IMPROVING SURFACE ENERGY AND HYDROPHILIZATION

OF POLY(ETHYLENE TEREPHTHALATE)

BY ENZYMATIC TREATMENTS

Isabel C. Gouveia

1,3*

, Laura C. Antunes

3

and João A. Queiroz

2,3

1

Departamento C.T. Têxteis,

2

Departamento Química,

3

R&D Materiais Têxteis e Papeleiros

Universidade da Beira Interior, 6201-001 Covilhã, Portugal

Keywords: Poly(ethylene terephtalate), Enzymatic treatment, Contact angle, Surface energy, Hydrophilicity, Esterases,

Lipases, Adhesion.

Abstract: In order to increase the hydrophilicity and adhesion of poly (ethylene terephthalate) (PET) fabrics it was

studied the action of three types of enzymes (Texazym PES sp5, Aspergillus niger and Aspergillus oryzae)

applied at different incubation times and concentrations. This processes aims to modify morphologically

and chemically the superficial structure of the polymeric materials (PET), forming new carboxyl, hydroxyl

and other polar groups at the surface, in order to increase adhesion and hydrophilicity. The increase in the

hydrophilicity of the fabric was evaluated by measuring the contact angle being the best results obtained for

the Texazym PES (87.45º), much smaller than the non-treated fabric (122.95º); and by the wicking height,

which revealed an important improvement in the hydrophilicity. The formation of carboxyl and hydroxyl

groups was evaluated by a staining procedure with a cationic and reactive dye, respectively. It was also

confirmed by the increasing in the polar component of the surface energy, determined by the Qwens-Wendt

method. The higher surface energy and thus, the higher adhesion properties, were obtained for the esterase

Texazym, using 0.12U during 90 minutes. The surface morphology of the non-enzymatic-treated and

enzymatic-treated samples was analyzed by scanning electron microscopy (SEM) showing no degradation

of fibers treated under the selected optimum conditions. In contrary, this method showed an important

surface cleaning action by removing some undesirable polyester oligomers.

1 INTRODUCTION

Advances of biotechnology in textile industry have

brought new products and processes for specialty

applications as for instance in biomedical materials.

Polymers and textiles are usually used as films

and foils for packaging, protective coating, material

for biomedical and sealing applications because of

their superior bulk properties, such as transparency,

high resistance, strength, good thermal resistance,

etc. But these excellent characteristics are often

unsuitable for biomedical applications due to their

low surface energies. Therefore, surface treatments

are usually necessary to improve surface wetting and

adhesion properties (Inagaki et al, 2001), (Yang and

Gupta, 2004), (Guebitz and Cavaco-Paulo, 2008),

(Huemann et al, 2006).

The synthetic fibers, in particular, polyester

made from poly(ethylene terephthalate), (PET) have

a reduced number of polar groups (hydroxyl and

carboxyl groups) capable to establish hydrogen

bonds with water, reflecting in its weak capacity to

absorb water also related to its high degree of

cristalinity. This property can be changed appealing

to chemical methods as, for example, the alkaline

treatment. This method can, however, damage not

only to the fibers but can also be harmful to the

environment. In this way, alternative processes,

simultaneously ecological, efficient and safe, have

been studied.

Earlier studies demonstrated that the application

of lipases, cutinases and esterases to synthetic fibers,

help increasing hydrophilicity through the hydrolysis

of ester bonds, under moderate conditions (low

concentration and low reaction time at room

temperature), accompanied by a slight reduction of

the resistance to rupture and weight loss

(Vertommen et al, 2005), (Heumann et al, 2006).

Several studies of enzymatic treatments have

been proposed in order to modify the surface

properties of polymers such as adhesivity,

268

Gouveia I., Antunes L. and Queiroz J. (2009).

IMPROVING SURFACE ENERGY AND HYDROPHILIZATION OF POLY(ETHYLENE TEREPHTHALATE) BY ENZYMATIC TREATMENTS.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 268-275

DOI: 10.5220/0001552102680275

Copyright

c

SciTePress

hydrophobicity, oleophobicity, wettability/

hydrophilicity, pilling and static charges, by

hydrolysing polymers without affecting the bulk

properties, having the advantage of being eco-

friendly compared with conventional chemical

treatments (Guebitz and Cavaco-Paulo, 2008),

(Heumann et al, 2006), (Vertommen et al, 2005).

