MESOTHERAPY DEVICE FOR ESTHETIC APPLICATIONS

M. S. Martins

1

, V. M. G. Correia

2

, J. G. Rocha

3

Industrial Electronics Department, University of Minho, Campus de Azurém, 4800-058 Guimarães, Portugal

J. M. Cabral

Industrial Electronics Department, University of Minho, Campus de Azurém, 4800-058 Guimarães, Portugal

Keywords: Mesotherapy, Galvanic current, Step-Up circuit, Master-Slave Architecture, Microcontroller, H-Bridge,

PWM, CPU

Abstract: This article describes a complete system prototype to be used in aesthetic mesotherapy. The system is

composed by two main blocks: a Master block, whose chief component is a CPU, which provides the user

interface and a Slave block, implemented with a micro controller and a wave generator, which produces the

appropriated voltages and currents compatible with the mesotherapy treatments. The whole system is

powered by a 12V power supply and the output signal has a voltage that range between -54 V and 54 V. The

output signal is composed by the overlap of two frequencies: the first one is selected in the range from 1.2

kHz to 1.8 kHz and the second one is in the range from 0.07 Hz to 2 Hz. The system is being tested in

clinical environment with real patients showing very good promising results.

1 INTRODUCTION

Mesotherapy is a non-surgical cosmetic medicine

treatment that employs multiple injections of

pharmaceutical and homeopathic medications, plant

extracts, vitamins, and other ingredients into the

subcutaneous fat. Mesotherapy injections are

purported to target adipose fat cells, apparently by

inducing rupture and cell death among adipocytes.

(Tosti, 2007).

Mesotherapy has presented new opportunities in

aesthetic medicine because it is a non-evasive

treatment capable of reducing cellulite and weight

(Ward, 2002). Into these two capabilities are also

included protocols like Cellulite, Obesity, Facial and

Body Contouring. Besides these applications, the

mesotherapy can be applied in other treatments such

as acne, arthritis, sports injuries, ulcers, vein

treatments and rheumatology.

In this article we report some aspects of the

design and fabrication of a device prototype that

allows mesotherapic treatments. These treatments,

based on different layers of skin, are able to reach

9cm of depth (e.g. hypoderm or fat most affected

area).

The basic working principle of the device

consists on a set of electrical pulses that are applied

on the skin surface, through two treatment

electrodes: a roll-on, used as active electrode, and a

glove, used as return electrode, originating two

reactions:

Expansion of the cell pores and epidermis

alignment, as shown in figure 1;

The electric field attracts the cream molecules

into the skin. The cream can be positively or

negatively charged, as shown in figure 2.

Figure 1: Transcellular and intercellular routes of

treatment cream through the lipid matrix.

256

Martins M., Correia V., Rocha J. and Cabral J. (2009).

MESOTHERAPY DEVICE FOR ESTHETIC APPLICATIONS.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 256-261

DOI: 10.5220/0001551802560261

Copyright

c

SciTePress

The main objective of this project is the

development of a device prototype capable to

perform the treatments referred above. In order to do

that, it is necessary to:

Develop a programmable signal generator;

Due to practical issues the system supply

voltage cannot exceed 12V, while the output

signal may contain peaks that reach 54V;

Develop the appropriate safeguards to avoid

patients injuries;

Develop a user-friendly interface to be used by

technical personal without expertise on

electronics and informatics;

Develop a flexible system able to introduce

new types of treatments without hardware

upgrades;

Develop a system capable to report any type of

anomaly;

Develop a system able to work 24h/7day.

Figure 2: Electric field generated by the electrodes It is

visible the response of cream particles along the

hypoderm.

2 BACKGROUND

This project is being funded by several companies

and its main goal is to develop an hardware

prototype capable of performing mesotherapy,

reducing the technical expertise needed in treatments

handling. On the other hand, it is possible to expand

the functionalities of this prototype in order to

achieve other treatments in the area of

electrotherapy, without the need of adding new

hardware components.

