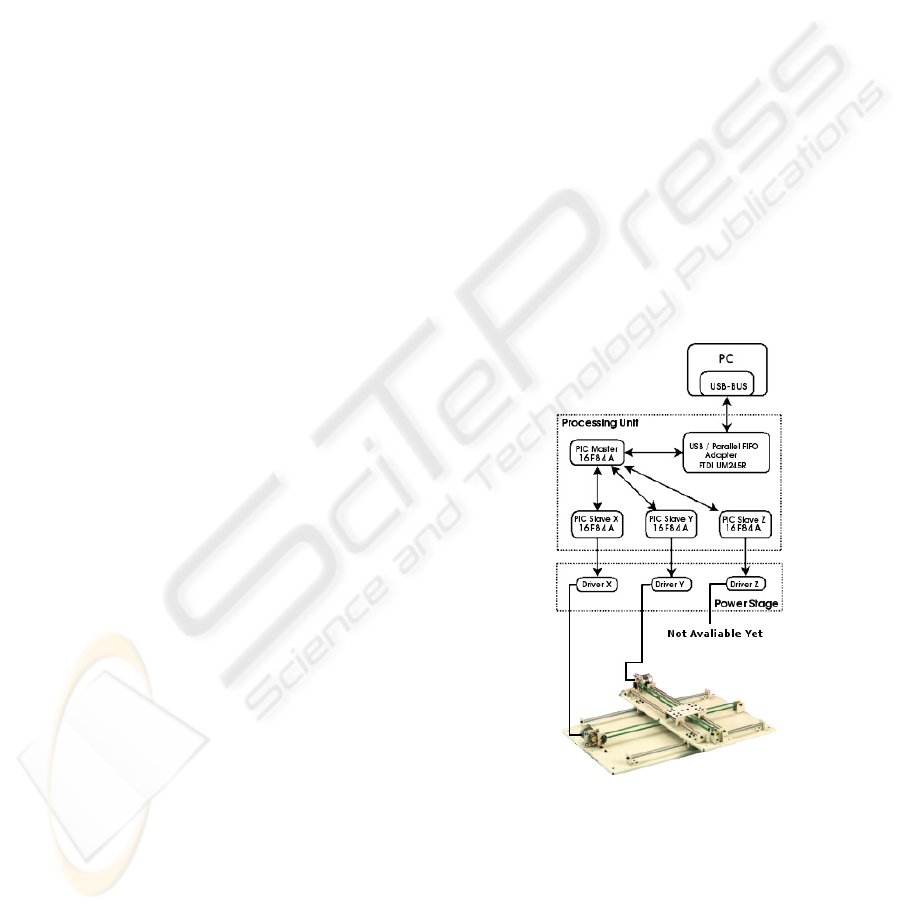

Figure 1: Hardware interconnection.

2 HARDWARE

A schematic representation of the overall hardware

used is presented in Figure 1.

The main part of this project is the positioning

table (Arrick robotics, model XY-18). This table

has two belt-driven axis with a moving range of

410

Medeiros M., Fernandes A., Teixeira C. and Ruano M. (2009).

A SCALABLE AND OPEN SOURCE LINEAR POSITIONING SYSTEM CONTROLLER.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 410-413

DOI: 10.5220/0001549804100413

Copyright

c

SciTePress

464.8 mm. Each axis includes a stepper motor

(Telcomotion, 4H5618C2906), which is responsible

for the automatic motion of a top plate (mobile point).

Each stepper motor has a resolution of 0.9 degrees per

step with an accuracy +/- 5%. The top plate is where

the load (transducers, hydrophones, or a third axis)

is to be attached. Each axis has two limit-switches,

which prevents from equipment damage and are also

reference points (Arrick Robotics, nd).

2.1 Power Stage

Between the Processing Unit (PU) and each mo-

tor there is a driver circuit, responsible to adapt the

current sent by the PU (in the range of mA) to a

current necessary (in the range of A) to move the

motor with high torque. To mention that all stepper

motors work in half-step mode (Yeadon and Yeadon,

2001).

2.2 Processing Unit

For the Processing Unit (PU) we used three microcon-

trollers PIC 16F84A (Microchip Technology, 2001)

from Microchip, to control both stepper motors.

One of the microcontrollers is called the PIC

Master (PICM), which receives orders from the PC.

The information from the PC to the PU is sent in a

group of 10 Bytes. The information transmitted is:

• target axis;

• direction;

• speed;

• number of steps;

• synchronization bytes.

After data processing the PICM starts the commu-

nication with the PIC Slaves (PICSs), that are

connected to the target stepper motors through the

driver circuit. Whenever a certain motor has to move

a step, PICM signals the corresponding PICS, which

only has to change the output pins state in order to

give a step.