Other authors (Heish and Cram, 1998) confirmed

that the increasing of the hydrophilicity after

modification of polyester with lipases was superior

to the one achieved with conventional chemical

treatments (alkaline treatment: 3N of NaOH during 2

hours).

Our new approach focus on the surface

modification of PET fabrics by enzymatic treatments

using three different enzymes (Texazym PES and

Aspergillus niger, Aspergillus oryzae, respectively),

in order to form new polar groups (carboxyl and

hydroxyl) at the surface, capable to establish

hydrogen bonds with water and capable to improve

surface adhesion. The study was undertaken to

analyze and compare the effect of enzymatic

treatments applied in a textile material (100% PET

fabric), by studying the morphological and chemical

changes at the surface, the mechanical properties

and surface energy, in order to establish whether or

not the material can be functionalized and its surface

adhesion properties can be improved.

2 EXPERIMENTAL

The enzymatic treatment aims to improve the

hydrophilicity without harming the mechanical

properties of the material. For that purpose, it was

investigated a new approach by studying the effect

of the three types of enzymes, esterases and lipases

(Texazym PES sp5, Aspergillus niger and

Aspergillus oryzae), varying the incubation time and

the enzyme concentration.

The chemical modifications were investigated by

measuring the contact angle and the wicking height.

The indirect determination of the formed carboxyl

and hydroxyl groups was measured by staining with

a cationic dye (Methylene Blue) and a reactive dye

(Reactive Black 5), respectively, and by measuring

the surface energy by the Owens-Wendt method.

The surface morphological changes were analyzed

by scanning electron microscopy (SEM).

2.1 Materials

The substrate (textile material) used in this work was

a 100% poly (ethylene terephthalate)

fabric, Batavia

Twill, with the characteristics indicated in Table 1.

The substrate was pre-washed with 1 g/L Plurafac

LF 400, at 50ºC during 60 minutes, with mild

mechanical agitation (25 rpm). Subsequently, the

substrate was rinsed and washed under running

water, followed by a thermofixation at 170ºC during

15 minutes.

2.2 The Enzymes

The enzymes selected for this study, were an

esterase (Texazym PES sp 5 from inoTEX Ltd.) and

two lipases (Aspergillus niger and Aspergillus

oryzae from Sigma). These enzymes were applied

according to the literature reviewed under the

conditions of pH and temperature indicated by the

manufacturer. In Table 2 are presented the principal

characteristics of the enzymes used.

It was studied the action of Texazym PES,

Aspergillus oryzae and Aspergillus niger, applied at

different concentrations (0.06, 0.09, 0.12, 0.15 and

0.18 U) and different incubation times (30, 60, 90

minutes and 24 hours) with a liquor ratio of 1:25.

The enzymatic treatments with Texazym were

performed at 30ºC, using 50 mM of sodium acetate

buffer solution (pH 5.5). The enzymatic treatments

with Aspergillus niger and Aspergillus oryzae were

performed by incubating 2 g of polyester fabric at

45ºC and 40ºC, using 50 mM phosphate buffer (pH

7.0).

Immediately before and after treatments all

samples were placed in a standard atmosphere

(

20 ± 2º C, 65% HR) during 24±2 hours.

Table 1: Fabric characterization.

Characterization Test Method Value

Warp direction

Linear Mass (Tex)

Density

(Yarns/cm)

Diameter (Den)

NP – 4105

NP – EN

1049-2

NP – 3160

48.47

21.4

3.3

Weft direction

Linear Mass (Tex)

Density

(Yarns/cm)

Diameter (Den)

NP – 4105

NP – EN

1049-2

NP – 3160

36.67

32

3.3

Weaving

construction

Mass per area

(g/m

2

)

Composition

NP EN 1700

NP EN 1701

NP EN 1808.

2247 and

2248

Batavia twill

211.65

100%

Polyester

IMPROVING SURFACE ENERGY AND HYDROPHILIZATION OF POLY(ETHYLENE TEREPHTHALATE) BY

ENZYMATIC TREATMENTS

269

2.3 The Dyes

The dyes were selected to fulfill the objectives

focalized on assessing the number of hydroxyl and

carboxyl groups.