With the support provided by ISAVE University

(ISAVE, 2008) we have been able to incorporate all

the information required to produce the proper

signals required to generate other therapy types of

currents:

Galvanic Currents;

Russian Electrical Simulation (Ward and

Shkuratova, 2002);

Transcutaneous Electrical Simulation;

Iontophoresis Current (Carter, 2003);

Pain-Free Currents (Johnson, 2003);

Electroforoporation Currents;

Thus, despite the development of this prototype

was targeted for aesthetic medicine, it can also

achieve other types of treatments since the platform

accepts other signals by changing only a few setup

parameters.

Electronic devices applied on esthetical medicine

must have a huge factor of accuracy and quality,

mostly the ones that are in direct contact with the

patient, leaving no space for errors.

In the past, all the options taken in the

development of these devices are mainly related

with the chosen materials and the methods that were

used to maximize perfection, quality, reliability and

performance.

In order to achieve the best results during a

treatment, the equipments must guaranty a clear and

precise signal output with a perfect repetition and

very low error tolerance.

In the esthetical medicine area there are different

types of treatments which can be held as a resource

of mesotherapy:

Anticellulite;

Located anticellulite;

Antistretch;

Antiflaccidity.

Each type of treatment needs a special signal

with a polarity, which may be positive or negative,

depending on the cream used. In all treatments the

applied signals obeyed to eq. 1:

SIGNAL = ((HF * LF) + LF)

(1)

where HF is the high frequency component,

whose value ranges between 1.2kHz and 1.8kHz,

and LF is the low frequency component, whose

frequency ranges from 0.07Hz to 2Hz (its period

ranges between 0.5 and 14 seconds).

Galvanic current is the base of this treatment. It

always circulates in the same direction (the voltage

is always positive or is always negative), once each

cream has its own polarity. Therefore the system

must guarantee this characteristic for the generated

voltage, that is, the system must follow the

algorithm:

Positive Polarity:

If ((HF * LF) + LF) < 0

MESOTHERAPY DEVICE FOR ESTHETIC APPLICATIONS

257

then SIGNAL=0

Else

SIGNAL = (HF * LF) + LF

Negative Polarity:

If ((HF * LF) + LF) > 0

then SIGNAL=0

Else

SIGNAL = (HF * LF) + LF

3 SYSTEM ARCHITECTURE

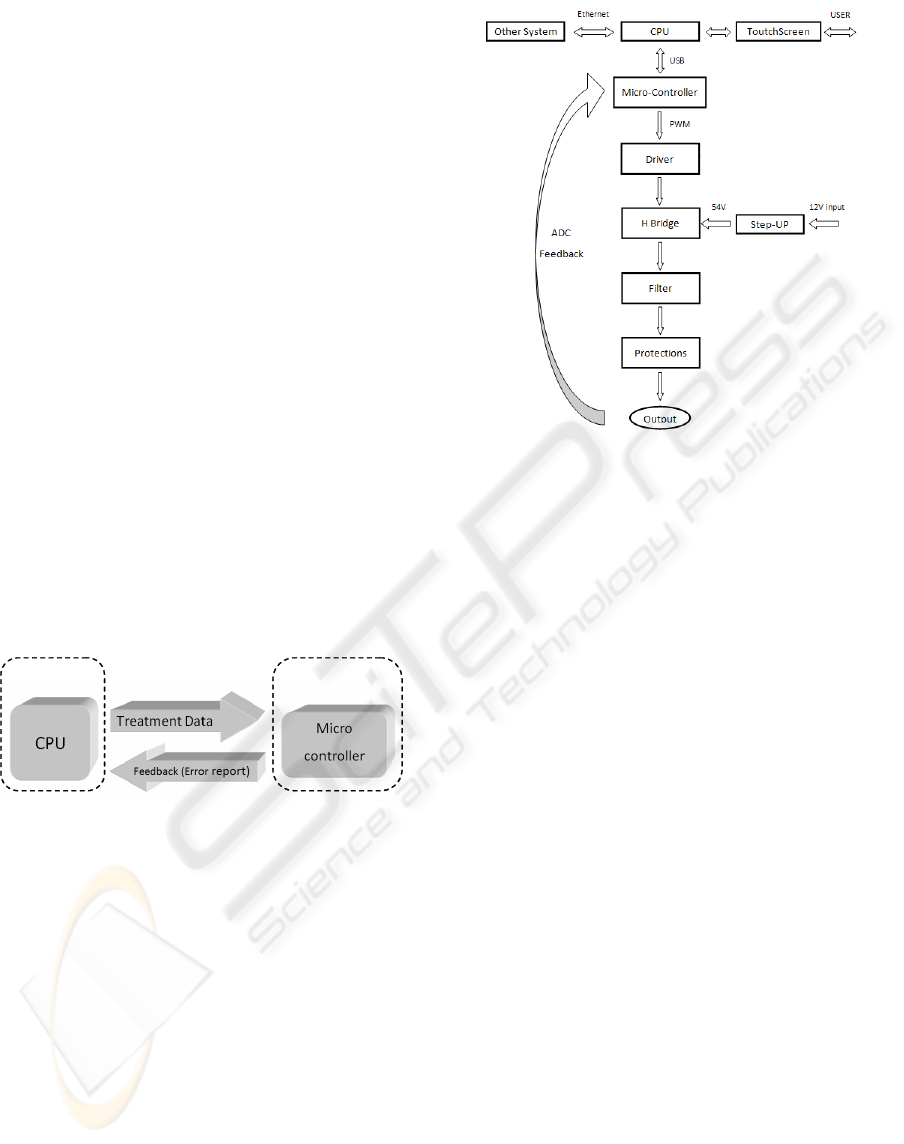

The general system architecture proposed in this

paper is a master-slave structure since there are two

control units: a high-level control unit (master) and a

low-level control unit (slave).

The high-level control unit or central processing

unit (CPU) is responsible for supporting the user

interface: exchanging and processing the necessary

information between the user and the low-level

control unit. The low-level control unit, whose main

component is a micro controller, is responsible to

convert digital data, received from the high-level, to

analogical signals that are applied directly to the

patient skin, through the connection devices.

Figure 3 shows the system architecture.

Maste

r

Slave

Figure 3: System architecture. The CPU operates as

master and the micro controller operates as slave. The

micro controller functionalities are controlled by the CPU.

Despite the system is of master-slave type, a

feedback from the output to the micro controller is

used in order to allow the detection of some

malfunctions.

The Master block is composed by a processor

unit, a touch-screen and an Ethernet interface, while

the Slave block is constituted by a micro controller,

a step-up converter, a driver, an H-bridge, a filter

and the patient’s protection circuit. Both blocks

communicate by means of an USB interface.

The following paragraphs describe, in detail, the

most important functions shown in figure 4.

Figure 4: Block Diagram of the device internal structure

and the links between the various sub-systems.

The CPU is the head of the system, responsible

for gather all the data, coming from the user-

interface console, process it and calculate the

appropriated coefficient vector that will be used by

the micro controller to produce the corresponding

output signal with a PWM (Pulse Width

Modulation).

If we consider that the technical personal do not

have expertise in informatics and electronics

technologies, it is important to provide an intuitive

graphical interface. For this purpose, it was used a

touch-screen monitor to operate the device in an

intuitive way. The programming language used was

C++, associated to an Open GL platform in order to

satisfy several requirements, namely the real time

operation, the support for micro controller systems

and the attainment of the maximum graphic

potentialities of the system.

It is important to refer that this platform is based

on a Linux operating system, due its great

potentialities for real time operation associated with

the advantage that it is a free software, making

easier and cheaper the system commercialization.

Another particular feature is the system

dynamism, which enables firmware upgrades and

interconnection with other devices in order to allow

a huge range of treatments.

All interconnections between CPU and other

functional blocks are bidirectional, allowing a

continuous feedback that enable instantaneous

detection of any anomaly.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

258

The micro controller is responsible for

assembling the information, sent by the CPU, in

order to drive the H-Bridge. It calculates the PWM

ON / OFF times, generating the desired signal to the

system output.