If a switch (at the limits) is pressed, the PICS

that detected it, signals the PICM. When the move-

ment stops, the PICM sends a feedback byte to the

PC, on which it informs if the operation was or not

successful.

Whenever both stepper motors have to move the

same distance (same number of steps), they move at

the same time. Otherwise, only one motor moves at a

time.

The PU is designed to allow to control up to four

axis. The PICM has some pins that are not connected

to anything and can be used to add a new axis. If

the new axis don’t have any special requeriment, the

firmware of the PICSs will all be the same. This char-

acteristics makes our system scalable.

2.3 PC/PU interface

The interface between the PC and the PU is done

through a USB to parallel FIFO module (FTDI

UM245R) (FTDI Ltd, 2005), integrated in the PU.

The UM245R is a module with a lot of poten-

tial, since that it’s not needed to develop USB-specific

firmware to handle the USB protocol. Besides this,

it’s possible to communicate through a Synchronous

Bit Bang Mode that allows to keep a synchronous

communication.

3 SOFTWARE

The software for this project was developed in an

open source environment, so it can be used in other

applications that involves stepper motors.

In Unix/Linux environments as in others OS, the

hardware is controlled by specific programs called de-

vice drivers. In particular case of Linux, this pro-

grams can be loaded to kernel at run time, and they are

called kernel modules. With this modules it’s possi-

ble in user mode, to communicate with the hardware

without direct access, hiding all the low level func-

tions.

One of the requirements was to develop the soft-

ware as a Python module, to be integrated in other

Python programs (Teixeira et al., 2006). Since a func-

tional userspace library in C language and at the mo-

ment there isn’t any Python module for FTDI modu-

les for Linux, it was necessary to create a C Python

Extension (van Rossum, 2008). This enabled the in-

tegration of the necessary C code to control the linear

positioning table.