Therefore, a reactive dye Remazol Black B (C.I.

Reactive black 5, from DyStar) and a cationic dye

(Methylene blue, from Sigma-Aldrivh) were

selected. The reason for this choice is essentially the

ability to establish bonds with hydroxyl and

carboxyl end groups in the polyester fabric,

respectively.

Table 2: Characterization of the enzymes.

Texazym PES

sp 5

Aspergillus

o.

Aspergillus

n.

pH Optimal 5.5 7.0 7.0

Temp. (º) 30 40 45

Origin Thermobifida

fusca

Aspergillus

oryzae

Aspergillus

niger

Activity 0.6 U/ml 50 U/mg 4 U/g

2.4 Evaluation of the Effectiveness

of the Enzymatic Treatments

2.4.1 Determination of the Contact Angle

and Surface Energy Estimation

The Dataphysics is composed by a camera, a

computer and a monitor which are used to measure

the contact angle on the samples. Liquid drops were

dispersed on each fabric sample using a micrometer

pipette. The image of each drop was captured by the

camera connected to a computer, and the captured

images were viewed at the monitor. The standard

testing methods were according to Tappi T 558 pm-

95. The liquid used in the experiment was glycerol

and a drop of 5 µl was deposited on the fabric

surface and the contact angles were measured. The

measurements were performed, after one week since

enzymatic application, were repeated eight times and

the average was calculated. Afterwards, surface

energies were determined according to the Owens-

Wendt approach (Owens and Wendt. 1969). This

method takes into account the dispersive and polar

components of the surface energy. Using different

test liquids, in this case water and glycerol, it is

possible to calculate the solid surface energy as the

sum of the polar and dispersive contributions.

Constant values for the test liquids used for contact

angle measurements are as follows:

Water: γ = 72.8 mJ/m

2

; γ

s

d

= 21.8 mJ/m

2

; γ

s

p

= 51.0

mJ/m

2

;

Glycerol: γ = 64.0 mJ/m

2

; γ

s

d

= 34.0 mJ/m

2

; γ

s

p

=

30.0 mJ/m

2

.

2.4.2 Wicking Rate

The determination of the wicking rate by measuring

the rising height was according to DIN 53924

vertical wicking tests and performed after one week

since the enzymatic application. Samples of 3cm ×

10 cm were prepared and were suspended in a

standard atmosphere (20 ± 2º C. 65% HR) for 24±2

hours. The samples were then placed in a solution

0.05 % w.o.f. of dye (Methylene Blue), and

immersed at a height of 1 cm. After 10 minutes the

samples were removed and the rinsing height was

measured up. It was used a solution of dye instead of

water to facilitate the reading and the measurement

of the rinsing height.

2.4.3 Determination of Carboxyl End

Groups

The carboxyl end groups were determinate after

dyeing the samples at 50º C with a cationic dye

(Methylene Blue. 0.5 % (w.o.f.)) during 20 minutes.

Subsequently, the samples were washed in hot and

cold water and then dried in an oven at 40º C during

24 hours. The dyed samples were analyzed in a

reflectance measuring apparatus (Spectraflash 300

Datacolor, LAV/Spec. Incl., d/8. D65/10º). This

procedure aims to evaluate the increase or decrease

in the intensity of color (by determining the value of

K/S), in order to evaluate the formation of carboxyl

groups. The relative color strength (K/S values)

were established according to the Kubelka-Munk

equation (1), where K and S stands for the

absorption and scattering coefficients and R stands

for the reflectance value, respectively (Shah and

Gandhi, 1990; Pandiyaraj and Selvaranjan, 2008):

(

)

R

R

S

K

2

1

2

−

=

(1)

An increase in the value of K/S, when compared

to the non-treated sample, indicates an increase of

carboxyl groups known to react with this type of

dye.