The micro controller uses an 8MHz crystal. In

order to generate a PWM signal that does not reach

frequencies higher than 30kHz, the sampling

frequency used by the micro controller is about 17

times higher than the frequency of the output signal

to ensure a low ripple at the filter output.

An AT90USB1287 low-power CMOS 8-bit

micro controller was used (Johnson and Tabasam,

2003), based on the AVR with 64/128K bytes of ISP

Flash and an USB device controller with full speed

and low speed data transfer support, enhanced RISC

architecture. By executing powerful instructions in a

single clock cycle, the AT90USB1287 achieves

throughputs approaching 1MIPS per MHz allowing

the system designer to optimize power consumption

versus processing speed.

The interface between master and slave blocks is

achieved by means of a USB connection due to is

large bandwidth and Plug and Play interoperability.

A full-duplex low speed (1.5Mbit/s) data rate

connection is used that guarantees up to 512kbit/s of

bandwidth in each direction.

The Bus topology used is the Reduced Host

Topology showed in figure 5 (Atmel, 2007).

Figure 5: Reduced Host Topology. A reduced host

controller has a unique USB port and does not handle full

USB tree with hub. It means that a reduced host controller

is designed to handle a unique point-to-point connection

with an unique USB device.

Its main characteristics are:

USB Host:

There is only one host in any USB system, and

it operates as the “master” of the USB bus;

The USB interface to the host system is referred

to as the Host Controller.

USB Device:

An USB device operates as a slave node on the

USB bus;

Thanks to the USB hub (that also operates as an

USB device) up to 127 devices can be

connected on the USB bus. Each device is

uniquely identified by a device address.

It would be only necessary to implement a more

elaborated connection topology if the micro

controller interacts with more than one device

because it would be necessary to guarantee that it

communicates with the correct device. As this

system is composed by just one device, the use of

the simplified topology facilitates the

implementation of the connection between the CPU

and the micro controller.

The micro controller output signal produces a

peak voltage of 3.3V. To manage an effective

treatment it is necessary to amplify this signal to

higher levels, such as 54V. To carry out this task it

was implemented an H-bridge with two quadrants,

allowing the change of the signal output polarity

according to the corresponding treatment. The H-

Bridge was implemented by means of L6225 DMOS

Dual Full Bridge chip which combines isolated

DMOS Power Transistors with CMOS and bipolar

circuits on the same chip (STMicroelectronics,

2007). Figure 6 shows the schematic diagram of this

circuit.

Figure 6: H-Bridge circuit based on BCD technology.

Combines isolated DMOS Power Transistors with CMOS

and bipolar circuits on the same chip.