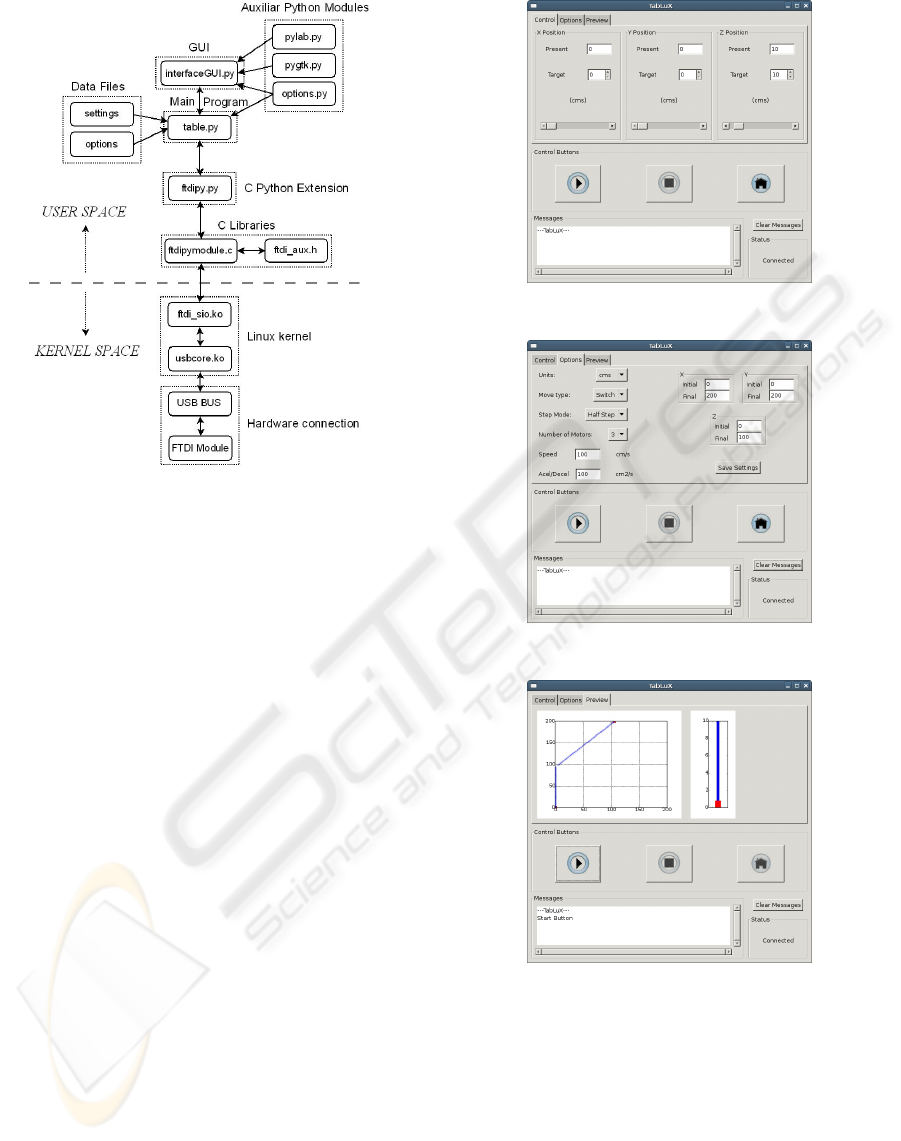

Figure 2 presents the software structure. The main

program is called table.py and implements a state ma-

chine that handles computer and user events. The

interfaceGUI.py file is responsible to create all the

graphical interface and the methods to access to all

the values that the user can change or configure. A

Python module called pylab included in matplotlib

library (Matplotlib Project, nd) was used to display

the motors movement. The options.py file includes

classes and methods for all the stepper motors op-

tions.

The session is saved in two data files, in order to

keep the data for next sessions. The options file has

the characteristics of each motor, and the settings file

A SCALABLE AND OPEN SOURCE LINEAR POSITIONING SYSTEM CONTROLLER

411

Figure 2: Software structure.

has the present positions of the motors after the move-

ment.

As mentioned before, in order to interface the C

libraries, a file named ftdipymodule.c was created as

an C Python Extension. This file is a wrapper between

C and Python languages.

4 GRAPHICAL USER

INTERFACE

The user interface was developed in GTK+, because

it’s portable, and his use with Python is easy with the

pygtk module (GNOME Project and PyGTK Team,

2006). The application front-end is presented in Fi-

gure 3.

We can define the amount of movement for each

motor or simply scroll the bar to the position, we can

also control the movement with the start, stop and

home buttons. In the messages box, it can be seen

a small report of what is happening, and check the

device status (connected or disconnected).

From the Options Tab (see Figure 4), its possible

to choose the metric units, move type, the step mode,

number of motors, speed, acceleration and the axis

size.

The output can be seen in Output Tab (see Figure

5), where it’s represented the table (X and Y axis) on

the left side, and a vertical bar (Z axis) on the right

side. When the top plate is moving the output is ge-

nerated according to the amount of movement.

Figure 3: Control tab.

Figure 4: Options tab.

Figure 5: Preview tab.

5 RESULTS & DISCUSSION

In order to determine how precise the system is, travel

distances for different number of steps were assessed

in order to verify how the system behaves. Six diffe-

rent number of steps were tested: 100, 200, 400,

600, 800 and 1000. For each one, ten measurements

(N = 10) were taken using a caliper ruler (accuracy

of 20 µm). The ratio between a measure (X) and the

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

412

number of steps (n), corresponds to the length of a

single step (X

N

). So, the mean (X

N

) of N values of

X

N

, is assumed to be a normalized mean and can be

computed by Equation 1.

X

N

=

∑

N

k=1

X

N

k

N

(1)

After the X

N

values of each test have been deter-

mined, their Standard Deviation (σ) can be computed

by Equations 2.

σ =

s

1

N − 1

N

∑

k=1

(X

N

k

− X

N

) (2)

The Variance (σ

2

) can easily be computed as the

positive square-root of σ.