2.4.4 Determination of Hydroxyl End

Groups

The hydroxyl end groups in the non-treated and

treated samples were determinate by a dyeing

procedure performed at 60º C with a reactive dye

(Remazol Black B) during 90 minutes. The dye bath

contains 2% w.o.f. of dye, 20 mg.ml

-1

of Na

2

CO

3

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

270

and 60 mg.ml

-1

of Na

2

SO

4

, pH 11, with a liquor ratio

1:100 and a mechanical agitation of 40 rpm.

Subsequently, the samples were washed in hot and

cold water and then dried in an oven at 40 ºC during

24 hours. After dyeing, the samples were analyzed

in the reflectance measuring apparatus above

described to evaluate the increase or decrease in the

intensity of color, in order to evaluate the formation

of hydroxyl groups. An increase in the K/S values

indicates an increase in the formation of hydroxyl

groups which react covalently with this type of dye.

2.5 Quality Control Test

2.5.1 SEM Analysis

The surface morphology of the treated polyester

fabric was observed using a scanning electron

microscope. SEM analysis was performed in all

samples after one week since the application of the

enzymatic treatments, using a HITACHI S2700

Electron Microscope and an EMITECH-K550 gold

evaporator.

2.5.2 Determination of the Resistance to

Abrasion

The Martindale evaluation system was used for

measuring the resistance to abrasion (mechanical

properties) of the non-treated and treated samples.

The standard testing method was according to IWS

TM 112. In this method, the samples are tested

under a weight of 9 KPa and run until the rupture of

two yarns.

3 RESULTS AND DISCUSSION

3.1 Evaluation of the Effectiveness of

the Enzymatic Treatments

The results for the effect of the enzymatic

treatments, over the contact angle and the

hydrophilicity are indicated in Figures 1 and 2. The

results for the contact angle (Figure 1) showed a

slight decrease for all enzyme concentration, but the

most significant decrease was observed with

Texazym PES, when compared to the non-enzymatic

treated sample (Control). For the others enzymes

(Aspergillus niger and Aspergillus oryzae) it can be

also observed a slight decrease. However, for higher

concentrations of enzyme and incubation times a

significant decrease of contact angle in relation to

the control can be observed, being in accordance

with the results obtained by other authors (Hsieh e

Cram. 1998).

After a comparative analysis, we can conclude

that either the use of Aspergillus oryzae or an

Aspergillus niger made possible to achieve a lower

contact angle, hence greater hydrophilicity for

polyester fabric. However the Texazym PES led to

the better results. Definitely, by applying the

Texazym PES with a concentration of 0.12 U during

90 minutes it can be achieved a contact angle of

87.45º; by applying the Aspergillus niger with a

concentration of 0.15 U during 60 minutes a contact

angle of 101.50º, is obtained.

The use of Aspergillus oryzae, (0.12 U during 60

min) also allows to achieve lower values for the

contact angle (109.03º). The more favourable

conditions to decrease the contact angle seens to be

using the Texazym PES with a concentration of 0.12

U during 90 minutes. For lower incubation times (30

to 60 minutes) there are no important changes in the

contact angle values.

80

85

90

95

100

105

110

115

120

125

130

0,00 0,05 0,10 0,15 0,20

Contact Angle (º)

Enzyme concentration (U)

Contro

l

Texazyme - 30 min

Texazym - 60 min Texazym - 90 min

Texazym - 1440 min Oryzae - 30 min

Oryzae - 60 min Oryzae - 90 min

Oryzae - 1440 min Niger - 30 min

Niger - 60 min Niger - 90 min

Niger 1440 min

Figure 1: Values of contact angle for all enzymes.

The results of hydrophilicity obtained by the

effect of capillary are illustrated in Figure 2. Their

analysis indicates that the best results are achieved

using the Texazym PES, followed by the use of the

Aspergillus niger. In those circumstances it’s

obtained a wicking height of 5.40 cm and 4.60 cm,

respectively. Other studies revealed that the

application of other enzymes promoted similar

results, however with a lower wicking height (≈ 4

cm) (Alisch-Mark et al, 2006). In agreement with

the results of the contact angle and hydrophilicity,

the use of Aspergillus oryzae leads to lower values

IMPROVING SURFACE ENERGY AND HYDROPHILIZATION OF POLY(ETHYLENE TEREPHTHALATE) BY

ENZYMATIC TREATMENTS

271

in the capacity of absorption of water by capillarity

effect (Figure 2).