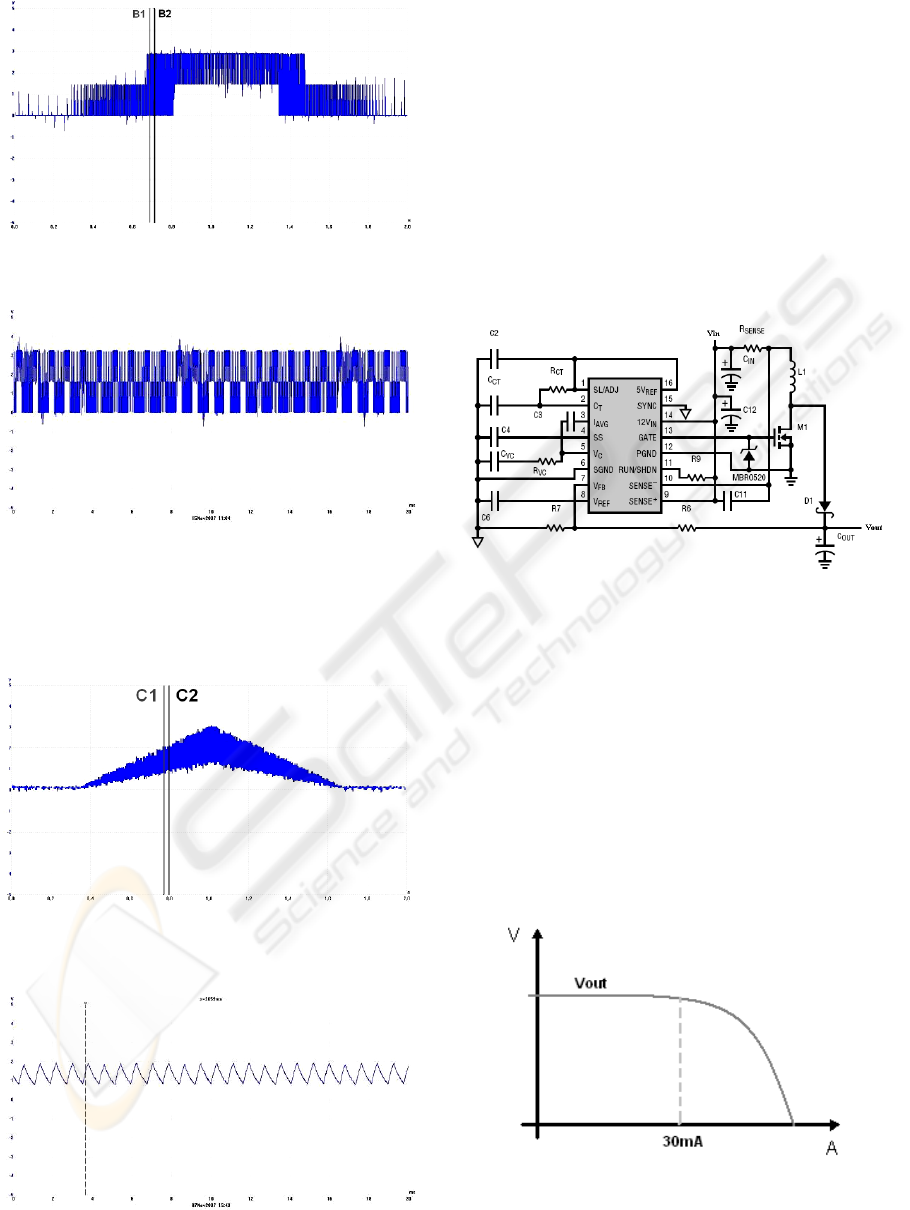

The signal output is a sum of two components: a

low frequency of 0.07Hz (Period = 14s) and a high

frequency of 1.8kHz. A low-pass active filter, with a

Q factor of 2, and a cut-off frequency of 2kHz were

used. Thus the filter output no longer presents the

high frequency components, produced by the PWM

modulator, and all variations of the sign are

smoothed. Figure 7 shows the output waveform of

the PWM modulator. Figure 8 depicts a time

expansion between B1 and B2 bars of figure 7.

MESOTHERAPY DEVICE FOR ESTHETIC APPLICATIONS

259

Figure 7: Signal obtained at the output of the H-Bridge

circuit, with 2s in time axis and 5V in voltage axis.

Figure 8: Signal of figure 7, expanded with 20ms between

B1 and B2 bars.

Figure 9 shows the low pass filter response. Figure

10 depicts a time expansion between C1 and C2 bars

of figure 9

.

Figure 9: Signal obtained at the system output. It

corresponds to the signal of Fig. 8 be low-pass filtered,

with 2s in time axis and 5V in voltage axis.

Figure 10: Signal Signal of figure 9, expanded with 20ms

between B1 and B2 bars.

Standard requirements (RSIUEE, 1974),

imposed on medical equipment, does not allow that

the power system, responsible for generating

treatment signals, have input voltages higher than

12V. Nevertheless, to obtain the expected results,

the signal output must produce peaks of 54V. This

task is achieved by means of a step-up circuit which

provides up to 54V linear voltage with small ripple

and 500mA of maximum current. In the present

application the current can not exceed 50mA. The

step-up circuit is implemented with the LT1680

(Linear Technology, 2007) whose schematic

diagram is shown in figure 11.

Figure 11: Step-Up circuit. High power, current mode

switching power supply controller optimized for boost

topologies. The IC drives an N-channel MOSFET switch

for DC/DC converter up to 60V output.