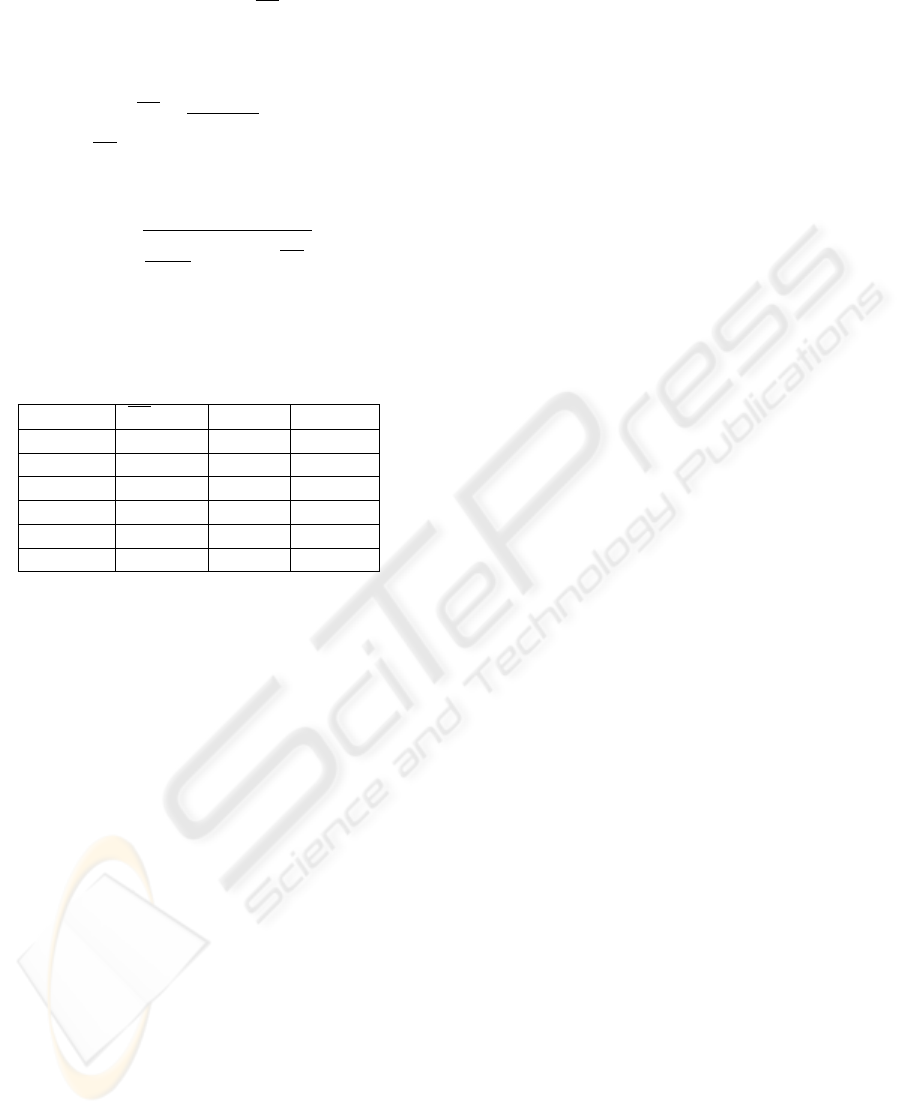

Table 1: Results.

n (steps) X

N

(µm) σ (µm) σ

2

(µm)

100 125.94 1.22 1.49

200 126.38 0.64 0.41

400 126.64 0.49 0.24

600 126.52 0.43 0.19

800 126.84 0.36 0.13

1000 126.76 0.23 0.05

From the values in Table 1, it can be seen that µ

presents a stable value on all the tests, with an accep-

table difference between them. Also, as the number

of steps increases, the values of σ and σ

2

decreases.

This happens becasuse of the initial inertia and im-

precisions of the system. The mechanical parts of the

table applies some forces to the system (belt has ten-

sion, top-plate has weight and the steel shafts have

friction) that will result in the resistance to a change

on its state of motion.

According to the data presented in Table 1, the re-

solution of each axis of the system can be defined has

127 µm. Due to the real application of the system,

small travel distances (n < 100 steps) will be often

used and the worst case (n = 100 steps) is used to de-

termine the accuracy value. For a 95 % confidence in-

terval (Normal distribuition) the accuracy is 2.44 µm

(2σ for n = 100 steps).

6 CONCLUSIONS & FUTURE

WORK

The system developed works as a linear positioning

system using step motors. It was created a hardware

driver in a modular way, which enables the addition

of a new axis easily. The software is open-source and

can be used and modified according to the user needs.

The motor movements have an acceptable resolution

and accuracy. The developed controller is an actu-

alized version of the system supplied with the linear

table. In the future this application can be used for ul-

trasound signal processing, and new improves can be

made, like operation in full-step mode and adding up

to four axis.

REFERENCES

Arrick Robotics (n.d.). X and XY Linear Positio-

ning Tables. Retrieved May 6, 2008, from

http://www.arrickrobotics.com.

FTDI Ltd (2005). UM245R USB-Parallel FIFO

Development Module. Retrieved from

http://www.ftdichip.com.

GNOME Project and PyGTK Team (2006). PyGTK:

GTK+ for Python. Retrieved May 12, 2008, from

http://www.pygtk.org/.

Matplotlib Project (n.d.). Matplotlib / pylab - matlab

style python plotting. Retrieved May 12, 2008, from

http://matplotlib.sourceforge.net.

Microchip Technology (2001). PIC16F84A Data Sheet. Re-

trieved from http://www.microchip.com.

Teixeira, C. A., Ruano, M. G., Ruano, A. E., and Pereira,

W. C. A. (2006). Open source data sensing software

for ultrasonic non-invasive temperature estimation. In

5

o

Congresso Ibero-Americano de Sensores - Ibersen-

sor 2006. Montevideo, 27-29 September. Uruguay.

van Rossum, G. (2008). Extending and Embedding the

Python Interpreter. Retrieved May 12, 2008, from

http://www.python.org.

Yeadon, W. H. and Yeadon, A. W. (2001). Handbook of

small electric motors. McGraw-Hill Professional.

A SCALABLE AND OPEN SOURCE LINEAR POSITIONING SYSTEM CONTROLLER

413