The results obtained by the analysis of the

carboxyl end groups (Figure 3), formed by the

application of Tezaxym PES for any concentration

and incubation time, showed a significant increase

detected by the reaction with the cationic dye, when

compared to the other enzymes and the control.

Figure 2: Values of hydrophilicity (expressed by the

wicking height).

Figure 3: Values of K/S (620 nm), after dyeing with

cationic dye.

The more favourable conditions to the grafting of

these groups are by applying a concentration of 0.12

to 0.15 U for any incubation time. These results are

in accordance with the results obtained before

(contact angle and hydrophilicity), showing that the

presence of carboxyl groups favours the

establishment of hydrogen bonds with water. An

application with Aspergillus oryzae seems to be less

desirable with regards with the formation of these

functional groups, reflecting up in the lower capacity

of the treated fabrics to absorb water.

The formation or not of the hydroxyl groups,

using different enzymes, can be indirectly measured

by the higher or lower intensity of color that results

from the reaction of a reactive dye with the hydroxyl

groups (-OH) by the formation of covalent bonds.

After analyzing the results presented in Figure 4, it

can be concluded that a higher formation of the

hydroxyl groups is achieved by using the Texazym

PES, whichever the incubation time, comparing with

the others enzymes and with the control. This feature

is extremely important with respect to future

applications of this enzyme in the textile industry,

where the incubation time is a cruel factor in textile

treatments.

Figure 4: Values of K/S (600 nm), after dyeing with

reactive dye.

To better elucidate which were the best

conditions for each enzyme, considering the best

results of the contact angle and wicking height, the

selected optimum conditions for each enzyme are

presented in Table 3. The best results regarding the

lower contact angle and higher wicking height are

obtained for the Texazym PES us1ing a

concentration of 0.12 U during 90 minutes, followed

by the Aspergillus niger using 0.15 U, 60 minutes

and finally, by the Aspergillus oryzae using 0.12U

during 60 minutes. In those conditions, an

application with Texazym PES yielded a rinsing

height of 5.40 cm, which is a very good value when

compared with the ones obtained by other authors

(Alisch-Mark et al, 2006). In this study they

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

272

achieved a rinsing height of 4.2 cm (approximately)

after 48 hours of incubation with T.fusca (16 U). Our

results revealed an important achievement since

much lower incubation time and enzyme

concentration was used.

However, the other results regarding the quality

control parameters are important to better define the

optimal conditions overall.

Table 3: Optimal conditions for different operating

parameters.

Contact

Angle

(glycerol)

(º)

Rising

Height

(cm)

Cationic

Dye

K/S

Reactive

Dye

K/S

Control 122.95 2.7 0.60 0.34

Texazym

PES

(0.12 U,

90min)

87.45 5.40 0.81 0.62

Asperg.

niger

(0.15 U,

60 min)

101.50 4.60 0.50 0.28

Asperg.

oryzae

(0.12U,

60 min)

109.03 0.40 0.60 0.34

The total surface energy, the dispersion

component and polar component of the fabrics were

calculated according to the Owens-Wendt approach

(γ

s

p

. γ

s

d

. γ

s

are the polar component, the dispersion

component and the total surface energy, of fabric,

respectively) and are indicated in Tables 4 to 6.

It is clear that the total surface energy increases

with incubation time and enzyme concentration. The

values of surface energy obtained for the control was

0.60 mJ/m

2

for the polar component, 3.28 mJ/m

2

for

the dispersion component and 3.88 mJ/m

2

for the

total surface energy. Analyzing the results, an

important increase of the polar component for the

Texazym PES is verified when compared with the

other enzymes. The higher value (187.31 mJ/m

2

)

was obtained to the incubation time of 1440 minutes

with a concentration of 0.15U. However, good

values for the polar component can be obtained for

lower incubation times (183.85 mJ/m

2

, 153.52

mJ/m

2

), when a concentration of enzyme between

0.12U to 0.18 U is used during an incubation time of

90 minutes. Considering the other enzymes, much

lower values for the polar component are obtained:

30.36 mJ/m

2

(using 0.18 U during 60 min for the

Aspergillus niger), and 11.47 mJ/m

2

and 10.04

mJ/m

2

using 0.12 U during 30 minutes and 0.15 U

during 60 minutes, respectively, for the Aspergillus

oryzae.