All equipment must obey to security rules

imposed by responsible entities. Therefore, in

addition to the main objective, that is, the

mesotherapic equipment development, we have also

to ensure the safety of the patient. In this way, it was

introduced a current limiter before the signal output.

When the current reaches higher values than 30mA,

the circuit output voltage is lowered, as it is shown

in figure 12.

Figure 12: Output voltage versus current. For currents

above 30mA the system protection responds by reducing

the output voltage.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

260

4 PROTOTYPE

To conduct the necessary system tests, a prototype

was built where the methodology described in this

article was implemented. This prototype is now

being used in the aesthetics mesotherapy treatments

in order to get a functionality and efficiency

diagnosis of the device. Therefore, it is necessary

that this prototype show the full potentialities of the

system but also show simple and functional user-

interface to simplify the use by the technical

personal. Figures 13 and 14 show some pictures of

the prototype.

Figure 13: Device internal circuits.

Figure 14: Device external appearance.

5 CONCLUSIONS

This article described a complete system prototype

for use in aesthetic mesotherapy. The system is

composed by a master-slave architecture in which

the master block is based on a CPU and the slave

block is based on a micro controller. The first

system prototype is already tested and fabricated in

laboratory conditions with performances that

correspond to the expected ones. It was also tested in

a clinical environment, with real patients. The results

of these tests are more or less subjective once consist

on the opinion of the technicians and patients, but

almost all consider the performance of the prototype

as good or very good. As a future work, the

prototype software will be adapted to perform

lymphatic draining or muscle stimulation treatments.

ACKNOWLEDGEMENTS

The authors would like to thank Doctor Cláudio

Javier Martinez Leon, who helps the authors in

understanding aesthetics mesotherapy treatments

fundamentals.

REFERENCES

A. Tosti, M. Pia De Padova, "Atlas of Mesotherapy in

Skin Rejuvenation", Informa Healthcare, United

Kingdom 1 September 2007.

ISAVE Website, “http://www.isave.edu.pt”.

Carter R. Anderson, Russell L Morris, Stephen D Boeh,

Peter C Panus, Walter L Sembrowich, “Effects of

Iontophoresis Current Magnitude and Duration on

Dexamethasone Deposition and Localized Drug

Retention”, Physical Therapy. Volume 83. Number 2.

February 2003.

Charles Godbout, Jérôme Frenette, “Periodic Direct

Current Does Not Promote Wound Closure in an In

Vitro Dynamic Model of Cell Migration”, Physical

Therapy. Volume 86. Number 1. January 2006.

Mark I. Johnson, Ghazala Tabasam, “An Investigation

Into the Analgesic Effects of Interferential Currents

and Transcutaneous Electrical Nerve Stimulation on

Experimentally Induced Ischemic Pain in Otherwise

Pain-Free Volunteers”, Physical Therapy. Volume 83.

Number 3. March 2003.

Alex R. Ward, Nataliya Shkuratova, “Russian Electrical

Stimulation”, Physical Therapy. Volume 82. Number

10. October 2002.

S. Madhere, "Aesthetic Mesotherapy and Injection

Lipolysis in Clinical Practice", Taylor & Francis Ltd,

United Kingdom 15 June 2006.

Atmel Corporation 2007 - Microcontroller at90USB1287,

http://www.atmel.com/dyn/resources/prod_documents

/doc7593.pdf.

STMicroelectronics 2007 - DMOS Dual Full Bridge

Driver L6225, http://www.st.com/stonline/products/

literature/ds/9451.pdf.

Decreto-Lei nº 740/74 Artº 598º Protecção contra

contactos indirectos, Regulamento de Segurança de

Instalações de Utilização de Energia Eléctrica

(RSIUEE), December 1974, Portugal.

Linear Technology 2007 - High Power DC/DC Step-Up

Controller LT1680,

http://www.linear.com/pc/downloadDocument.do?navId=

H0,C1,C1003,C1042,C1031,C1115,P1597,D1509

MESOTHERAPY DEVICE FOR ESTHETIC APPLICATIONS

261