Table 4: Surface energy determination for different

operating parameters of Texazym PES.

Time

(min)

Concentration of

enzyme (U)

γ

s

p

(mJ/m

2

)

γ

s

d

(mJ/m

2

)

γ

s

(mJ/m

2

)

30

0.06 22.49 1.9 29.4

0.09 67.88 15.9 83.78

0.12 99.57 29.15 128.72

0.15 97.6 29.76 127.36

0.18 82.13 20.29 102.41

60

0.06 31.02 1.78 32.8

0.09 81.07 21.81 102.88

0.12 98.54 24.12 122.66

0.15 110.76 32.74 143.5

0.18 102.32 32.31 134.62

90

0.06 61.00 6.32 67.32

0.09 122.07 29.78 151.85

0.12 183.85 63.43 247.38

0.15 153.52 39.21 192.73

0.18 141.68 29.69 171.36

1440

0.06 45.98 5.70 51.68

0.09 117.12 42.4 159.53

0.12 147.85 54.21 202.06

0.15 187.31 91.66 278.97

0.18 145.94 57.2 203.14

Table 5: Surface energy determination for different

operating parameters of Aspergillus niger.

Time

(min)

Concentration of

enzyme (U)

γ

s

p

(mJ/m

2

)

γ

s

d

(mJ/m

2

)

γ

s

(mJ/m

2

)

30

0.06 2.67 2.76 5.43

0.09 3.9 1.94 5.84

0.12 0.1 11.34 11.43

0.15 0.00 11.55 11.55

0.18 14.95 0.02 14.97

60

0.06 0.52 6.49 7.01

0.09 0.88 5.84 6.71

0.12 0.04 15.78 15.82

0.15 0.45 25.27 25.72

0.18 30.36 1.77 32.13

90

0.06 2.44 2.94 5.37

0.09 3.11 3.82 6.93

0.12 0.28 10.81 11.09

0.15 1.79 3.62 5.41

0.18 5.82 1.39 7.21

1440

0.06 5.31 1.01 6.38

0.09 9.47 0.42 9.89

0.12 21.49 1.47 22.97

0.15 3.03 2.19 5.22

0.18 0.42 8.99 9.42

It is mainly due to the incorporation of polar

groups like carboxyl and hydroxyl on the fabric

IMPROVING SURFACE ENERGY AND HYDROPHILIZATION OF POLY(ETHYLENE TEREPHTHALATE) BY

ENZYMATIC TREATMENTS

273

surface, verified by other authors (Pandiyaraj and

Selvarajan, 2008) and in our present study.

Table 6: Surface energy determination for different

operating parameters of Aspergillus oryzae.

Time

(min)

Concentration

of enzyme (U)

γ

s

p

(mJ/m

2

)

γ

s

d

(mJ/m

2

)

γ

s

(mJ/m

2

)

30

0.06 18.48 2.11 20.59

0.09 4.85 0.07 4.92

0.12 3.24 2.66 5.09

0.15 11.47 0.17 11.64

0.18 0.92 6.98 7.89

60

0.06 2.66 1.97 4.63

0.09 6.74 0.29 7.03

0.12 0.05 12.22 12.27

0.15 10.04 0.22 10.26

0.18 1.91 4.07 5.98

90

0.06 6.68 0.06 6.74

0.09 0.00 10.31 10.31

0.12 8.77 0.01 8.78

0.15 5.49 0.72 6.21

0.18 0.95 5.31 6.26

1440

0.06 1.18 2.21 3.39

0.09 3.16 1.48 4.64

0.12 5.69 0.07 5.76

0.15 2.05 2.39 4.43

0.18 1.54 3.61 5.15

The change in the polar component verified for

all enzymatic treatments, when applying different

enzyme concentrations and incubation times, affects

the total surface energy as a function of enzymatic

operating parameters. These results show that the

main contribution to the increase in surface energy is

due to the polar components which can incorporate

with moisture through hydrogen bonds. Thus, good

wettability is obtained when the values of polar

component is high (Pandiyaraj and Selvarajan,

2008), being the most favorable conditions the one’s

for the enzymatic treatment with Texazym PES.

3.2 Quality Control Tests

With the test of resistance to abrasion was intended

to assess whether the mechanical properties of

polyester fabrics would have suffered any significant

change after the treatment with enzymes (Texazym

PES, Aspergillus niger and Aspergillus oryzae).

These results were referenced in Table 7.

After their evaluation it can be seen that there

weren´t verify important losses in the resistances to

abrasion using any enzymatic treatment when

compared with the control. The loss of around 4% in

the resistance is perfectively safe for the textile.

Table 7: Values of the resistance to the abrasion in the

optimal conditions for each enzymatic treatment.

Resistance to

abrasion (cycles)

Control 24000

Texazym PES (0.12 U. 90min) 23000

Aspergillus niger (0.15 U. 60 min) 23000

Aspergillus oryzae (0.12U. 60 min) 23000

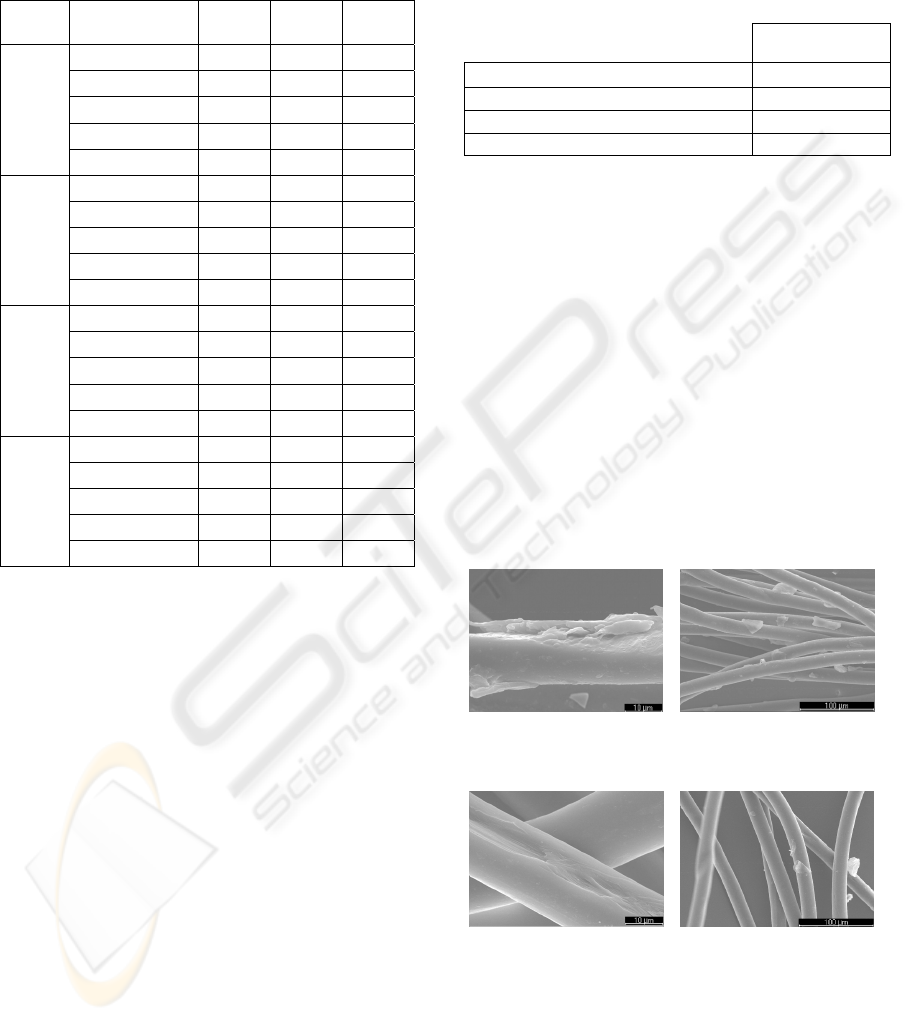

The SEM analysis aims to observe any surface

changes on fibers after the enzymatic treatment. The

images presented are referred to the control and to

the optimum conditions of application of the

Texazym PES. The others enzymes didn’t revealed

any changes when compared to the control. Looking

at images of Figures 5 and 6 it can be seen that there

is no degradation of the surface of the fibers under

study. In contrary, the use of the Texazym PES

applied under the optimum conditions seems to be

the cause of a greater effect of cleaning since it can

be seen the presence of a smaller number of particles

deposited on the fibers (oligomers). This effect of

total or partial elimination of them is of utmost

importance, especially in what concerns to adhesion

and dyeing properties.

A B

Figure 5: SEM micrographs of Control samples (A-

magnification: 2500x, B-magnification: 500x).

A B

Figure 6: SEM micrographs (Texazym PES, using 0.12 U

during 90 min).

4 CONCLUSIONS

The effect of the different enzymatic treatments,

incubation time and enzyme concentration on the

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

274

hydrophilization of PET fabrics and surface energy

increasing was analyzed. Depending on the

enzymatic process used, the wettability of PET

fabrics can be significantly improved. It was found

the formation of carboxyl and hydroxyl polar groups

by the Texazym PES action. The enhancement of

polar groups on the fabric surface was confirmed

with a cationic dye (Methylene blue) and a reactive

dye (Remazol black B). Thus, improvement in

adhesion properties can be expected.

Our results revealed an important achievement

since much lower incubation time and enzyme

concentration was used, comparing to previous

investigations.

The increasing in the hydrophilicity and surface

energy of PET fabrics are also known to have

importance in the increasing in adhesion of cells and

tissues, which is a very important property for

permanent biomedical implants.

REFERENCES

Alisch-Mark, M., Herrmann, A., Zimmermenn, W., 2006.

Increase of the hidrophilicity of polyethylene

terephthalate fibres by hidrolases from T.fusca and

F.solani f. sp. pisi. Biotechnology Letters, 28, 681-685.

Guebitz, G. M., Cavaco- Paulo, A., 2008. Enzymes go big:

surface hydrolysis and functionalisation of synthetic

polymers. Trends in Biotechnology, 26 (1), 32-38.

Heumann, S., Eberl, A., Pobeheim, H., Liebminger, S.,

Fischer-Colbrie, G., Almansa, E., Cavaco-Paulo, A.,

Guebitz, G.M., 2006. New model substrates for

enzymes hydrolysing polyethyleneterephthalate and

polyamide fibres. J. Biochem. Biophys. Methods, 39,

89-99.

Hseih, Y. and Cram, L. A., 1998. Enzymatic Hydrolysis to

Improve Wetting and Absorbency of Polyester

Fabrics. Textile Research Journal, 68 (5), 311-319

Inagaki, N., Tasaka, S., Narushima, K., Kobayashi, H.,

2001. Surface Modification of PET Films by Pulse

Argon Plasma. Journal of Applied Polymer Science,

85 (14), 2845-2852.

Owens, D.K., Wendt, R.C., 1969. Estimation of the

surface free energy of polymers. J. Appl. Polym. Sci.,

13, 174.

Pandiyaraj, K.N., Selvarajan, V., 2008. Non-Thermal

plasma treatment for hydrophilicity improvement of

grey cotton fabrics. Journal of Materials Processing

Technology, 199,130-139.

Shah, H.S., Gandhi, R.S., 1990. Instrumental Colour

Measurements and Computer aided Colour matching

for Textile, (Eds) Mahajan Book Distributors.

Vertommen, M.A.M.E., Nierstrasz*, V.A., van der Veer,

M., Warmoeskerken, M.M.C.G., 2005. Enzymatic

surface modification of poly(ethylene terephthalate).

Journal of Biotechnology, 120, 376-386.

Yang, S., Gupta, M.C., 2004. Surface modification of

polyethyleneterephthalate by an atmospheric-pressure

plasma surce. Surface & Coatings Technology, 187

(2/3), 172-176.

IMPROVING SURFACE ENERGY AND HYDROPHILIZATION OF POLY(ETHYLENE TEREPHTHALATE) BY

ENZYMATIC TREATMENTS

275